As promised, update time!

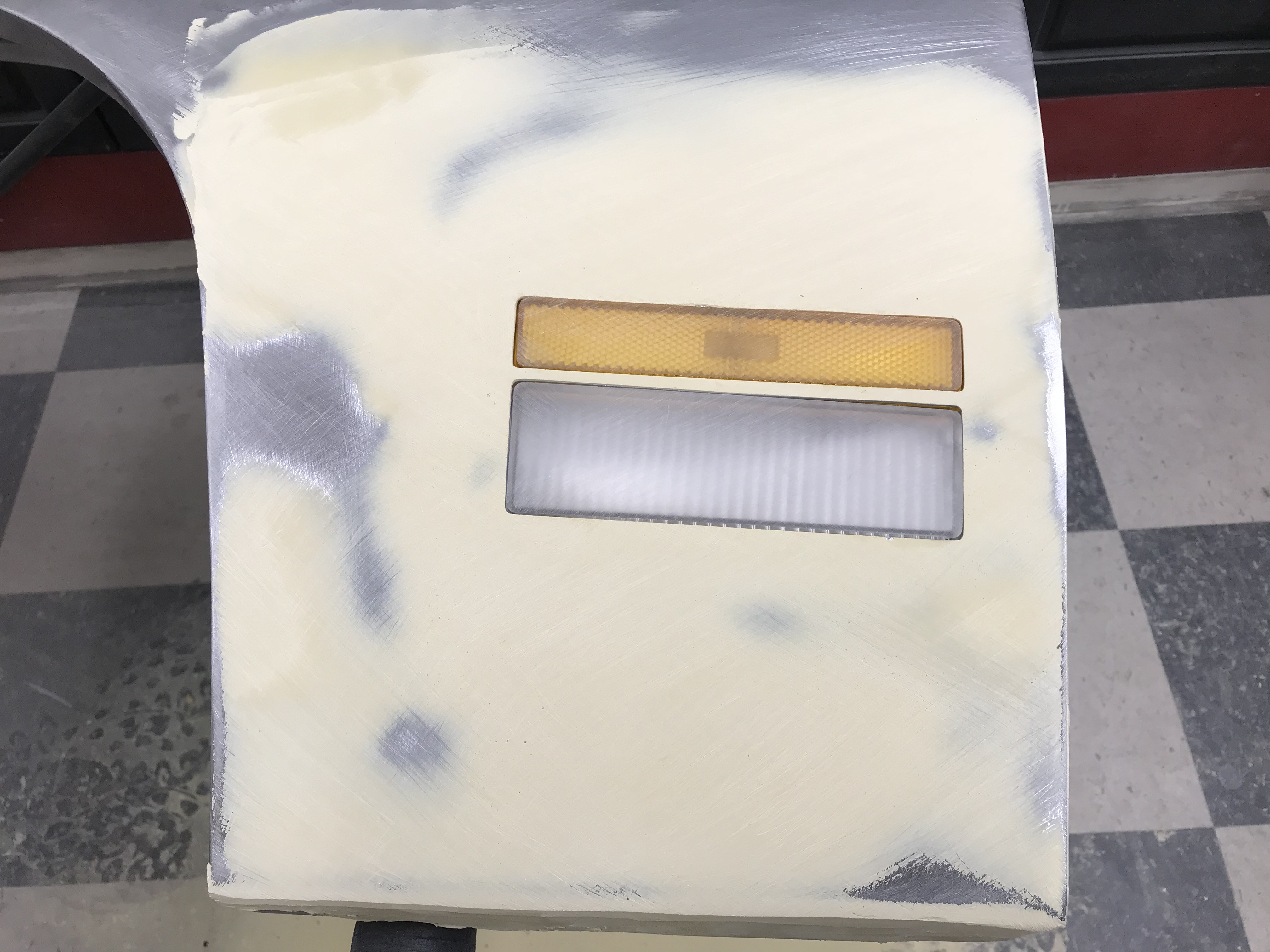

Since the last one, much progress has been made. Once the thin strip of the marker light patch was repaired, I gave the surrounding area two skims of filler, blocking them out between each.

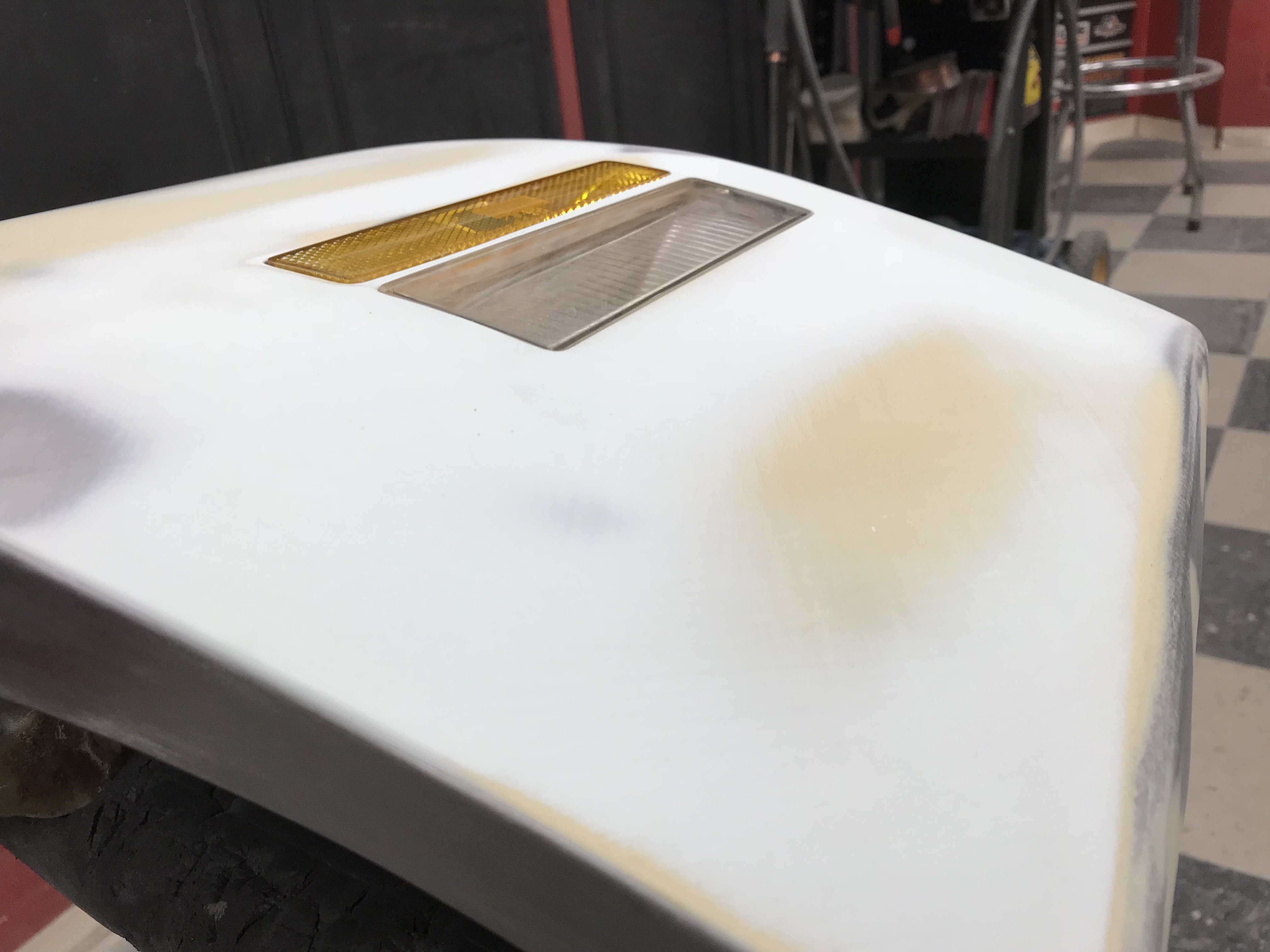

That gave me a foundation to work from with the light installed. It’s a bit difficult to explain, but I did several rounds of sanding the filler WITH the light installed, then I’d remove a pair of the shimming washers from the backside, skim and block again. This had the effect of gradually shaping the outer lens to the curvature of the fender:

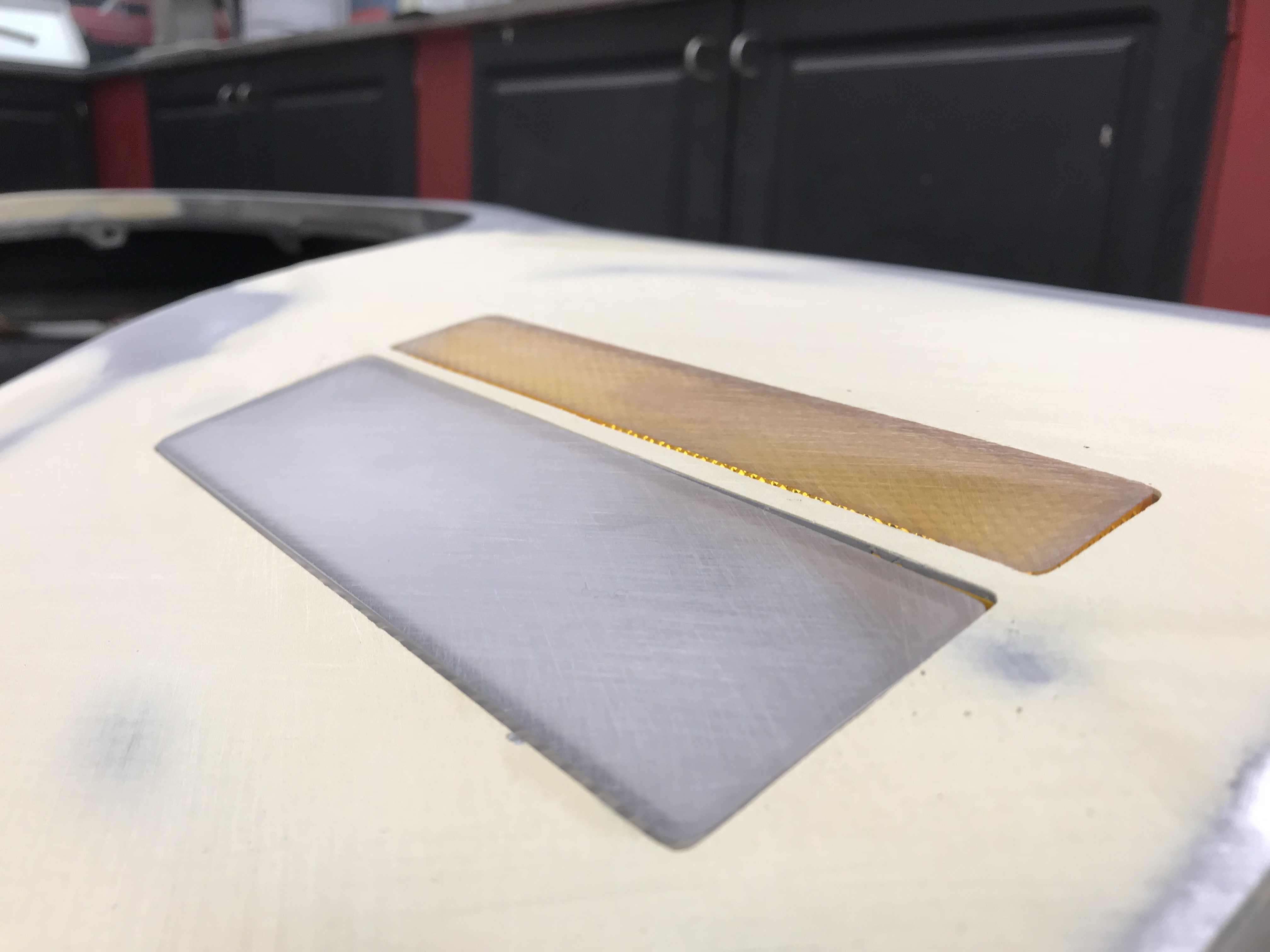

When I had the curvature close, I decided to go “Mad Scientist” and try something completely out of the ordinary. With the light installed and close to the right shape, I applied a coat of filler on the panel, right over the light and everything!

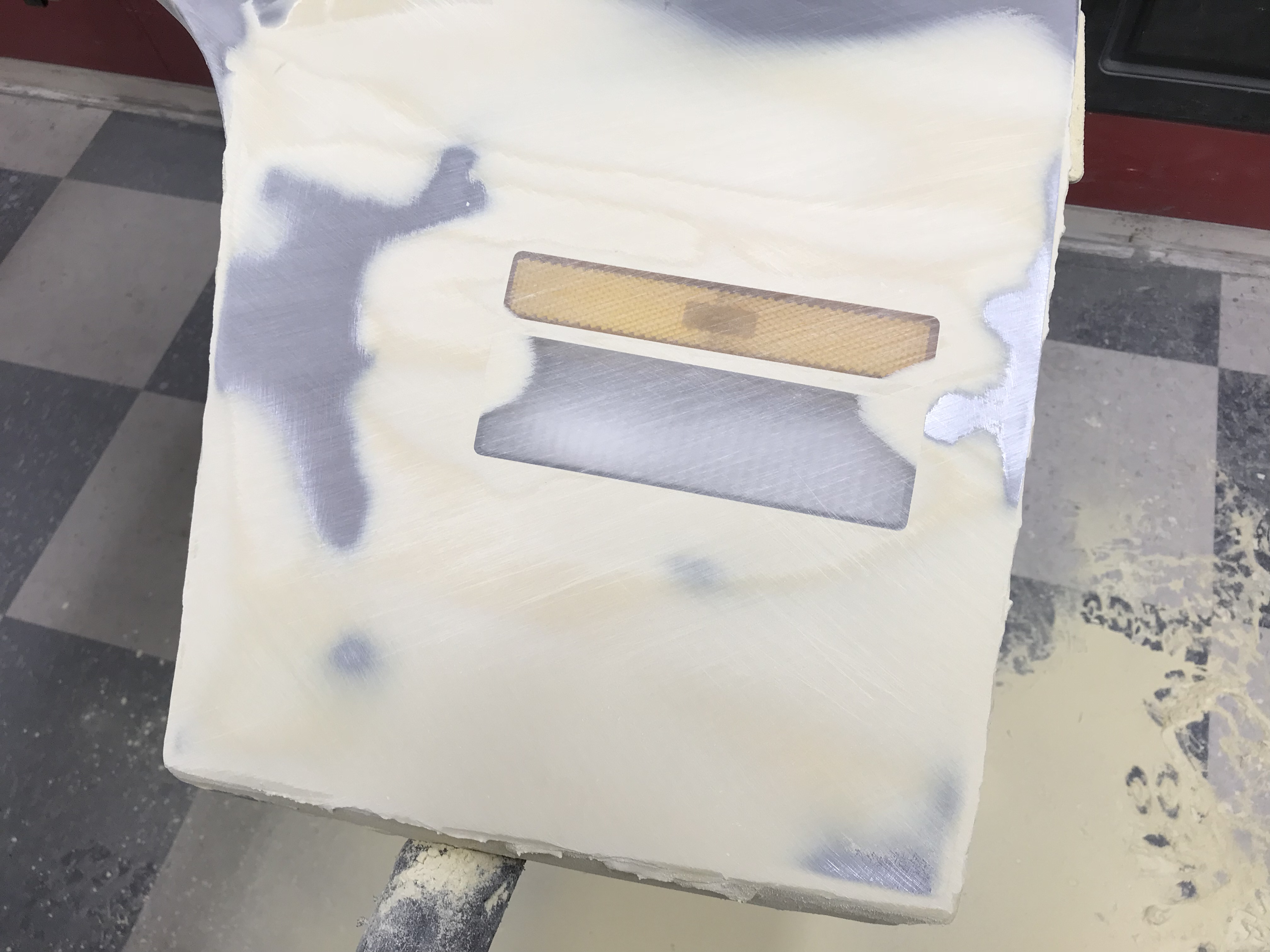

I treated the light just like it was a part of the fender, and blocked the area out. Here you can see where most of it became exposed as I was working it:

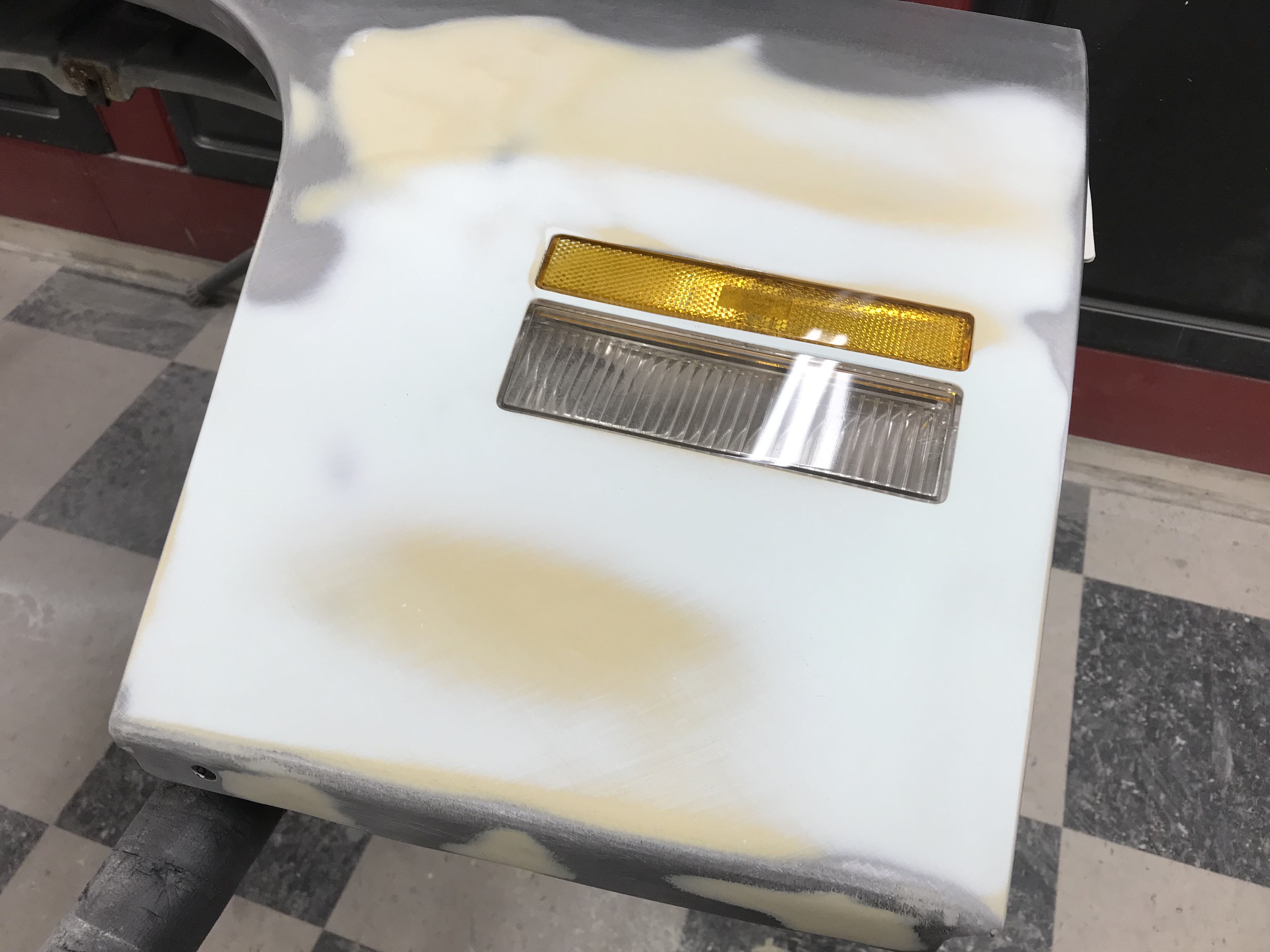

I continued on in this fashion for a bit, each time getting the fit and curvature better and better each time. Filler gave way to putty, and once everything was straight and finished in 120, I finally removed the light. Some minor sanding and addressing the edges of the openings was done, then I turned my attention to just the light itself.

Continuing on with progressively finer and finer grits of sanding, the lenses were hit with 220, 320, 400, 600, 1000, 1500, and finally 2000 grit. At the end of the 2000, the lenses were smooth enough to hand polish. Of course I had to do a test fit at that point to see how it’d look in place...

Coming along pretty good!

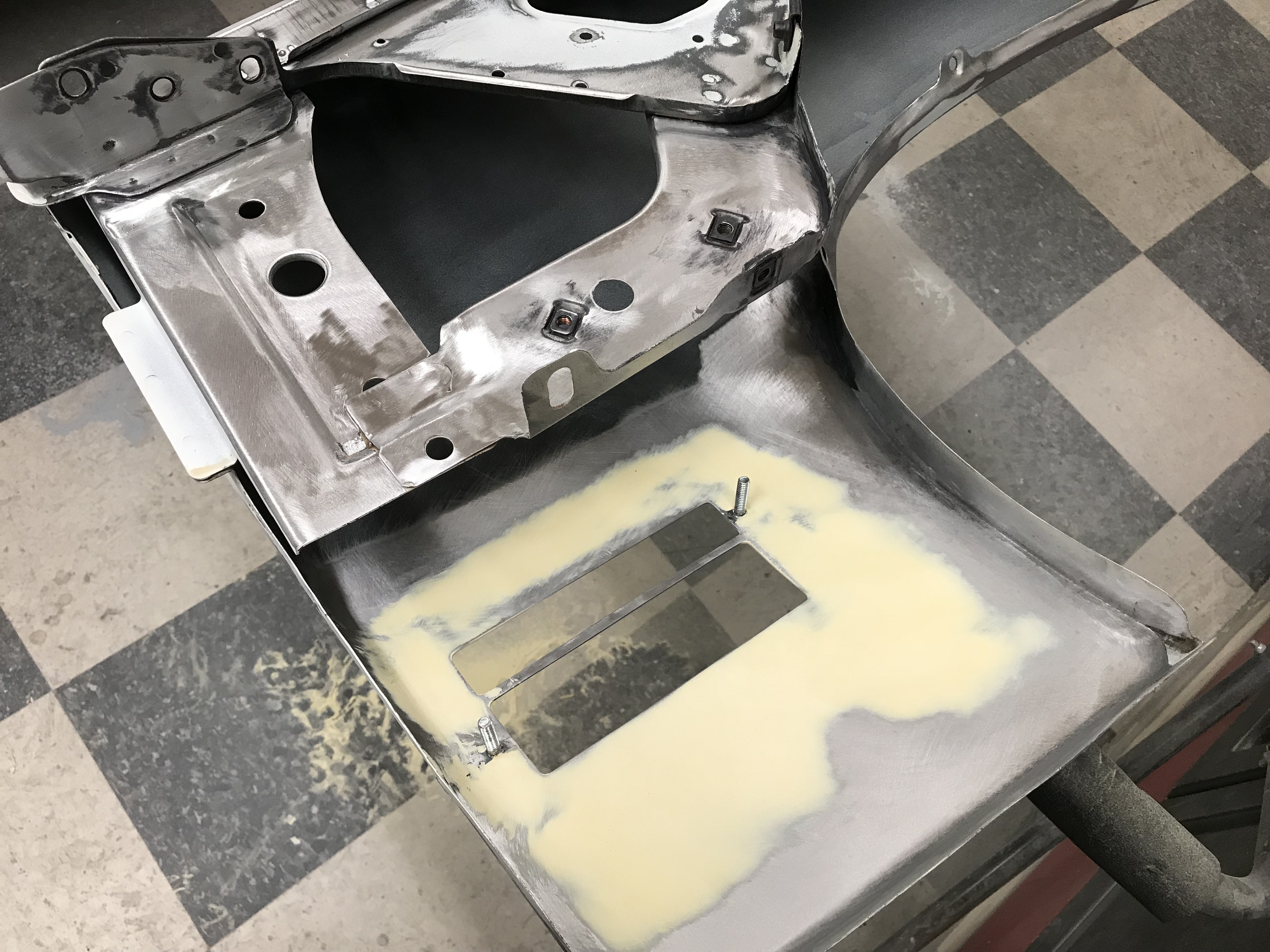

At this point, the outside of the fender was, for all intents and purposes, done for now. Time to start looking at the inside. Much to my disappointment, the inside was quite rough and fairly rusty around many of the seams. I spent a considerable amount of time stripping old paint and primer from many of the areas, grinding/sanding out rust where I could access it, and feathering out the marks.

Here’s a look as I was in the middle of this process:

As you can see, there’s a lot of bare metal areas now. Once again, the surface rust I came across was directly due to the factory’s poor application of paint. Most of the more severe areas were by seams where there wasn’t enough paint and primer applied.

Here’s a few closeups of these areas:

With as many of the areas mechanically sanded and ground out, the only option left for the inaccessible spots was to treat them chemically. My rust converter concoction came out, and they were all treated. The converter is visible as a purple/turning to black film as it works and dries. There were still quite a few areas:

After letting the converter cure overnight, I went back the following night and sanded and feather edged out all the treated spots. This too took quite some time, but it had to be done. The rest of the “unaffected” areas were scuffed up with red ScotchBrite.

With all that nonsense out of the way, I gave the inside of the patch a light skim of filler and blocked it out. As mentioned earlier, this was primarily cosmetic, there should be next to no evidence a modification was done here.

Continued >>>

Yeah, I've been known to do that . . . between the wife and I, total vehicles = 11 cars, 7 trucks, 5 SUVs, no turning lights until the 2010 model.

Yeah, I've been known to do that . . . between the wife and I, total vehicles = 11 cars, 7 trucks, 5 SUVs, no turning lights until the 2010 model.