Well gents, another night and another small victory.

Tonight was all about getting the headliner material attached to the slider board, the very last step before the rest of the AstroRoof assembly can be completed.

I don’t know if I mentioned it previously or not, but the slider board has to go in before the outer pan to complete the reassembly. That meant it had to be recovered with the headliner material first. Hence my buying the material already.

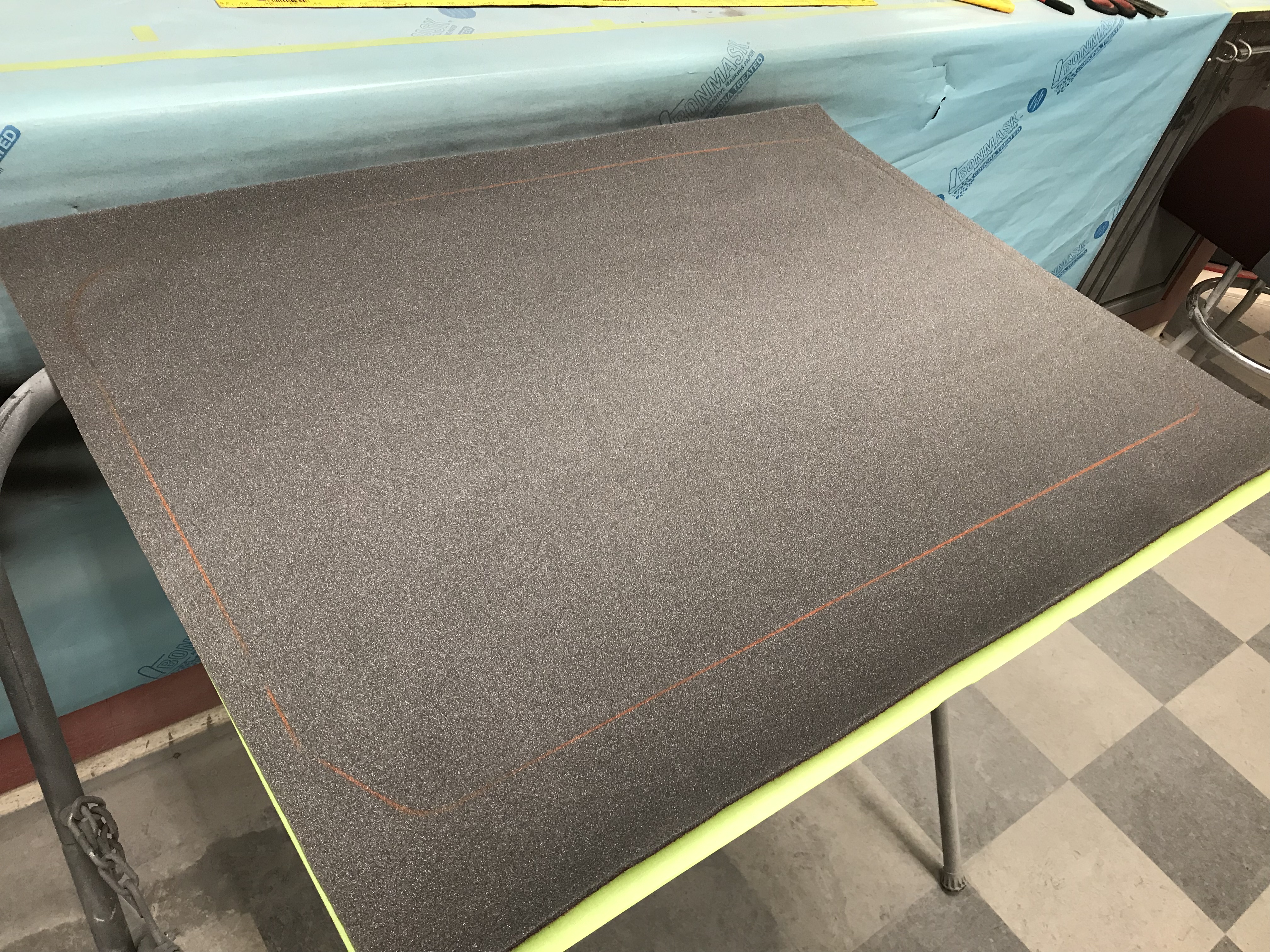

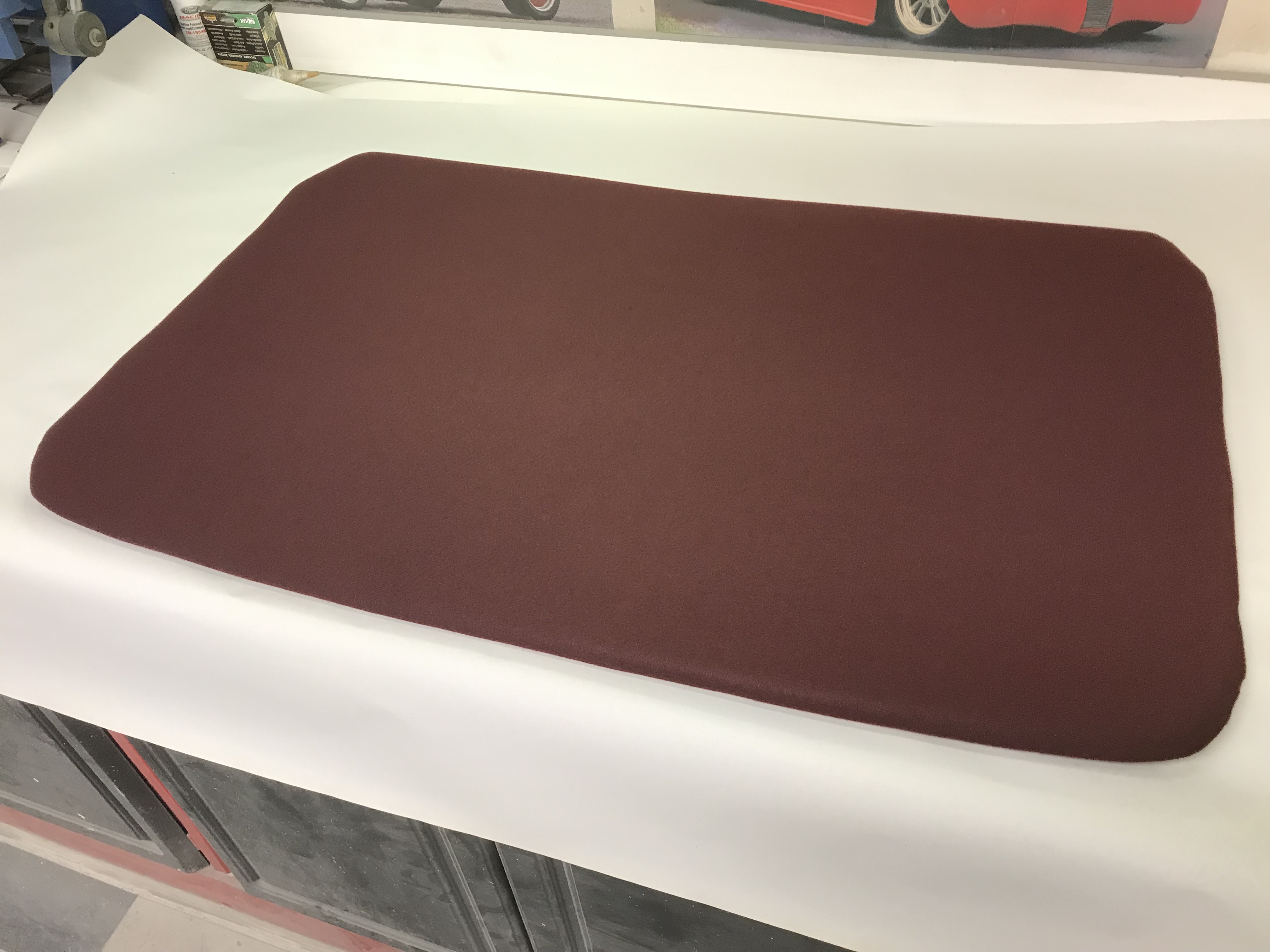

Earlier today, I found some 3M heavy duty spray adhesive from NAPA, we just won’t discuss the astronomical amount it cost. Tonight, I began by cutting a slightly larger piece of the material than I needed, and laying it out on a nice clean surface on the stand.

Flipped it over, and made sure the backside was clean and relaxed as well:

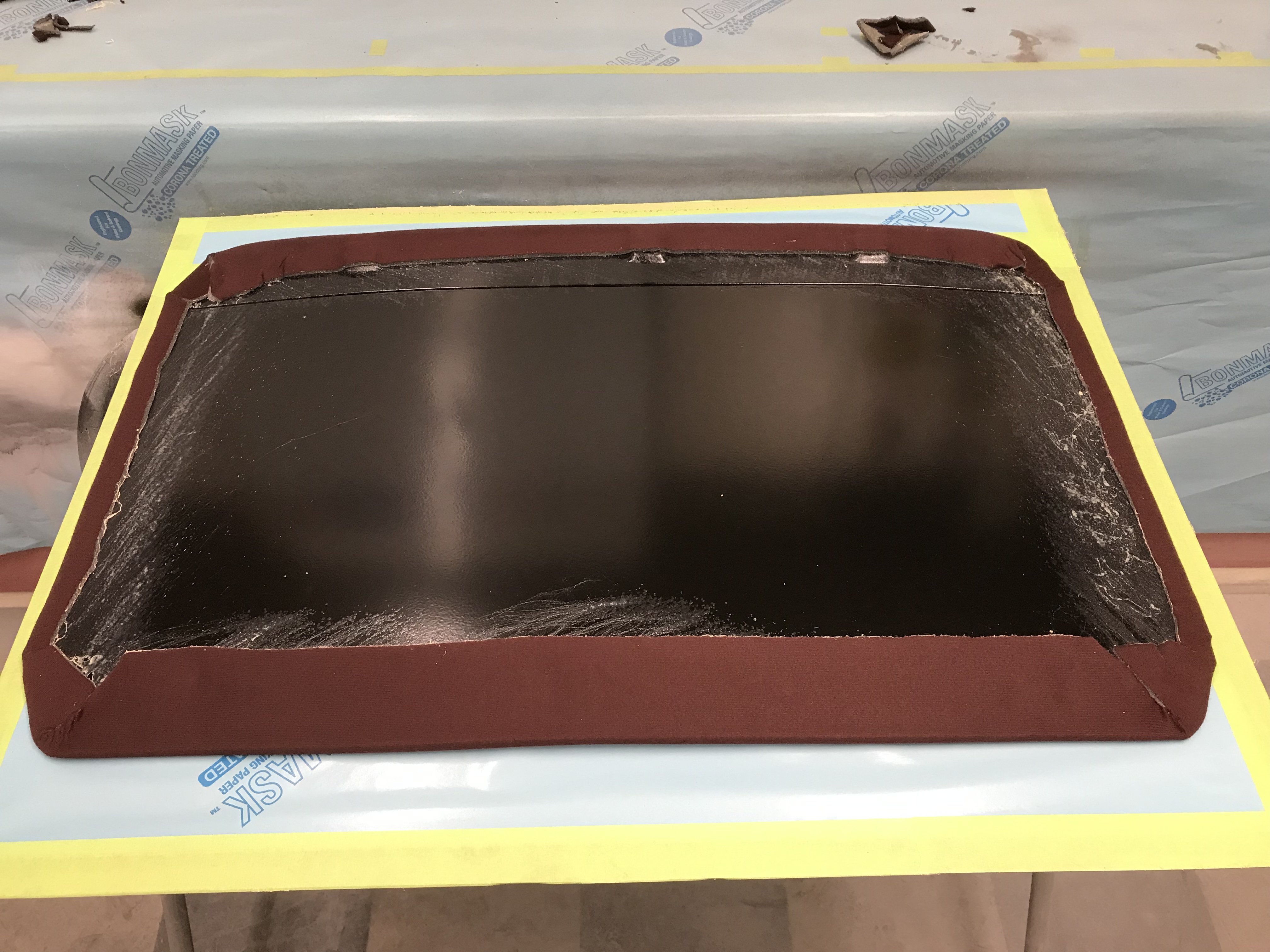

The next step was to lay the slider board on top, and figure out where I needed the excess material overlap to be:

Once I had the slider positioned where I was happy with it, I traced around the perimeter with a grease pencil so that I could see where to position it once the glue was down:

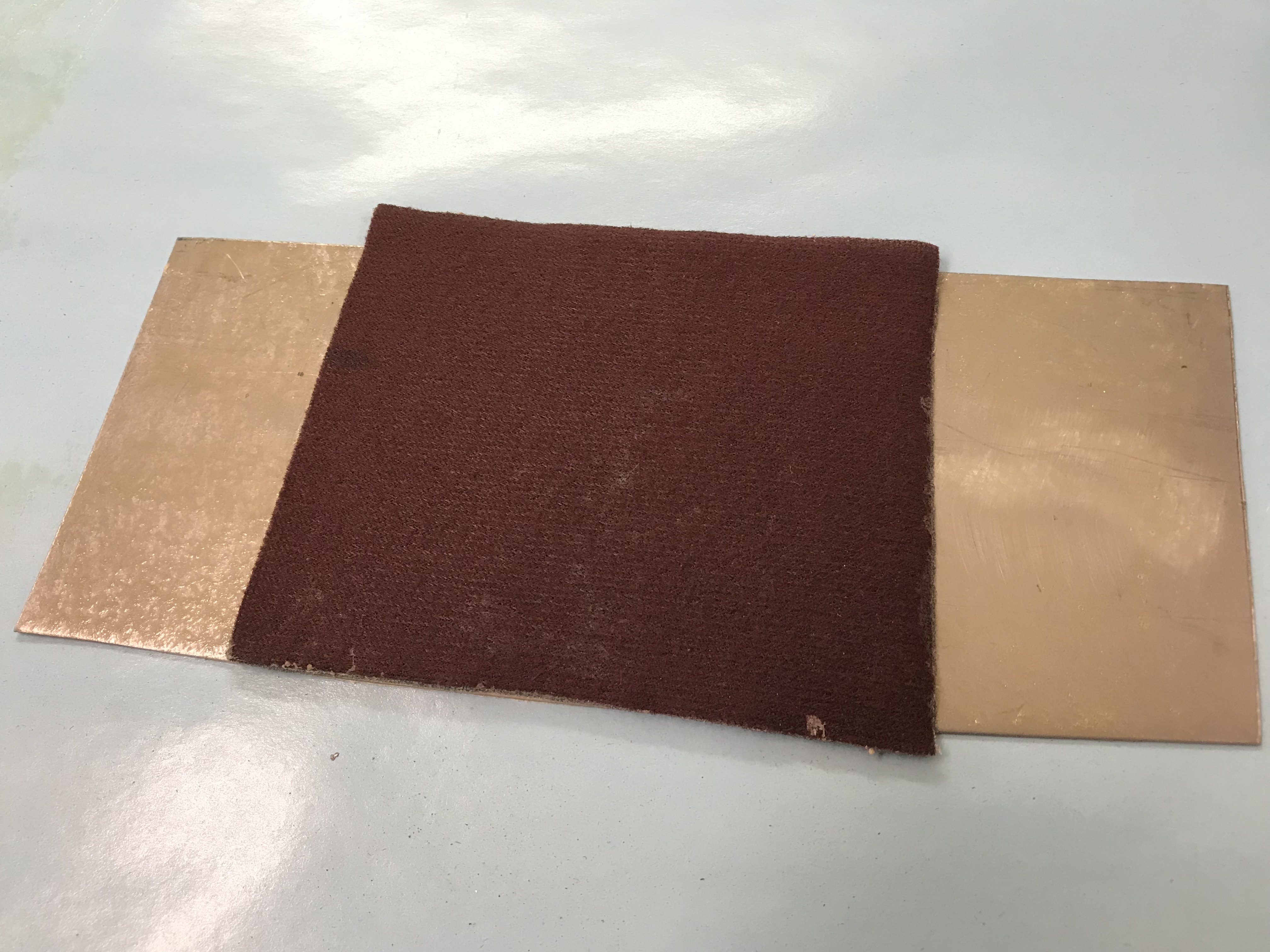

Almost ready to begin, I lopped off a small piece of the headliner scrap, and set out to do a test. Anytime you work with new or different or unfamiliar materials, you always need to test for compatibility. You do all do this RIGHT???

Yeah, me neither usually.

But since a bit of grief is potentially at stake here, I felt it worthwhile. This is the spray glue I picked up today, it’s rated for heavy duty use, and for heavy weight headliners in particular:

Nothing particularly interesting or special here, I just followed the instructions on the can, and gave both pieces 2 overlapping coats:

Here’s where I DON’T recommend following the directions on the can. It claims that the pieces can be joined together after a 4 minute period, but not more than 30 minutes. That’s a bunch of hooey. I waited roughly 10 minutes to ensure both pieces had “tacked up”, but I found that was too long. Both pieces were basically already dry. No sticky sticky together.

So I reapplied a bit more, and joined them together after only 3 minutes. Much better success, and an important lesson learned. Glad I did the test piece.

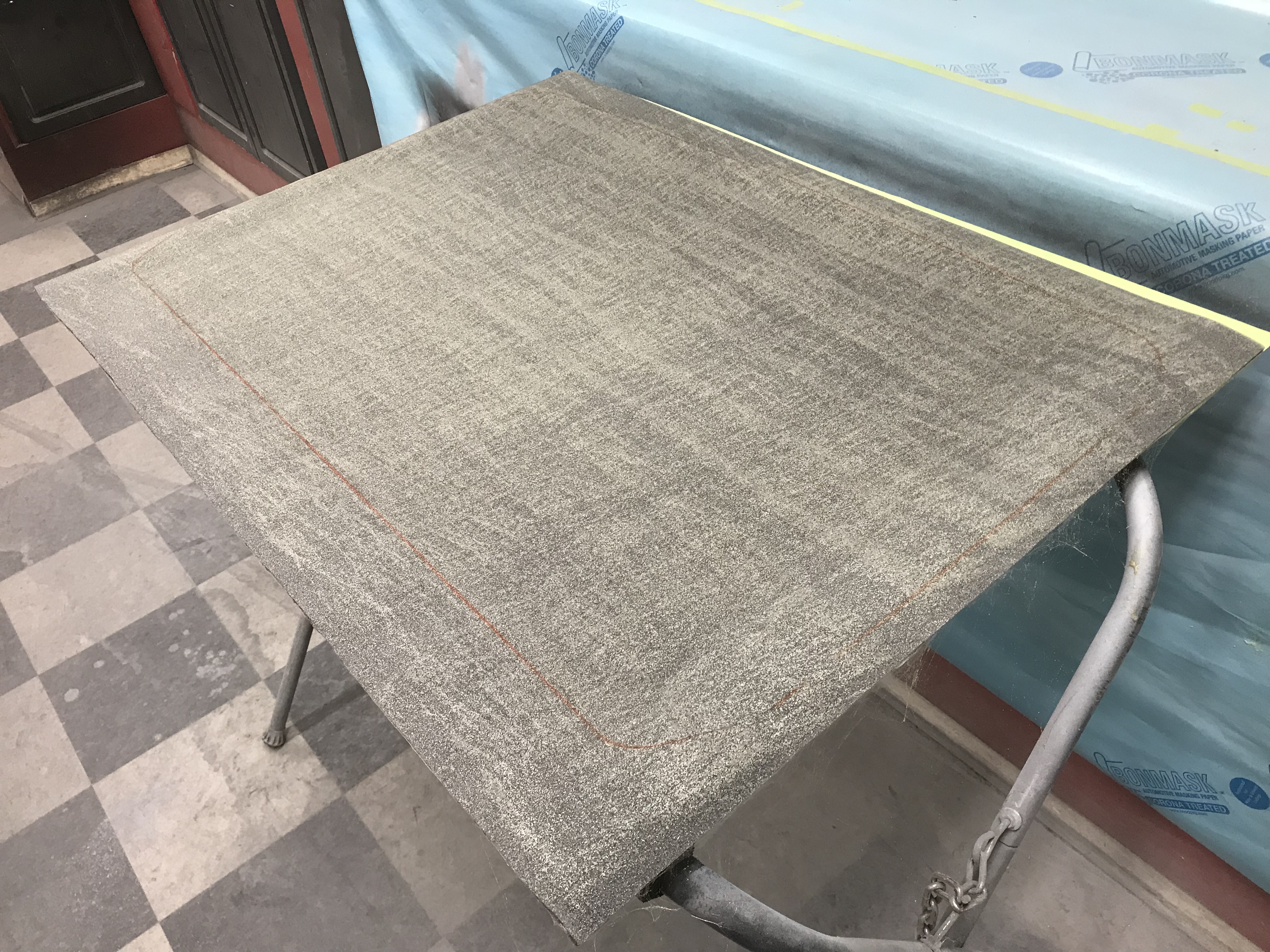

Next was to lay out the slider board with the side that needs to be glued facing up:

Now or never, time to get after it!

Glue down on the material...

...and on the slider:

Once the glue is down, time becomes a priority. So I didn’t have a chance to take the couple pictures in between that I would’ve liked, but the slider was placed on the material, pressed into place and then the overlapping edges were hit with a bit more glue. Then stick down the overlapping edges:

Be prepared to do a little stretching and trimming here, the edges of the slider aren’t perfectly square so I had to do some minor repositioning. I hadn’t given much thought to the corners, but what I found worked well was to just let the excess material bunch up and stick to itself. Then just trim it off almost flush from the outside. A pair of sharp scissors are a requirement here.

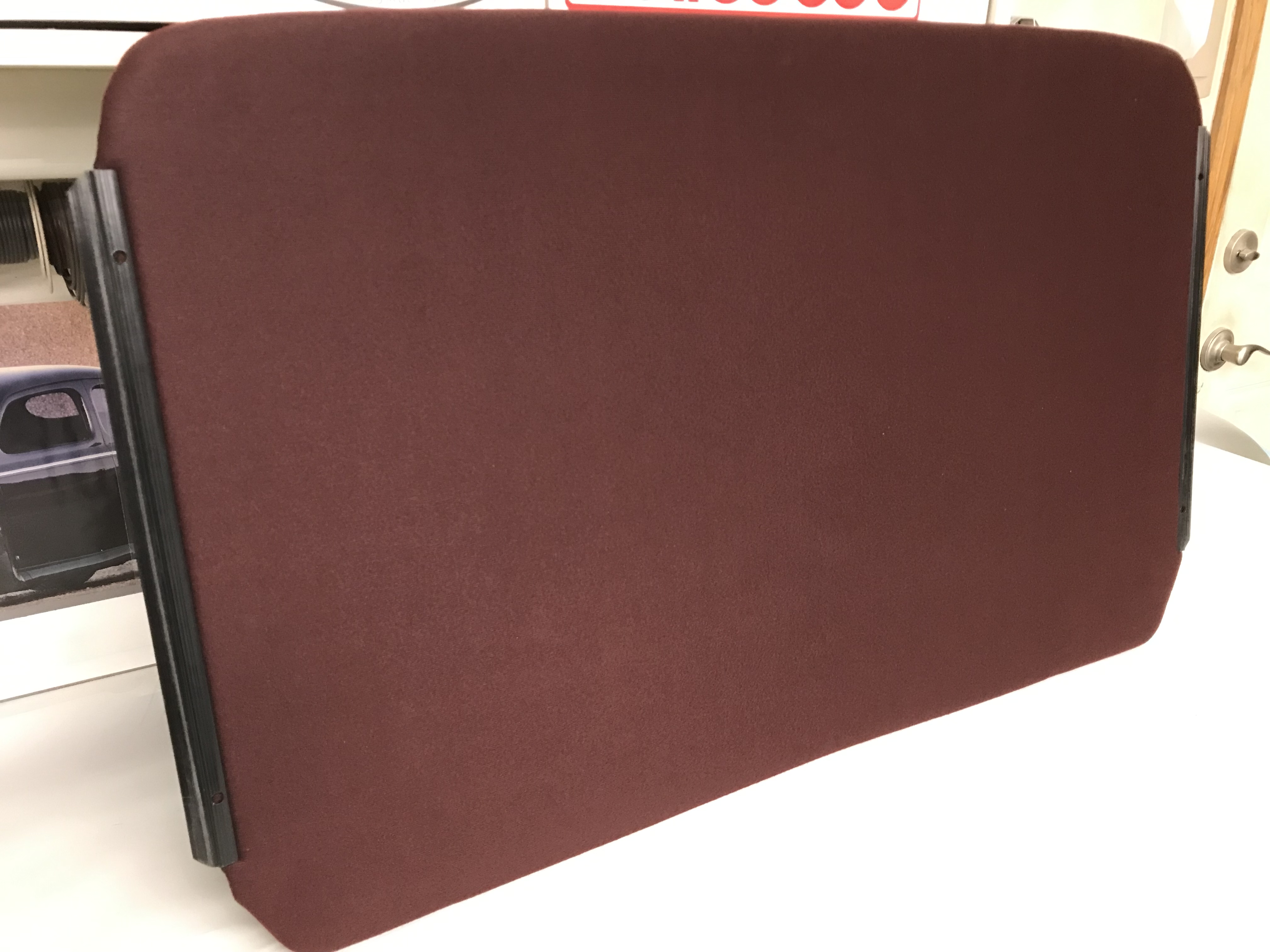

Flipped it over, and laid it out on a clean surface. Inspected my work, success!!!

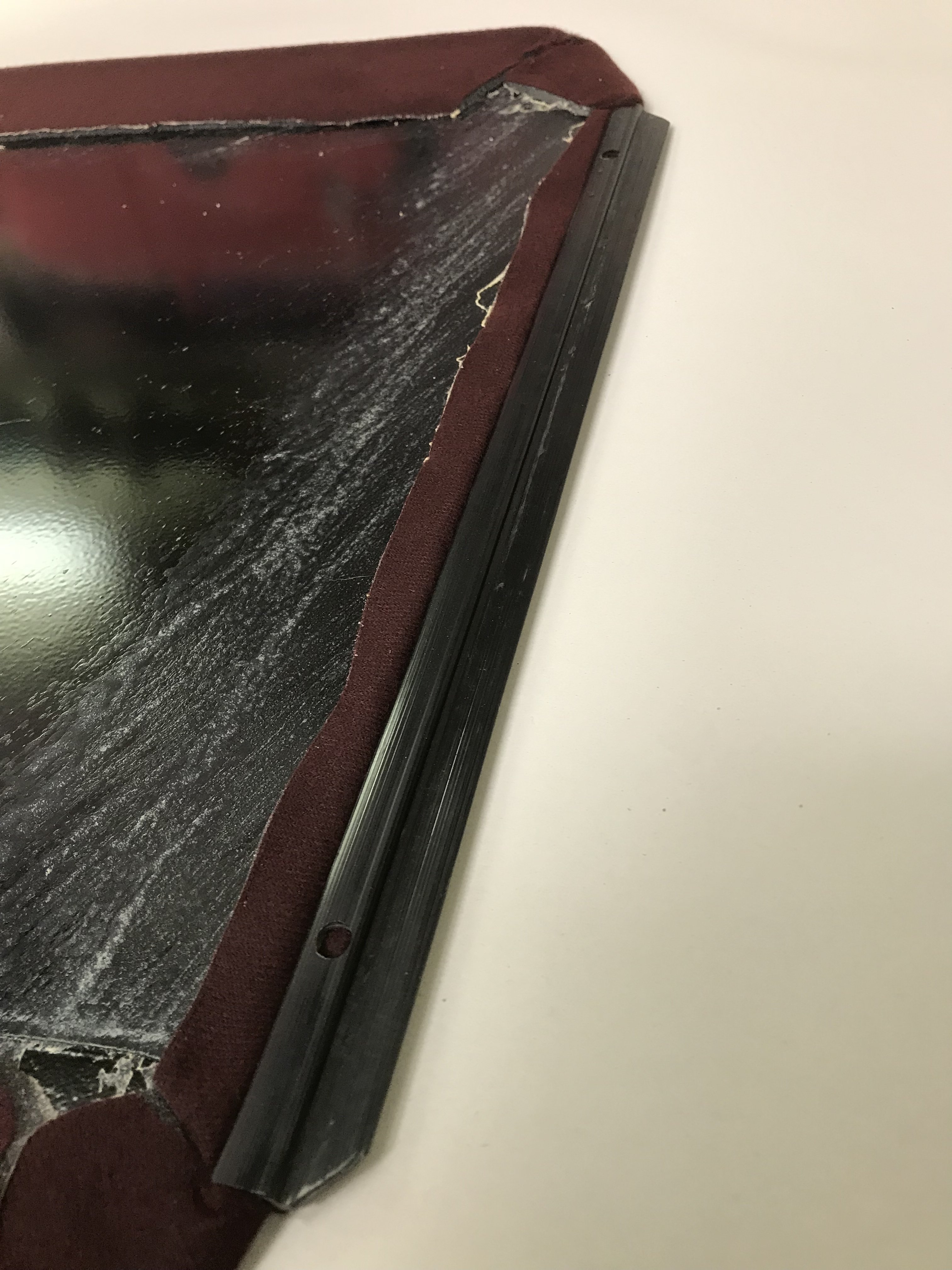

I wasn’t quite done yet, the last couple pieces still needed to go back on. The sides of the slider board get plastic rub strips, these just friction fit over the sides:

These rub/slider strips are why I was a bit concerned when I realized the new headliner material was foam backed, I wasn’t sure the foam was going to compress enough to allow the strips to go back on. However I’m pleased to report, they’re a bit snug but they went on fine with a little persuasion from a small dead blow mallet:

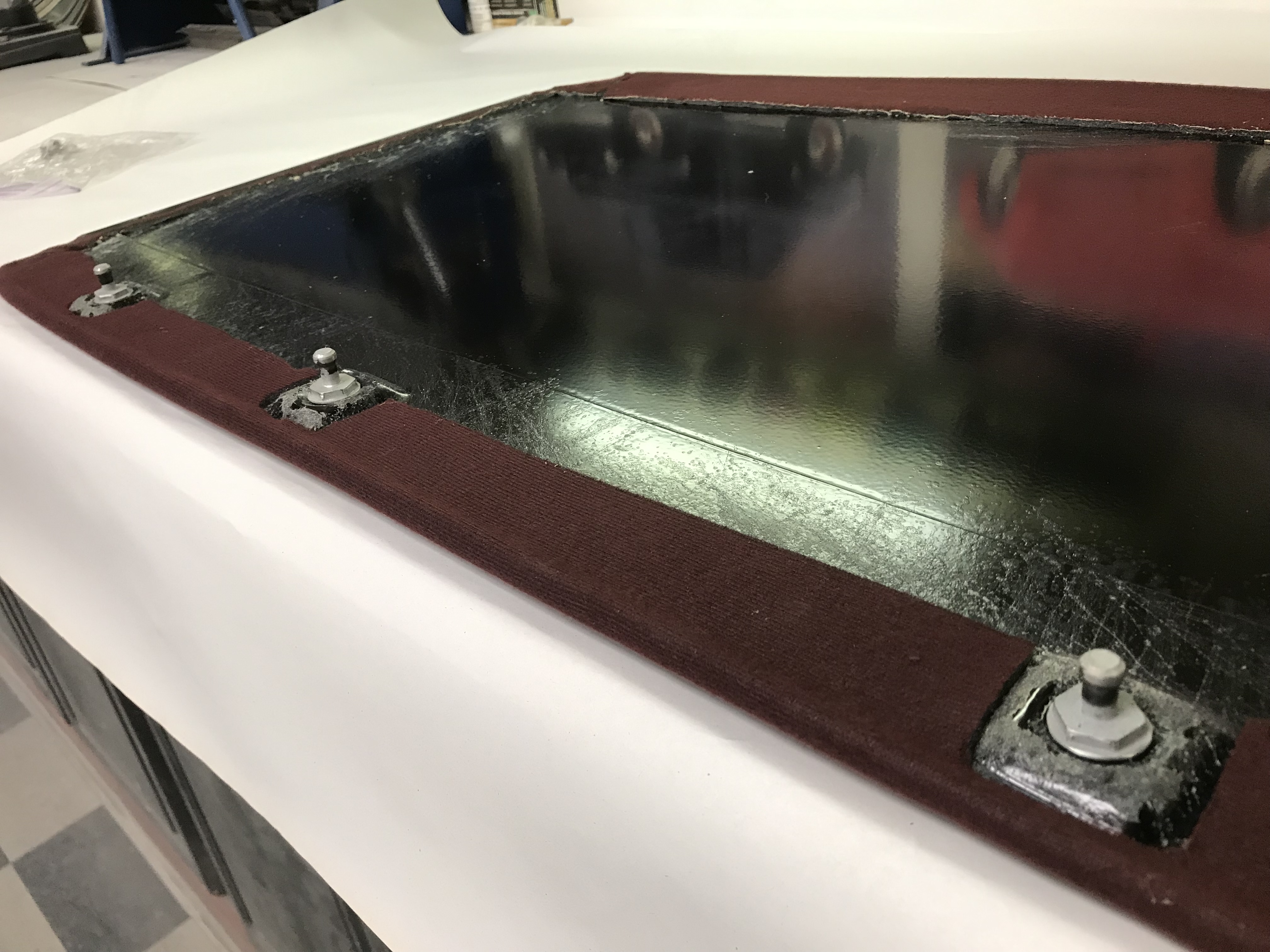

Last thing was to trim around the embossed areas and reinstall the pins. These just thread in and hook into the underside of the outer pan. The pan then pulls the slider back with it when you open the roof:

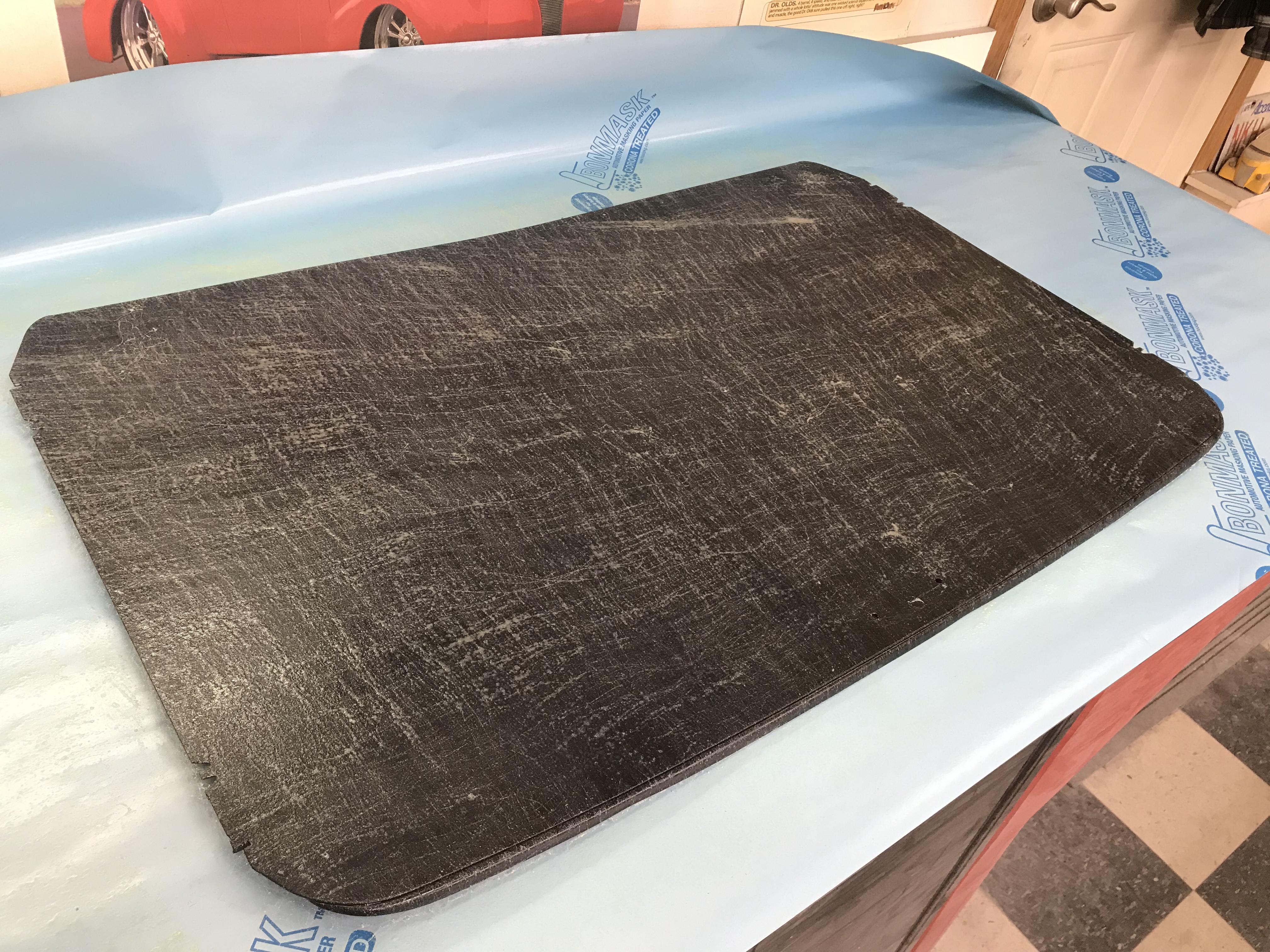

Underside of the now completed assembly...

...and of course the important side again:

Jeez, mechanical, body work and paint, plumbing and electrical, with a small bit of millwright thrown in for good luck, and now upholstery, and I’m becoming rather well-rounded!!

Mike is unavailable tomorrow, off camping or some such foolhardy thing, so after letting this cure overnight I’ll be doing the final assembly of the cartridge tomorrow. Then Monday, he should be back in town and we can get this beast of a project reinstalled back into the car!

Until then...

D