Alright gents, a little Sunday morning reading for most of you.

I’m still in the holding pattern waiting for the big weekend, but it’s now less than a week away and the reality is finally sinking in.

Not a whole lot has happened in the past week, but I did manage to track down and install the Moroso baffled valve cover grommets:

I’m pleased to report that these covers are tall enough that the deep grommets clear the valvetrain no problem. I wasn’t 100% sure they would as I had to drill the holes in non-stock locations so that I wasn’t drilling into the lettering, but it all worked out just fine.

Installed:

This engine is still pretty fresh and strong and I’ve never seen it push oil or blowby anywhere, so I’m pretty confident these grommets will do the trick.

The big news for me this week however came on Friday. I got some time to stop in at my paint supplier and have a good discussion with the guys there about what I planned to do and choose my products. A huge shoutout to Terry, Rick and Jared at Advanced Coatings in Calgary for helping this ole dude out.

I started by showing them pictures of the car in it’s current state so that we were all on the same page and then outlined what has to be done. I listed the products and methods I had planned to use in the booth, and they patiently listened and made some suggestions that might be more appropriate for what I need to do.

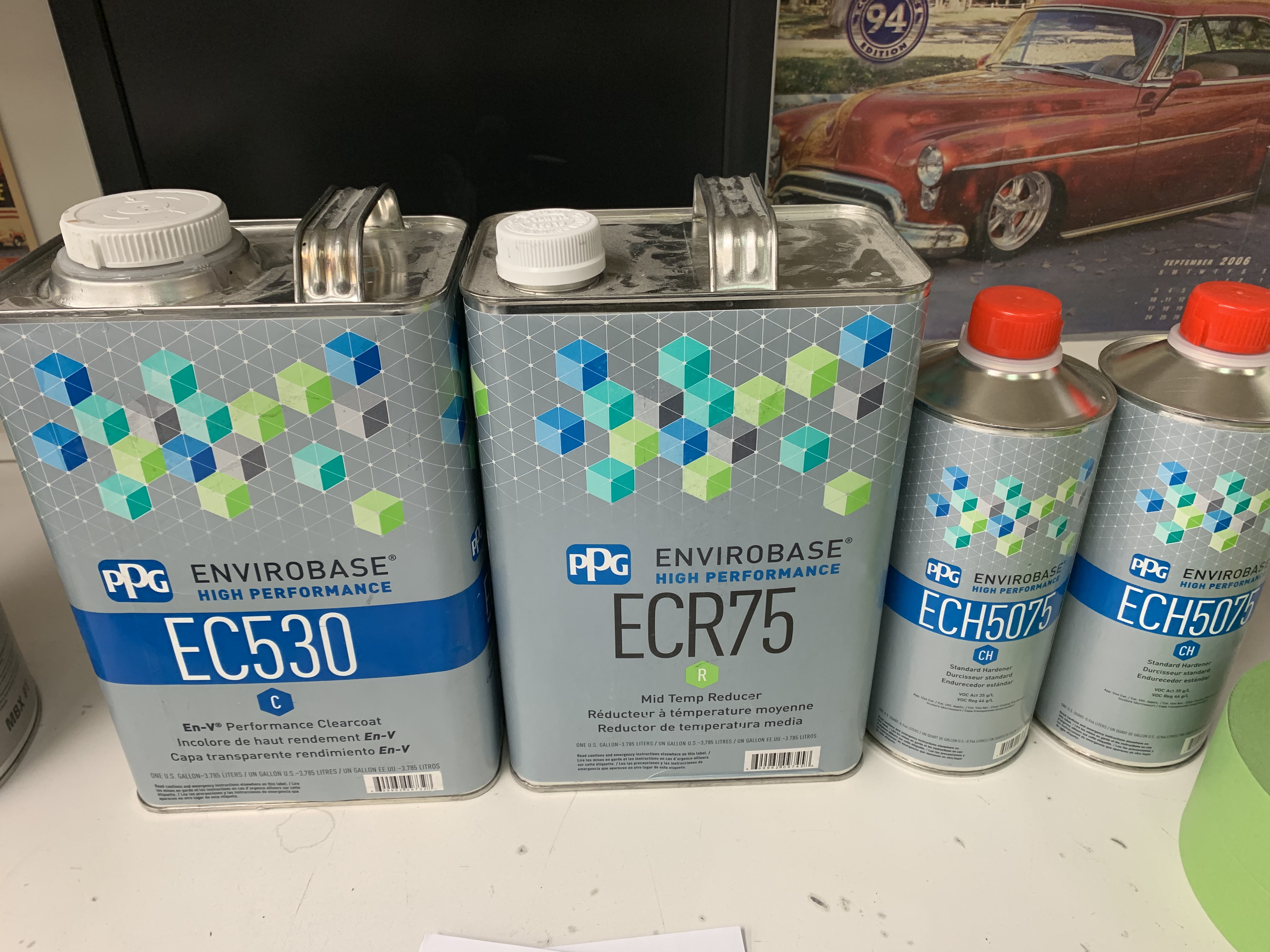

We started with the clearcoat, I had planned on using the EnviroBase EC550 EN-V clear, but Terry suggested if I didn’t know the cleanliness of the booth, the EC530 might be a better choice because it doesn’t stay “open” as long. Less chance of dust settling in the clear that way. Just as we were having this discussion, the owner’s son Jared interjected and said that they had an open but unused gallon of the 530 and it’s matching reducer that he would sell to me at a substantially reduced cost.

Perfect!! Easy decision made there.

Next we talked about the color coats. I had already done the legwork and crunched some numbers so that I knew roughly how many square feet would need coverage and multiplied that by the number of coats that would likely be needed. After some discussion and debate, we ultimately decided that 3 sprayable quarts of the Cameo white and 2 sprayable quarts of the Sterling grey combined with the pints of each I already had at home would get it done.

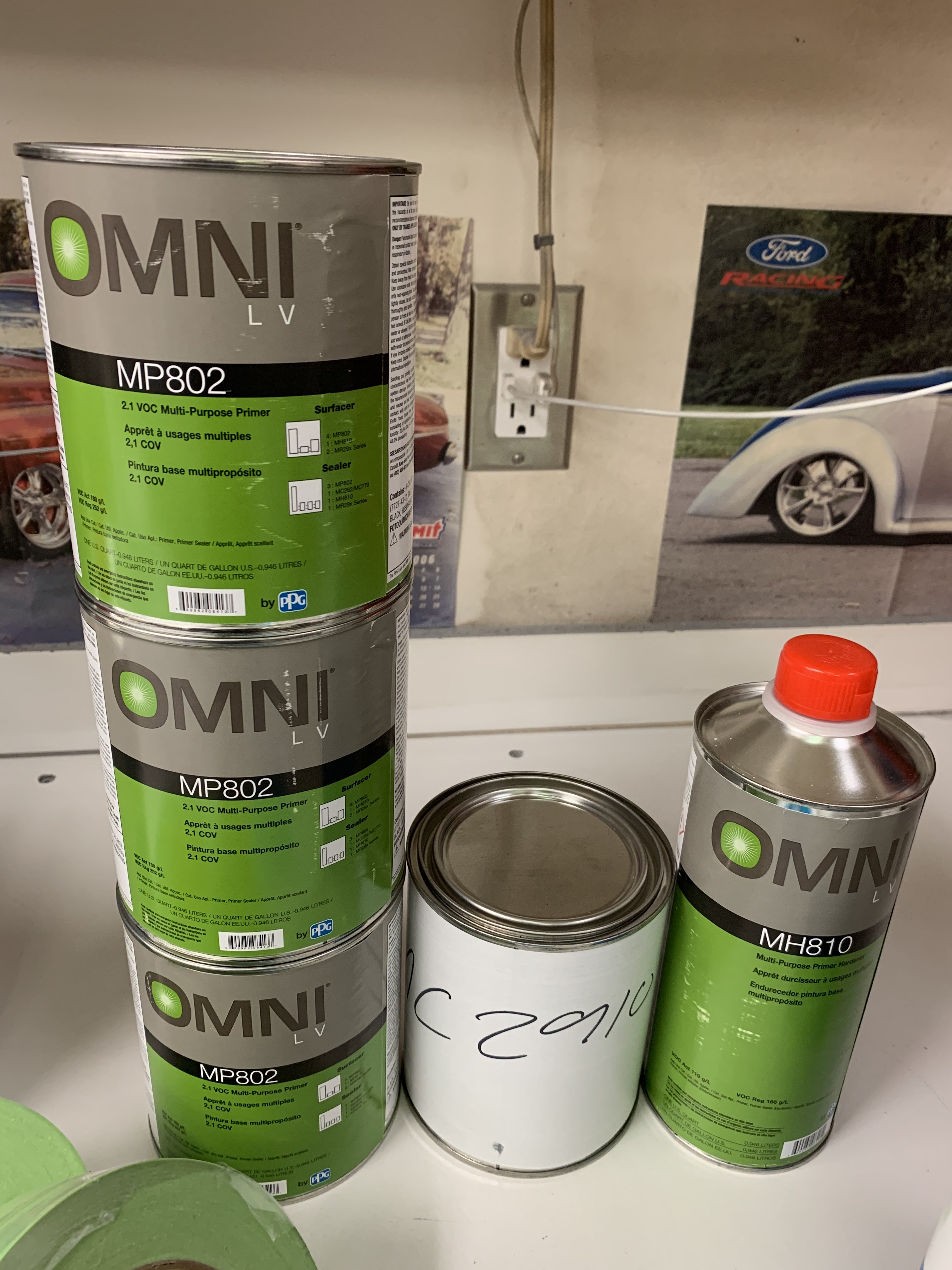

The big unknown area for me was the sealer selection next. I knew that I would need to stick with an Omni sealer to keep all the products compatible right up to the clear, but beyond that I was completely unsure because I’ve never used a sealer before. I mentioned that I thought an epoxy based sealer might be the way to go, but Terry quickly shot that down saying that he thought it would be a waste of money for my application. “It’s way overkill and unneeded” were his words.

Instead, we decided that we’d stick with the Omni MP 802 which, some of you might recognize, is also the high build primer I’ve been using. It’s turns into a wet on wet sealer in a 3:1:1:1 combination with the addition of some Omni clear.

That about took care of the product selection and quantities, then it was time to add the sundries. Painter’s suit, disposable gloves, wax and grease remover, more tape, tech sheets for everything, etc etc. Now for the nerve racking part:

Totalling up the bill.

Before I go any further, I should mention that I had already previously priced out the clear and it’s components, and to make one gallon of sprayable clear, it was going to be $700 my cost!

So I nervously stood by as Rick tallied up all the stuff and quietly wondered to myself if my $2000 budget was going to be adequate to cover it all. Imagine my delight as the total bill, tax in, came out to just a hair over $1200. Yes, I know that’s still a sh*t-ton of dough, but I was getting what by rights, was over $2000 worth of products and materials for that price!

To say I was grateful to Jared for speaking up about the stuff that wasn’t in his inventory and otherwise saleable is a huge understatement.

In exactly the right place and the right time I guess!

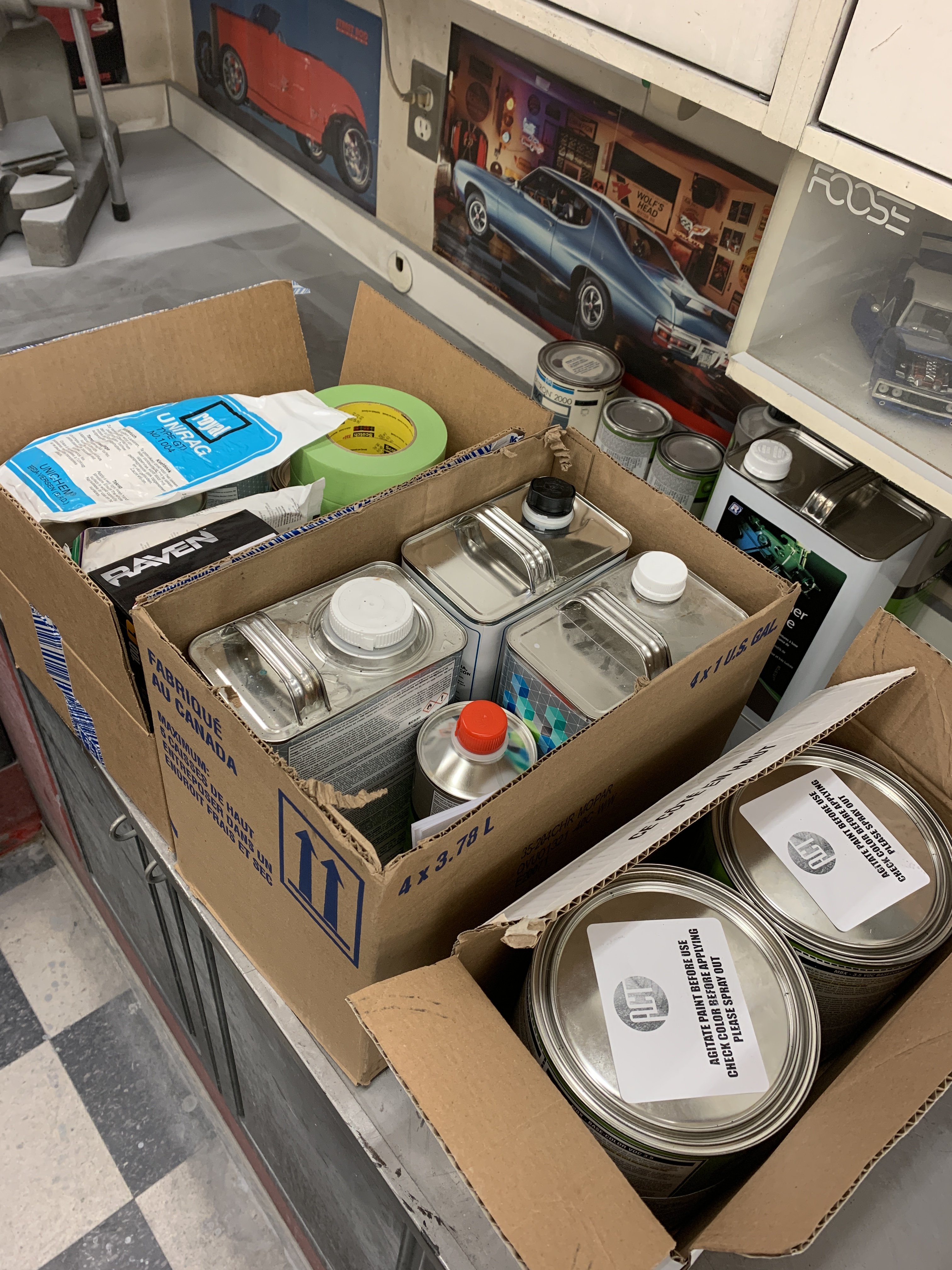

So there ya have it. All the products and materials have been officially selected and bought, and they’re quite substantial when all complied. 3 boxes worth in fact!

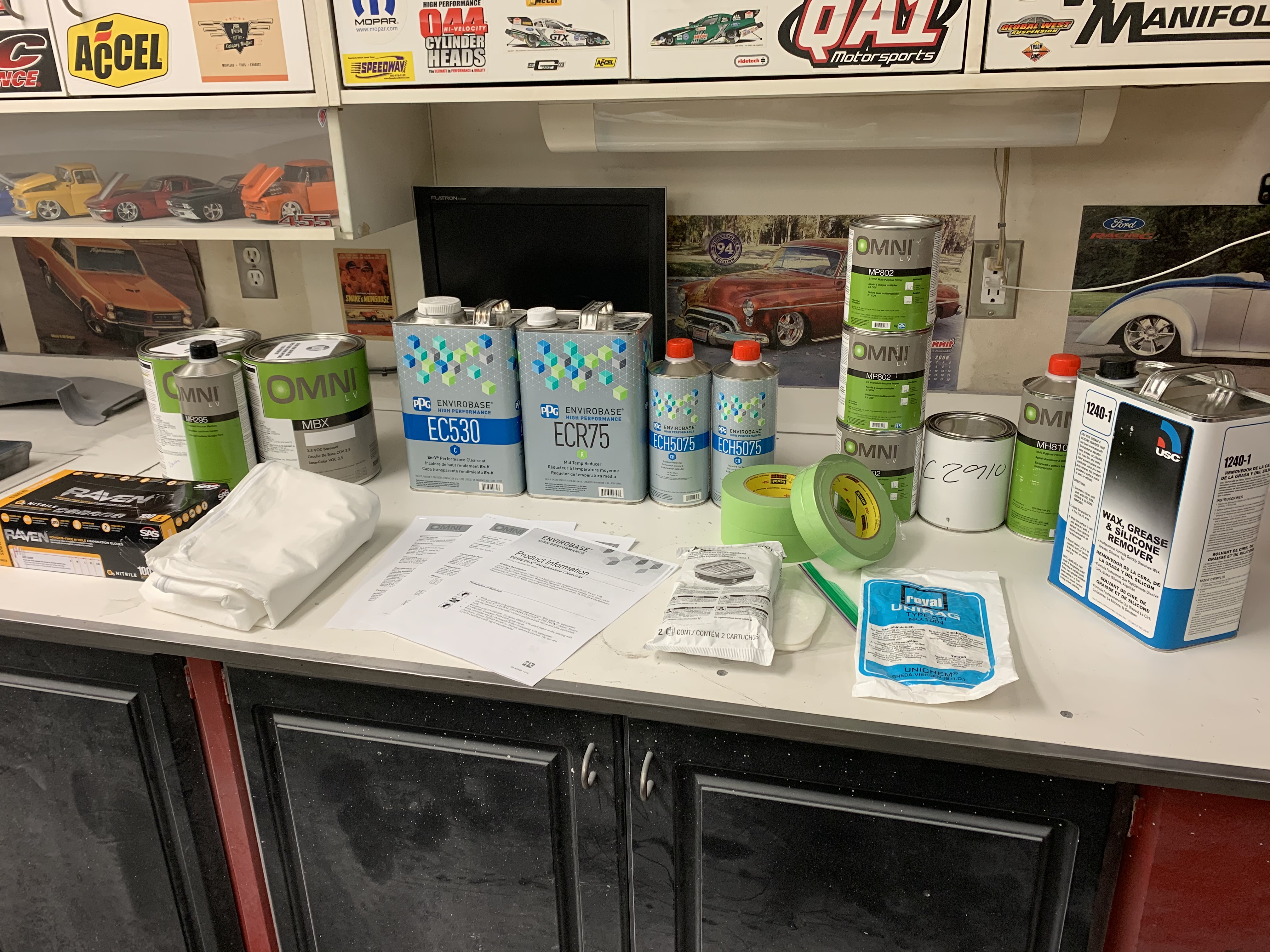

Here they are all laid out on the counter:

From left to right in groupings, the basecoat colors, 3 quarts Cameo White and 2 quarts Sterling Grey in gallon cans along with some of its reducer:

The clear and it’s components, hardener and reducer, enough to make the entire gallon sprayable:

The sealer and it’s components, hardener, reducer and Omni clear required as it’s carrier:

And then the miscellaneous stuff.

Tech sheets for all the products:

Gloves and painter’s suit:

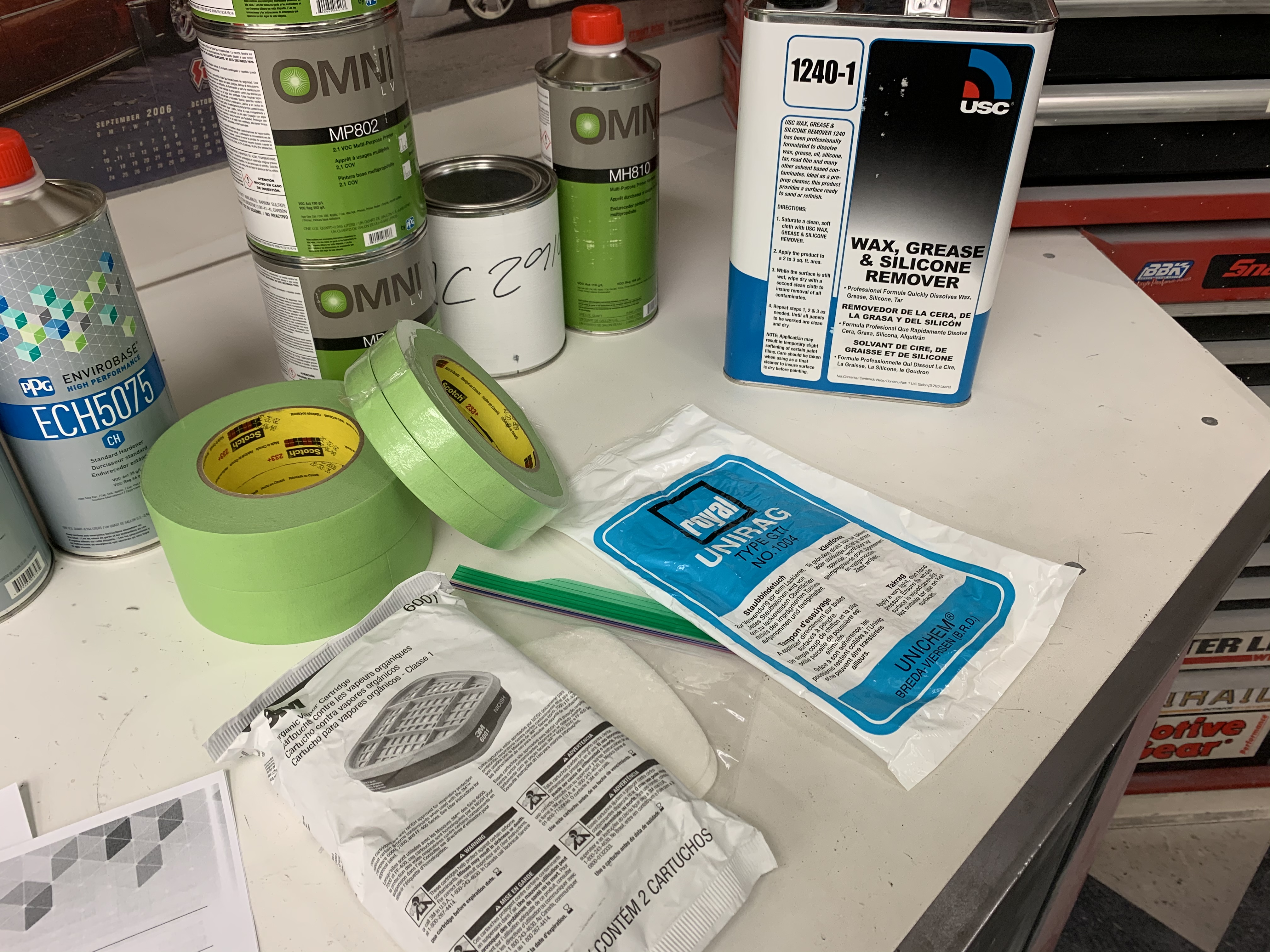

Tape, cartridges and pre-filters for my mask (last ones they had in stock!), tack rag, and wax and grease remover:

This is just the stuff I bought on Friday, and doesn’t take into account the materials I already have and will need to take along as well.

Overall it was a huge relief that I not only came in under budget, but by a substantial amount too! I now have an extra $800 left over that I wasn’t planning on having.

THAT, my friends is a great feeling for a change.

As these last few days tick down, I’ll be doing some preliminary masking on the car up until Friday, then Friday morning I will be bringing our trailer home from work and paying for half the booth up front. If the weather is nice, I’ll load up the car on the trailer Friday night and load the truck with all the products and stuff I’ll need so that I can head straight out bright and early Saturday morning.

It’s almost time friends!

D.