Q jet Rebuild?

- Thread starter Bri guy

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Try contacting Everyday Performance. He's a member of this forum and his specialty is Q-jets.I have a qjet that came off a 76 olds 455. Think it's 800cfm. Can't find anyone to rebuild them where I'm at. I have never rebuilt 1 before. What will happen if I put it together wrong and try to start the car?

Several guys who have had their carbs done by him seem to be pleased with the outcome.

https://gbodyforum.com/threads/need-a-good-carb-for-built-403.68766/page-3#post-629443

They aren’t any harder than any other carb to rebuild cliff ruggles has a good book that would help you through it

Here's a link to Everyday Performance website http://www.everyday-performance.com/

Btw, they're not too difficult to rebuild. Get a good book like Rochester Carburetors by Doug Roe....or Cliff Ruggles book as mentioned. Like anything else, you have to be patient and pay attention to detail. I just recently rebuilt mine and it seems to be running well.

There's certainly enough help on the site in case you decide to take it on yourself.

Btw, they're not too difficult to rebuild. Get a good book like Rochester Carburetors by Doug Roe....or Cliff Ruggles book as mentioned. Like anything else, you have to be patient and pay attention to detail. I just recently rebuilt mine and it seems to be running well.

There's certainly enough help on the site in case you decide to take it on yourself.

The hardest part, will be aligning the primary metering rods in the jets. That's it. Top lifts off like an edelbrock, just gotta knock the accel arm roll pin back (I use a dime inbetween the roll pin and air horn so I can still wiggle it back in), undo the choke rod from the air horn, undo ALL 9 screws (two under the choke flap).

The most expensive and time consuming part, is the throttle shaft bushings. You can send your baseplate to everyday performance, among others, and have them do it, but if you have a dremel, the bit, and the bushings, it will take about 20 minutes. You need to dremel the staked backsides of the throttle blade screws off so you can back them out without snapping them or mangling the holes.

I have the bit, it was $30 dollars, it's a fluted reaming bit I actually chuck the flute part in the drill and run it backwards. The smooth shank goes into the throttle shaft bores and it self aligns. Bushings are $20 for a set of 10 (5 carbs worth). Usually when I rebuild them, I don't do any modifications internally like drilling out passages. I buy my parts from Quadrajetparts.com, usually ends up being about $100. Rebuild kit (gaskets, needle, seat, lil bits, might have an accel pump check ball), float, accel pump (I don't use the accel pump rebuild stuff, i buy new), o-ring well plugs (drill out the old ones carefully, tamp these ones in, I then epoxy over them, alternatively you can chop up some bolts, slot them for a screwdriver, and run em in), etc.

Plus the QJetParts kits come with all the instructions on how to setup the carb, what level the floats should be, etc. really neat stuff.

The most expensive and time consuming part, is the throttle shaft bushings. You can send your baseplate to everyday performance, among others, and have them do it, but if you have a dremel, the bit, and the bushings, it will take about 20 minutes. You need to dremel the staked backsides of the throttle blade screws off so you can back them out without snapping them or mangling the holes.

I have the bit, it was $30 dollars, it's a fluted reaming bit I actually chuck the flute part in the drill and run it backwards. The smooth shank goes into the throttle shaft bores and it self aligns. Bushings are $20 for a set of 10 (5 carbs worth). Usually when I rebuild them, I don't do any modifications internally like drilling out passages. I buy my parts from Quadrajetparts.com, usually ends up being about $100. Rebuild kit (gaskets, needle, seat, lil bits, might have an accel pump check ball), float, accel pump (I don't use the accel pump rebuild stuff, i buy new), o-ring well plugs (drill out the old ones carefully, tamp these ones in, I then epoxy over them, alternatively you can chop up some bolts, slot them for a screwdriver, and run em in), etc.

Plus the QJetParts kits come with all the instructions on how to setup the carb, what level the floats should be, etc. really neat stuff.

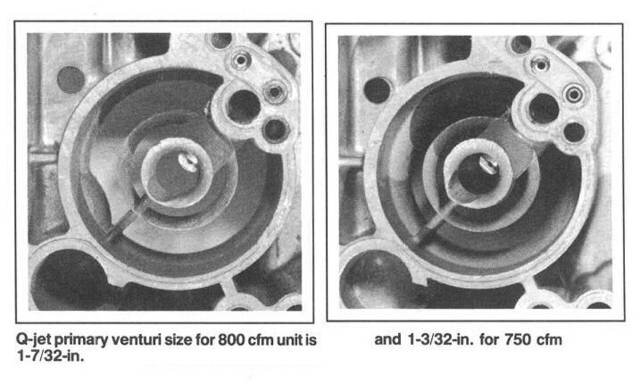

There's a more fundamental question. Why do you think you need 800 CFM? Bigger is not necessarily better when it comes to carburetors. Fortunately a Quadrajet that is too big will not harm your power because the secondaries only open based on airflow.

the answer to your question is if you do a bad job rebuilding it your car will run like crap or not at all.

the answer to your question is if you do a bad job rebuilding it your car will run like crap or not at all.

- Status

- Not open for further replies.

Similar threads

- Replies

- 1

- Views

- 252

- Replies

- 8

- Views

- 1K

- Replies

- 6

- Views

- 205

- Replies

- 26

- Views

- 943

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.