Square body crew

- Thread starter Clutch

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

It's my own fault I thought it through as I was doing it. But it's a busy road and I didn't want to back up with all the traffic. Better it happens now than when I'm plowingYou have some luck!

I would venture a guess that with the wheel cut near lock flexing the suspension one or both of the tie rods from the pitman arm to the steering arm on the axle was in a bind and is now slightly tweaked. Believe it or not, the older straight axle Toyota's use virtually the same set up and when I used to 4 wheel them they would bend the tie rods or break the steering arm. Until I changed to crossover steering.

Big day tomorrow somebody is bringing a pig to my house and I'm going to make some pulled pork in the smoker for dinner. Probably pick up some surf in the morning to go with the turf. And spend the day fixing the truck can't wait I'm psyched!

Where do I start with this update? So much fixed so few pictures. Yesterday morning I started the day by putting a pork but in the smoker and before I could run over to the seafood co-op there was a pig wearing lipstick in my driveway and it's nicer than its thread makes out it to be. This was also the first time anyone besides me has worked on the truck with the exception of Brian the kid from work giving me a hand a few times. I'm shore Bruce will chime in on what all he did to it it's been a day and a half of fixing wiring. I told him it was a mess. More so than he expected lol but we got a lot of it knocked out. He can tell you the logistics of it all better than I can. Here's what's fixed.

Headlights high-beam and low-beam

Plow lights high-beam and low-beam

Gas gauge

Oil pressure gauge

Accessory power with key

and with all that done I think it was a few other things that started working correctly along the way.

Bruce thank you so much! Your welcome here anytime but Lauren says your not getting her car lol

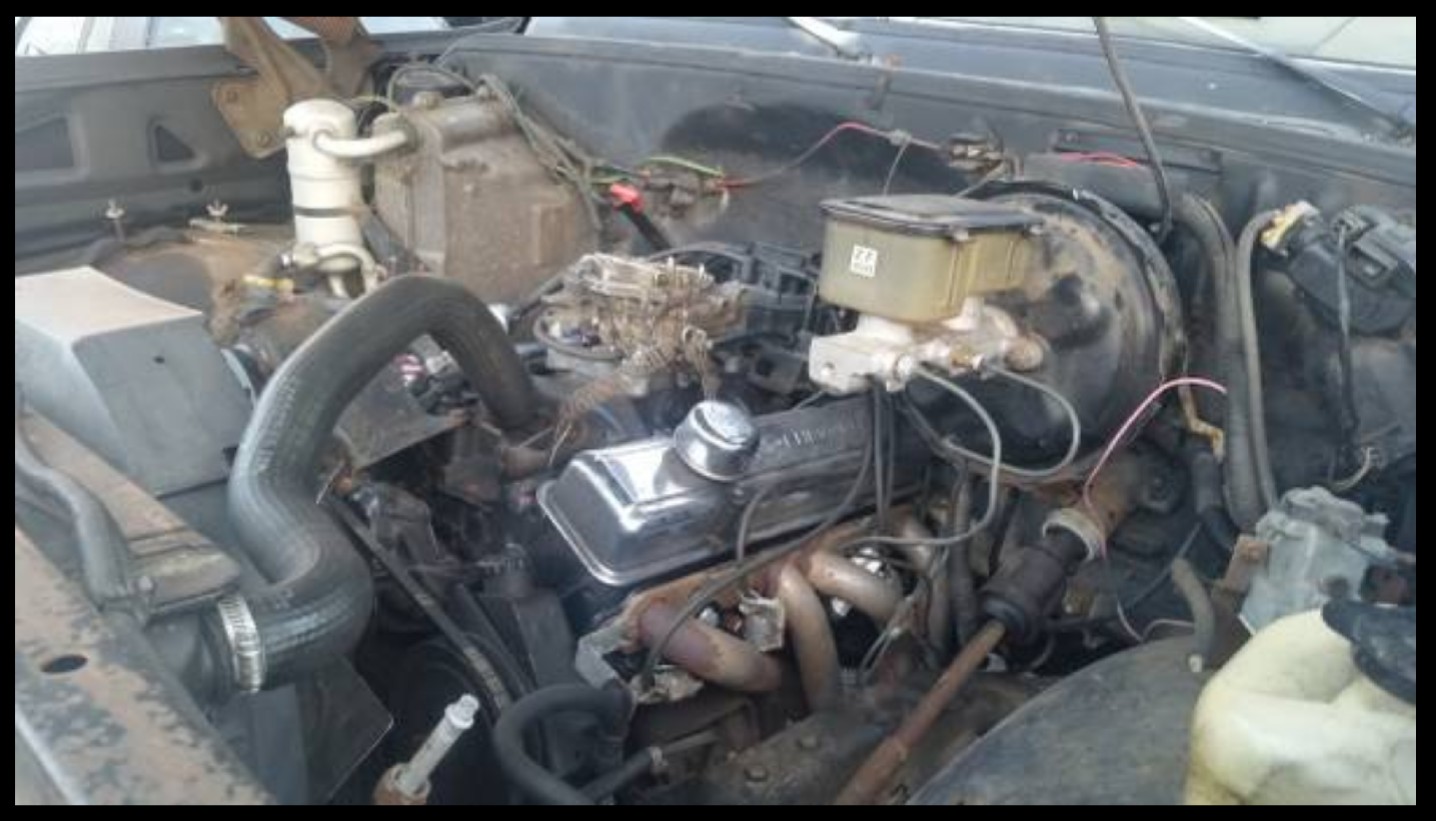

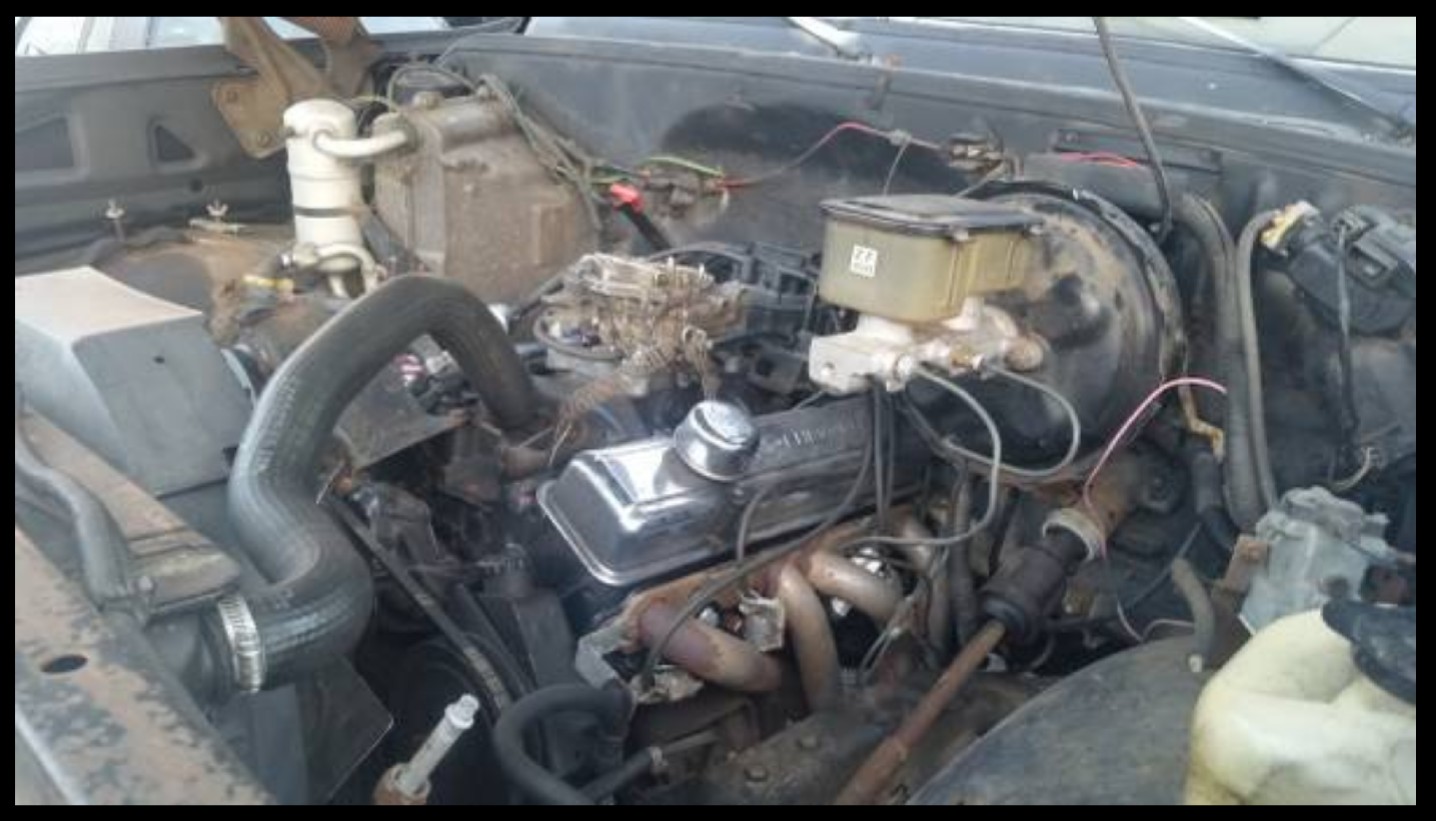

Here's some weight we shed off the nose

And here's Bruce leaving

and here's my working dash

and here's my working dash

Right down to the now working shift indicator

Headlights high-beam and low-beam

Plow lights high-beam and low-beam

Gas gauge

Oil pressure gauge

Accessory power with key

and with all that done I think it was a few other things that started working correctly along the way.

Bruce thank you so much! Your welcome here anytime but Lauren says your not getting her car lol

Here's some weight we shed off the nose

And here's Bruce leaving

Right down to the now working shift indicator

Last edited:

that's awesome that he was able to come out and give you a hand!

Yes yes it was I've been trying to figure out things for 3 years that are now fixed! Ask him about the pink wire that the schematics said should be tan! There's literally a picture of it on the very first page of the thred.that's awesome that he was able to come out and give you a hand!

Chef Clutch, thanks for the hospitality and some killer pulled pork!

Here's the technical deets:

-passenger headlight dim, driver okay: Western plow harness from previous vehicle installed. Crusty looking spade terminals on relays, 4.2v on low beam, high beam inop. FIX: clean bulkhead connector, discover bent pin for unrelated wiper circuit. Replace hardwired relays with conventional 5 pins on sockets, ground headlights directly to core support, eliminate spade connections into factory plugs.

-inop fuel gauge- FIX: determine proper wire color for sending unit for 87 sending unit and 80 fuel gauge (it's pink, btw). Confirm gauge is good, rewire from tan (pump power) to pink (sender), locate pink wire on firewall side of bulkhead connector ("this pink wire is hot all the time, and I have no idea where it goes", hey, it's got the same 8.1v as the back of the gauge, what happens when I ground it?, the gauge moves, ok, let's hook it up!)

-inop oil pressure gauge: locate brown wire in engine compartment, determine open circuit in 3-4 feet of wire. EASY FIX: laser bypass (new wire from sender to cluster plug.

-crazy gauge and turn indicator operation: folded over ribbon pin on PCB. FIX: carefully straighten and install plug.

-inop high beam indicator- FIX: install bulb socket

-intermittant accessory power with no power on key back to accessory- FIX: buy new ignition switch, drop column, determine switch is incorrect, return switch, get interrogated by manager, point out flaw, get refunded, go back across town opposite direction, get new switch, and install correct switch.

It was a great weekend that truly defines what GBF is all about- meeting great people, sharing a common interest and helping each other out.

Here's the technical deets:

-passenger headlight dim, driver okay: Western plow harness from previous vehicle installed. Crusty looking spade terminals on relays, 4.2v on low beam, high beam inop. FIX: clean bulkhead connector, discover bent pin for unrelated wiper circuit. Replace hardwired relays with conventional 5 pins on sockets, ground headlights directly to core support, eliminate spade connections into factory plugs.

-inop fuel gauge- FIX: determine proper wire color for sending unit for 87 sending unit and 80 fuel gauge (it's pink, btw). Confirm gauge is good, rewire from tan (pump power) to pink (sender), locate pink wire on firewall side of bulkhead connector ("this pink wire is hot all the time, and I have no idea where it goes", hey, it's got the same 8.1v as the back of the gauge, what happens when I ground it?, the gauge moves, ok, let's hook it up!)

-inop oil pressure gauge: locate brown wire in engine compartment, determine open circuit in 3-4 feet of wire. EASY FIX: laser bypass (new wire from sender to cluster plug.

-crazy gauge and turn indicator operation: folded over ribbon pin on PCB. FIX: carefully straighten and install plug.

-inop high beam indicator- FIX: install bulb socket

-intermittant accessory power with no power on key back to accessory- FIX: buy new ignition switch, drop column, determine switch is incorrect, return switch, get interrogated by manager, point out flaw, get refunded, go back across town opposite direction, get new switch, and install correct switch.

It was a great weekend that truly defines what GBF is all about- meeting great people, sharing a common interest and helping each other out.

Last edited:

This picture was emailed to me by the previous owner before I bought the truck there's that dam pink wire hooked up to nothing and running the wrong way

- Status

- Not open for further replies.

Similar threads

- Replies

- 13

- Views

- 432

- Replies

- 13

- Views

- 611

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.