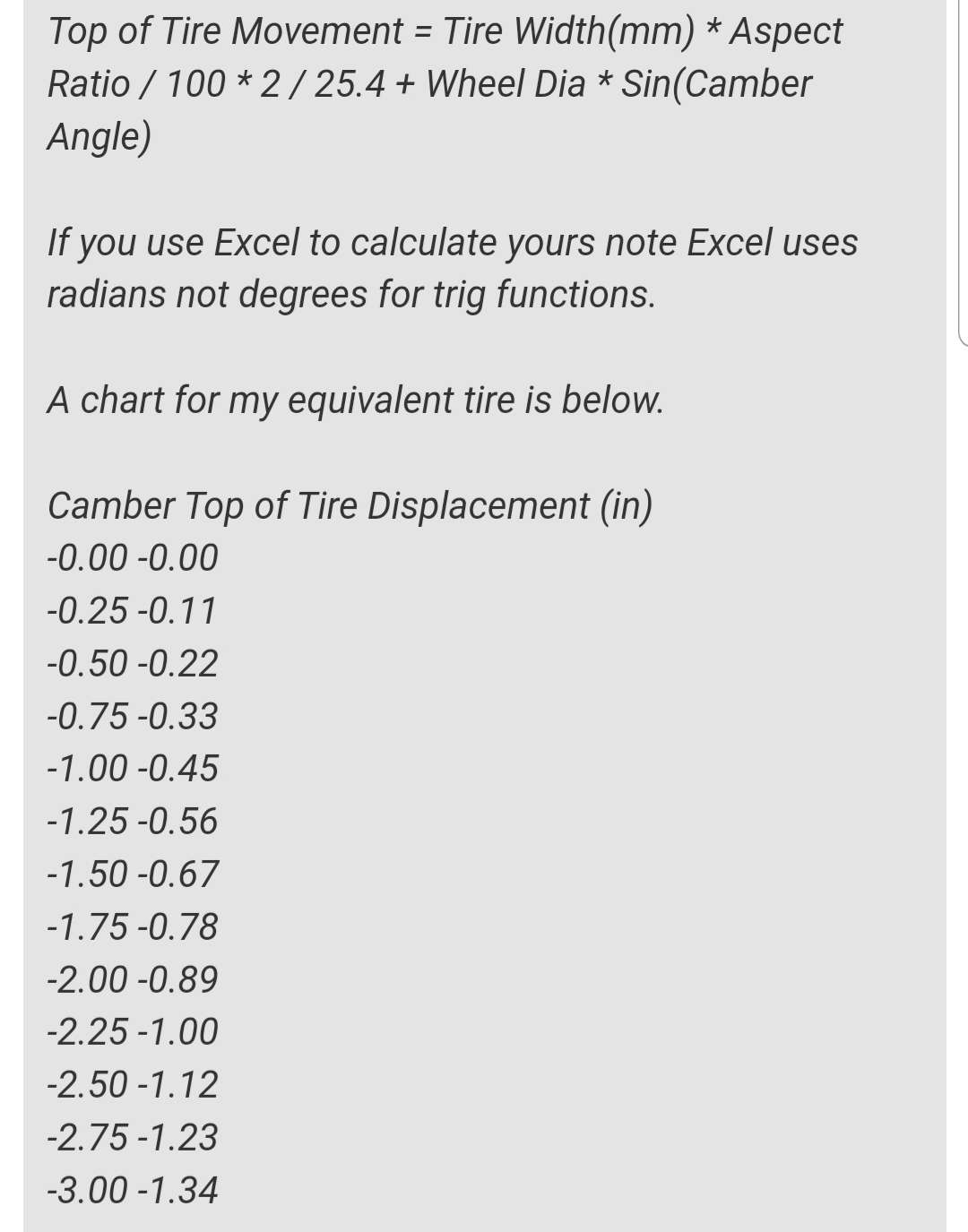

Ok so I am turning to you guys as I need some help figuring this out for my buddies 1963 Impala. The car is on air bags and at driving height the car is sitting at negative 2.5° of camber. There are no shims in the a-arm at all right now...so no way to pull shims out to get it even. The car had hydraulics years back so we are sure the the front end of the frame is sagging..thus giving us the negative camber. We can get and install upper a-arms extended 1, 1.5 or 2 inches. This would obviously push the ball joint out adding positive camber and we could shim back as needed. Is there a formula or way to determine about what extension we should go to get it close?

He is not intrested in adjustable tubular a arms as his car is full show and he would like to keep to a extended and molded chrome upper to match the rest of the suspension. Any help on the math would be killer!

He is not intrested in adjustable tubular a arms as his car is full show and he would like to keep to a extended and molded chrome upper to match the rest of the suspension. Any help on the math would be killer!