Hmm. Then I guess the reverse fix apparently did work. You just need one now for Drive Fix. 🙂That what I have found also, basically just a plate that may not do anything.... Reverse always engaged perfectly on this one, drive was a different story, slow when cold.

TH2004R tear down and build

- Thread starter olds307 and 403

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

That is why this is a good candidate for a rebuild with a new pump. It had one issue and pump buzzing but had all 4 gears. The one outside only has first and second and was ran low on fluid.Hmm. Then I guess the reverse fix apparently did work. You just need one now for Drive Fix. 🙂

The first broken accumulator spring

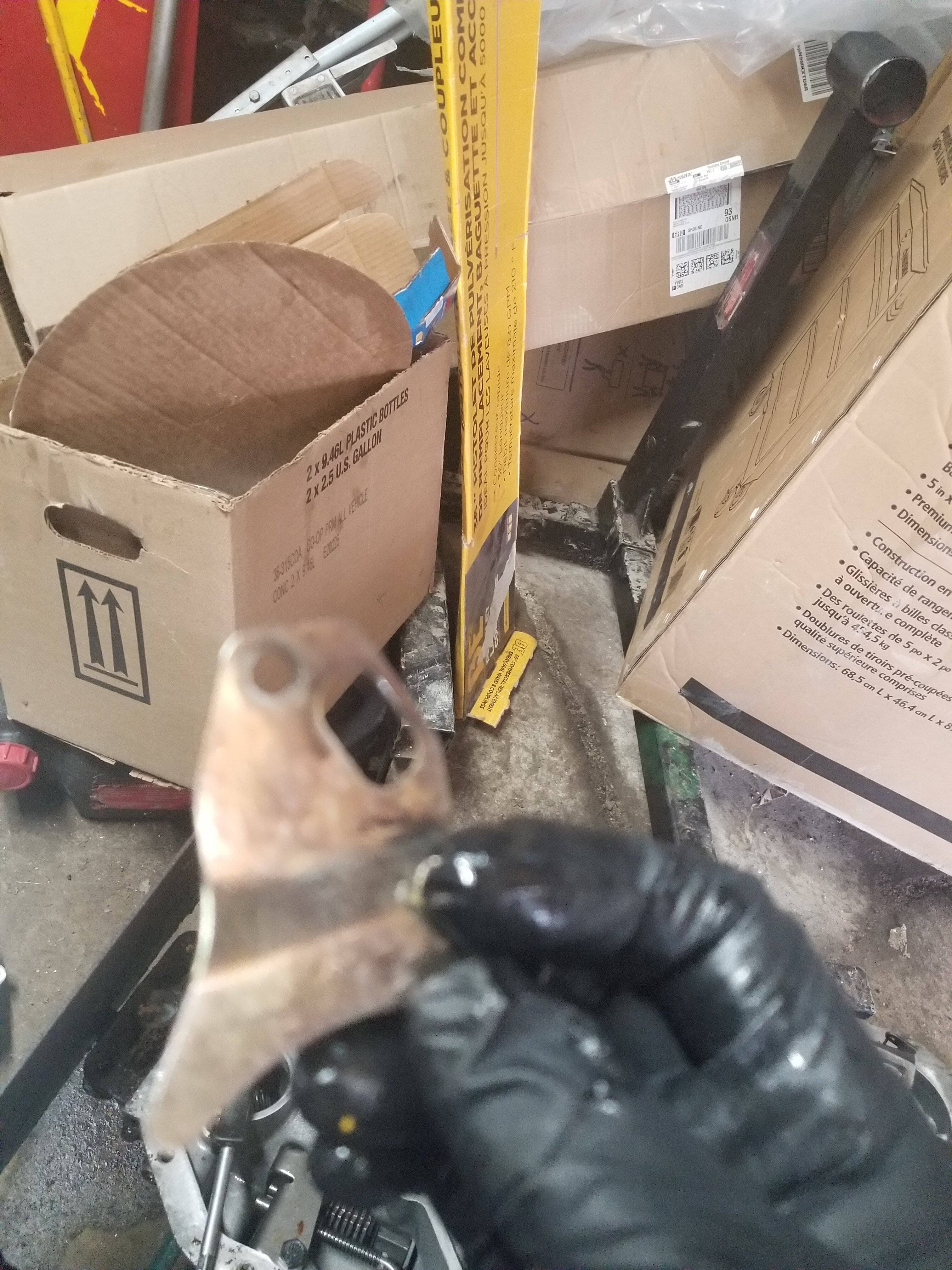

The "Guppy" Reverse fix plate

Center support

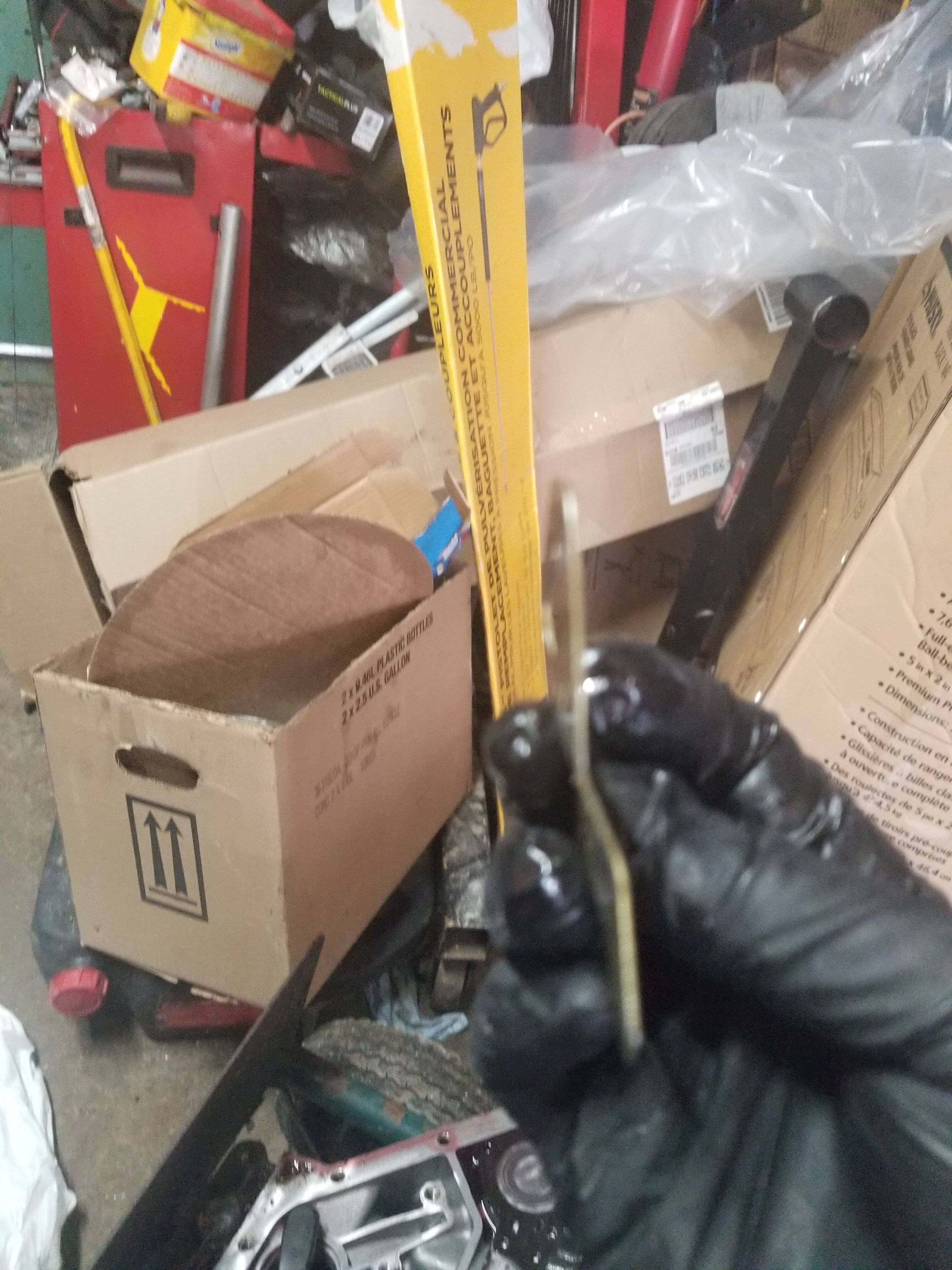

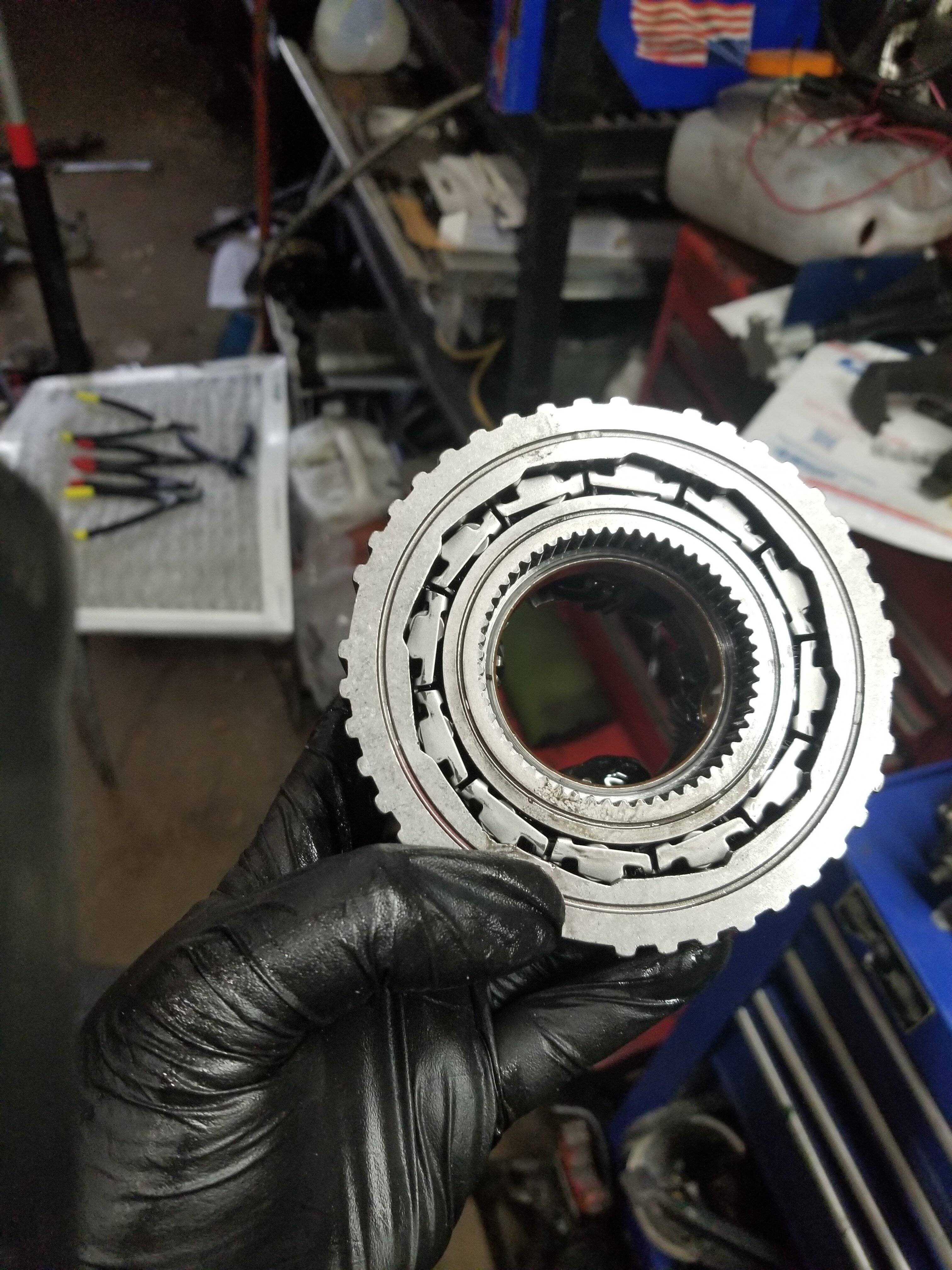

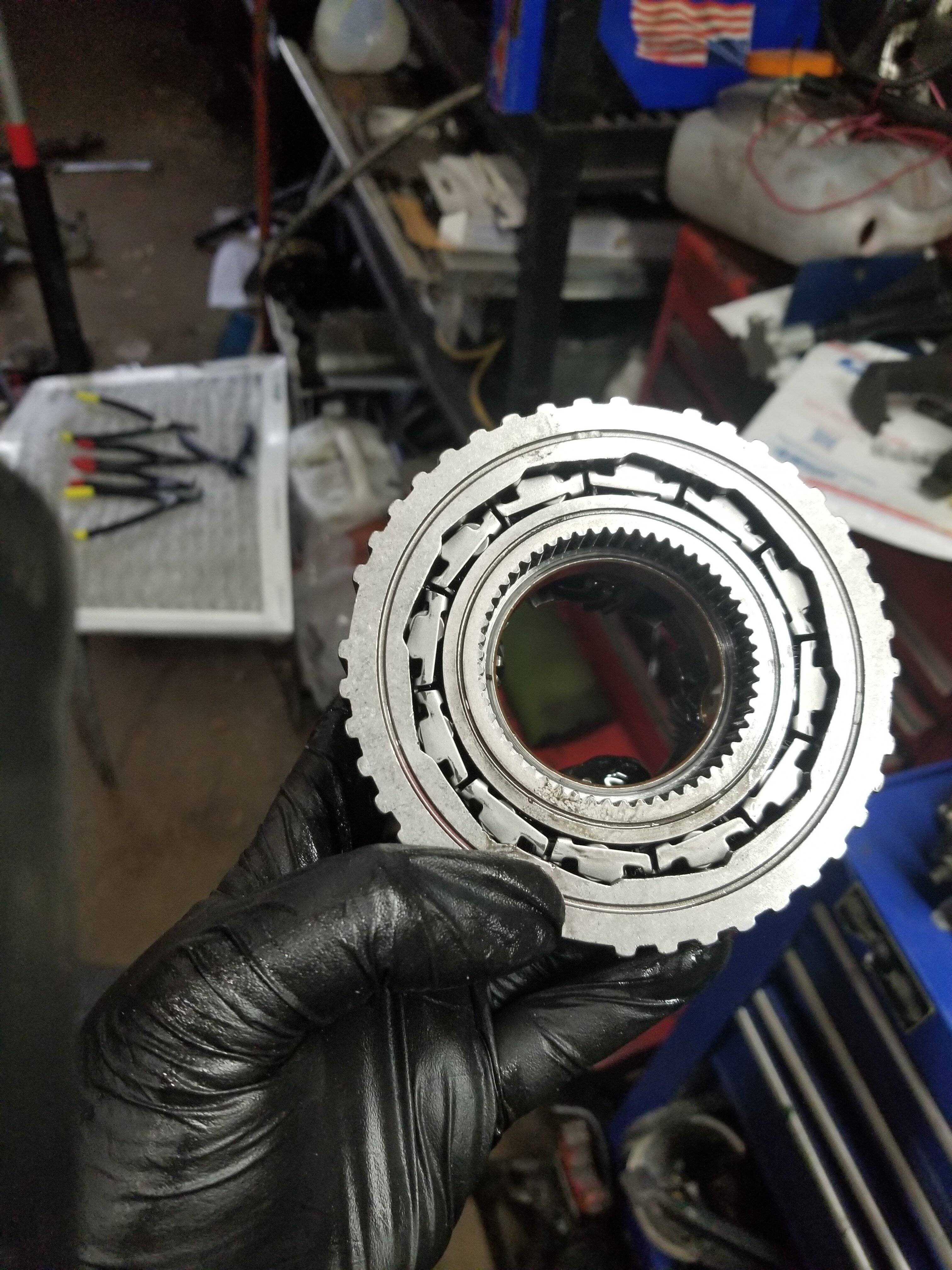

Direct clutch housing

Intermediate band and pin

Internal front planetary gear

Drum and rear Sun gear

Looks like a step in the right direction. I built mine a few years ago and still running great. I also did the billet forward drum, and three clutch on the od plus the other mods you typically do on these.

You can check out my build on here. If you have any questions feel free to ask. I bought the atsg manual for reference.

You can check out my build on here. If you have any questions feel free to ask. I bought the atsg manual for reference.

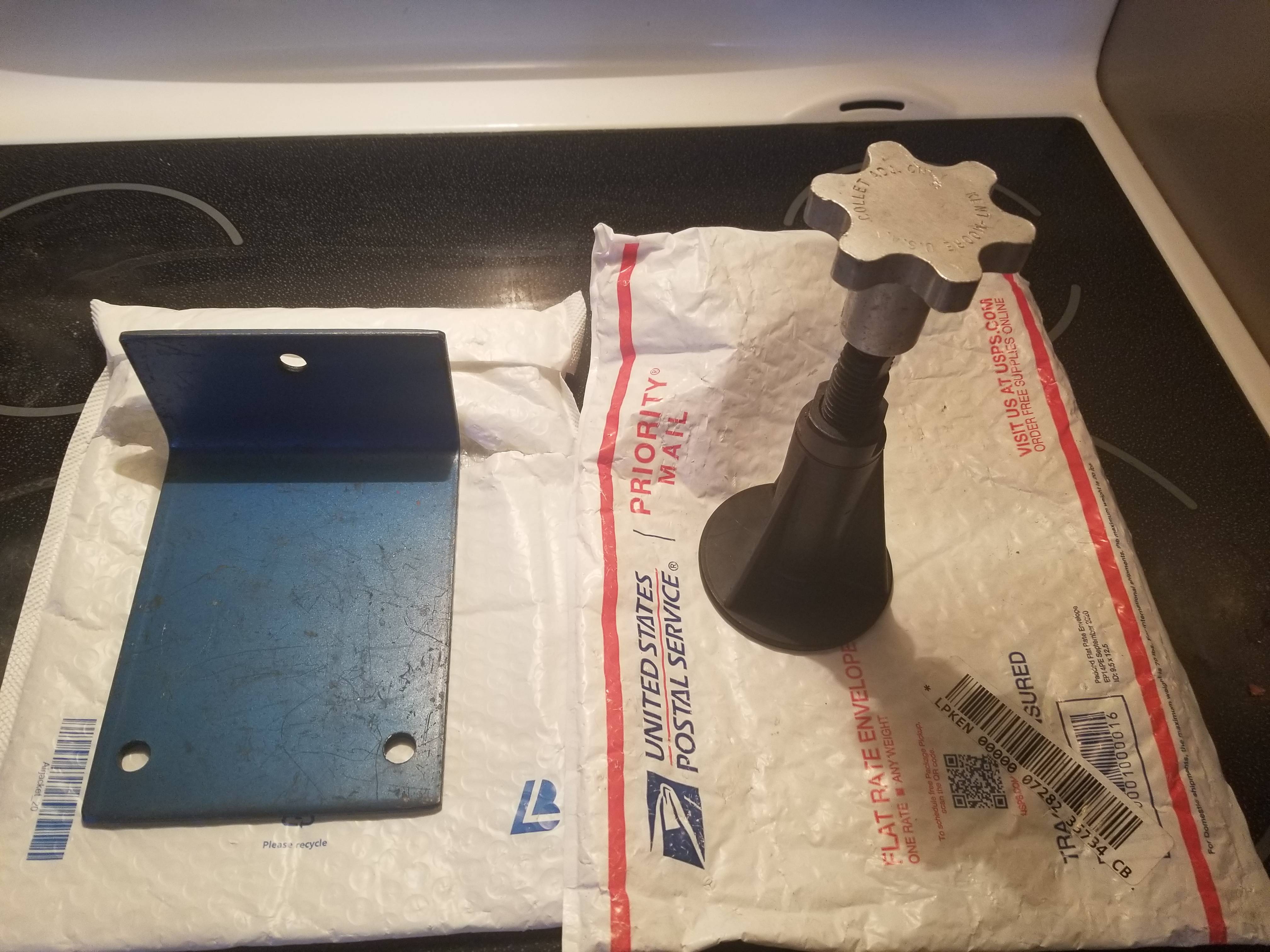

One of the many important things when putting in the lip seals check the part #inside to match with the new ones. Some look the same size but have different #'s.

I visited turbo Buick performance and picked his brain on the build and he mentioned this to me. There is a lip seal tool. I used a feeler gauge.

I visited turbo Buick performance and picked his brain on the build and he mentioned this to me. There is a lip seal tool. I used a feeler gauge.

TexasT was a great resource in here with my build. Super guy.

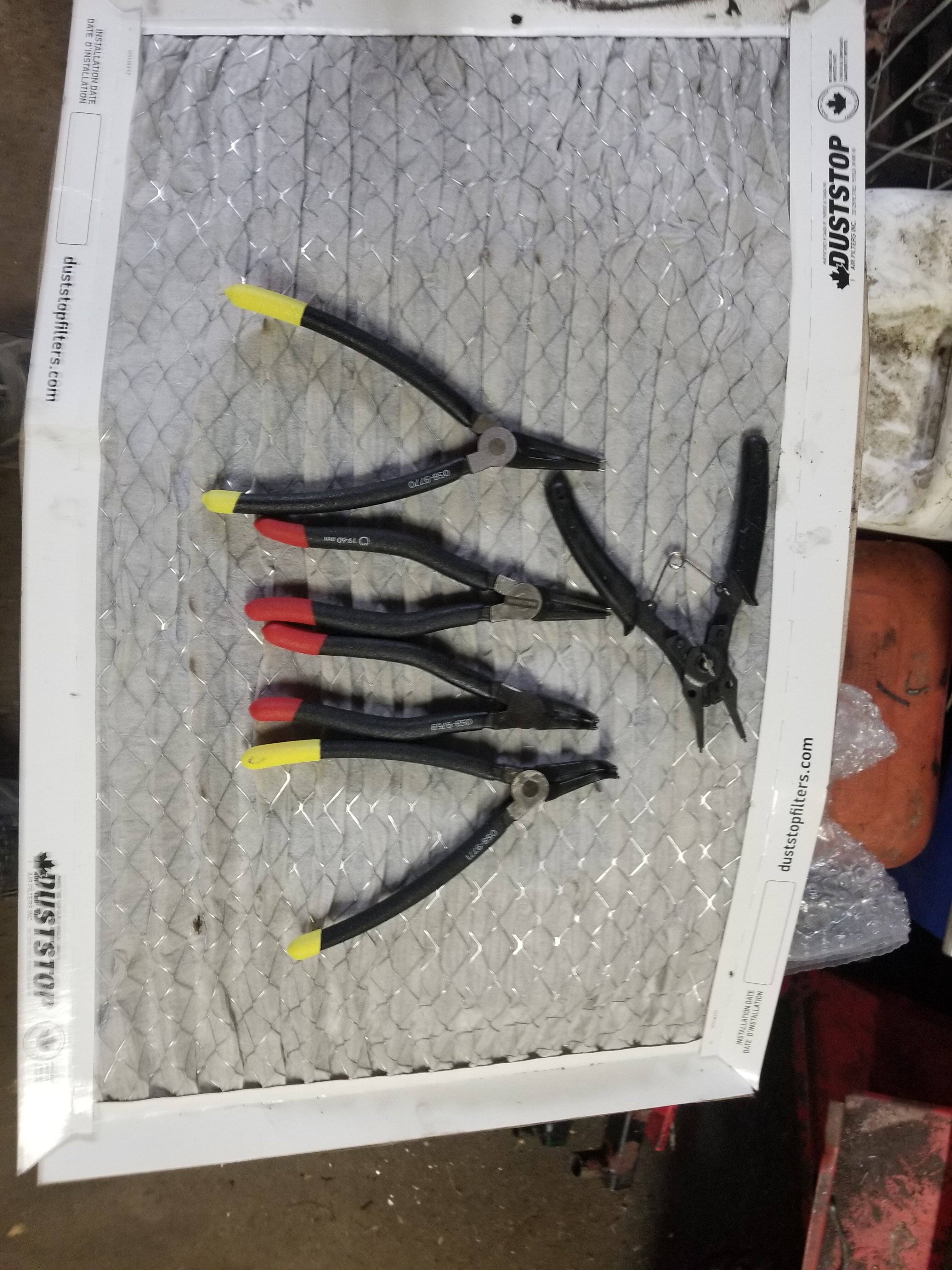

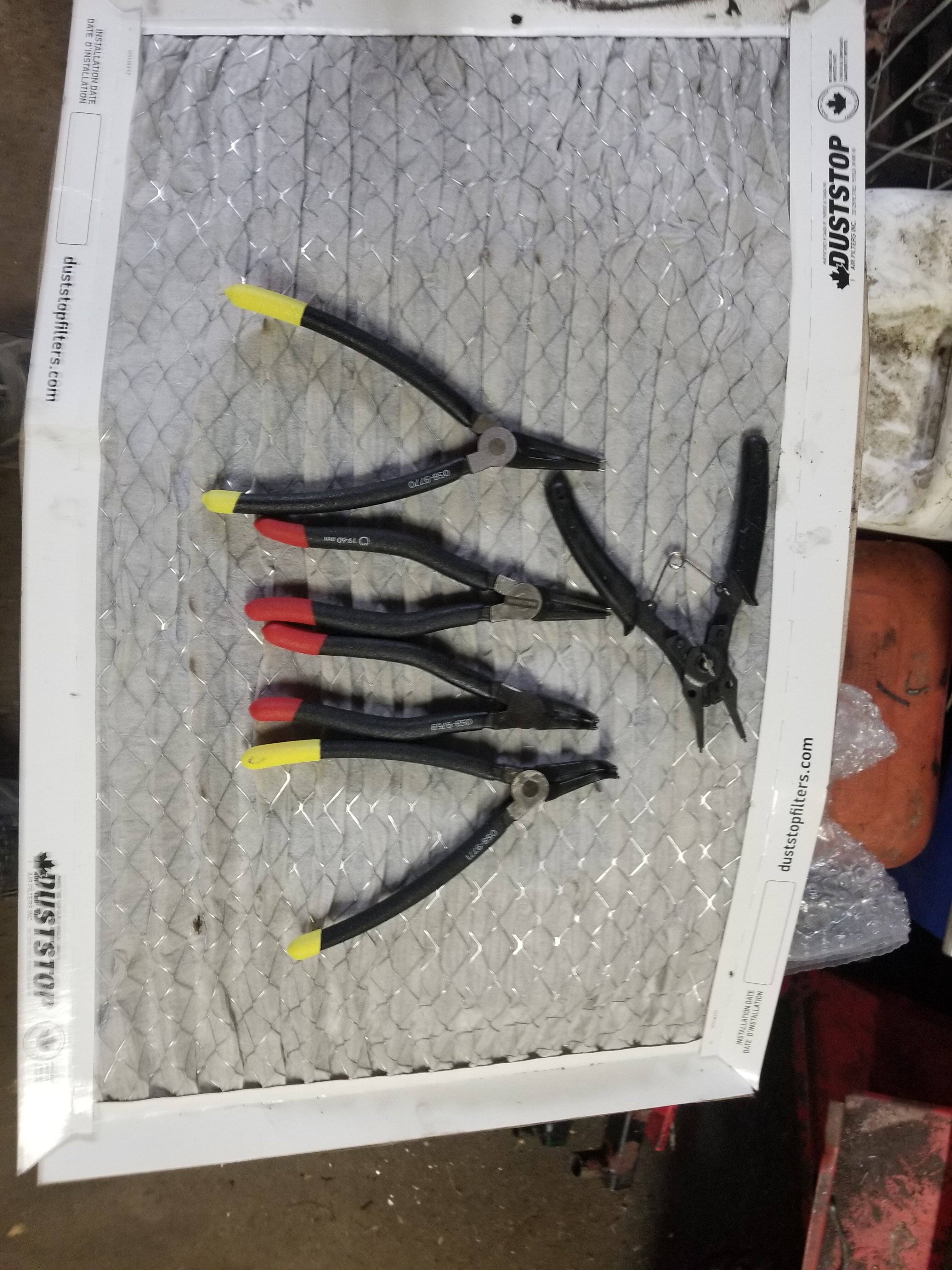

I upgraded my snap ring pliers, one multi head POS wasn't cutting it. Got all the low reverse assemblies and the output shaft out. The snap ring against the case lugs was a challenge to remove. I also sprayed the housing with degreaser and will pressure washer the case. I will be spending $1200 US on all the upgrades after the 351 is complete

.

.

Attachments

- Status

- Not open for further replies.

Similar threads

- Replies

- 6

- Views

- 181

- Replies

- 3

- Views

- 212

- Replies

- 8

- Views

- 823

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.