Hello all. I run a Olds motor with a T-5 trans in a 88 Cutlass Supreme. My clutch system uses a stock 88 F-body clutch master cylinder and a Howe Racing hydraulic Throw-Out bearing. I did this set up in 2013. I have pictures of the install in my photo albums and in my post "Hydraulic clutch set up T-5 swap. Wish me luck".

As far as operation, the Howe TOB was great. The car is a daily driver and the only issues I had with it was a bearing change after I drove through a flood and the bearing seized in early 2016 and again in late 2017. Also i had to change O rings 3 times through the years. The first in 2015.

The rebuilding process was pretty easy and parts were reasonable. The problem was pulling the transmission out every time to fix the unit.

Out of the 5 times I fixed the TOB, only during 2 of them did I change the clutch. (The clutch was changed 3 times since 2013)

The last O-ring change was in Feb of this years during whitch, I found a burr in the surface of the piston that I had to polish out. Now it's leaking again.

I'm done because the Howe unit needs to be replaced. It's $149.99, which isn't bad compared to other units. (Most around $250)

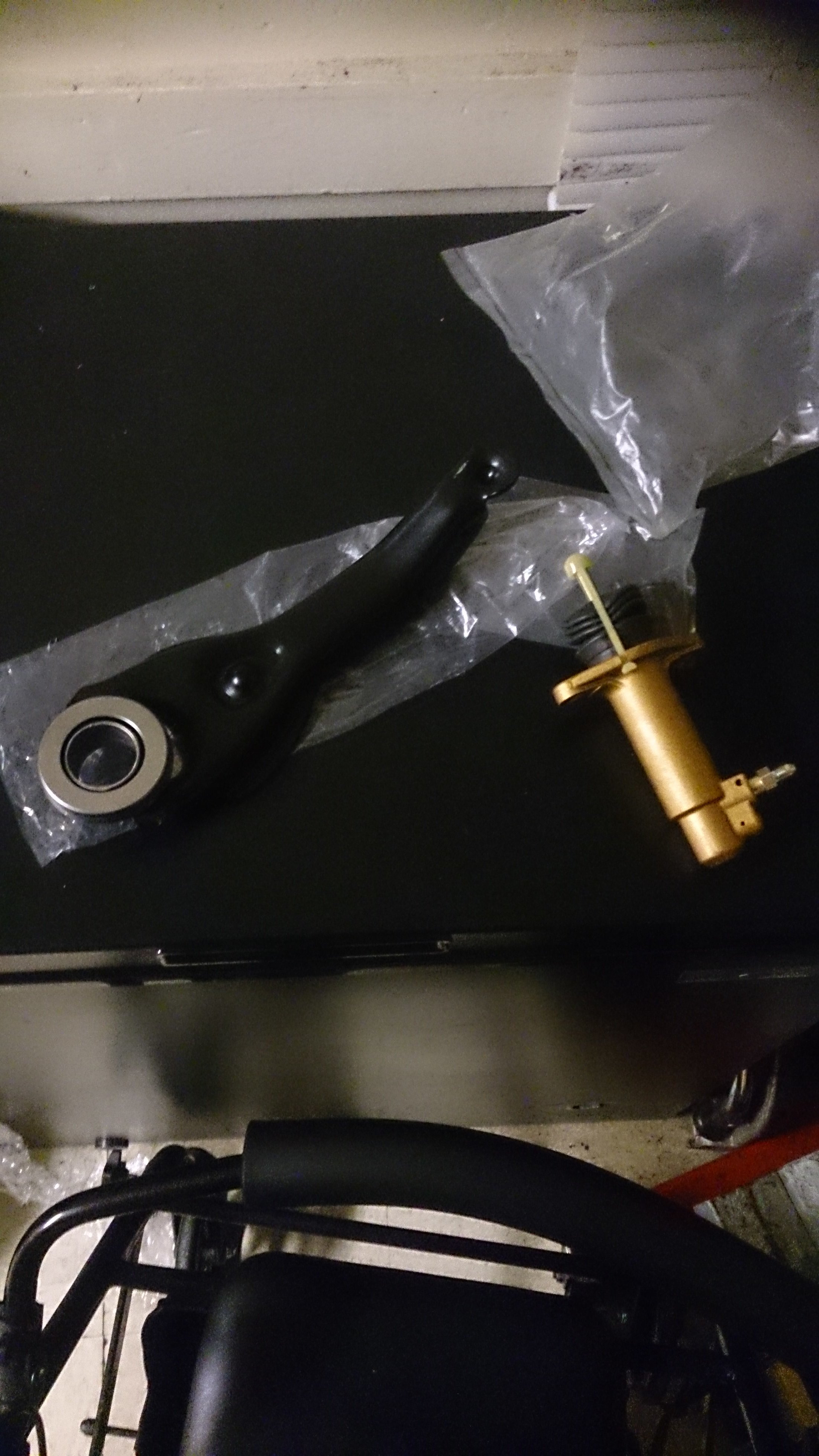

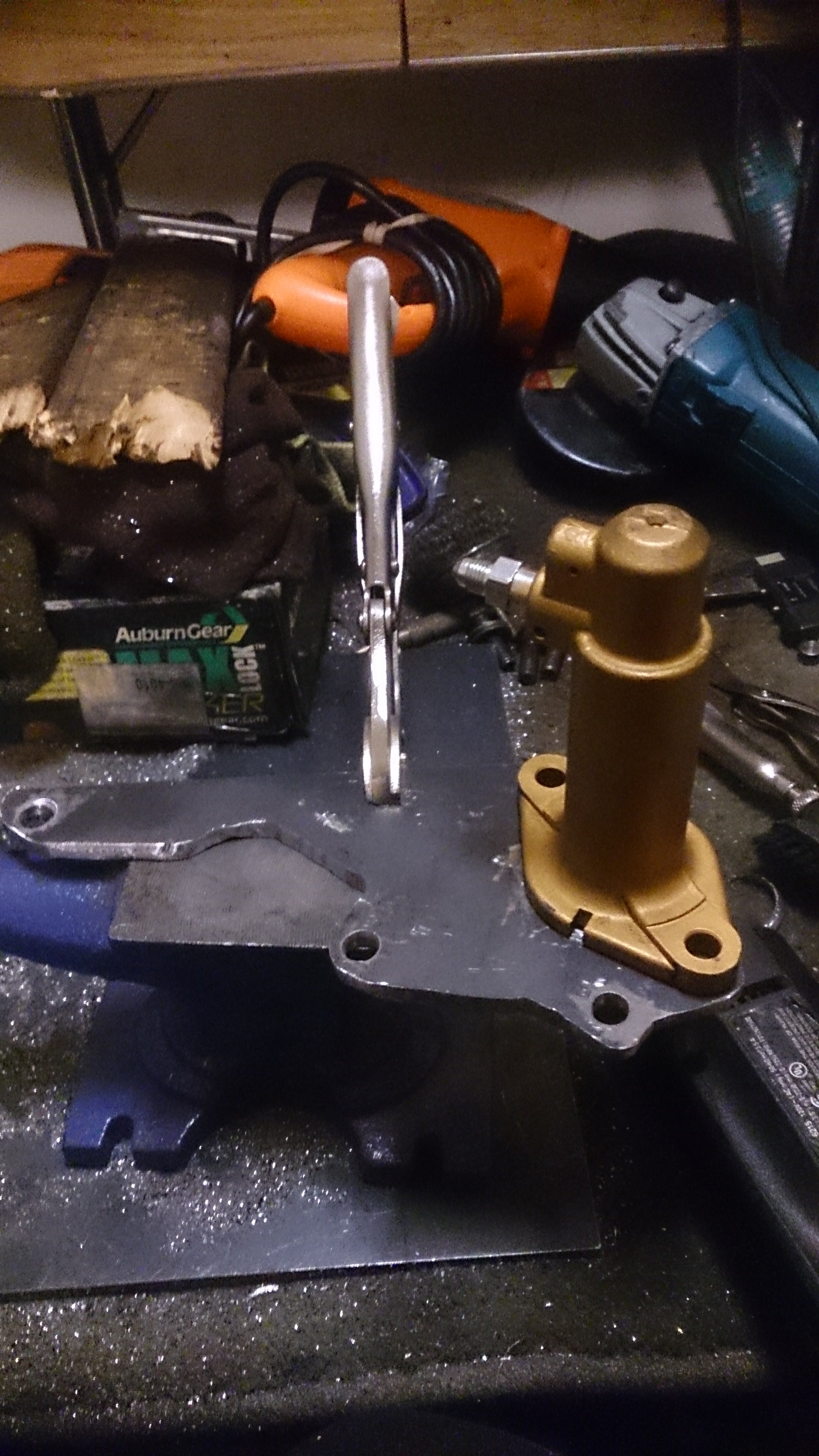

I am switching to a 88 Camaro external slave cylinder. All the parts cost me under 100 bucks.

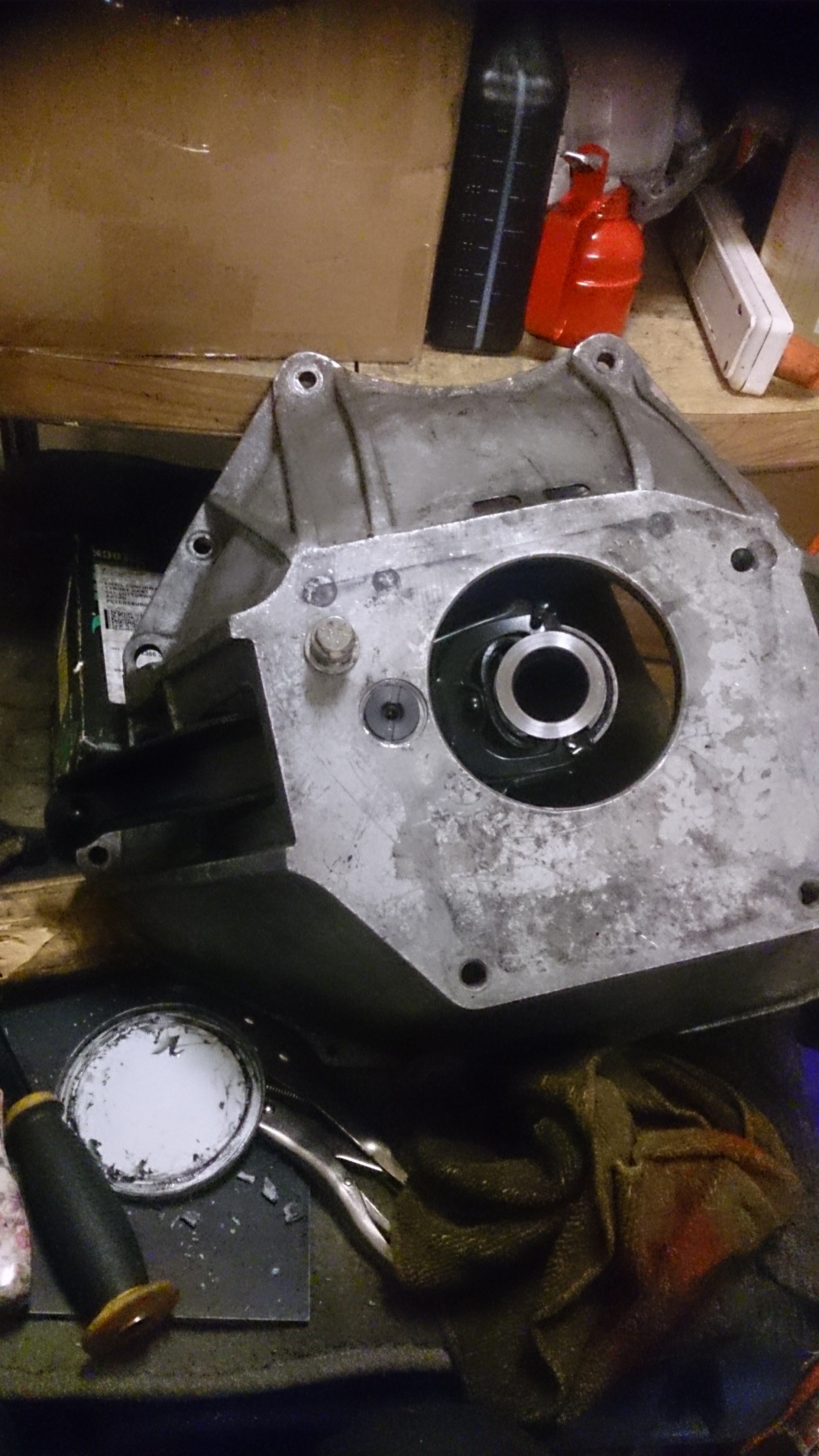

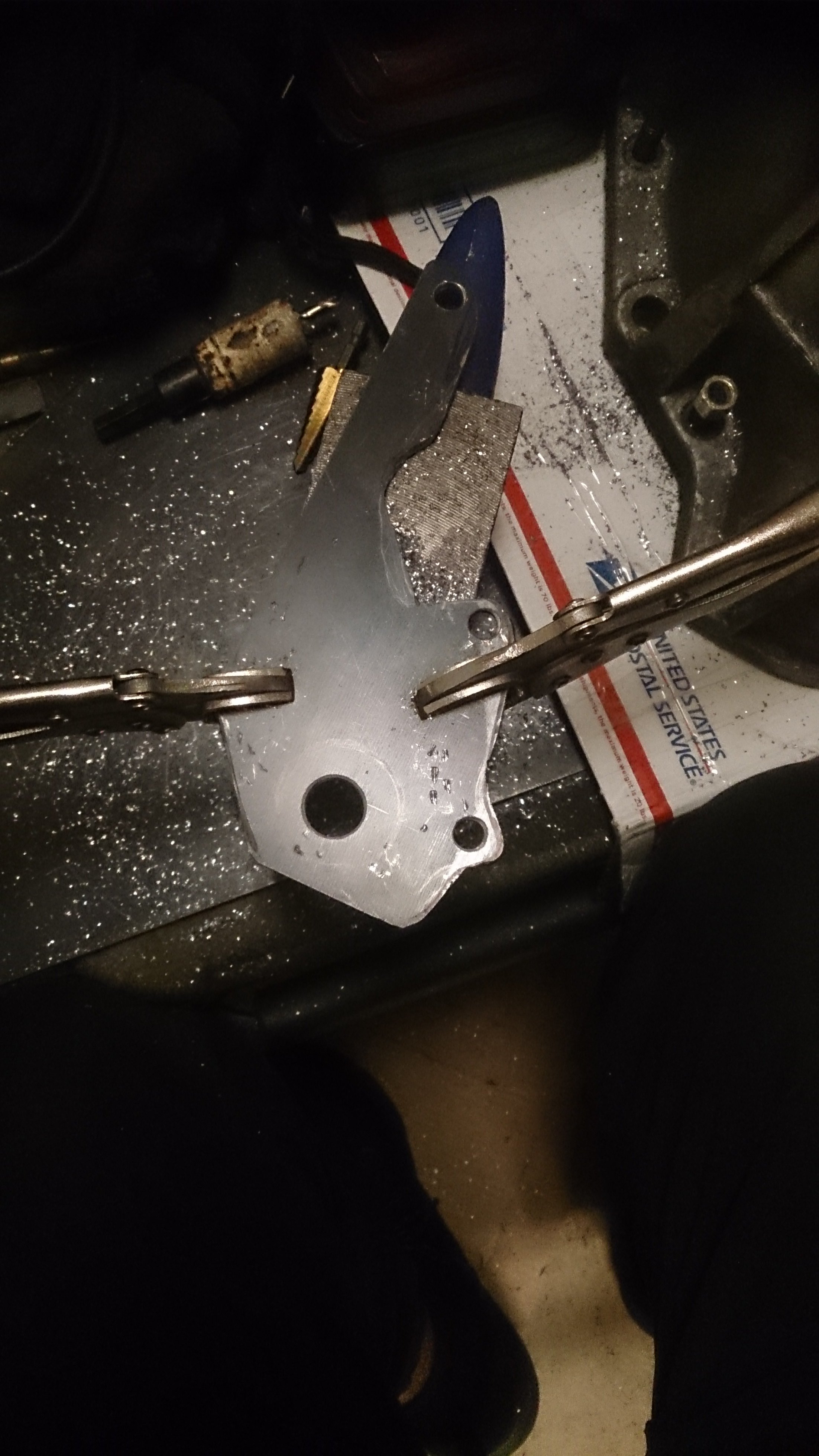

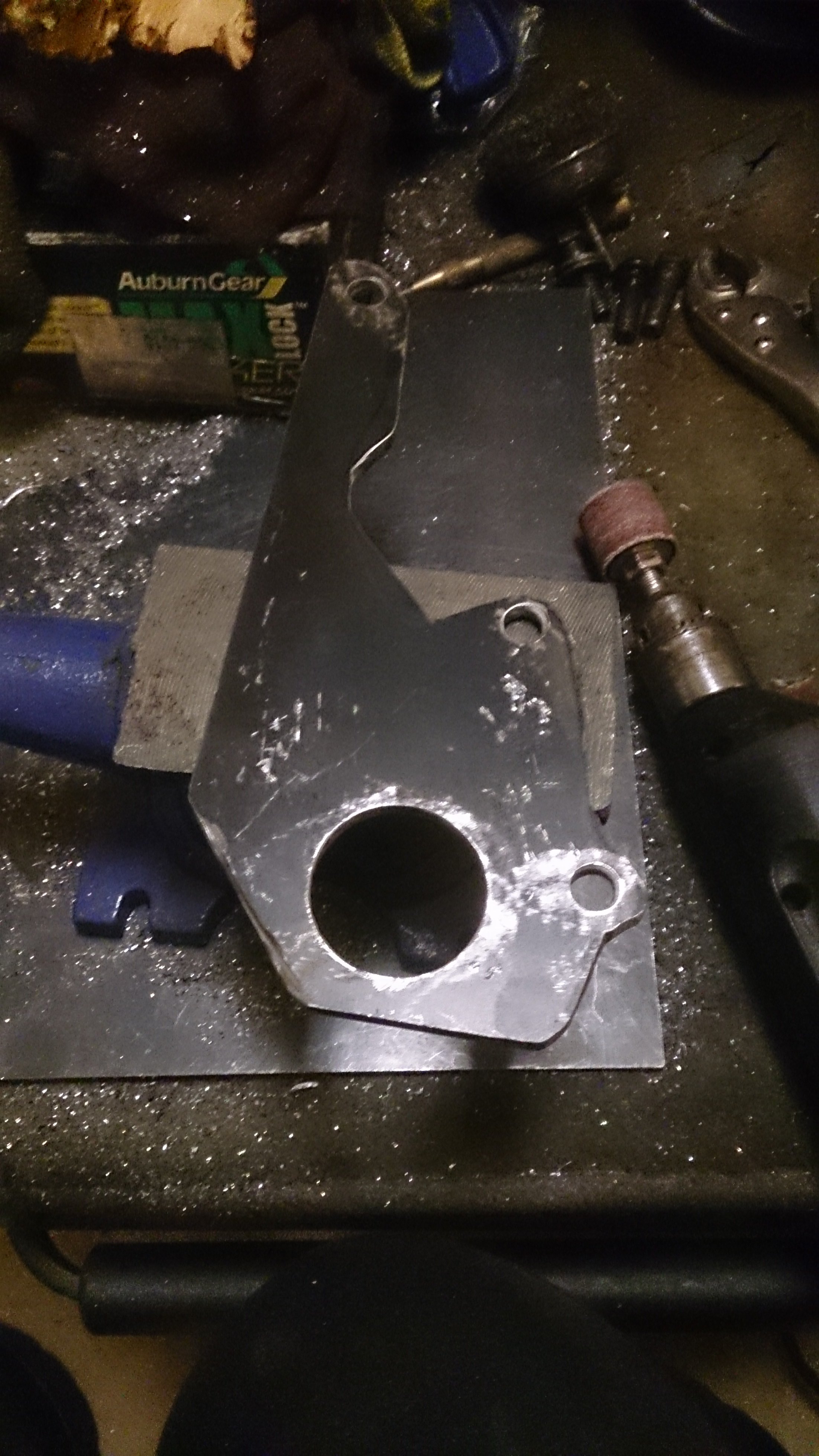

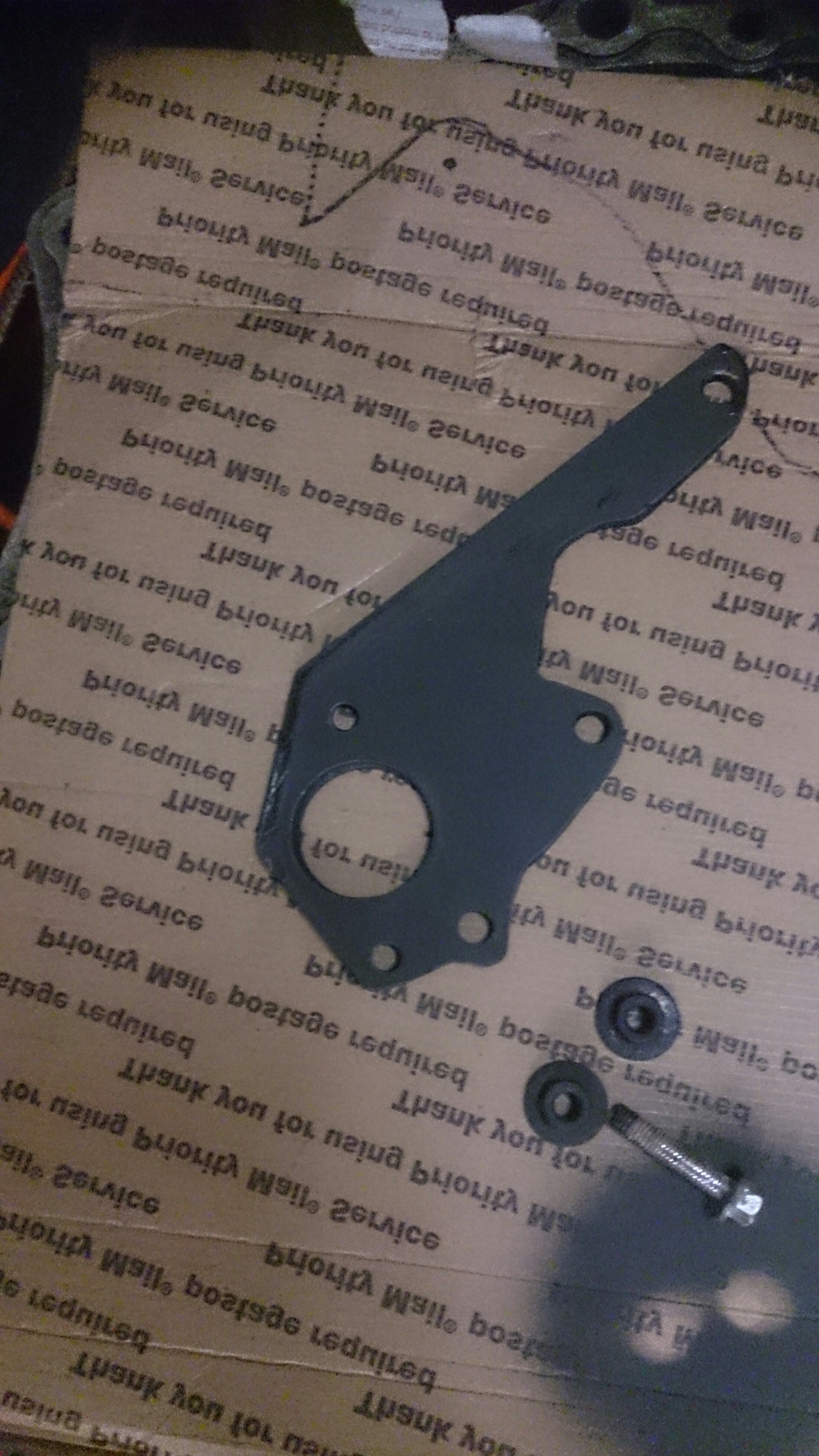

The only snag was the Cylinder bracket. I had to make one for my Oldsmobile Bell Housing.

As far as operation, the Howe TOB was great. The car is a daily driver and the only issues I had with it was a bearing change after I drove through a flood and the bearing seized in early 2016 and again in late 2017. Also i had to change O rings 3 times through the years. The first in 2015.

The rebuilding process was pretty easy and parts were reasonable. The problem was pulling the transmission out every time to fix the unit.

Out of the 5 times I fixed the TOB, only during 2 of them did I change the clutch. (The clutch was changed 3 times since 2013)

The last O-ring change was in Feb of this years during whitch, I found a burr in the surface of the piston that I had to polish out. Now it's leaking again.

I'm done because the Howe unit needs to be replaced. It's $149.99, which isn't bad compared to other units. (Most around $250)

I am switching to a 88 Camaro external slave cylinder. All the parts cost me under 100 bucks.

The only snag was the Cylinder bracket. I had to make one for my Oldsmobile Bell Housing.