Thanks Doug! Will update again tonight. Thanks for following!Lots of pictures and follow up information makes your build thread awesome in my book! Great job!

Doug

BUILD THREAD “The Juggernaut”

- Thread starter Rktpwrd

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Looks great kinda makes me feel like a failure at the same time though:/

Trust me I feel the same way....🙁 like Rktpwrd said maybe on round two of my rebuild i'll pay more attention to the frame... everytime I check out the follow ups is more awesome work and attention to detail. How did you decide to cut off your finger? Thanks for the inspiration and ideas!

So for this next update, I'm going to switch gears here a bit, and cover the fabrication of the exhaust system.

You're all pretty much up to speed as far as the frame and plumbing are concerned anyways. What you saw in the previous pics is pretty much how it sits in the garage now, with the exception that the body is now sitting on the new frame and the old frame has been "disposed" of.

By rights, I should be covering the many body mods I've made, because that's what I've moved onto after test fitting the body on the frame. However, I'm not going to get into that just yet, because that will lead into present day updates, and I still haven't finished bringing you up to speed on the work that's already been completed. But I digress...

As mentioned before, the car was built once already with the 455 and a Th400 automatic transmission. The exhaust that was in the car previously was functional, but that's about it. Certainly nothing to write home about. It consisted of 3 1/2" to 2 1/2" reducers bolted to the header flanges, 2 1/2" dual pipes with an "H" pipe to balance exhaust flow, and 2 Flowmaster 50 series mufflers with 90 degree turn downs ending just past the rear crossmember.

After the engine was gone through and beefed up with a bigger cam, I felt it was time to upgrade the exhaust as well. Gone are the 2 1/2" pipes, this time to full 3" front to back. Also gone is the mildly effective "H" pipe, now replaced with a more effective "X" pipe. These were planned for from the start. In addition, I wanted to have dual cut outs before the mufflers so I could run open headers if I wanted. Taking that one step further, it was planned for mounting electronic exhaust cutouts here, wired thru a momentary switch so that I could alter the exhaust sound. That way I could have anything from a slightly more aggressive sound to all out open headers. Like I said earlier, full adjustability! After that was when things kinda took on a life of their own tho. Inspired by the look of custom side exit exhaust (the "through the body kind", not the the 70's Corvette side pipes kind), I started looking at my options to do something similar.

I wanted the exhaust system to be short and sweet, no pipes up and over the rearend to contend with, so that left the available real estate somewhere in front of the rear wheels. In my usual dare to be different way, I refused to take the easy way out and just have them hang under the frame. To say nothing of severely reduced ground clearance on an airbag equipped vehicle. So now, that left me with exiting the pipes thru the quarter panel in front of the rear wheels. Perfect. That was actually the look I was hoping for anyways.

Making this happen however proved to be an entirely different problem tho. As you know, our G bodies have not only body mounts in this area, but also the mounts for the rear lower trailing arms on the frame. That ruled out sleeving the frame and passing the pipes thru there. After much head scratching and tossing around of ideas with a good friend, I was ready to give up on the whole idea. He wouldn't let it go tho, and proposed an outrageous idea. I'm still not sure how I let him convince me of it...

It was decided that we would cut out the back seat passenger's foot well areas (I've deleted the rear seat, it's not a damn taxi!) and fab new rear floor pans kicked up higher. This would give us room for the mufflers. From there, the pipes would pass up and THROUGH the floor, through the interior structure, and end up in the exact spot I wanted on the quarter panels. This would be done at a 45 degree angle to reduce restrictions and have that cool oval shape where it exits the quarters. This is how it went...

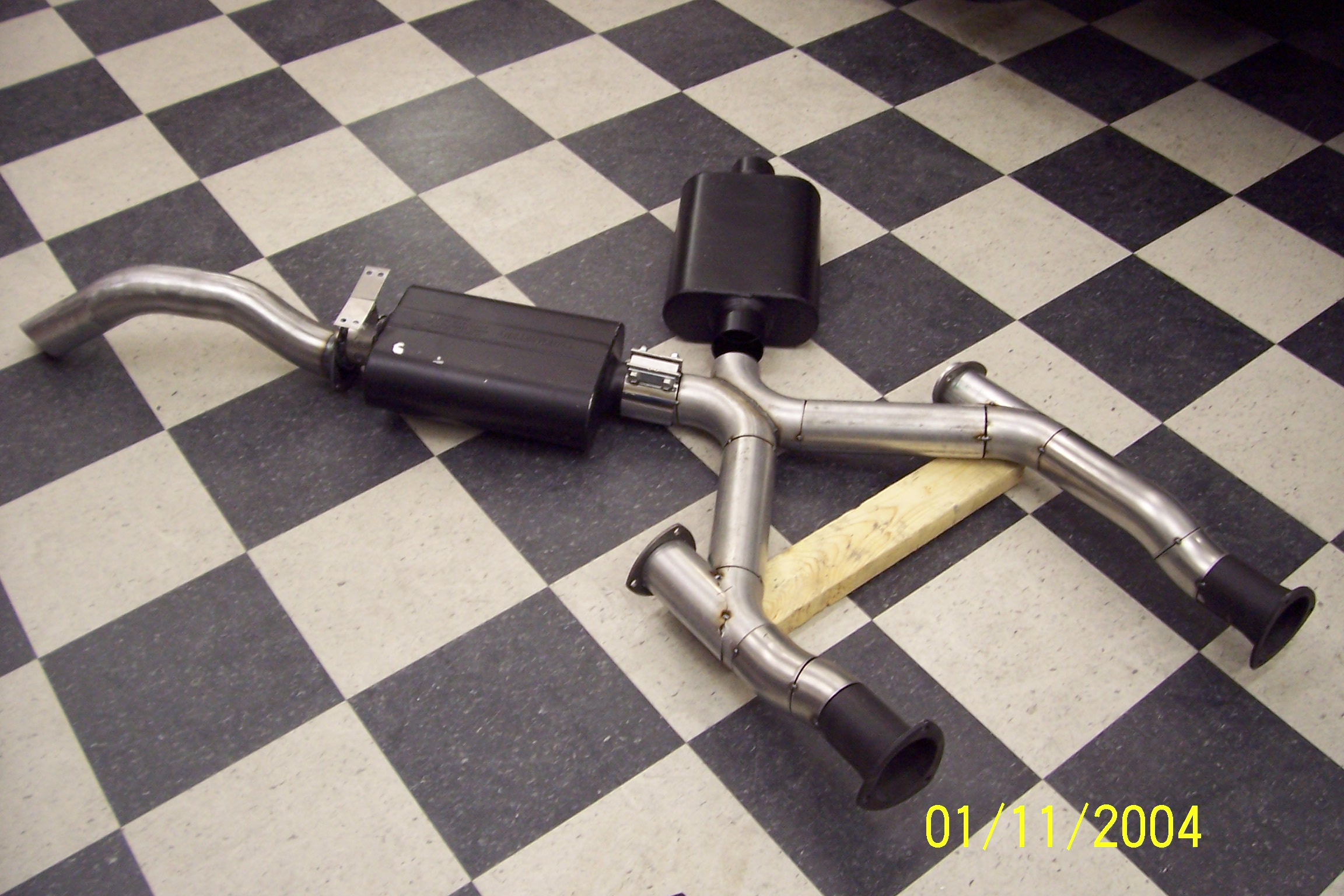

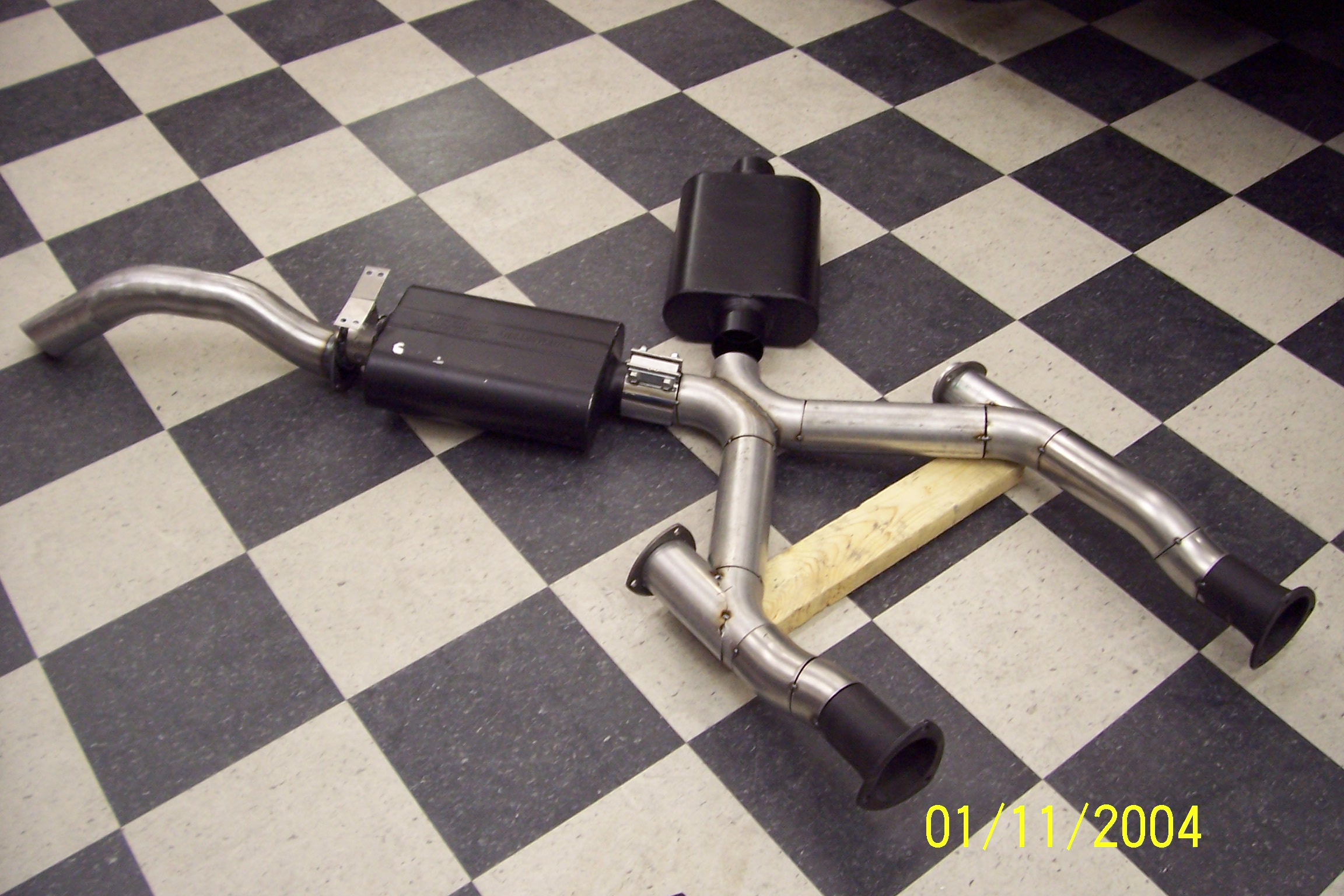

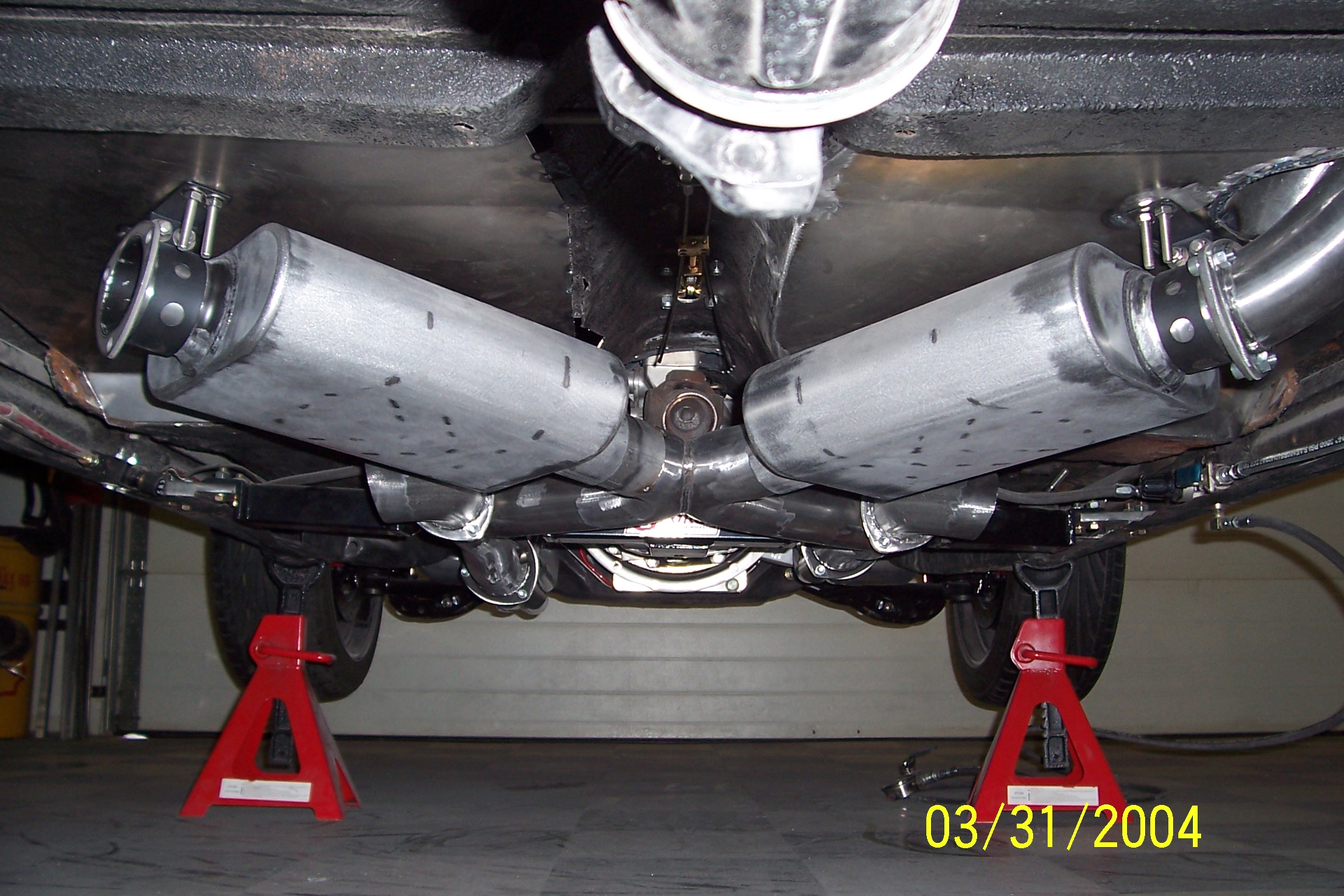

Laying out the pieces on the floor for full welding after everything was tacked together in place under the car. It should be noted that this wasn't a kit, all the pieces were purchased and cut and fit independently. There are no slip fit joints, they're unsightly and restrictive in my opinion,

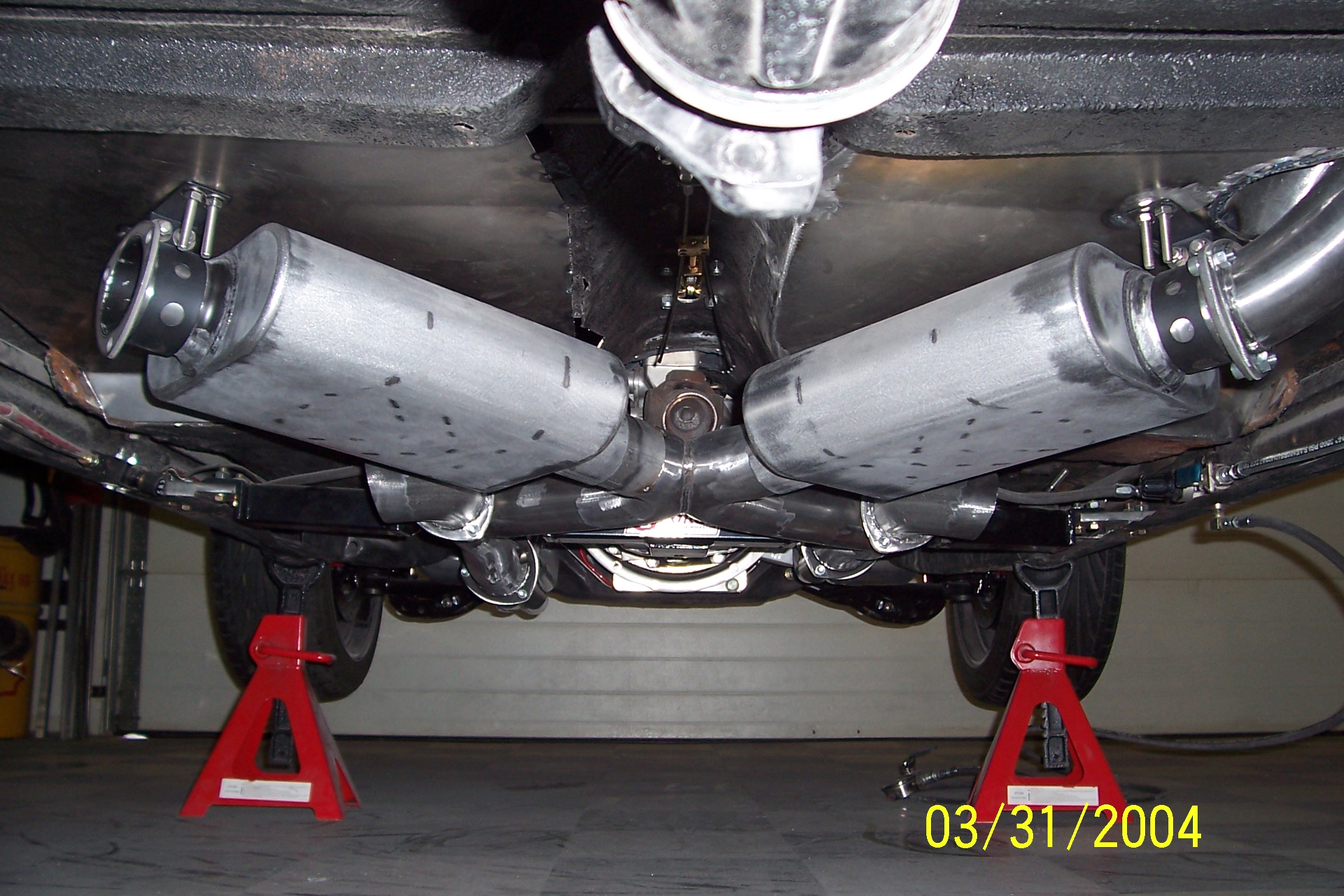

The band clamps visible in the pics were just an idea, they were discarded in favour of having all flanged connections. This will make servicability a breeze, as each individual component can be removed separately or all together. This was actually quite a complicated system to build. Each floor tile in the background is 1'. If you count the tiles, the entire system is only 5 1/2' long. In that distance, there is an elevation change (the left and right headers don't hang at the same height), 2 cutouts, 2 turndowns, 2 "Y"'s, an "X" pipe, 2 mufflers, 2 tailpipes, and 8 flanges!

Once the first "tailpipe" as I call them was made, a temporary jig was made on the metal bench to act as a template for forming the same bends for other side.

Everything was fully welded out and ground smooth, cutout turndowns were made, and all connections were flanged. Note the two O2 sensor bungs tacked into place on the reducers for using an in-dash air/fuel ratio gauge. The entire system will be ceramic coated to help control heat and corrosion.

This was the driver's side rear footwell before "surgery"

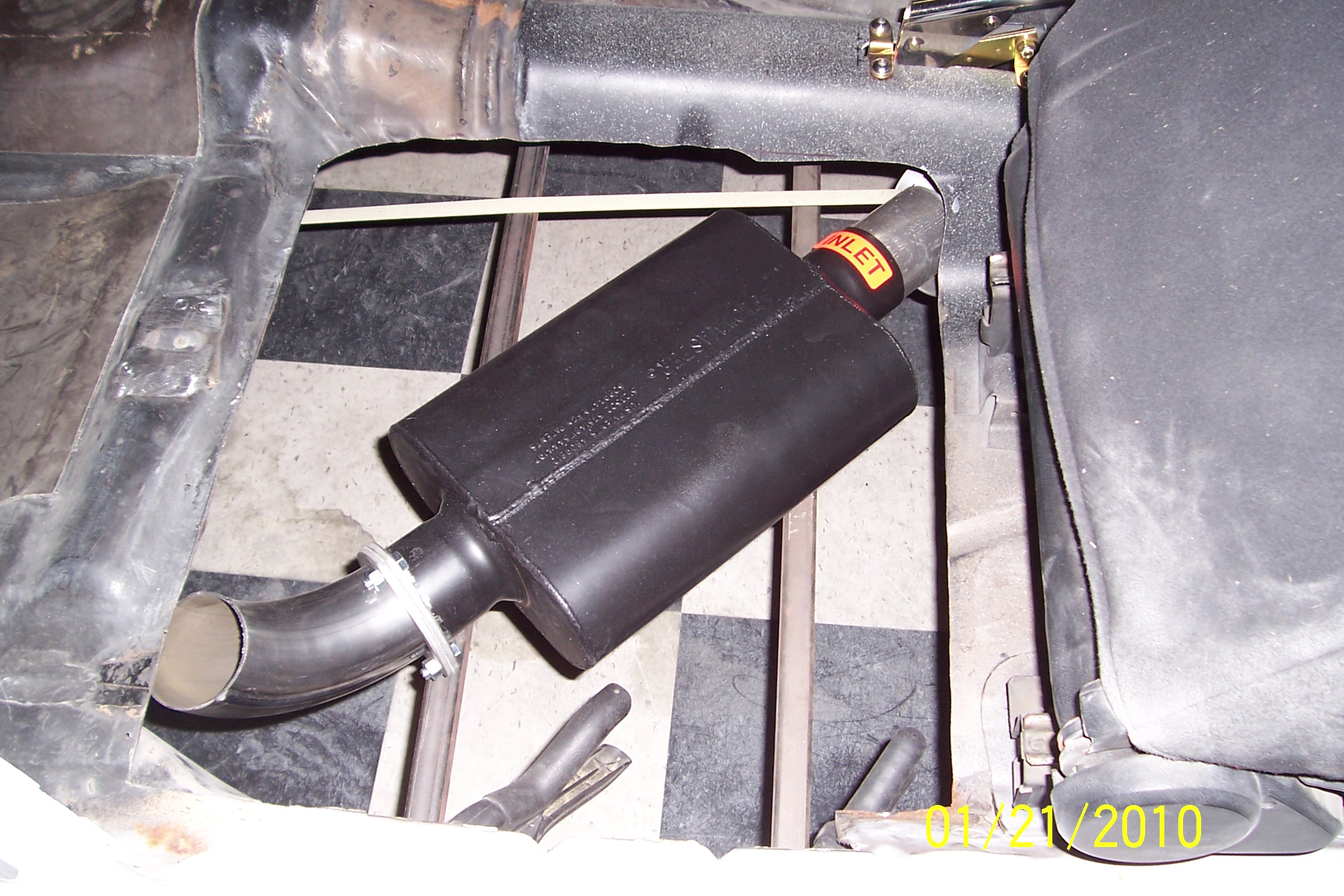

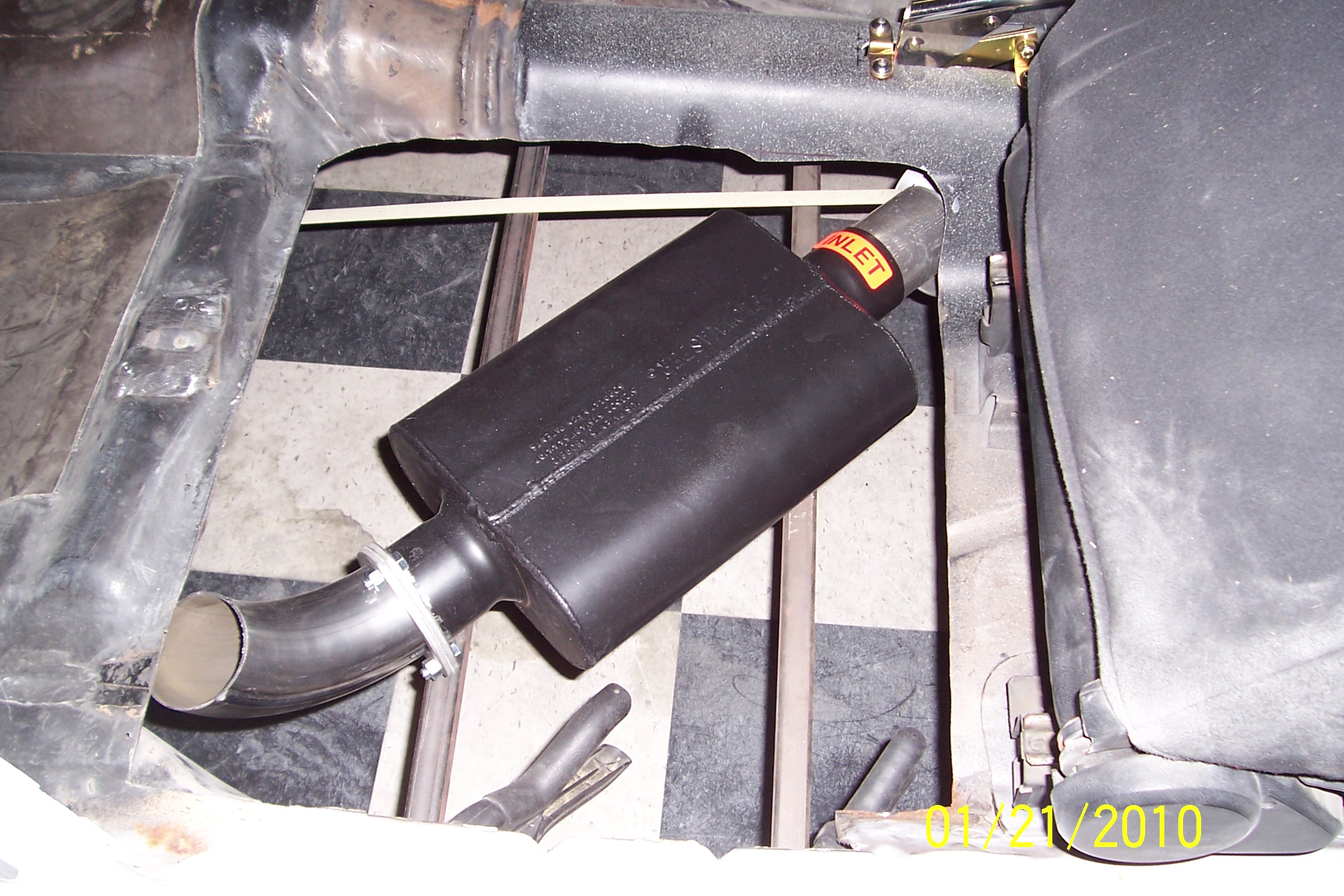

Passenger side rear footwell removed, and the muffler mocked up into place.

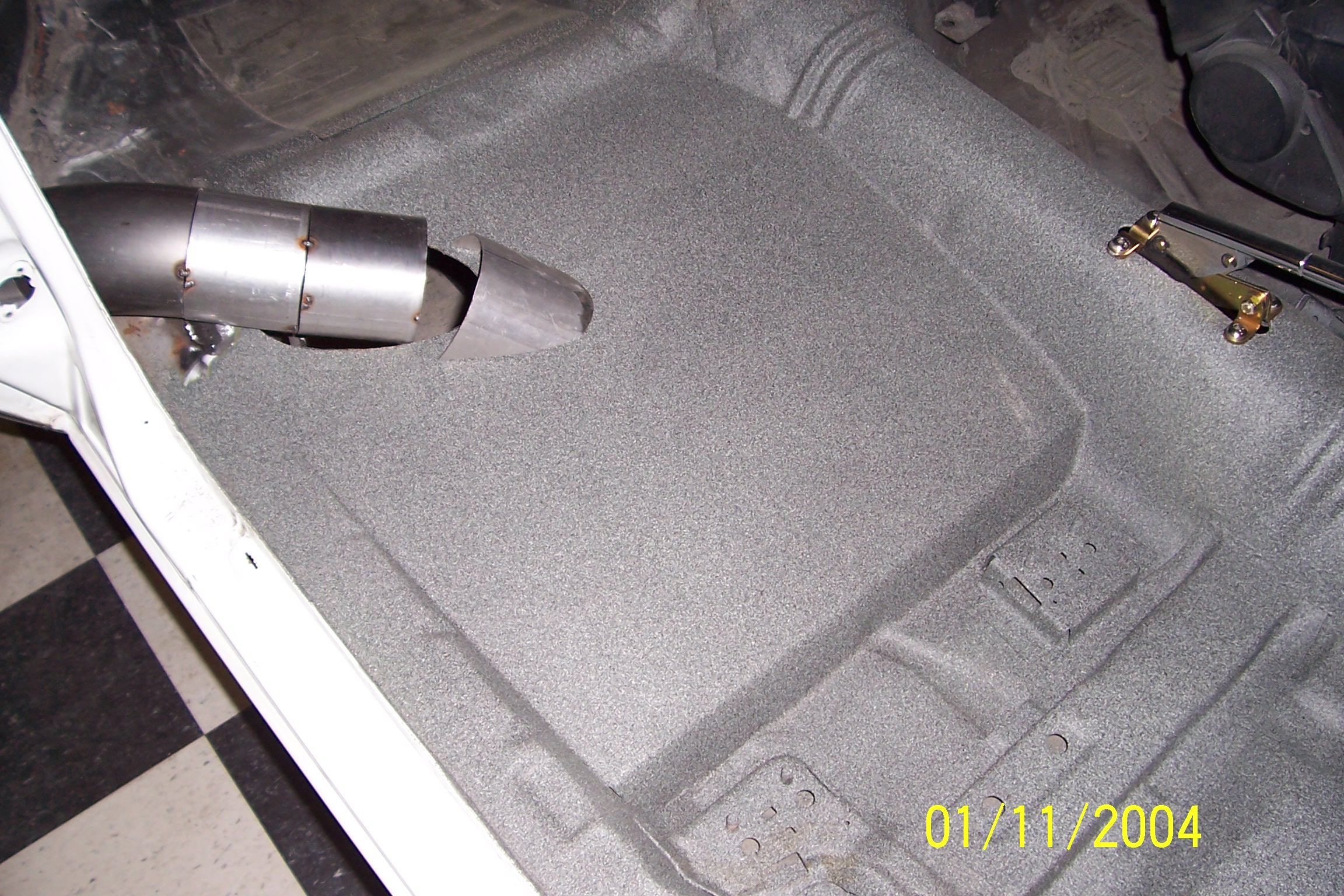

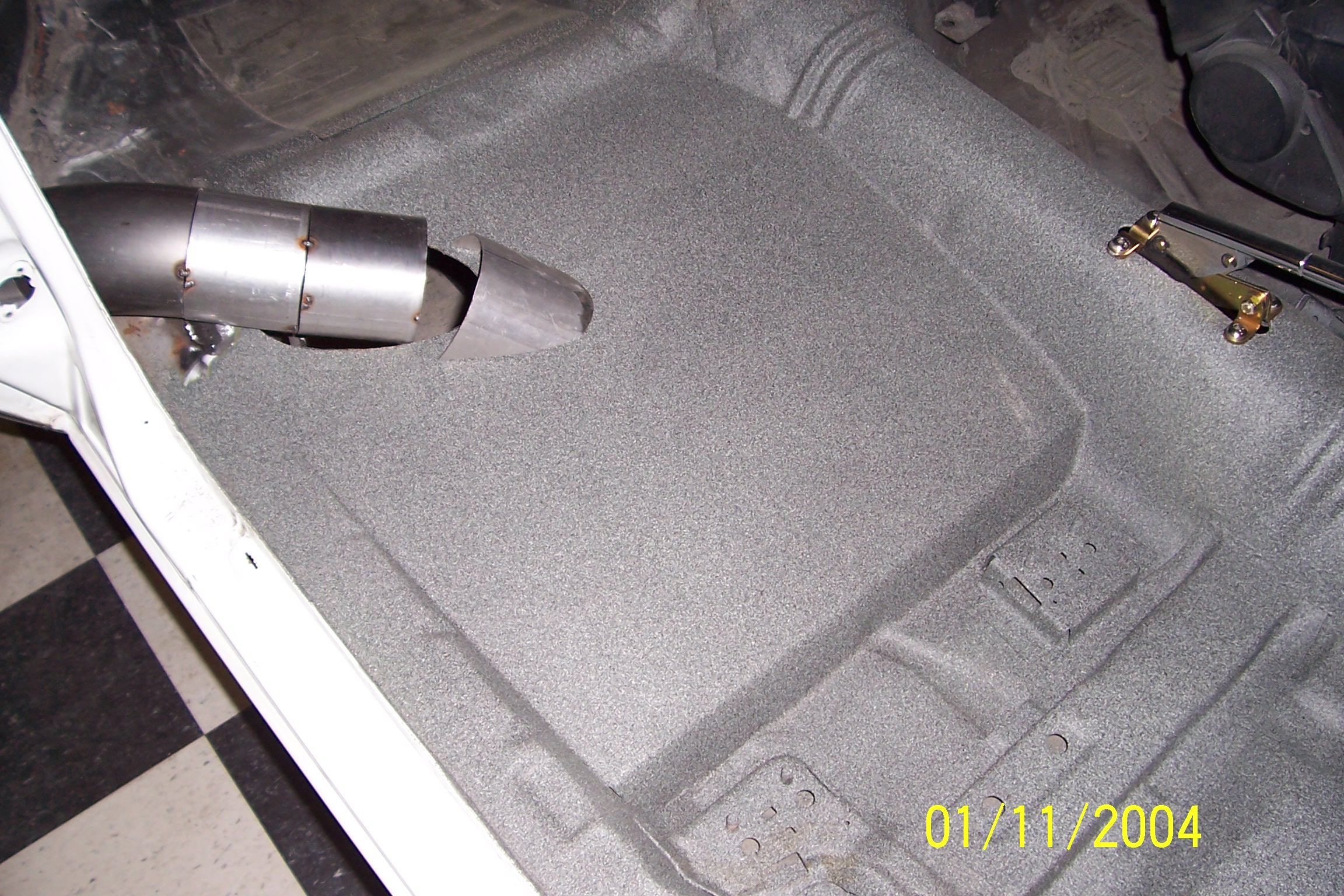

The completed kicked up passenger side rear floorpan painted, and starting to layout a 4" tube "housing" for the 3" pipe to run inside.

The view of the drivers side muffler and tailpipe passing through the floor. Note the exhaust hanger supporting the end of the muffler. I fabbed these up out of some sheetmetal, folded the mounting ends over on themselves for strength, and drilled progressively sized holes for some added flair.

You're all pretty much up to speed as far as the frame and plumbing are concerned anyways. What you saw in the previous pics is pretty much how it sits in the garage now, with the exception that the body is now sitting on the new frame and the old frame has been "disposed" of.

By rights, I should be covering the many body mods I've made, because that's what I've moved onto after test fitting the body on the frame. However, I'm not going to get into that just yet, because that will lead into present day updates, and I still haven't finished bringing you up to speed on the work that's already been completed. But I digress...

As mentioned before, the car was built once already with the 455 and a Th400 automatic transmission. The exhaust that was in the car previously was functional, but that's about it. Certainly nothing to write home about. It consisted of 3 1/2" to 2 1/2" reducers bolted to the header flanges, 2 1/2" dual pipes with an "H" pipe to balance exhaust flow, and 2 Flowmaster 50 series mufflers with 90 degree turn downs ending just past the rear crossmember.

After the engine was gone through and beefed up with a bigger cam, I felt it was time to upgrade the exhaust as well. Gone are the 2 1/2" pipes, this time to full 3" front to back. Also gone is the mildly effective "H" pipe, now replaced with a more effective "X" pipe. These were planned for from the start. In addition, I wanted to have dual cut outs before the mufflers so I could run open headers if I wanted. Taking that one step further, it was planned for mounting electronic exhaust cutouts here, wired thru a momentary switch so that I could alter the exhaust sound. That way I could have anything from a slightly more aggressive sound to all out open headers. Like I said earlier, full adjustability! After that was when things kinda took on a life of their own tho. Inspired by the look of custom side exit exhaust (the "through the body kind", not the the 70's Corvette side pipes kind), I started looking at my options to do something similar.

I wanted the exhaust system to be short and sweet, no pipes up and over the rearend to contend with, so that left the available real estate somewhere in front of the rear wheels. In my usual dare to be different way, I refused to take the easy way out and just have them hang under the frame. To say nothing of severely reduced ground clearance on an airbag equipped vehicle. So now, that left me with exiting the pipes thru the quarter panel in front of the rear wheels. Perfect. That was actually the look I was hoping for anyways.

Making this happen however proved to be an entirely different problem tho. As you know, our G bodies have not only body mounts in this area, but also the mounts for the rear lower trailing arms on the frame. That ruled out sleeving the frame and passing the pipes thru there. After much head scratching and tossing around of ideas with a good friend, I was ready to give up on the whole idea. He wouldn't let it go tho, and proposed an outrageous idea. I'm still not sure how I let him convince me of it...

It was decided that we would cut out the back seat passenger's foot well areas (I've deleted the rear seat, it's not a damn taxi!) and fab new rear floor pans kicked up higher. This would give us room for the mufflers. From there, the pipes would pass up and THROUGH the floor, through the interior structure, and end up in the exact spot I wanted on the quarter panels. This would be done at a 45 degree angle to reduce restrictions and have that cool oval shape where it exits the quarters. This is how it went...

Laying out the pieces on the floor for full welding after everything was tacked together in place under the car. It should be noted that this wasn't a kit, all the pieces were purchased and cut and fit independently. There are no slip fit joints, they're unsightly and restrictive in my opinion,

The band clamps visible in the pics were just an idea, they were discarded in favour of having all flanged connections. This will make servicability a breeze, as each individual component can be removed separately or all together. This was actually quite a complicated system to build. Each floor tile in the background is 1'. If you count the tiles, the entire system is only 5 1/2' long. In that distance, there is an elevation change (the left and right headers don't hang at the same height), 2 cutouts, 2 turndowns, 2 "Y"'s, an "X" pipe, 2 mufflers, 2 tailpipes, and 8 flanges!

Once the first "tailpipe" as I call them was made, a temporary jig was made on the metal bench to act as a template for forming the same bends for other side.

Everything was fully welded out and ground smooth, cutout turndowns were made, and all connections were flanged. Note the two O2 sensor bungs tacked into place on the reducers for using an in-dash air/fuel ratio gauge. The entire system will be ceramic coated to help control heat and corrosion.

This was the driver's side rear footwell before "surgery"

Passenger side rear footwell removed, and the muffler mocked up into place.

The completed kicked up passenger side rear floorpan painted, and starting to layout a 4" tube "housing" for the 3" pipe to run inside.

The view of the drivers side muffler and tailpipe passing through the floor. Note the exhaust hanger supporting the end of the muffler. I fabbed these up out of some sheetmetal, folded the mounting ends over on themselves for strength, and drilled progressively sized holes for some added flair.

Last edited:

let's just say you shouldn't use your non-locking Swiss Army knife can opener attatchment as a screwdriver. There's a fairly sharp blade on the end of that sucker. When I applied pressure to a stubborn screw, the attatchment folded on me slicing pretty deep. Lesson learned, go out to the truck and get the right damn tool!Trust me I feel the same way....🙁 like Rktpwrd said maybe on round two of my rebuild i'll pay more attention to the frame... everytime I check out the follow ups is more awesome work and attention to detail. How did you decide to cut off your finger? Thanks for the inspiration and ideas!

lol

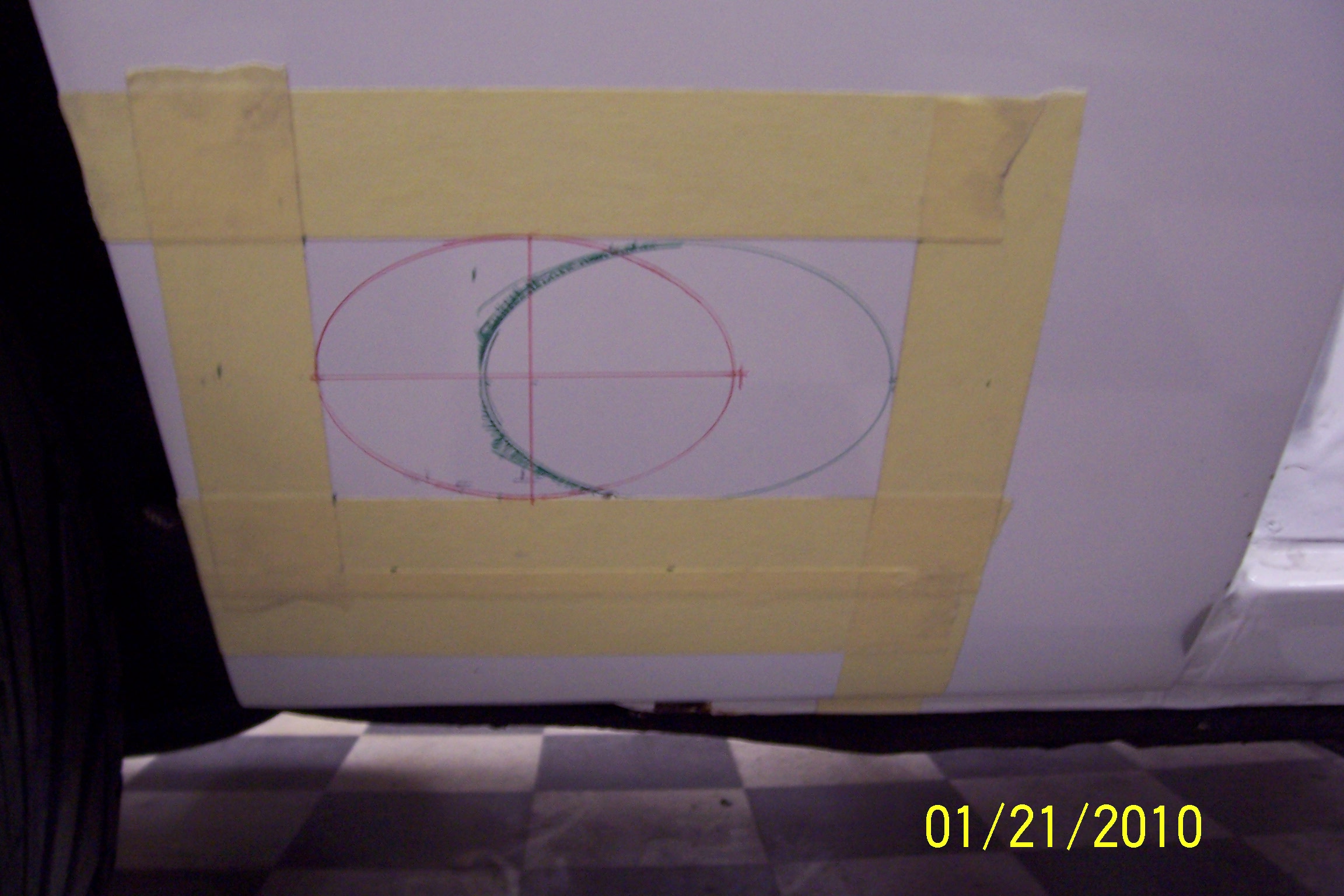

Once the floor pan and housing situation was figured out, it was time to determine where the pipes would exit. The green marks indicate the center of the panel between the door and the wheel opening, and the red marks are where I thought it had to actually be due to the exit angle out of the muffler. Thankfully with a little tweaking I was able to get it to come out where I wanted it.

Once the opening location was determined, the measurements were transferred to a heavier gauge of sheetmetal so that the housing could be easily welded to the backside. Once this was done, the new panel was tacked into place.

View from inside the car at the housing. The innermost 6" or so is welded to the outer skin. The seatbelt box has been removed for easy access, but by keeping it as low as I could, the seatbelt box was notched and can actually be used if needed.

All the individual sections of the housing were then welded and ground down and mated with the floor. The plate welded to the floor in front of the housing is drilled and tapped, and is where the exhaust hanger mounts.

A close-up of the seatbelt box notched. A new floor for the box still needs to be made and welded in to make it as strong as before.

Once the bulk of the fabrication was completed, it was time to turn my attention to finishing out the opening in the panel. A fellow gearhead friend of mine is an excellent machinist, and I turned to him to make me up some trim rings out of aircraft grade aluminum. He provided me with the raw pieces, and I took them home and polished them up to a high lustre.

Then the entire procedure was repeated again on the driver's side.

Last edited:

Just some more pics of the system in the car. Still not 100% complete, I wish it was, but I think it'll look killer once it's done. The trick will be to finish out the interior with carpet and such so that it doesn't look too out of place like it does now. I've got some ideas for heat and sound control too, so I don't see that as being an issue either.

Aaaaand I'm throwing this one in just because. Call it a sneak peek ahead to what's ahead soon...😀

Aaaaand I'm throwing this one in just because. Call it a sneak peek ahead to what's ahead soon...😀

Last edited:

Oh, one other thing I forgot to mention -

The mufflers I'm using this time are Flowmaster's Super 44's, their most aggressive sounding muffler. This thing is going to be a beast this time around, and I want it to sound the part. 🙂

It should sound absolutely AWESOME with dual 3" pipes! I can't wait...

The mufflers I'm using this time are Flowmaster's Super 44's, their most aggressive sounding muffler. This thing is going to be a beast this time around, and I want it to sound the part. 🙂

It should sound absolutely AWESOME with dual 3" pipes! I can't wait...

Great as usual any advice for a through the floor exhaust? I plan to try to route mine behind the wheels in the lower quarters .

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.