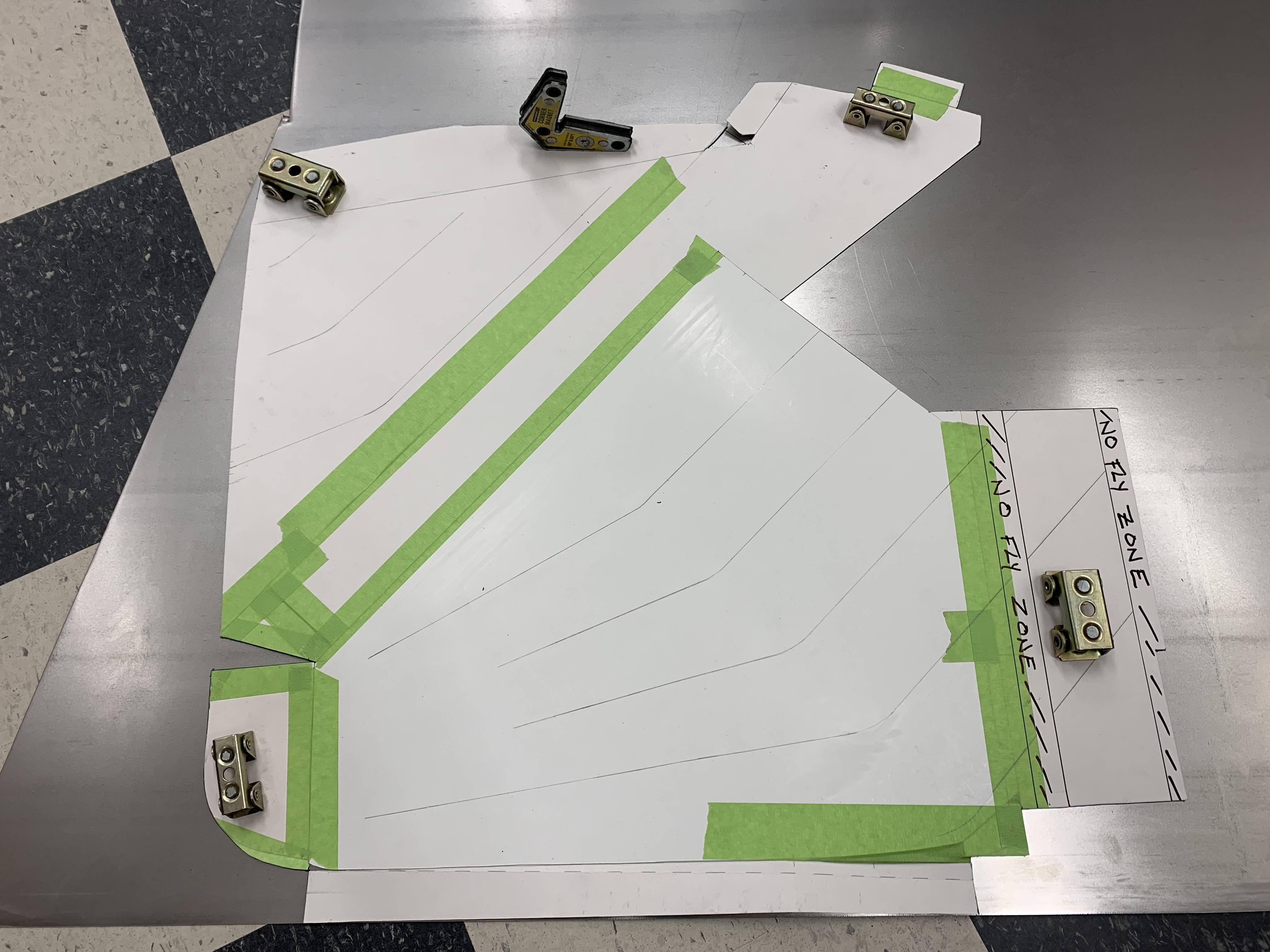

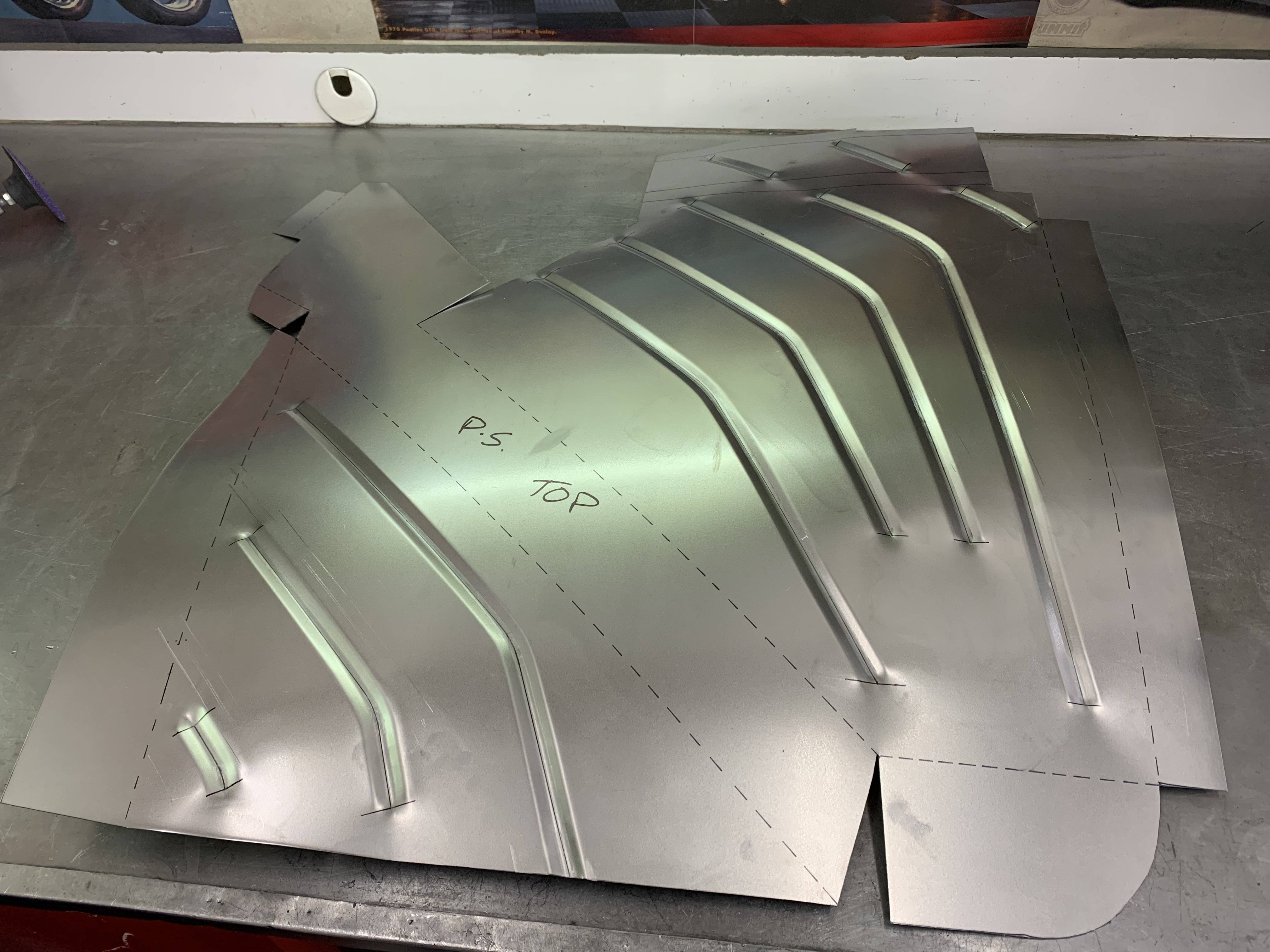

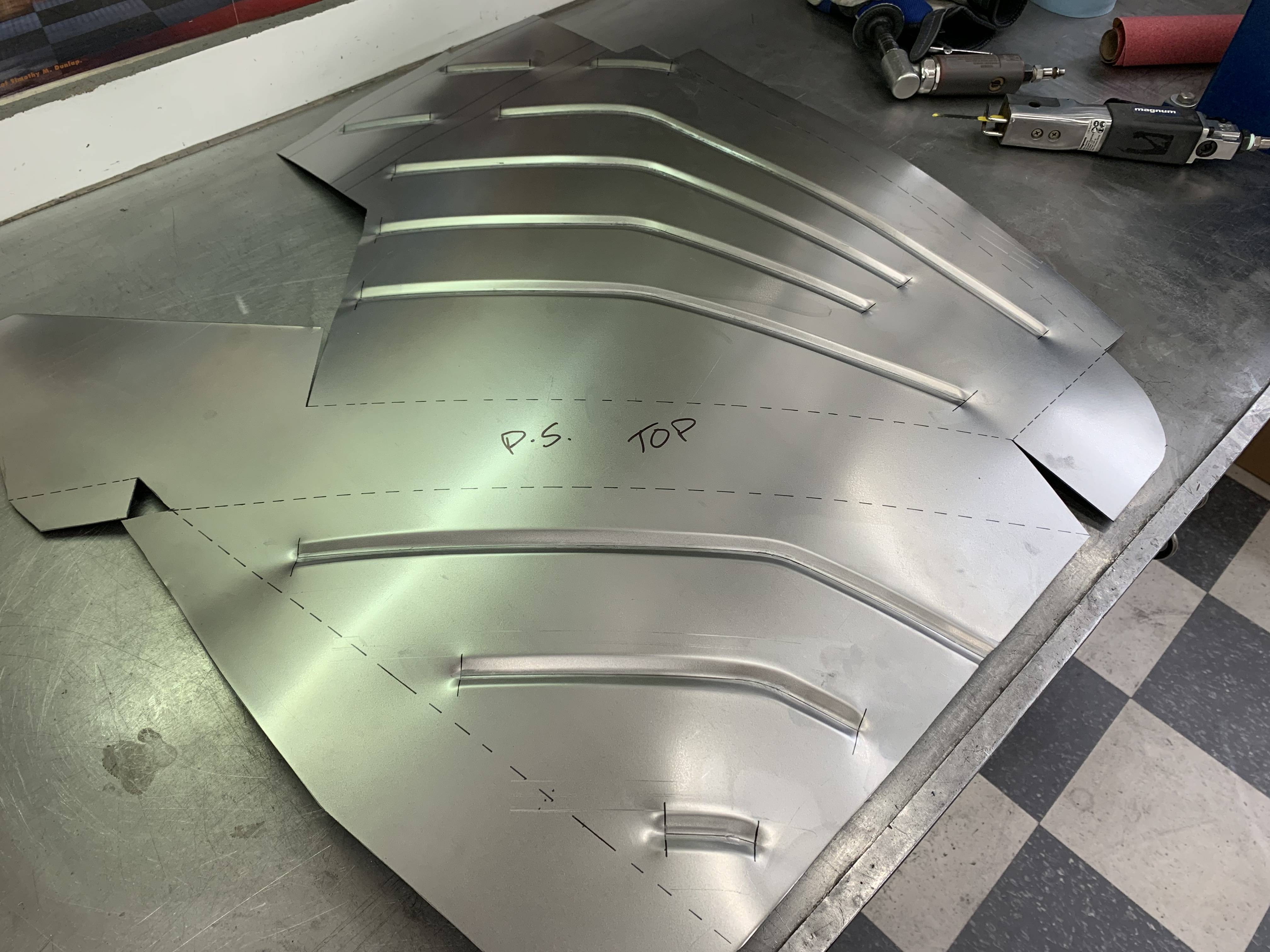

Proposed change. Minor, but substantial in the overall feel. Still 6 lines, but now only 3 converge at the narrowest point.

New thoughts? Send it??

New thoughts? Send it??

Nix that 6th line for sure as it's too close to the edge. It's close enough the bead isn't there for rigidity & is only for looks.Ok guys, I need some opinions.

Really. Your chance to have a say in how to do something on The Juggernaut.

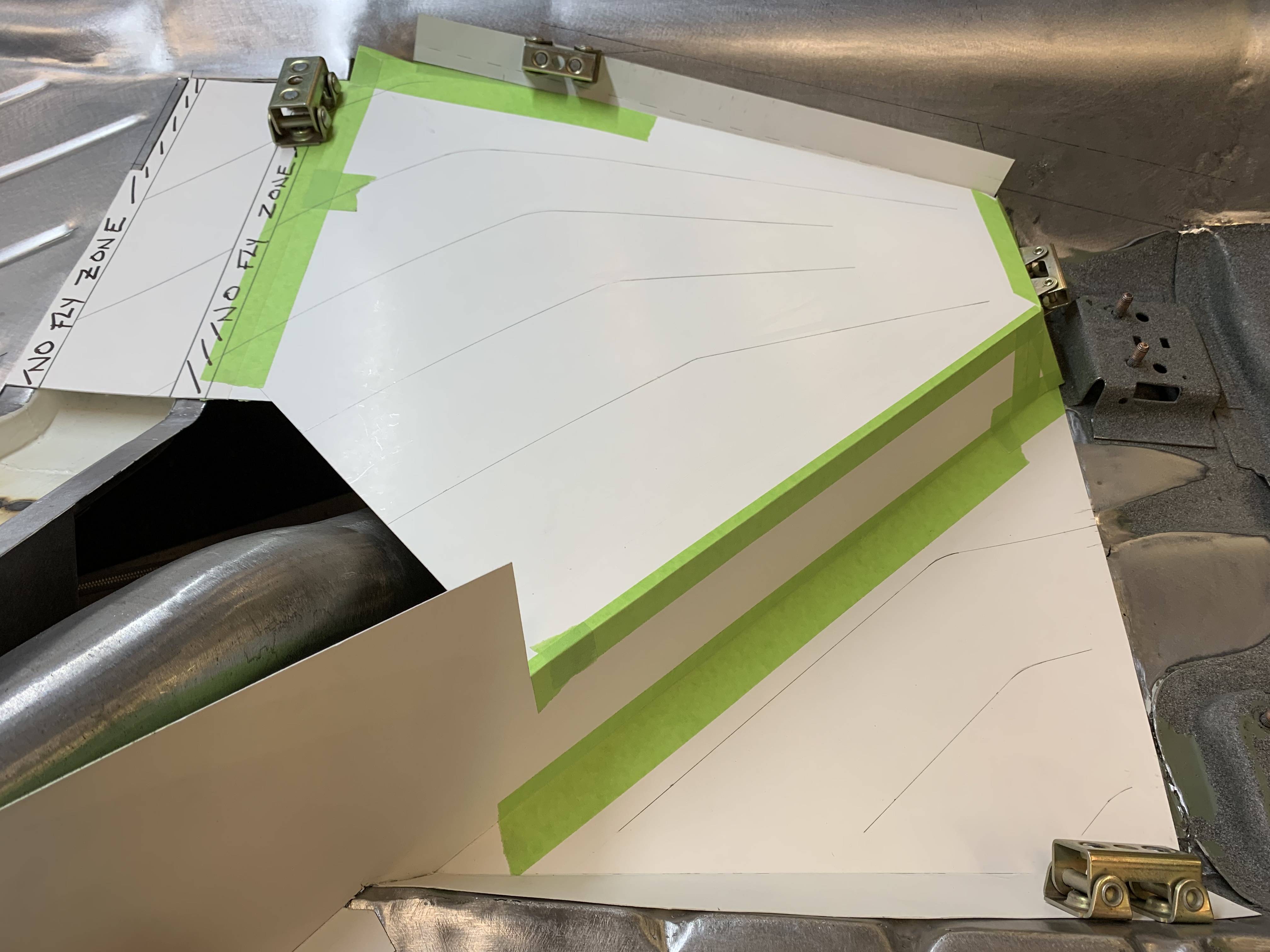

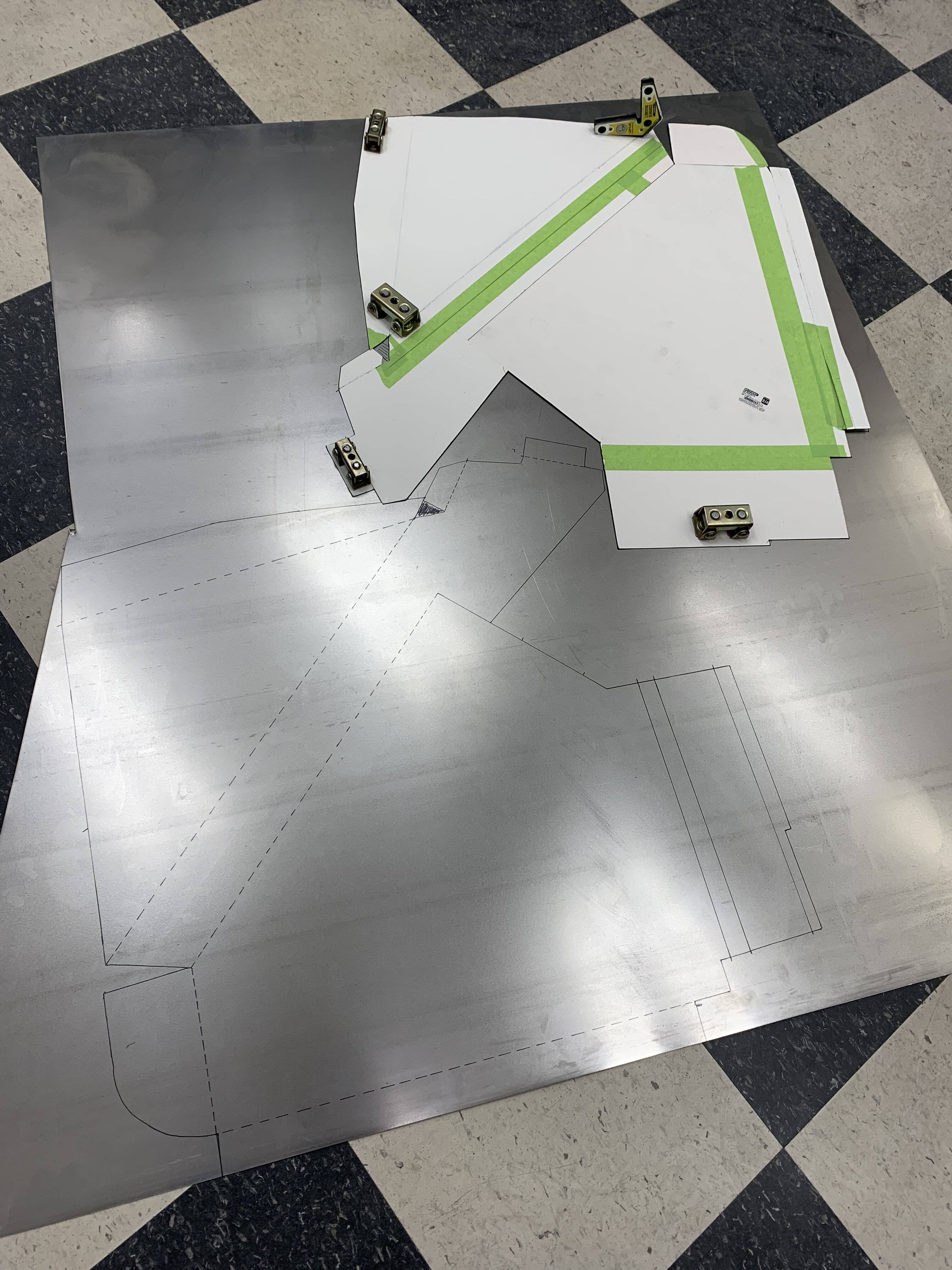

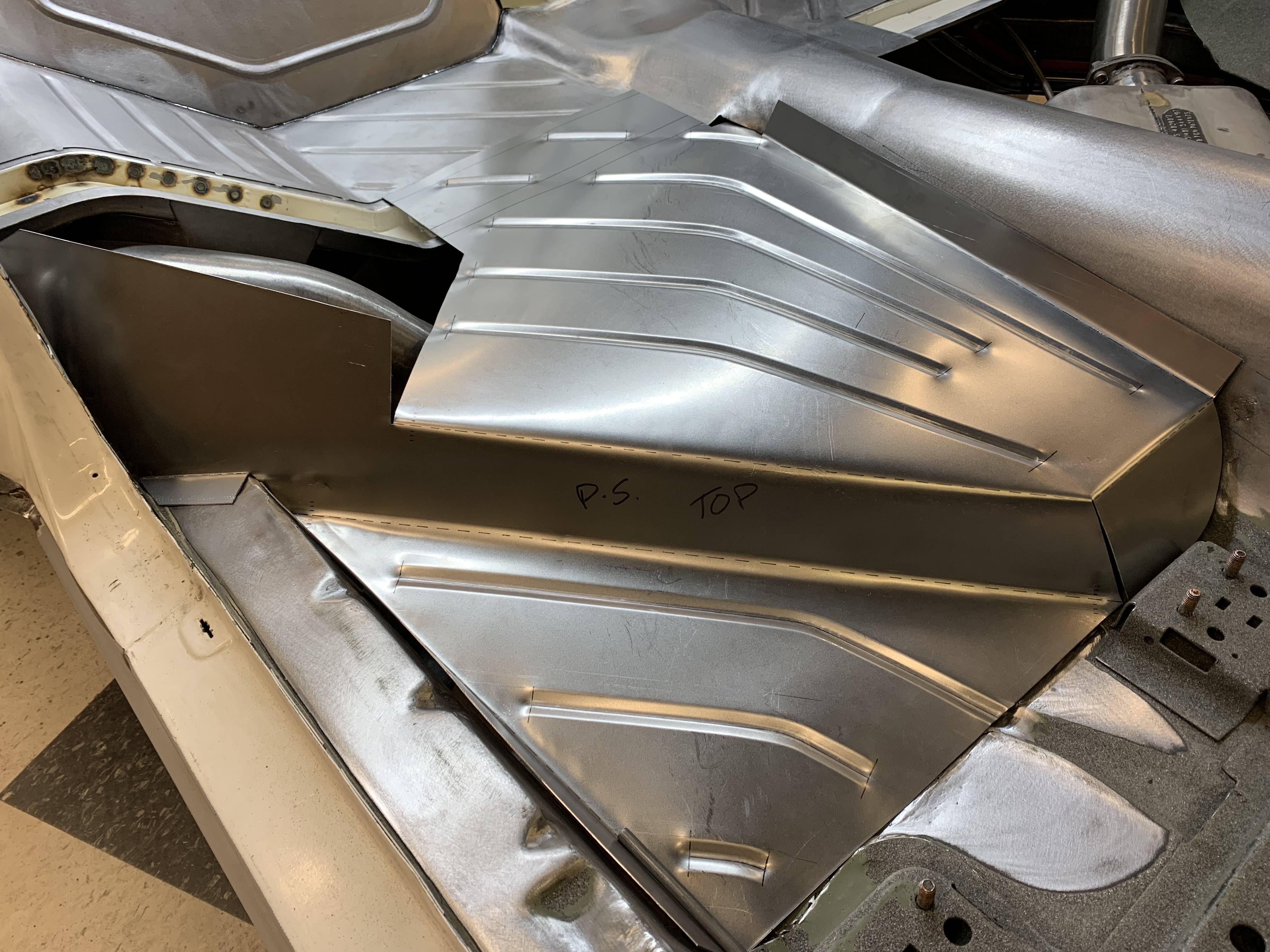

After 2 days and 3 different cardboard template versions, I finally have one that fits in all the areas and is going to work. I know it looks exactly like the version Mike and I came up with a week ago, but I assure you it’s completely different in almost every aspect.

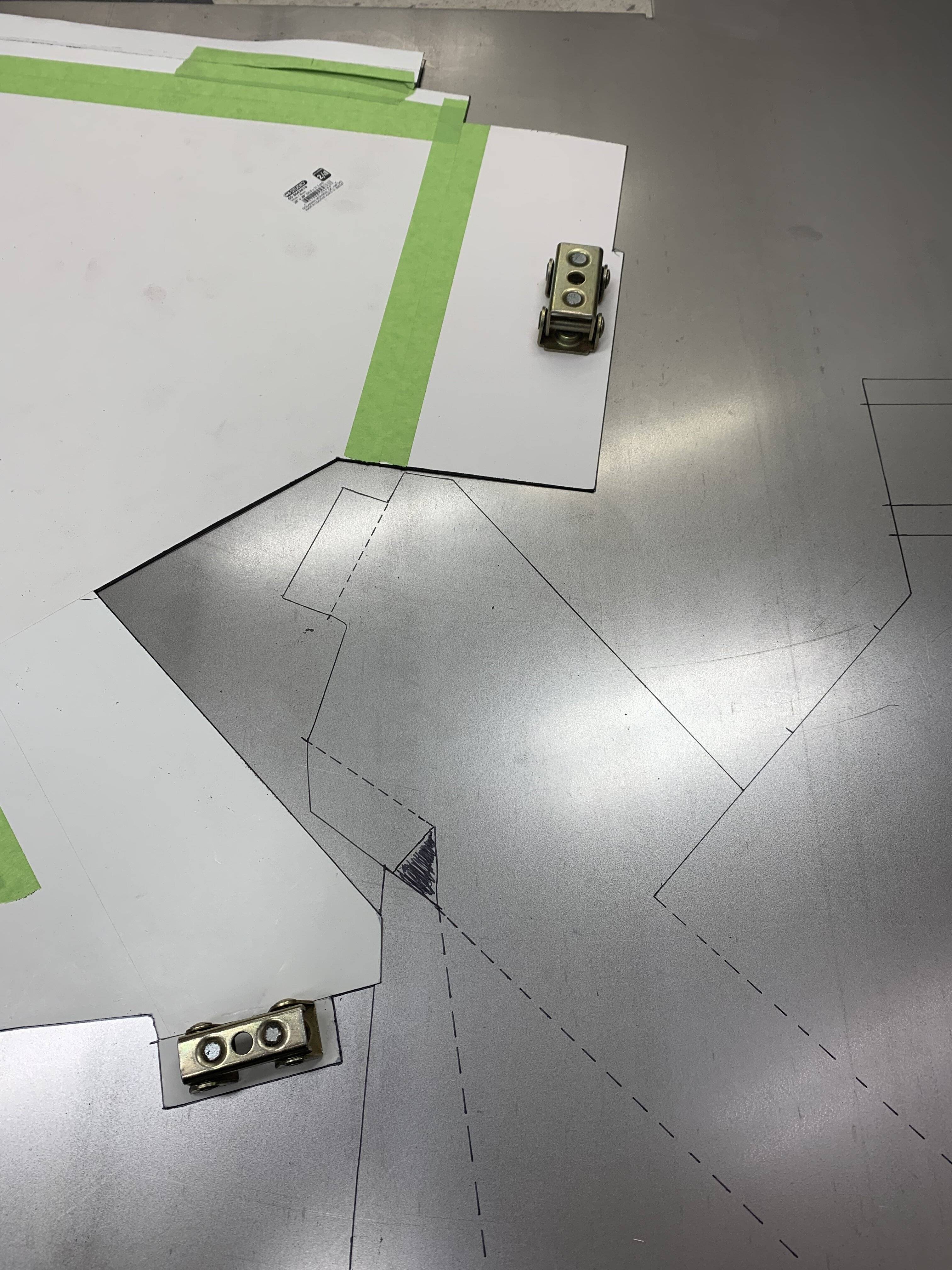

......The area I need y’alls opinions on is my proposed bead roll lines. Once I have the flat metal piece cut out to the template, the first thing I have to do is roll the beads. The piece won’t fit through the bead roller once the bends are made.

There’s 5 full length lines across the top if you look carefully, and there could possibly be part of a 6th in the top right corner if room allows. You’ll note that they all “kick” over to a different angle. That angle aligns with the existing bead roll lines in the section of floor I’ve already got done.

So what’s the general consensus?

Cool and run with it, or come up with something different?

Thanks everyone.

D.

Nix that 6th line for sure as it's too close to the edge. It's close enough the bead isn't there for rigidity & is only for looks.

I like the layout idea but as mentioned it might be too busy. The issue is how to reduce while still maintaining the consistency w/the other areas. I like that idea of staggering/alternating the reduction of lengths to help tame things.

Cake spatulas work really well for tooling seam sealer. There’s also certain degreasers that give a little bit of lubricity to your skin and allow you to smooth the tape edge before the seam sealer dries all the way.You may be right, I may be a masochist given the self inflicted crap I put myself through, but I assure you it’s completely unintentional. It just kinda seems to work out that way.

I’m quite familiar with the tape line method, I’ve used it several times myself, and on various areas of this car too. But while the tape method keeps the excess off the adjacent areas, it still leaves a line or ridge when the tape is removed. Sometimes it’s better to forego the tape just to not leave the ridge, which is what I elected to do here. By blending it completely flush with the adjacent panels like I did there, there’ll be no visible ridge to contend with. Looks a little uglier until it has a coating on it, but that’s short term in the big picture.

I appreciate the suggestion though, thank you.

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.