Get some 3m cubitron belts. 60 or 80 grit. Guys tell me 80 grit seems to last longer than the 60.I actually have one, but I hardly ever use it. I find the belts never last long, I’m always shredding them. I imagine it would take forever to sand down a weld with one.

BUILD THREAD “The Juggernaut”

- Thread starter Rktpwrd

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I've used Norton's blaze line of belt abrasives for a while with good luck.

I’ve been picking away at the driver’s side mirror reinforcement the last couple nights, and I’m much happier with how it’s turning out. Turns out I learned a thing or two. You can teach me, you just can’t teach me much.

😅

Working almost in reverse order from the passenger’s side, I carefully cut out the access pieces in two stages first, rather than blindly cutting through both layers like I did on the other side.

Making the 3/16” reinforcement on the drill press…

And this time, rather than just cutting out an unnecessarily large hole and try and fill in the gaps, I first attached the reinforcement from the inside with longer bolts and traced around the edges.

The reinforcement fits in the inner structure a lot tighter now with less disturbance. I should’ve done this to begin with on the other side.

I’m almost ready to plug weld the reinforcement to the outer skin next, but first I have to strip back all the old paint from around the perimeter of the hole so I can weld this to the inner structure.

Turns out you can teach this old dog a new trick.

D.

😅

Working almost in reverse order from the passenger’s side, I carefully cut out the access pieces in two stages first, rather than blindly cutting through both layers like I did on the other side.

Making the 3/16” reinforcement on the drill press…

And this time, rather than just cutting out an unnecessarily large hole and try and fill in the gaps, I first attached the reinforcement from the inside with longer bolts and traced around the edges.

The reinforcement fits in the inner structure a lot tighter now with less disturbance. I should’ve done this to begin with on the other side.

I’m almost ready to plug weld the reinforcement to the outer skin next, but first I have to strip back all the old paint from around the perimeter of the hole so I can weld this to the inner structure.

Turns out you can teach this old dog a new trick.

D.

Looks like that one went much smoother- things are decidedly cleaner and tighter. Not that there was anything wrong with the first one.I’ve been picking away at the driver’s side mirror reinforcement the last couple nights, and I’m much happier with how it’s turning out. Turns out I learned a thing or two. You can teach me, you just can’t teach me much.

😅

Working almost in reverse order from the passenger’s side, I carefully cut out the access pieces in two stages first, rather than blindly cutting through both layers like I did on the other side.

View attachment 236155

View attachment 236156

Making the 3/16” reinforcement on the drill press…

View attachment 236157

And this time, rather than just cutting out an unnecessarily large hole and try and fill in the gaps, I first attached the reinforcement from the inside with longer bolts and traced around the edges.

View attachment 236158

View attachment 236159

The reinforcement fits in the inner structure a lot tighter now with less disturbance. I should’ve done this to begin with on the other side.

View attachment 236160

I’m almost ready to plug weld the reinforcement to the outer skin next, but first I have to strip back all the old paint from around the perimeter of the hole so I can weld this to the inner structure.

Turns out you can teach this old dog a new trick.

D.

Looks like that one went much smoother- things are decidedly cleaner and tighter. Not that there was anything wrong with the first one.

Now hes gonna tear it all back apart on the other side, hahah JK

I wouldn't be surprised at this point. Dude's attention to detail is impeccable.

Now hes gonna tear it all back apart on the other side, hahah JK

Been waiting for this day for a while now, a free Saturday and warm enough weather to do some spraying.

I loaded up all my priming and painting crap, plus the mirrors, and headed into work. We have an old 1/4 size paint booth there, not big or nice enough to shoot a car in, but satisfactory enough for spraying little parts. It keeps the overspray off my stuff in The Skunkworks that way, so it’s worth the extra effort.

Once there and set up, I sandblasted the insides of the housings, both where the glass resides, and inside the pedestals. Mask up the mounting studs, hang ‘em up, and wipe ‘em down. Not even halfway through the first pass of epoxy primer inside the first housing, I very nearly had a catastrophic disaster. One of the damn mirrors slipped out of the mechanics wire I had it wired up with, and bounced off the floor.

You can imagine the particular expletive I said loud enough for passersby outside to hear me with.

After carefully examining and cleaning it off, it was determined that no damage was done thankfully, so I re-rigged both mirrors and carried on. Somewhat flustered by this irritating incident, I managed to put several runs in the epoxy. Not a big deal on the outsides, but the whole point of today’s exercise was to get some color on the insides. And wouldn’t you know it, I even managed to get one inside, and of course, right near the edge at the bottom where it could theoretically be seen if the glass is at the right angle.

Not to be deterred, I cleaned the gun, then managed to remove the run with a clean lint-free rag soaked in reducer (thinner for the paint). Here they are after 2 coats of epoxy, runs and all.

Again, the runs I put on the outside aren’t a problem, the outsides are going to have to be sanded before the high build primer goes on anyway.

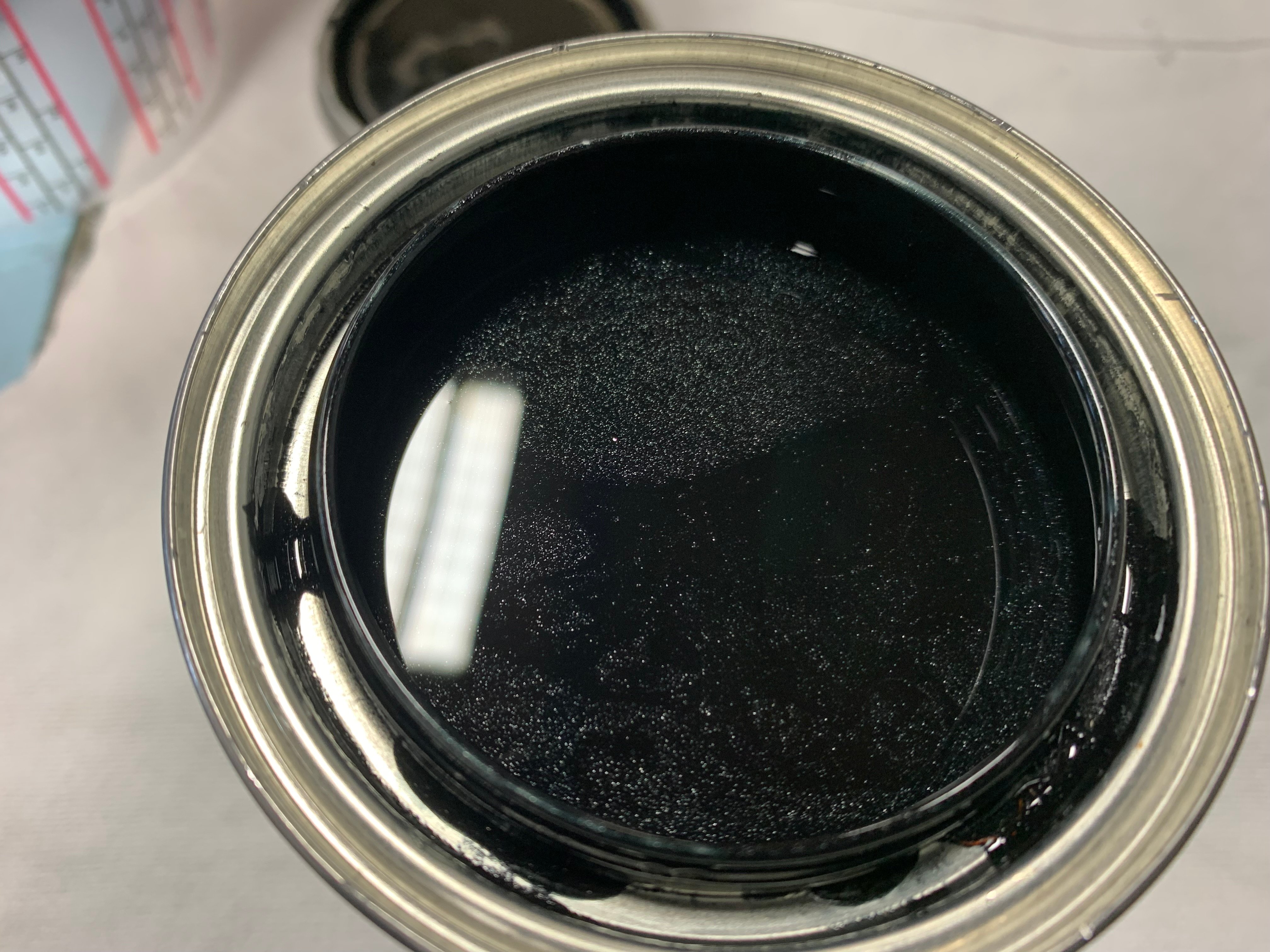

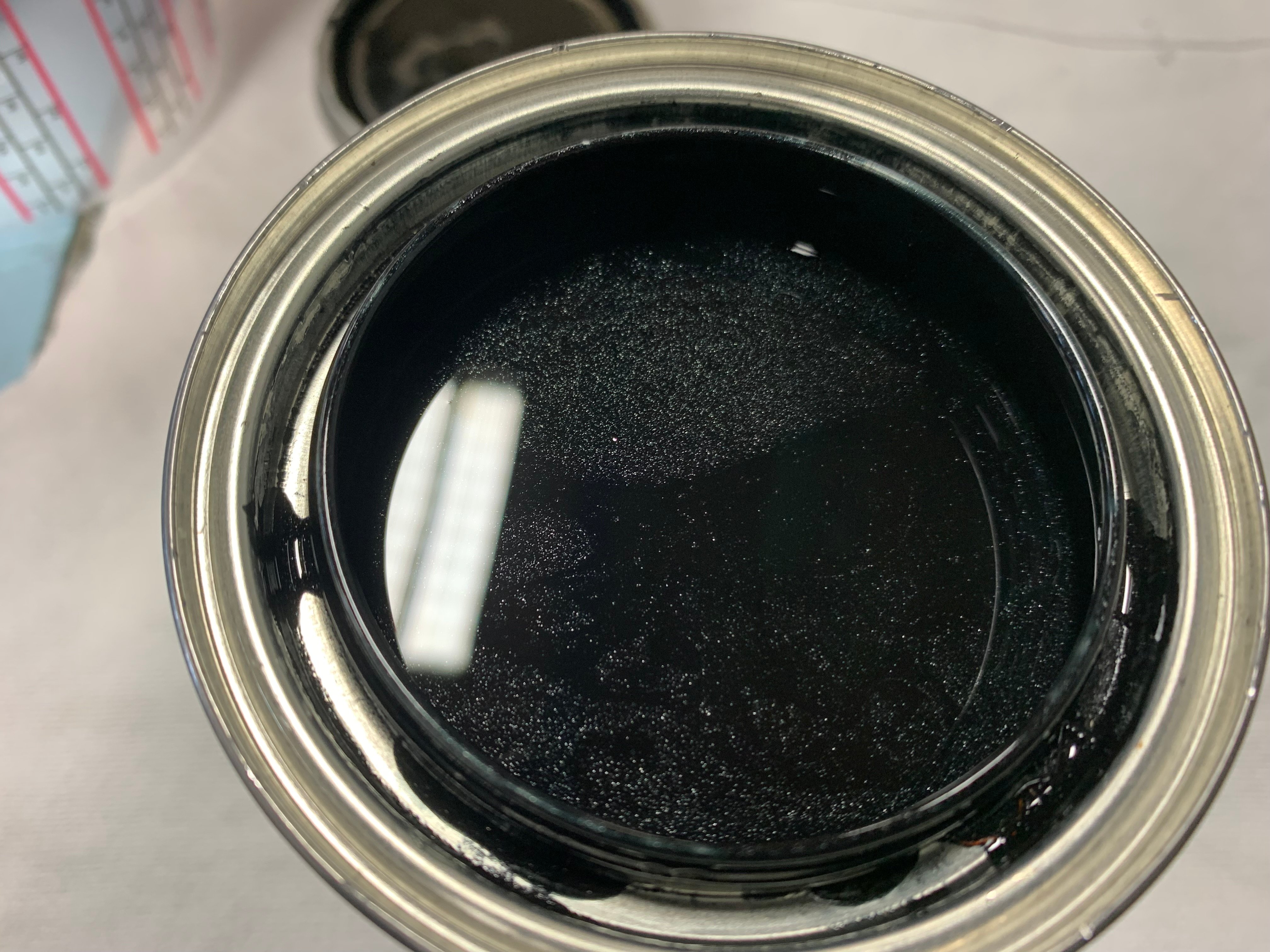

After waiting the one hour cure time , I next mixed up the first of the new basecoat color to go on the car. To reiterate, this isn’t black, but it’s about as dark a metallic gray as I can get without being black. It is most definitely gray.

Two coats of base later, it was time to clean the gun again. After another half hour of flash time, I mixed up and shot 2 coats of some cheap Omni clear I had kicking around. Not gonna use the fancy expensive show clear for just the insides of the mirrors.

Unfortunately the lighting in the booth is terrible, so the metallic doesn’t really show as well as it would if it was outside. But it still looks pretty damn good, so I think it’s going to be a winner for my upper color choice.

After yet another round of gun cleaning, I could finally pack everything up and head for home. Just this simple process is very time consuming, four hours from start to finish.

I’m glad I didn’t try and spray the high build at the same time too, that probably would’ve added another 2 hours to the total.

So now tomorrow, providing the clear has cured enough, I should be able to assemble the power motor mounting brackets, the motors, the glass housings, and finally the new glass in both. That’ll be a whole lot less parts scattered all over my workbench.

D.

I loaded up all my priming and painting crap, plus the mirrors, and headed into work. We have an old 1/4 size paint booth there, not big or nice enough to shoot a car in, but satisfactory enough for spraying little parts. It keeps the overspray off my stuff in The Skunkworks that way, so it’s worth the extra effort.

Once there and set up, I sandblasted the insides of the housings, both where the glass resides, and inside the pedestals. Mask up the mounting studs, hang ‘em up, and wipe ‘em down. Not even halfway through the first pass of epoxy primer inside the first housing, I very nearly had a catastrophic disaster. One of the damn mirrors slipped out of the mechanics wire I had it wired up with, and bounced off the floor.

You can imagine the particular expletive I said loud enough for passersby outside to hear me with.

After carefully examining and cleaning it off, it was determined that no damage was done thankfully, so I re-rigged both mirrors and carried on. Somewhat flustered by this irritating incident, I managed to put several runs in the epoxy. Not a big deal on the outsides, but the whole point of today’s exercise was to get some color on the insides. And wouldn’t you know it, I even managed to get one inside, and of course, right near the edge at the bottom where it could theoretically be seen if the glass is at the right angle.

Not to be deterred, I cleaned the gun, then managed to remove the run with a clean lint-free rag soaked in reducer (thinner for the paint). Here they are after 2 coats of epoxy, runs and all.

Again, the runs I put on the outside aren’t a problem, the outsides are going to have to be sanded before the high build primer goes on anyway.

After waiting the one hour cure time , I next mixed up the first of the new basecoat color to go on the car. To reiterate, this isn’t black, but it’s about as dark a metallic gray as I can get without being black. It is most definitely gray.

Two coats of base later, it was time to clean the gun again. After another half hour of flash time, I mixed up and shot 2 coats of some cheap Omni clear I had kicking around. Not gonna use the fancy expensive show clear for just the insides of the mirrors.

Unfortunately the lighting in the booth is terrible, so the metallic doesn’t really show as well as it would if it was outside. But it still looks pretty damn good, so I think it’s going to be a winner for my upper color choice.

After yet another round of gun cleaning, I could finally pack everything up and head for home. Just this simple process is very time consuming, four hours from start to finish.

I’m glad I didn’t try and spray the high build at the same time too, that probably would’ve added another 2 hours to the total.

So now tomorrow, providing the clear has cured enough, I should be able to assemble the power motor mounting brackets, the motors, the glass housings, and finally the new glass in both. That’ll be a whole lot less parts scattered all over my workbench.

D.

Man, I'll never not be surprised by bouncing glass and have been distracted by far less.Been waiting for this day for a while now, a free Saturday and warm enough weather to do some spraying.

I loaded up all my priming and painting crap, plus the mirrors, and headed into work. We have an old 1/4 size paint booth there, not big or nice enough to shoot a car in, but satisfactory enough for spraying little parts. It keeps the overspray off my stuff in The Skunkworks that way, so it’s worth the extra effort.

Once there and set up, I sandblasted the insides of the housings, both where the glass resides, and inside the pedestals. Mask up the mounting studs, hang ‘em up, and wipe ‘em down. Not even halfway through the first pass of epoxy primer inside the first housing, I very nearly had a catastrophic disaster. One of the damn mirrors slipped out of the mechanics wire I had it wired up with, and bounced off the floor.

You can imagine the particular expletive I said loud enough for passersby outside to hear me with.

After carefully examining and cleaning it off, it was determined that no damage was done thankfully, so I re-rigged both mirrors and carried on. Somewhat flustered by this irritating incident, I managed to put several runs in the epoxy. Not a big deal on the outsides, but the whole point of today’s exercise was to get some color on the insides. And wouldn’t you know it, I even managed to get one inside, and of course, right near the edge at the bottom where it could theoretically be seen if the glass is at the right angle.

Not to be deterred, I cleaned the gun, then managed to remove the run with a clean lint-free rag soaked in reducer (thinner for the paint). Here they are after 2 coats of epoxy, runs and all.

View attachment 236245

View attachment 236246

View attachment 236247

View attachment 236248

View attachment 236249

Again, the runs I put on the outside aren’t a problem, the outsides are going to have to be sanded before the high build primer goes on anyway.

After waiting the one hour cure time , I next mixed up the first of the new basecoat color to go on the car. To reiterate, this isn’t black, but it’s about as dark a metallic gray as I can get without being black. It is most definitely gray.

View attachment 236250

Two coats of base later, it was time to clean the gun again. After another half hour of flash time, I mixed up and shot 2 coats of some cheap Omni clear I had kicking around. Not gonna use the fancy expensive show clear for just the insides of the mirrors.

Unfortunately the lighting in the booth is terrible, so the metallic doesn’t really show as well as it would if it was outside. But it still looks pretty damn good, so I think it’s going to be a winner for my upper color choice.

View attachment 236251

View attachment 236252

View attachment 236253

View attachment 236254

View attachment 236255

View attachment 236256

View attachment 236257

View attachment 236258

After yet another round of gun cleaning, I could finally pack everything up and head for home. Just this simple process is very time consuming, four hours from start to finish.

I’m glad I didn’t try and spray the high build at the same time too, that probably would’ve added another 2 hours to the total.

So now tomorrow, providing the clear has cured enough, I should be able to assemble the power motor mounting brackets, the motors, the glass housings, and finally the new glass in both. That’ll be a whole lot less parts scattered all over my workbench.

D.

And is that an official color selection? Cuz that's a nice one.

Man, I'll never not be surprised by bouncing glass and have been distracted by far less.

And is that an official color selection? Cuz that's a nice one.

It wasn’t the glass that bounced off the floor, it was the entire mirror housing! I’m still amazed it didn’t dent or otherwise deform as it dropped a solid 3-3 1/2 feet.

And yes, it could quite possibly be the official upper color selection, but I’ll reserve that decision until I see it on an outer surface and in direct sunlight. Especially beside the Viper Blue Pearl that the lower color is going to be.

That’ll be the decision maker.

I'm not sure why I thought you were referring to the glass- you mentioned mechanic's wire which should make things obvious.It wasn’t the glass that bounced off the floor, it was the entire mirror housing! I’m still amazed it didn’t dent or otherwise deform as it dropped a solid 3-3 1/2 feet.

And yes, it could quite possibly be the official upper color selection, but I’ll reserve that decision until I see it on an outer surface and in direct sunlight. Especially beside the Viper Blue Pearl that the lower color is going to be.

That’ll be the decision maker.

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.