That color with Viper Blue should be a killer combo. I just did my mirrors as well but haven't posted anything yet. I'm more excited about yours than mine. Lol. Keep up the progress Donovan!Been waiting for this day for a while now, a free Saturday and warm enough weather to do some spraying.

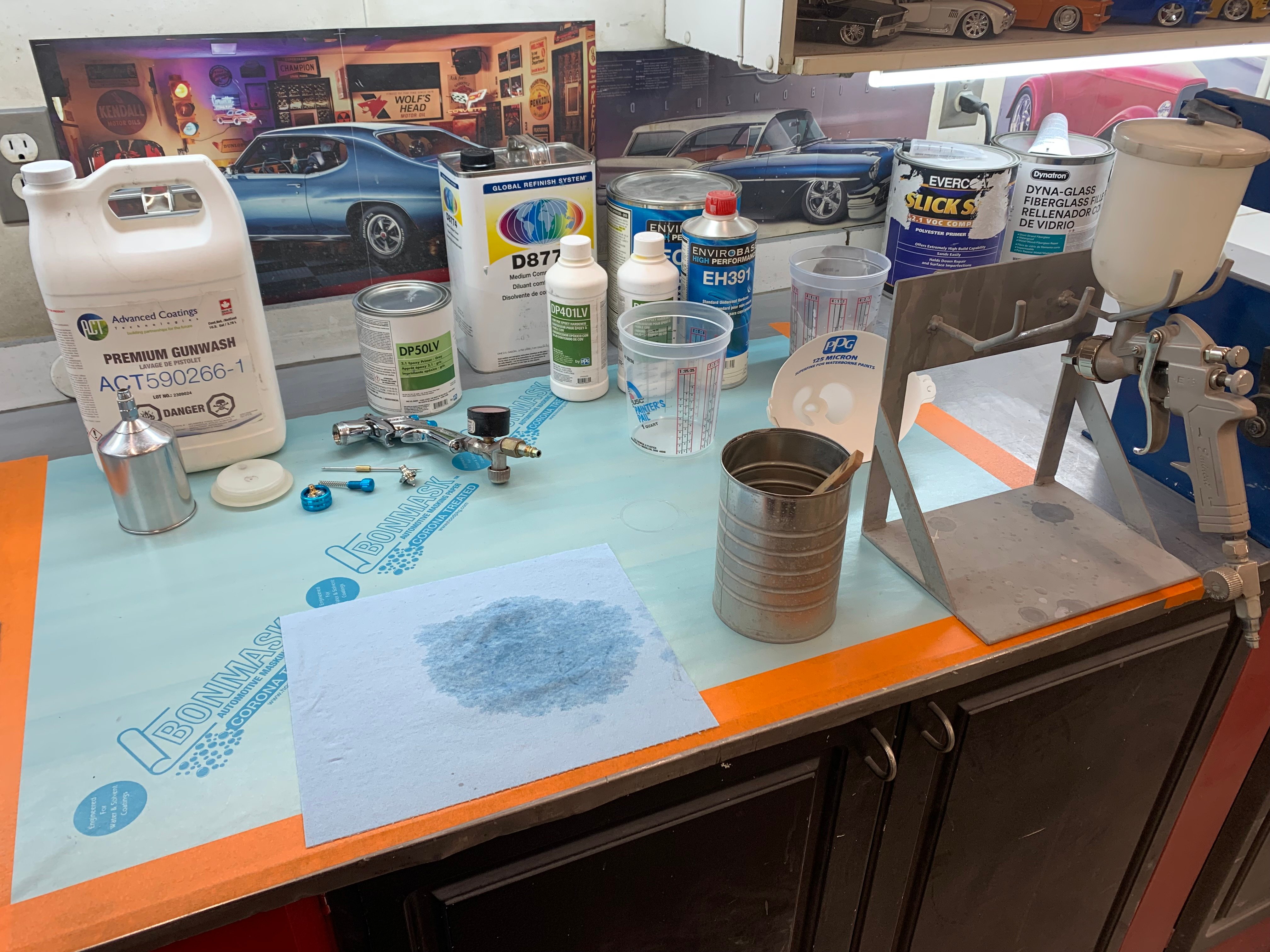

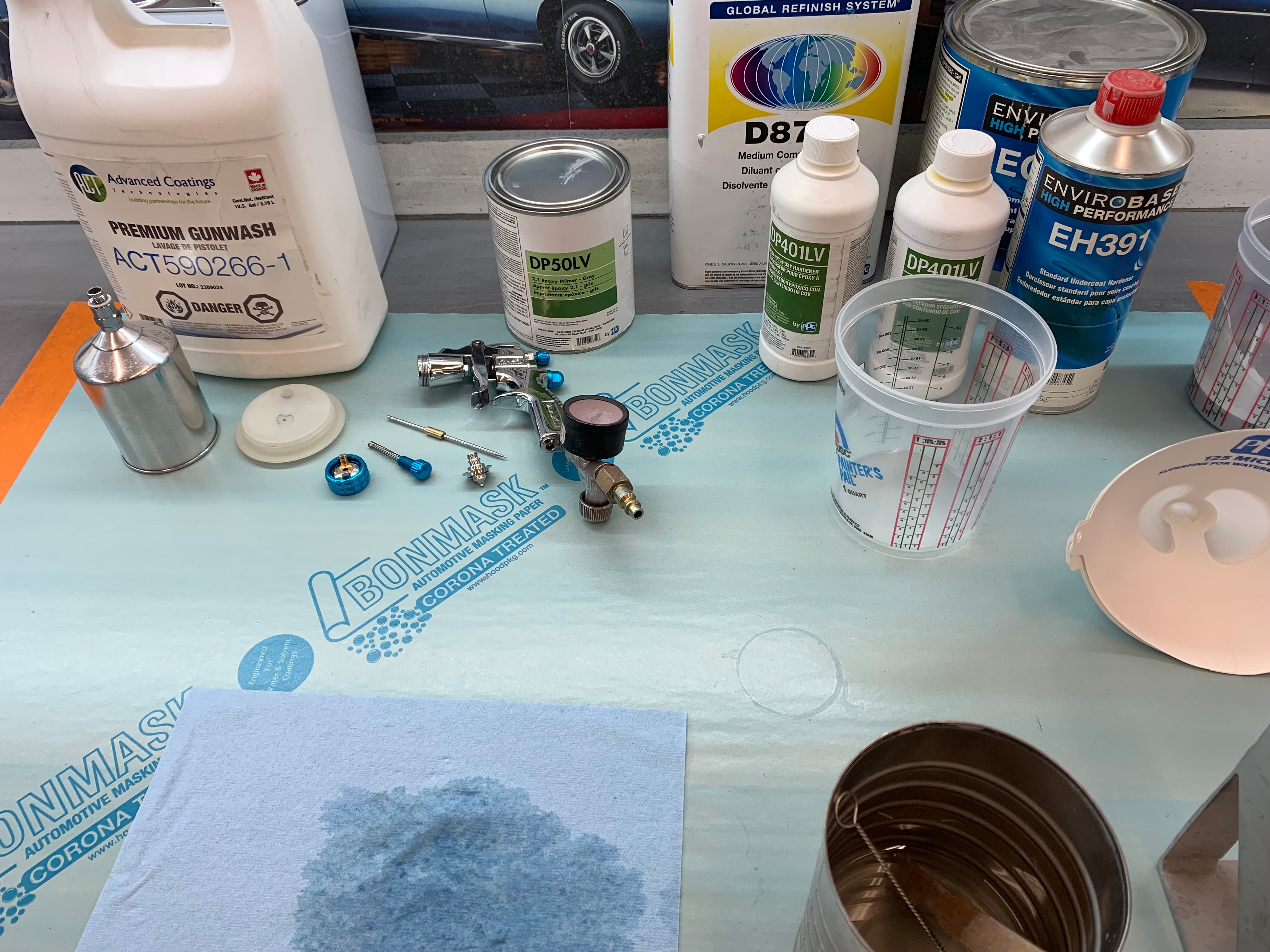

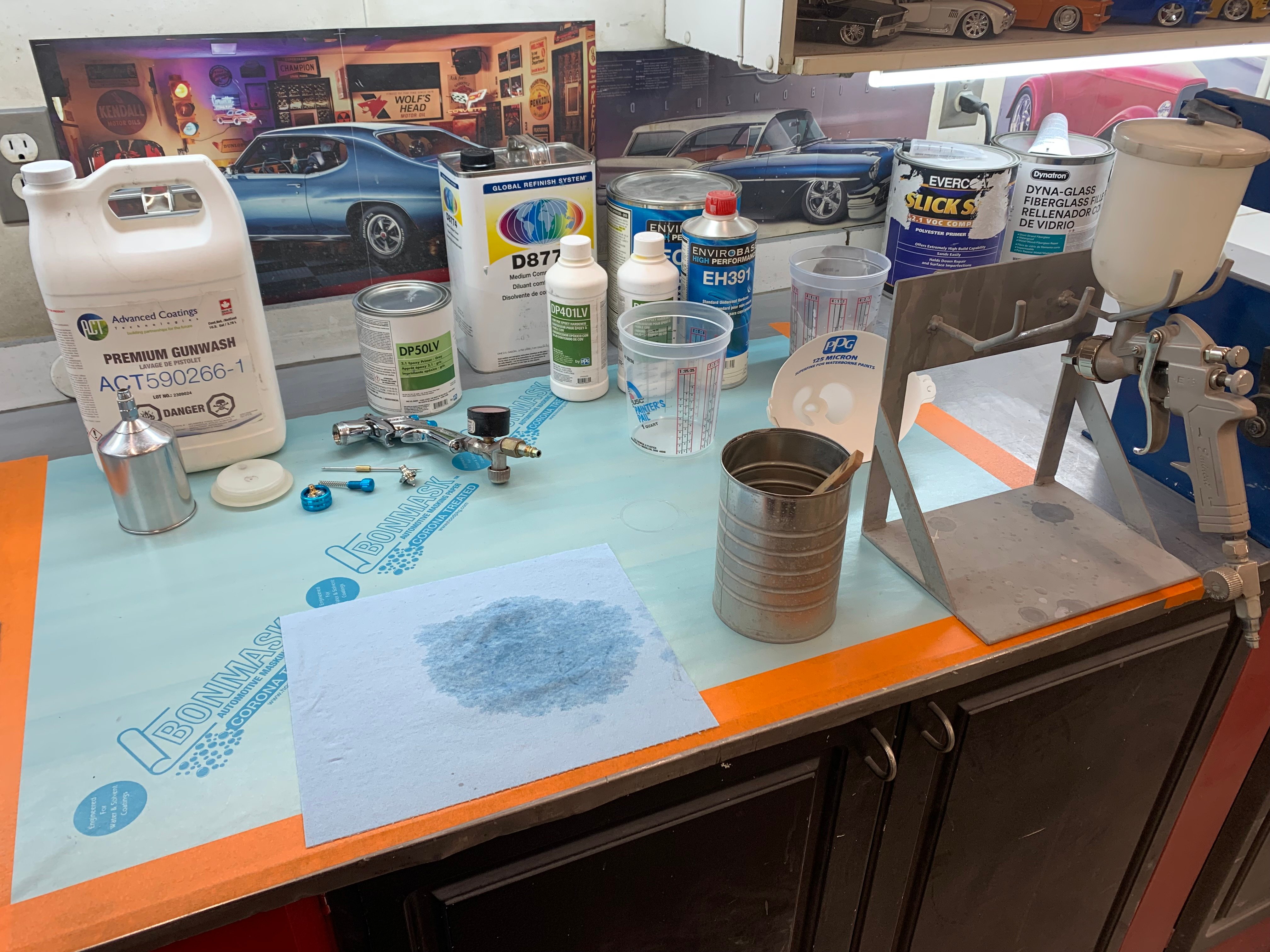

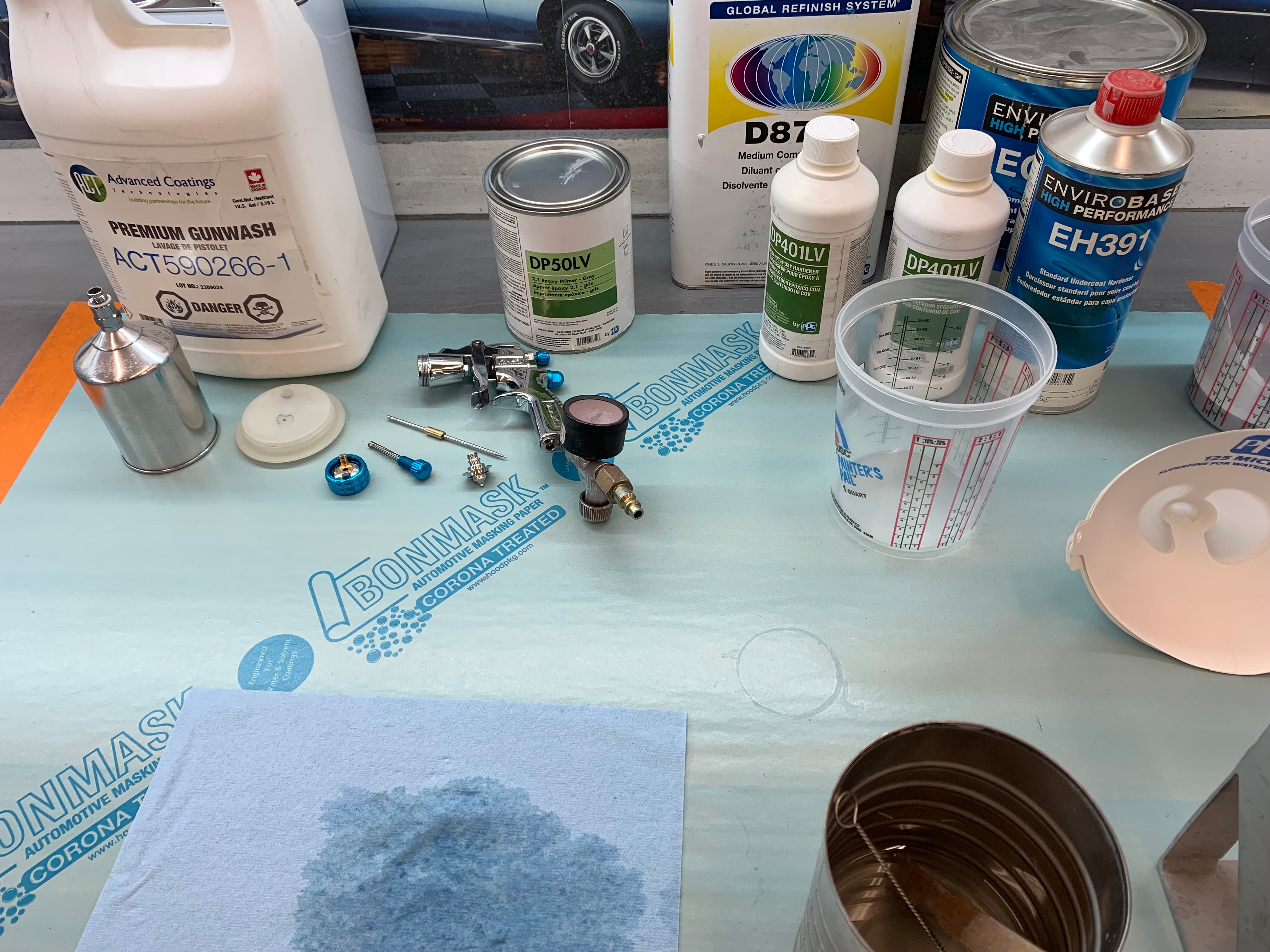

I loaded up all my priming and painting crap, plus the mirrors, and headed into work. We have an old 1/4 size paint booth there, not big or nice enough to shoot a car in, but satisfactory enough for spraying little parts. It keeps the overspray off my stuff in The Skunkworks that way, so it’s worth the extra effort.

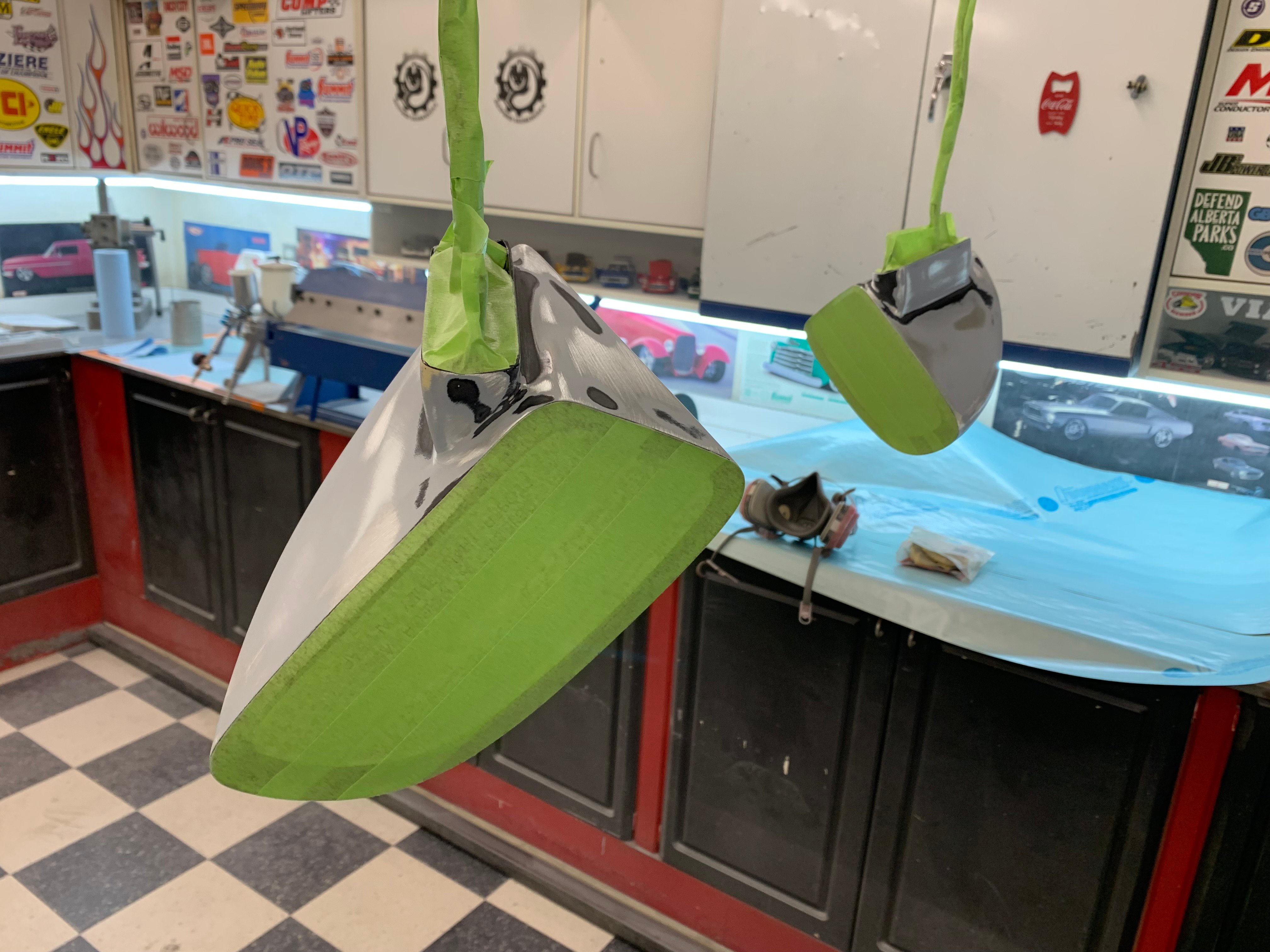

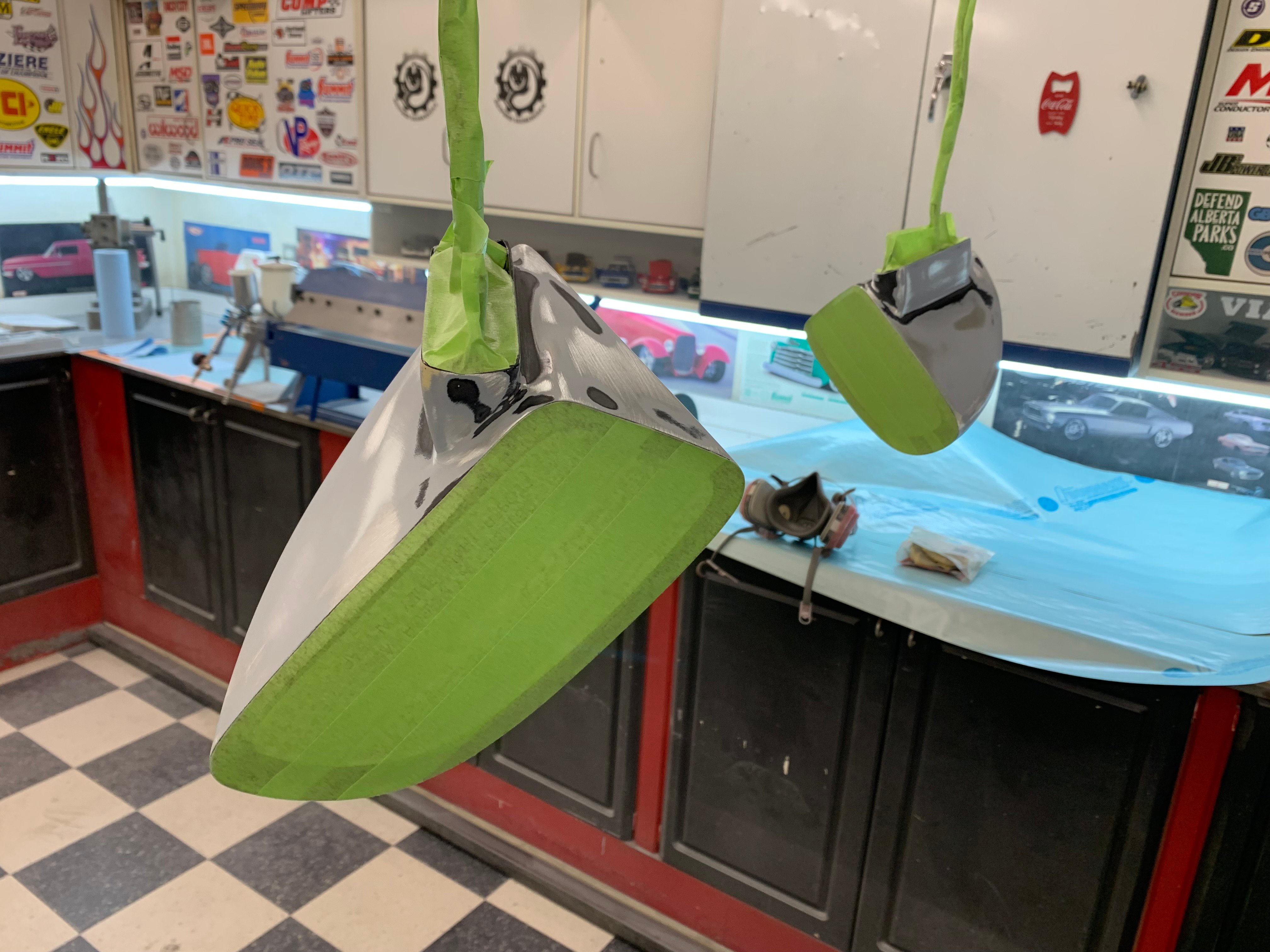

Once there and set up, I sandblasted the insides of the housings, both where the glass resides, and inside the pedestals. Mask up the mounting studs, hang ‘em up, and wipe ‘em down. Not even halfway through the first pass of epoxy primer inside the first housing, I very nearly had a catastrophic disaster. One of the damn mirrors slipped out of the mechanics wire I had it wired up with, and bounced off the floor.

You can imagine the particular expletive I said loud enough for passersby outside to hear me with.

After carefully examining and cleaning it off, it was determined that no damage was done thankfully, so I re-rigged both mirrors and carried on. Somewhat flustered by this irritating incident, I managed to put several runs in the epoxy. Not a big deal on the outsides, but the whole point of today’s exercise was to get some color on the insides. And wouldn’t you know it, I even managed to get one inside, and of course, right near the edge at the bottom where it could theoretically be seen if the glass is at the right angle.

Not to be deterred, I cleaned the gun, then managed to remove the run with a clean lint-free rag soaked in reducer (thinner for the paint). Here they are after 2 coats of epoxy, runs and all.

View attachment 236245

View attachment 236246

View attachment 236247

View attachment 236248

View attachment 236249

Again, the runs I put on the outside aren’t a problem, the outsides are going to have to be sanded before the high build primer goes on anyway.

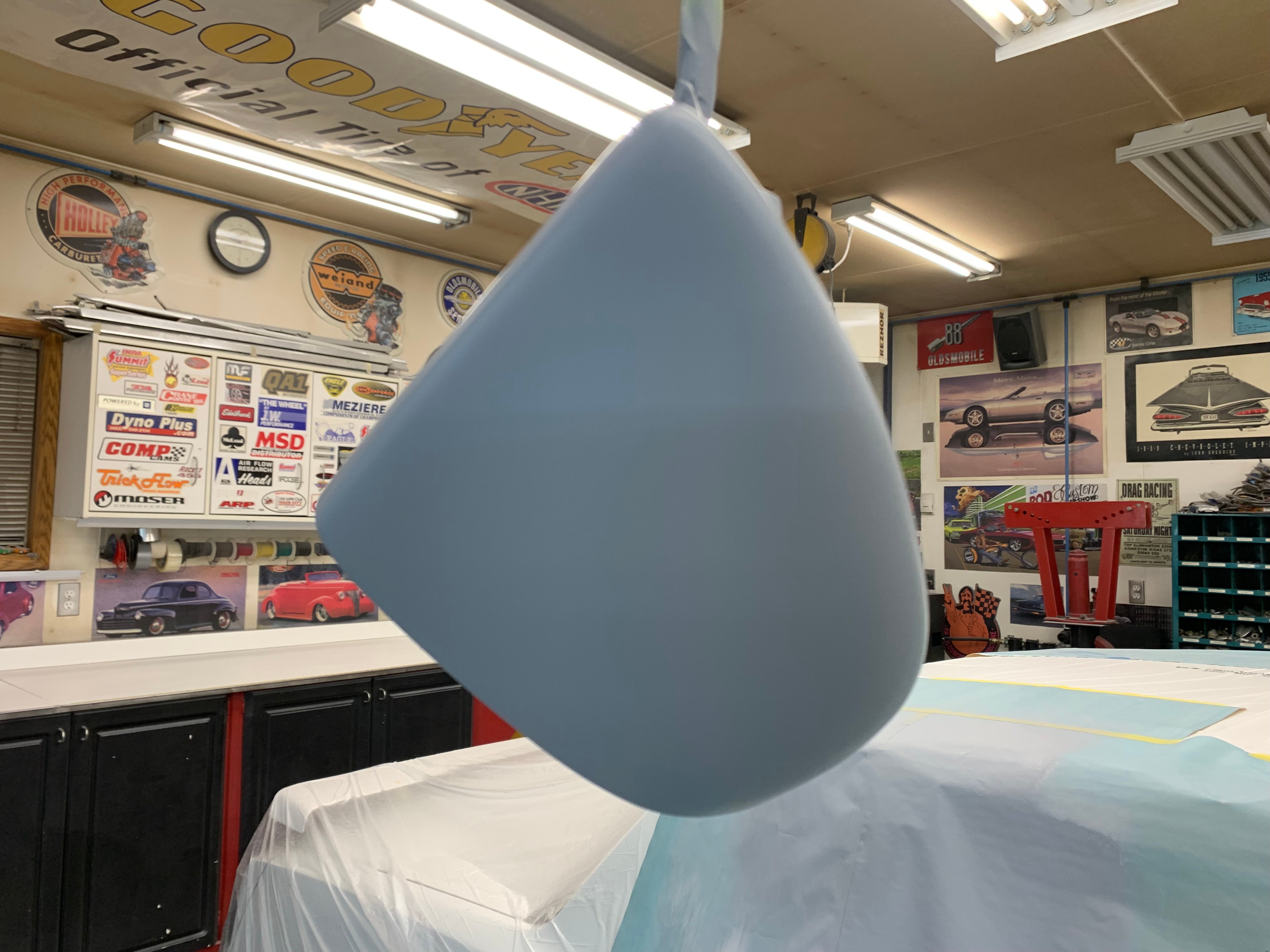

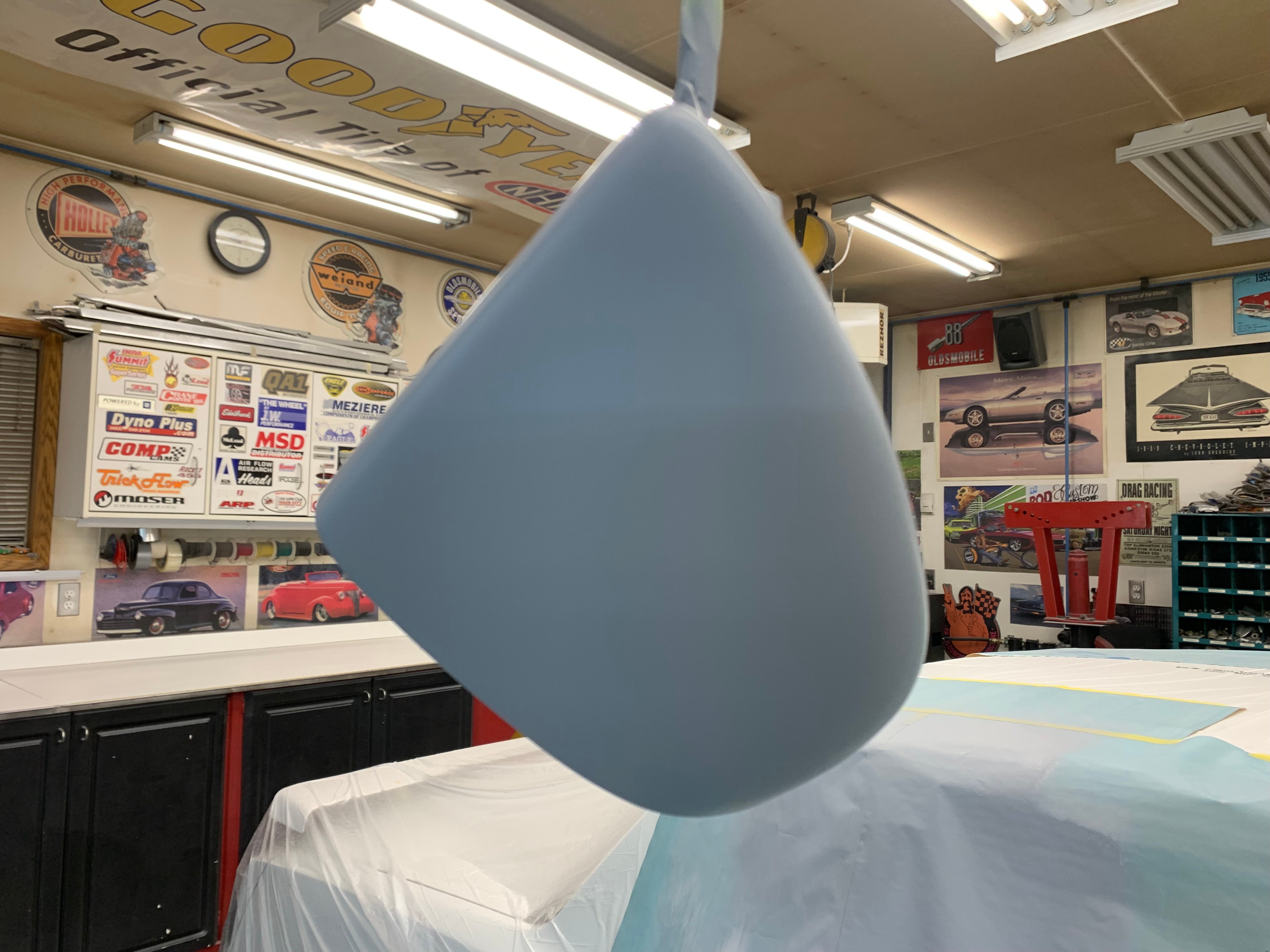

After waiting the one hour cure time , I next mixed up the first of the new basecoat color to go on the car. To reiterate, this isn’t black, but it’s about as dark a metallic gray as I can get without being black. It is most definitely gray.

View attachment 236250

Two coats of base later, it was time to clean the gun again. After another half hour of flash time, I mixed up and shot 2 coats of some cheap Omni clear I had kicking around. Not gonna use the fancy expensive show clear for just the insides of the mirrors.

Unfortunately the lighting in the booth is terrible, so the metallic doesn’t really show as well as it would if it was outside. But it still looks pretty damn good, so I think it’s going to be a winner for my upper color choice.

View attachment 236251

View attachment 236252

View attachment 236253

View attachment 236254

View attachment 236255

View attachment 236256

View attachment 236257

View attachment 236258

After yet another round of gun cleaning, I could finally pack everything up and head for home. Just this simple process is very time consuming, four hours from start to finish.

I’m glad I didn’t try and spray the high build at the same time too, that probably would’ve added another 2 hours to the total.

So now tomorrow, providing the clear has cured enough, I should be able to assemble the power motor mounting brackets, the motors, the glass housings, and finally the new glass in both. That’ll be a whole lot less parts scattered all over my workbench.

D.

BUILD THREAD “The Juggernaut”

- Thread starter Rktpwrd

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

This is why I subscribe to Donovan's threads:

In the past, people have asked me how I learned to 'fix cars'. Mostly trial and error, mixed with a lack of fear. The slower you go, the more control you have over committing tragic errors.

The placement of your first couple of tacks will determine the outcome of the rest of the welding. Notice I placed the first two tacks on the outer edges, and not along the long edge or on the vertical seams. This is because heat from the welds will draw the two pieces together slightly throwing off the alignment and closing up the gaps.

Serious gratitude for contributing to the tribal knowledge and education of us wannabes whose standards far exceed our personal skills...Turns out I learned a thing or two. You can teach me, you just can’t teach me much.

😅

Working almost in reverse order from the passenger’s side, I carefully cut out the access pieces in two stages first, rather than blindly cutting through both layers like I did on the other side.

In the past, people have asked me how I learned to 'fix cars'. Mostly trial and error, mixed with a lack of fear. The slower you go, the more control you have over committing tragic errors.

We had a little bit of sunshine here this morning, so I tried to get a couple of pictures of the metallic in the direct sunlight but the stupid camera just won’t pick it up. The color is very nice and extremely sparkly with a hint of dark green in the metallics.

These are the best I could do, and they don’t do it justice. I think the color is a keeper.

When I mentioned earlier that I had a pile of mirror parts all over my workbench, I wasn’t kidding. These have been here for months now, time to get rid of them with reassembly.

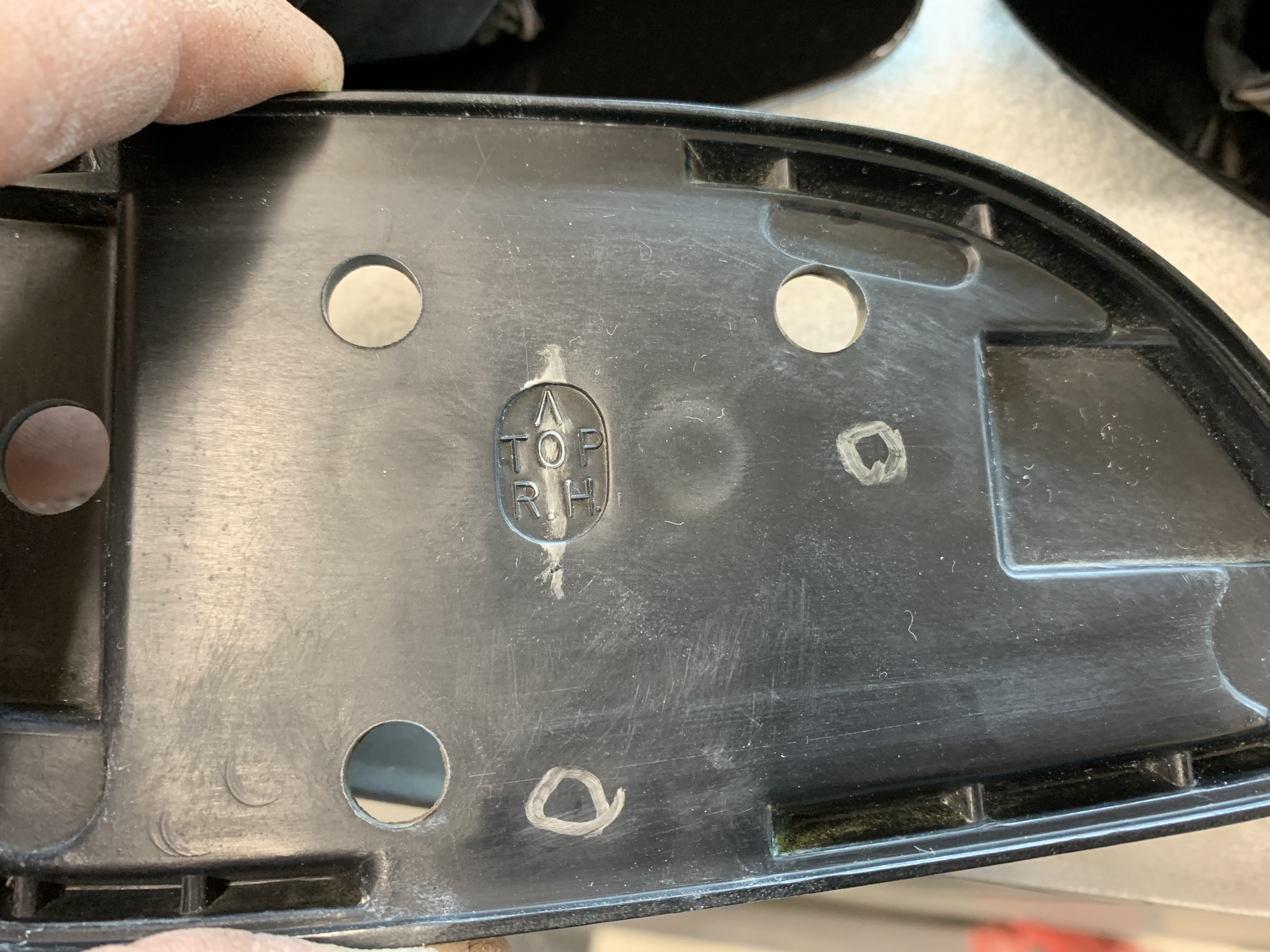

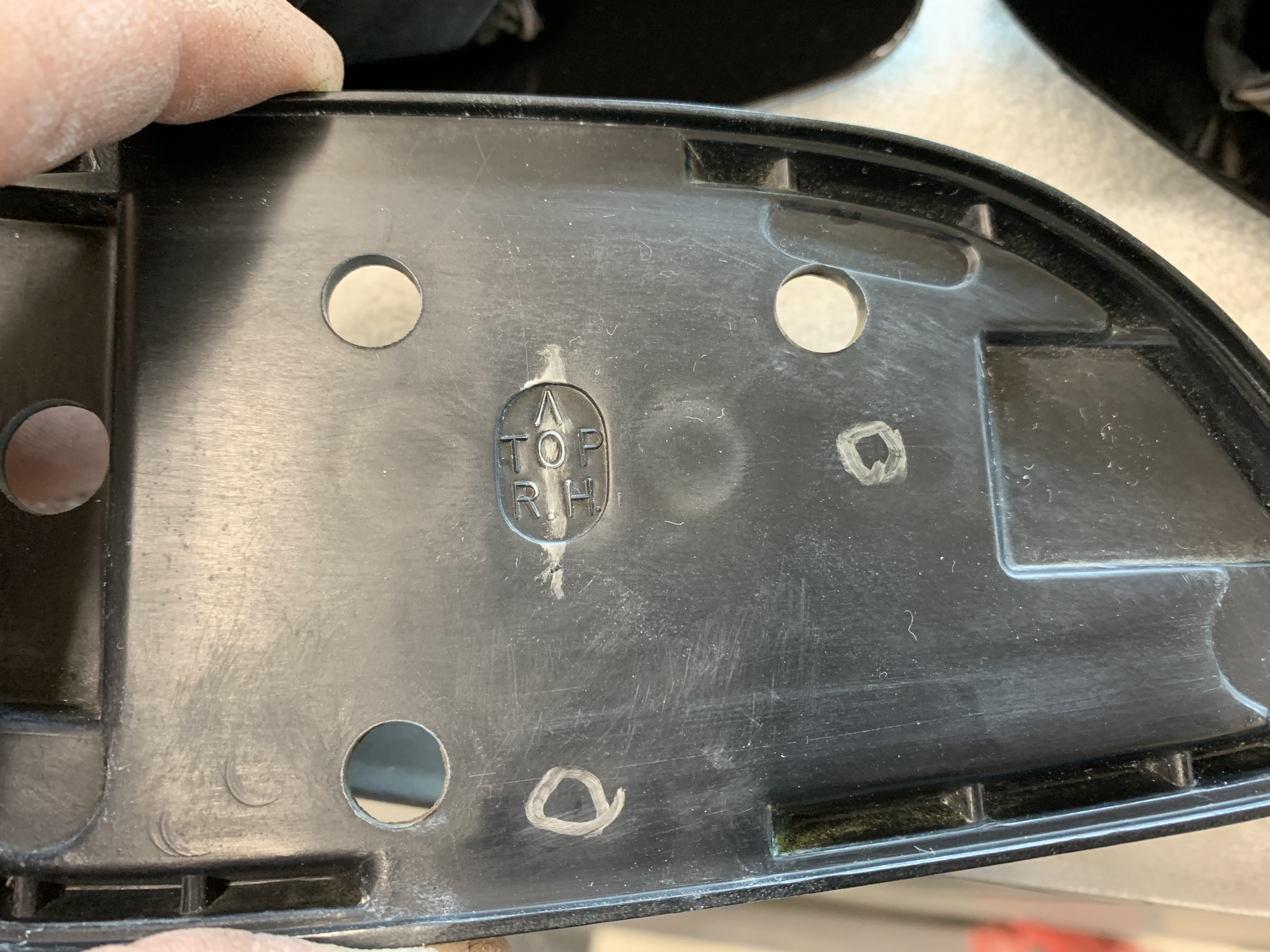

The green mirrors are the ones I bought off eBay, they were the power F body versions. Great for the innards, but not so good for the housings as the pedestal portions are too short. The housings I painted yesterday are Monte SS versions I acquired from our good friend O. D. Showtime. Thanks Kevin! The good news is, the Monte housings will accept the F body power motors.

Here’s a couple of gems for 69hurstolds, part numbers and date stamps on the motors from June and August of 1990:

Pretty cool, I love seeing stuff like that.

The clear coat was dry enough for reassembly today, so this’ll be a step by step of how they go together. This’ll be information I wish I had access to months ago. First off, the motor mounting cages attach to the housings with the short screws:

Then, the motors attach to the cages with the longer screws.

Once those are installed, next is the plastic mirror glass carriers. Note I have 3 sitting on the bench here, 2 are the power mirror versions, and 1 is a manual version. There is a substantial difference between them.

The manual version has a plastic pivot attached to the backside…

…whereas the power versions have two pivoting studs and a groove for the pot metal cross to clip into:

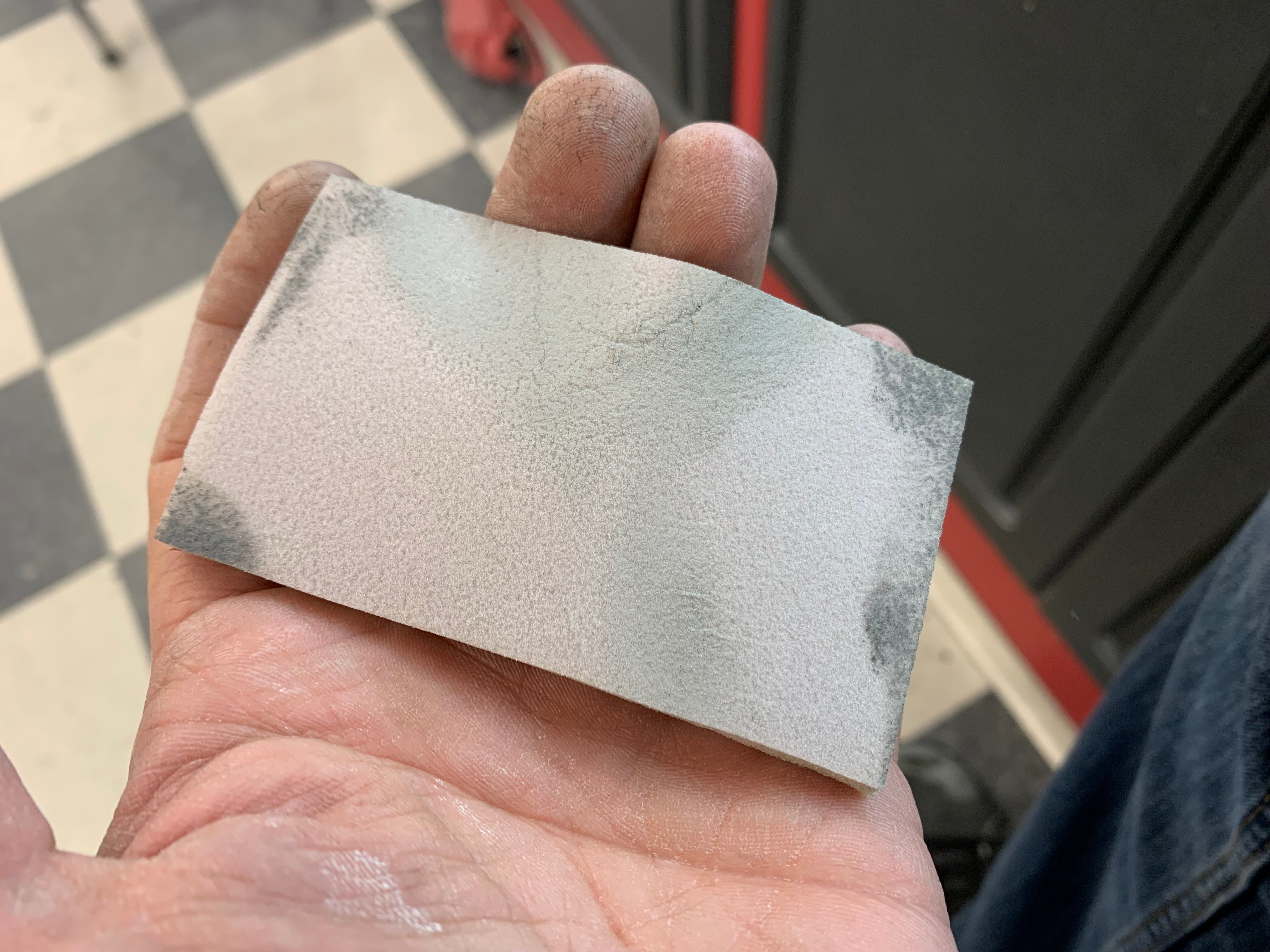

The edges of the glass carriers were looking pretty chalky and faded, and one had green overspray on it. After cleaning that off with some lacquer thinner, this is what it looked like:

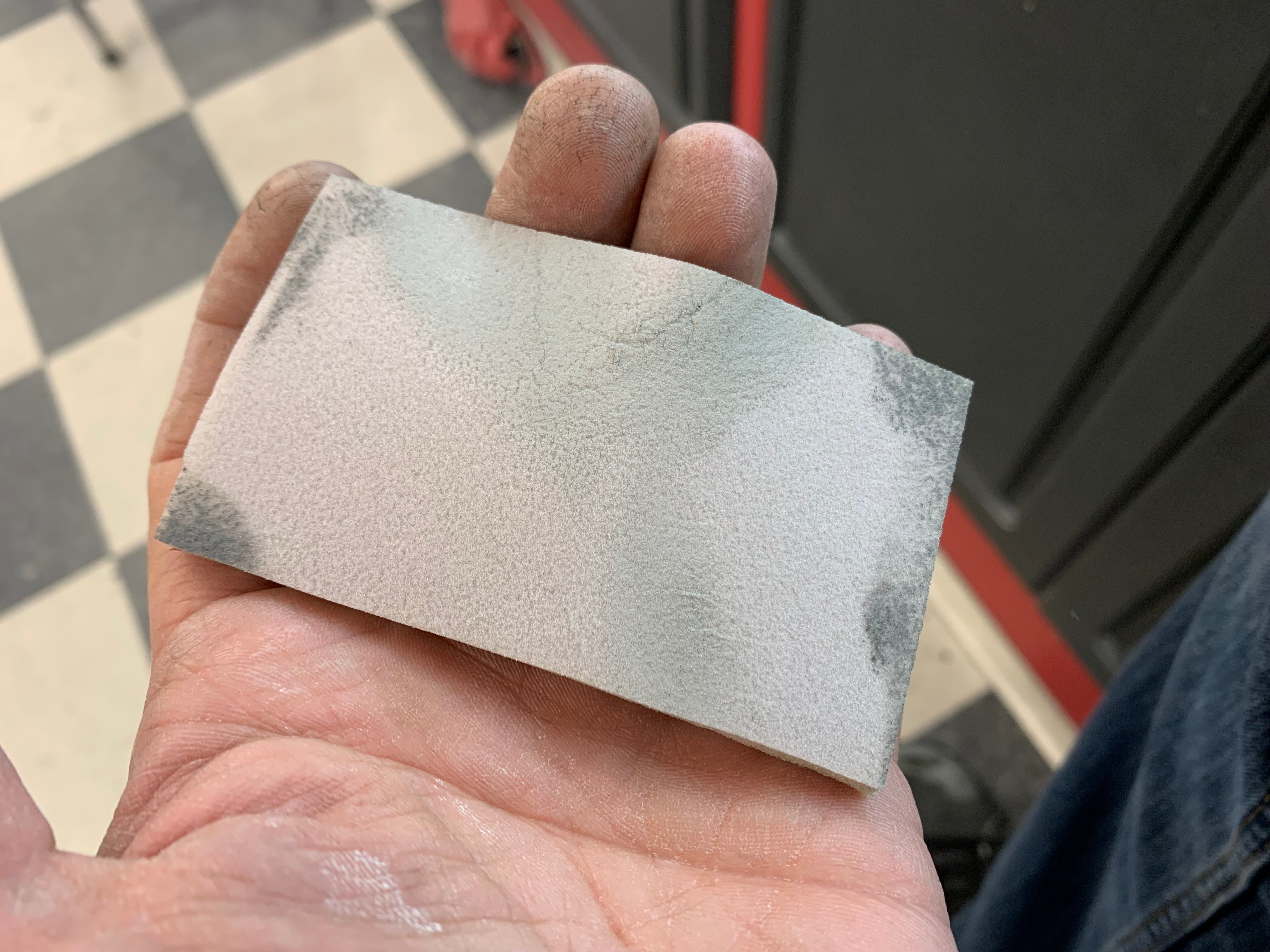

Now ordinarily, most people wouldn’t be concerned with this, but we can do better right? After a little effort with a piece of super fine soft backed sanding sponge…

…the chalky plastic oxidation was knocked off leaving a nice smooth surface:

But we’re not done yet. Mother’s Mag and Aluminum Polish makes for a nice, not too aggressive polishing compound for plastic.

A little elbow grease here, and the lustre is restored and looking like new again.

This is the difference between actually restoring an assembly, and just slapping it back together again. The details matter. Think they don’t? Check out the difference between restored and unrestored:

Continued >>>

These are the best I could do, and they don’t do it justice. I think the color is a keeper.

When I mentioned earlier that I had a pile of mirror parts all over my workbench, I wasn’t kidding. These have been here for months now, time to get rid of them with reassembly.

The green mirrors are the ones I bought off eBay, they were the power F body versions. Great for the innards, but not so good for the housings as the pedestal portions are too short. The housings I painted yesterday are Monte SS versions I acquired from our good friend O. D. Showtime. Thanks Kevin! The good news is, the Monte housings will accept the F body power motors.

Here’s a couple of gems for 69hurstolds, part numbers and date stamps on the motors from June and August of 1990:

Pretty cool, I love seeing stuff like that.

The clear coat was dry enough for reassembly today, so this’ll be a step by step of how they go together. This’ll be information I wish I had access to months ago. First off, the motor mounting cages attach to the housings with the short screws:

Then, the motors attach to the cages with the longer screws.

Once those are installed, next is the plastic mirror glass carriers. Note I have 3 sitting on the bench here, 2 are the power mirror versions, and 1 is a manual version. There is a substantial difference between them.

The manual version has a plastic pivot attached to the backside…

…whereas the power versions have two pivoting studs and a groove for the pot metal cross to clip into:

The edges of the glass carriers were looking pretty chalky and faded, and one had green overspray on it. After cleaning that off with some lacquer thinner, this is what it looked like:

Now ordinarily, most people wouldn’t be concerned with this, but we can do better right? After a little effort with a piece of super fine soft backed sanding sponge…

…the chalky plastic oxidation was knocked off leaving a nice smooth surface:

But we’re not done yet. Mother’s Mag and Aluminum Polish makes for a nice, not too aggressive polishing compound for plastic.

A little elbow grease here, and the lustre is restored and looking like new again.

This is the difference between actually restoring an assembly, and just slapping it back together again. The details matter. Think they don’t? Check out the difference between restored and unrestored:

Continued >>>

So we got the edges polished, but don’t forget the raised ridges that the glass sits inside of. This will be just as visible, if not more so, than the edges.

Both done, and ready to go:

Earlier I mentioned a little pot metal cross. This is the part here, and one side was pretty heavily corroded when I got it. This one isn’t too bad:

It clips into the backside of the glass carrier here:

Then there are these 2 plastic studs that also insert into the motor here:

I anticipated that the clipping of the cross into the backside of the carrier would take some considerable effort, so that’s why I have held off on installing the glass yet. Too easy to break the new glass that way. To make it easier to facilitate this, I marked the location of the 2 studs and the cross clip location on the frontside of the carrier with a silver Sharpie.

Now the nerve racking part. The plastic studs go in without too much effort, but getting the cross to clip in takes a bit of concentrated effort. I found the most effective way was to push very firmly with both thumbs over the clip location. If you don’t hear it snap in, it’s not in yet. Keep working at it until you hear it snap in.

Success!

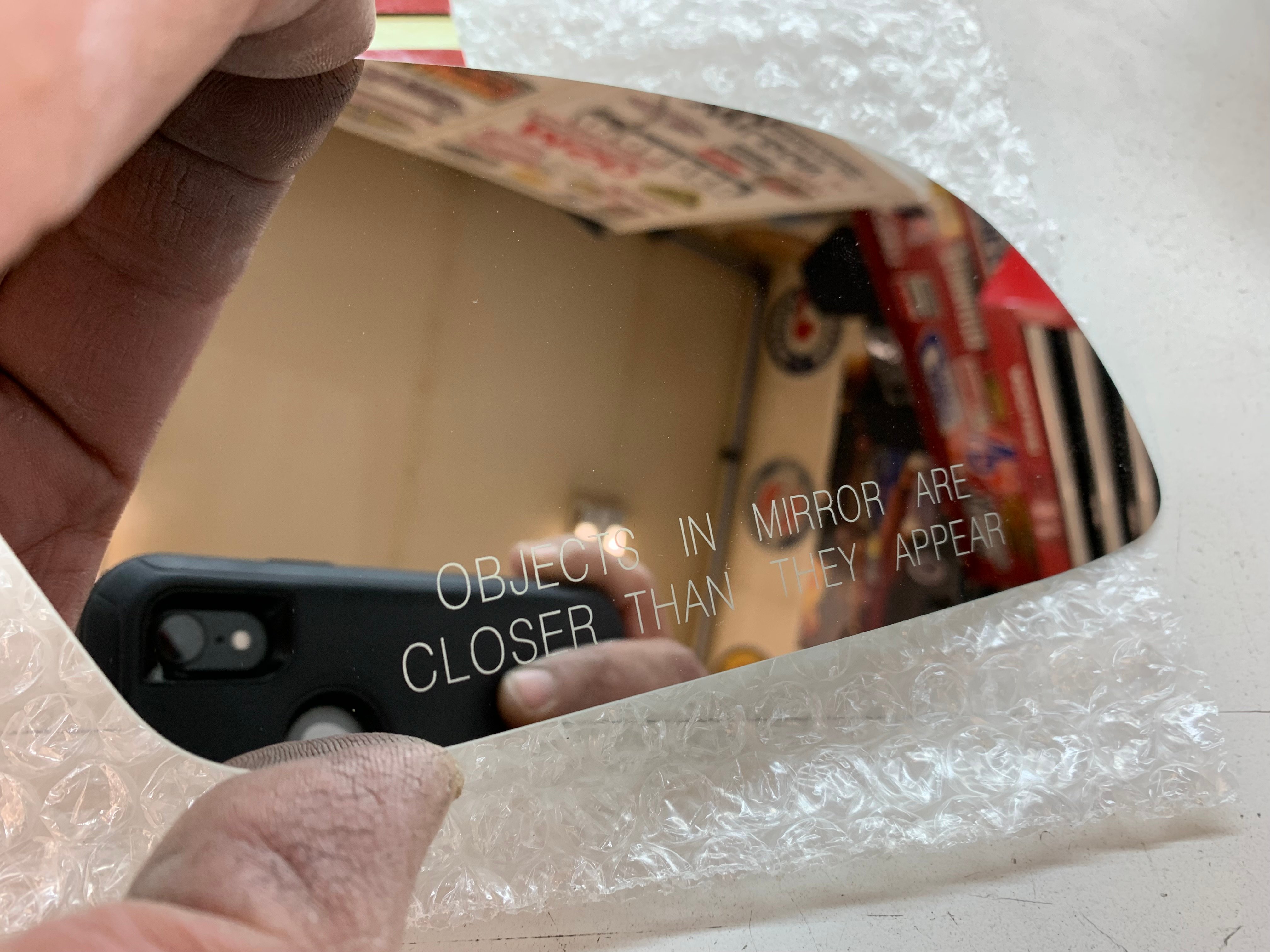

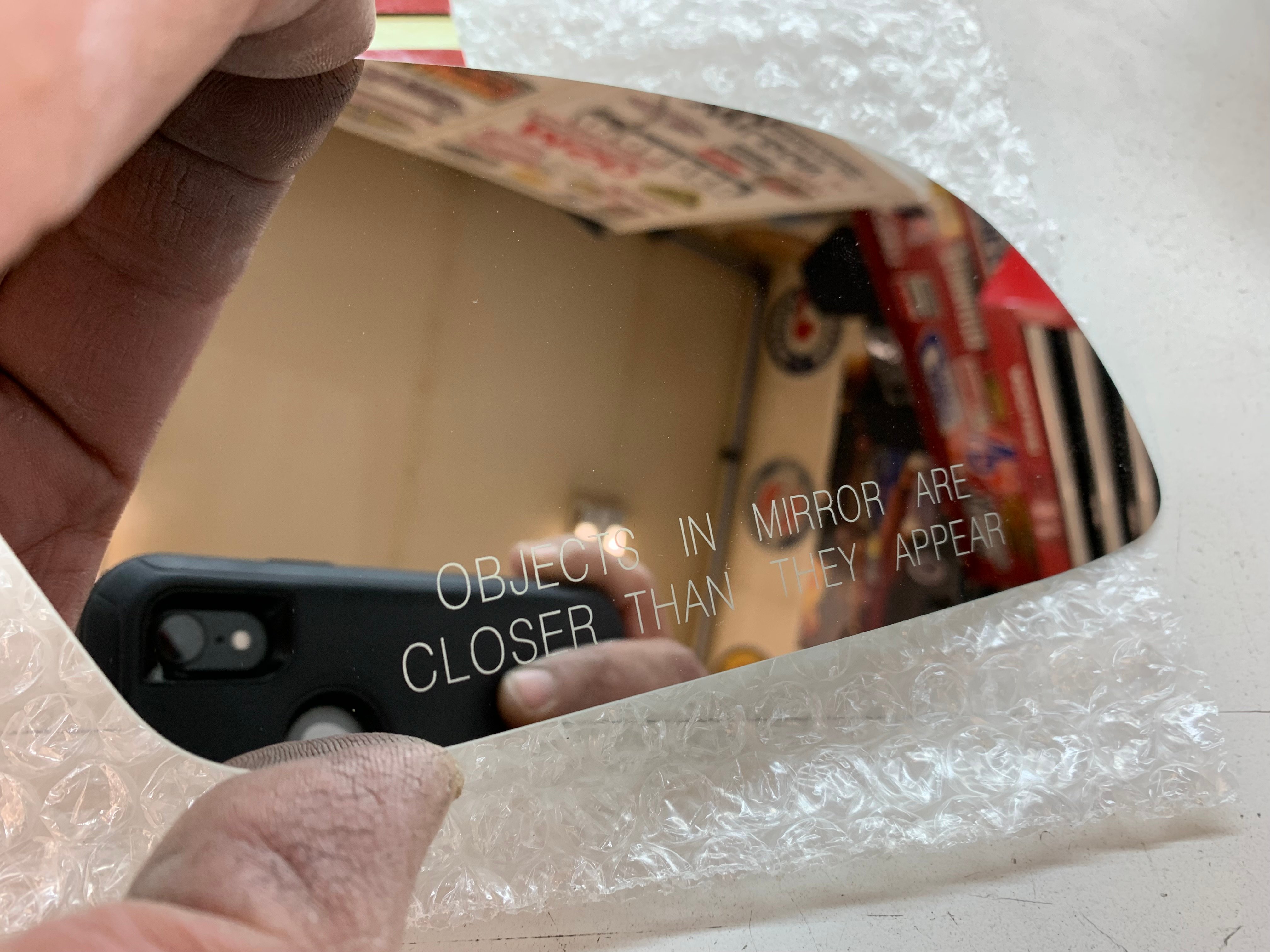

Time for the glass. The originals were held in with urethane, the aftermarket replacements use double sided tape that’s included with them.

Now personally, I’m not an overly trusting person. If I’m not familiar with a certain product, I don’t automatically assume it’s quality. So rather than using the two little pieces of double sided tape that came with the glass, I instead substituted for some ProForm brand stuff that I’ve had good success with in the past. Plus this way I can cut it to whatever length I want and I’m not stuck with an unknown quality product that’s provided. Don’t forget to thoroughly clean the surfaces with wax and grease remover first, and it’s also not a bad idea to hit them with some adhesion promoter too.

Both sides done and ready to go.

Attaching the glass is the second most nerve racking part behind clipping the carriers in. You’ve only got one shot at getting it in and aligned, so don’t screw it up! Once it’s stuck, it’s stuck for good. Thankfully these went ok, but I’m not terribly impressed with the fit. That’s the aftermarket for ya.

Case in point: The top corner of the passenger’s side is cut wrong and has a pretty substantial gap. 😡

The driver’s side fits quite a bit better, but still not perfect. It’s a little too tall, the bottom doesn’t sit inside the raised ridge like it should. I might be going to the GM dealership to see if original replacements are still available and change these out at some point.

And that’s it. I threw the passenger’s side on just for some satisfaction, the driver’s side is still under construction for the reinforcement.

The view from the driver’s seat:

And one last one, just for fun.

Once I get the driver’s side reinforcement completed and can mount up that mirror, I’ll probably make up a temporary wiring harness from the mirrors to the switch and test ‘em out. The 3D printed gaskets are still in the works, and I still have to sand and prime the outsides of the housings, but the mirrors are nearly done!

Stay tuned…

D.

Both done, and ready to go:

Earlier I mentioned a little pot metal cross. This is the part here, and one side was pretty heavily corroded when I got it. This one isn’t too bad:

It clips into the backside of the glass carrier here:

Then there are these 2 plastic studs that also insert into the motor here:

I anticipated that the clipping of the cross into the backside of the carrier would take some considerable effort, so that’s why I have held off on installing the glass yet. Too easy to break the new glass that way. To make it easier to facilitate this, I marked the location of the 2 studs and the cross clip location on the frontside of the carrier with a silver Sharpie.

Now the nerve racking part. The plastic studs go in without too much effort, but getting the cross to clip in takes a bit of concentrated effort. I found the most effective way was to push very firmly with both thumbs over the clip location. If you don’t hear it snap in, it’s not in yet. Keep working at it until you hear it snap in.

Success!

Time for the glass. The originals were held in with urethane, the aftermarket replacements use double sided tape that’s included with them.

Now personally, I’m not an overly trusting person. If I’m not familiar with a certain product, I don’t automatically assume it’s quality. So rather than using the two little pieces of double sided tape that came with the glass, I instead substituted for some ProForm brand stuff that I’ve had good success with in the past. Plus this way I can cut it to whatever length I want and I’m not stuck with an unknown quality product that’s provided. Don’t forget to thoroughly clean the surfaces with wax and grease remover first, and it’s also not a bad idea to hit them with some adhesion promoter too.

Both sides done and ready to go.

Attaching the glass is the second most nerve racking part behind clipping the carriers in. You’ve only got one shot at getting it in and aligned, so don’t screw it up! Once it’s stuck, it’s stuck for good. Thankfully these went ok, but I’m not terribly impressed with the fit. That’s the aftermarket for ya.

Case in point: The top corner of the passenger’s side is cut wrong and has a pretty substantial gap. 😡

The driver’s side fits quite a bit better, but still not perfect. It’s a little too tall, the bottom doesn’t sit inside the raised ridge like it should. I might be going to the GM dealership to see if original replacements are still available and change these out at some point.

And that’s it. I threw the passenger’s side on just for some satisfaction, the driver’s side is still under construction for the reinforcement.

The view from the driver’s seat:

And one last one, just for fun.

Once I get the driver’s side reinforcement completed and can mount up that mirror, I’ll probably make up a temporary wiring harness from the mirrors to the switch and test ‘em out. The 3D printed gaskets are still in the works, and I still have to sand and prime the outsides of the housings, but the mirrors are nearly done!

Stay tuned…

D.

Last edited:

Bookmarked and saved. That's a very informative and useful write up, thank you! I especially like the tip about using Mother's on plastics.

Played Mad Chemist tonight.

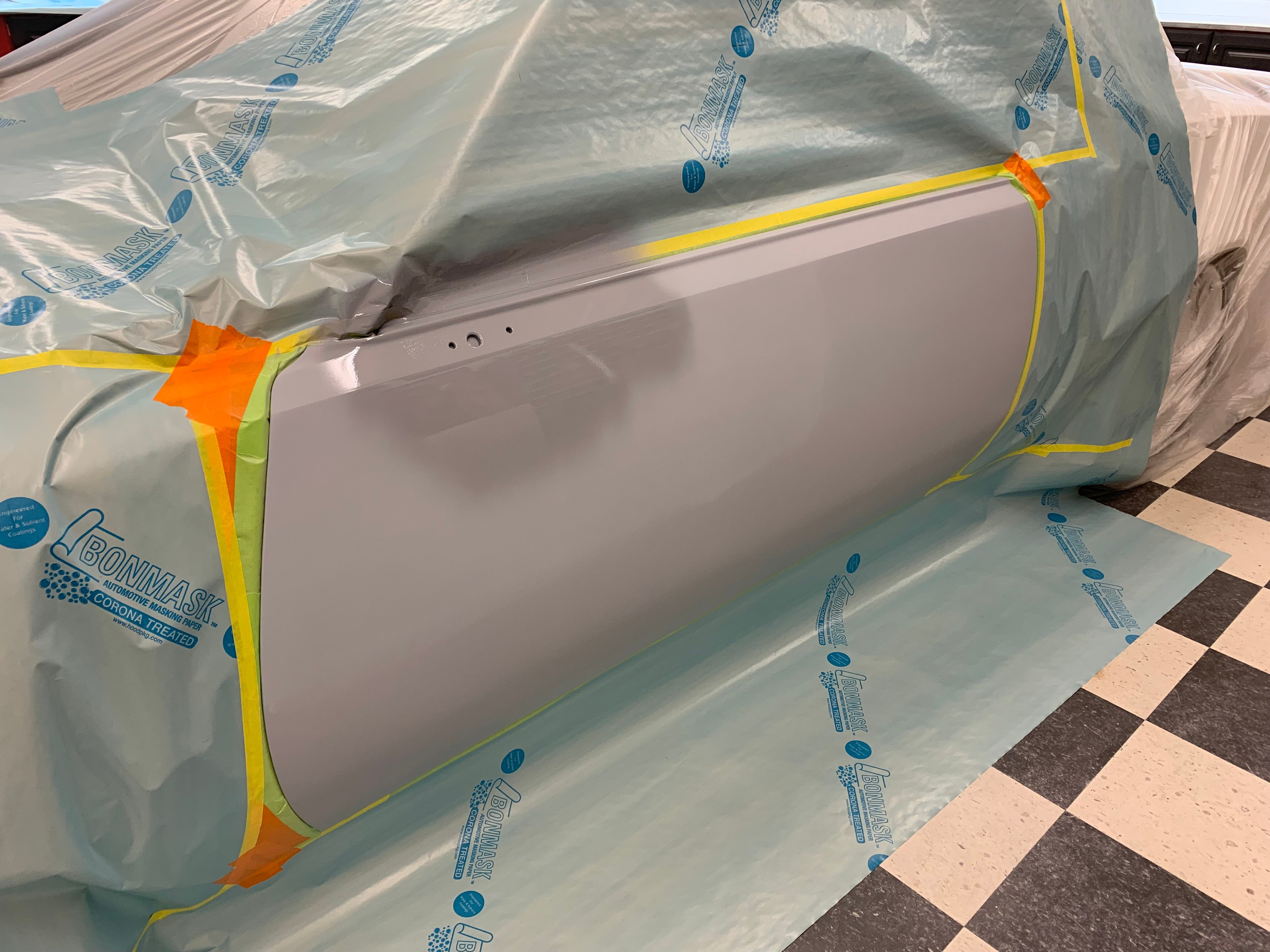

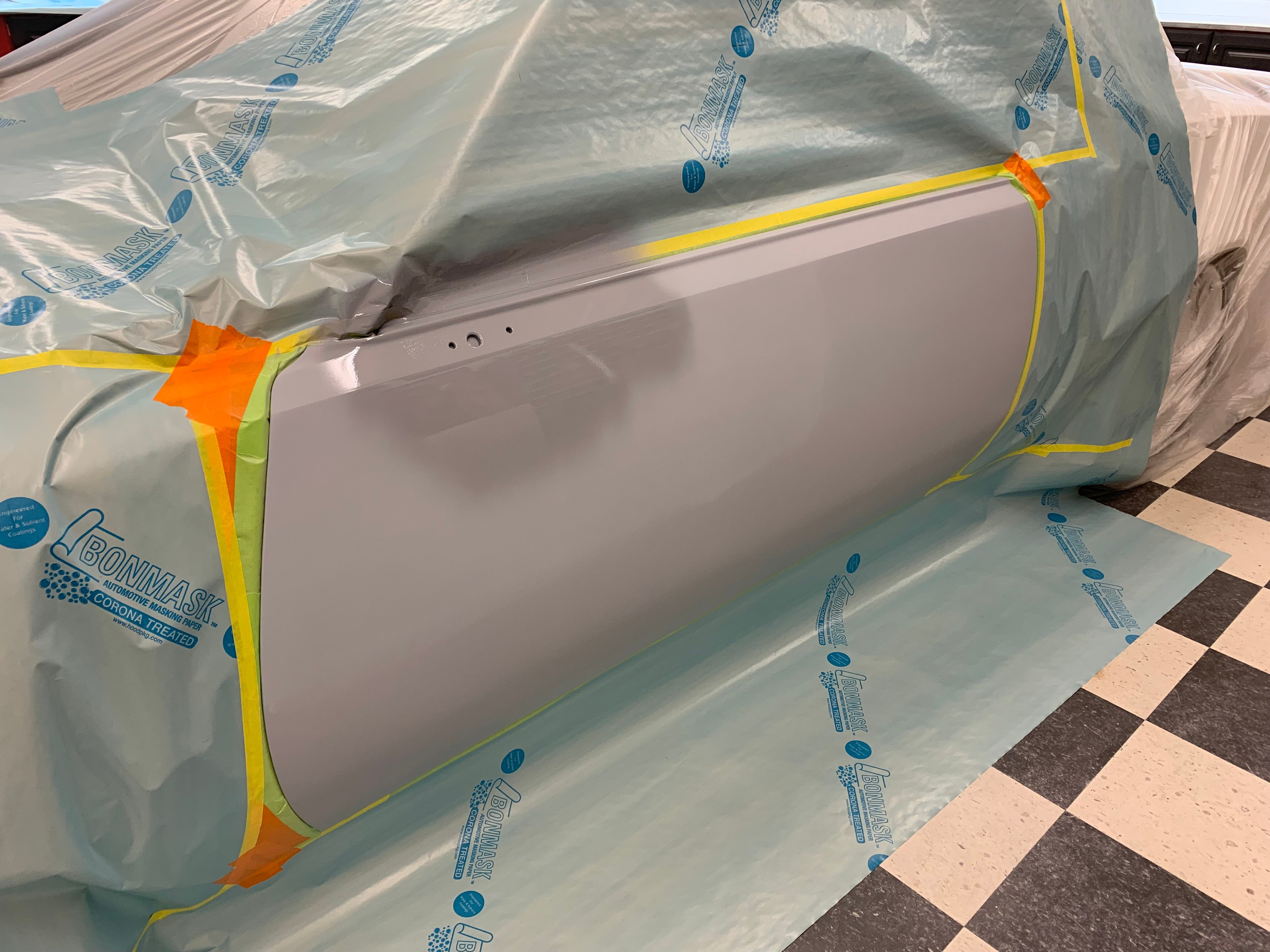

Mixed up some epoxy and shot 2 coats on the mirrors after I sanded out the “fit of rage” runs in them from painting the insides, and spot primed the doors after touching up the filler repairs earlier last week.

Once the epoxy had set up for an hour, everything got 3 coats of high build primer-surfacer. No runs in anything this time thankfully.

I sure hope that’s it for these poor doors, I’m getting sick of revisiting them over and over.

This kind of “Prime Time” beats the other kind any day of the week though.

Mixed up some epoxy and shot 2 coats on the mirrors after I sanded out the “fit of rage” runs in them from painting the insides, and spot primed the doors after touching up the filler repairs earlier last week.

Once the epoxy had set up for an hour, everything got 3 coats of high build primer-surfacer. No runs in anything this time thankfully.

I sure hope that’s it for these poor doors, I’m getting sick of revisiting them over and over.

This kind of “Prime Time” beats the other kind any day of the week though.

It’s been a busy several days in The Skunkworks since getting the doors and mirrors into high build primer.

After giving them time to dry and cure, I unmasked everything and mounted the mirrors back on the car. I’m getting more and more used to seeing them on there now and they’re looking more at home with every step.

The next thing I wanted to do was to test the function of the mirrors. The mirror motors, wiring pigtails, and switch were all used items purchased off of eBay. Up until this point I still didn’t know if they all worked or if I had a couple of complete duds despite the seller claiming they all worked when they were pulled.

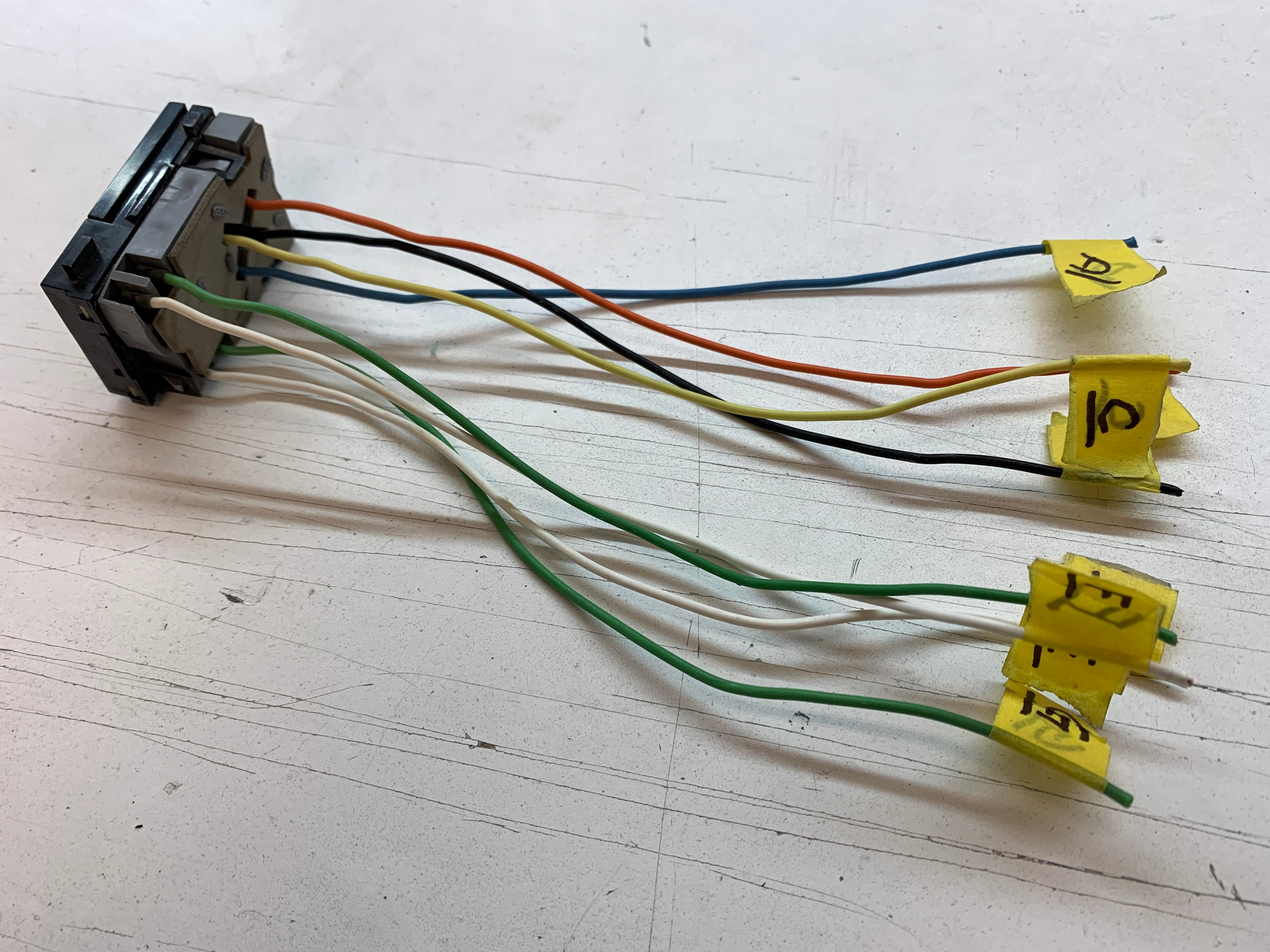

So I set about making a temporary harness for testing, matching color for color until I realized that there were 4 wires per side for a total of 8 running to the switch, but only 6 wires coming out of the switch not including the power and ground. I figured 2 of the wires would have to be spliced together, but which 2?

And so began a couple of head scratching days of testing, research, pouring over wiring diagrams and schematics, as well as quizzing anyone I could think of who might understand how this was supposed to work. Despite multiple different combinations of wire connections to the switch, nothing seemed to work properly. Up would be down, left would be right, and things were off even side to side.

I finally reached out to the minds on this wonderful forum, and a couple individuals smarter than me got me pointed in the right direction. I’ll save you the gory details of my struggles, but you can read about it here if you haven’t already:

gbodyforum.com

gbodyforum.com

Once I had everything functioning properly the way it should, I was breathing a whole lot easier. I wasn’t originally planning on making a permanent mirror harness just yet, but I figured I’d better build one while everything was still fresh in my head. So today I went to the parts store and stocked up on some wiring supplies I was short on.

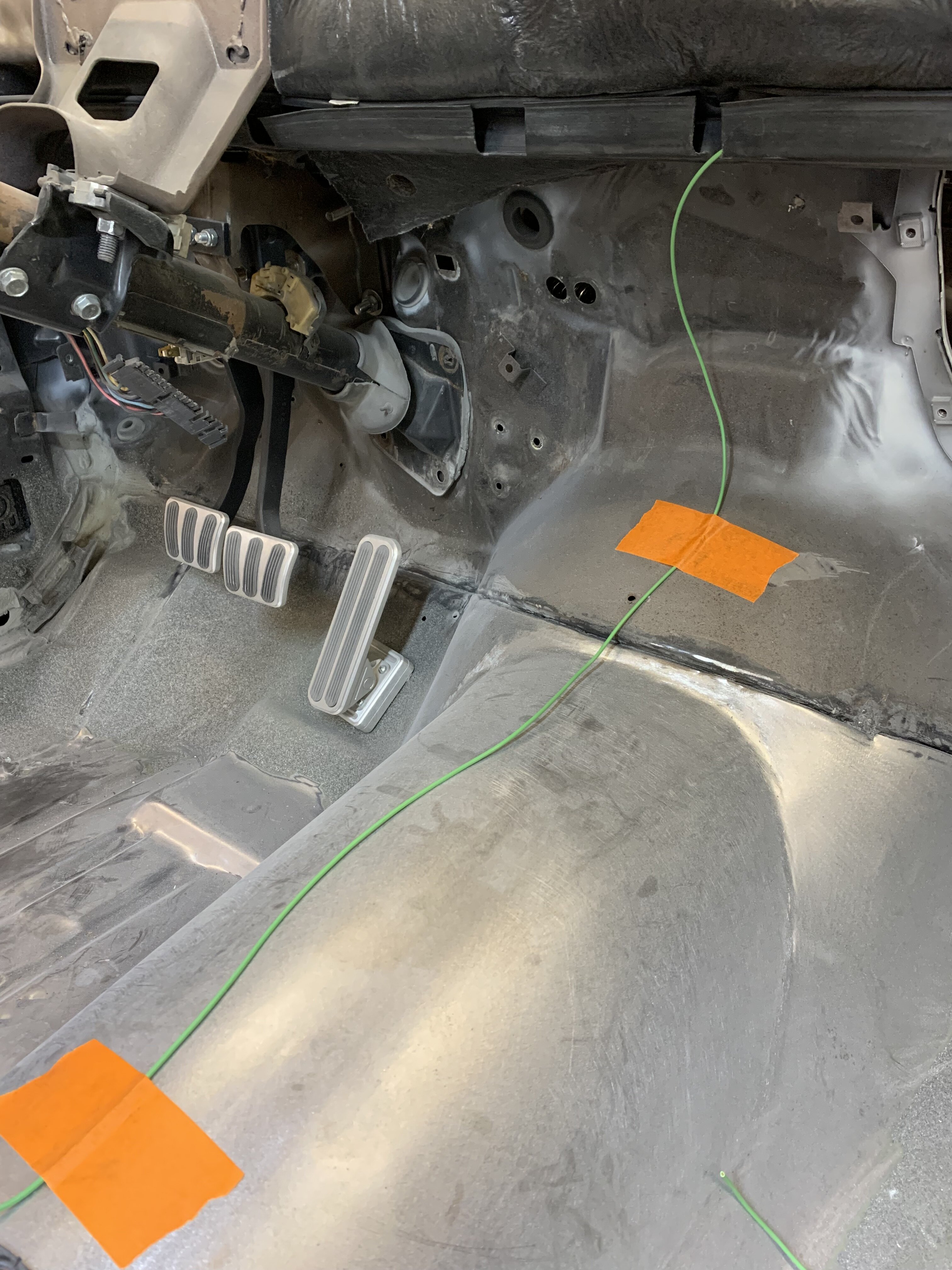

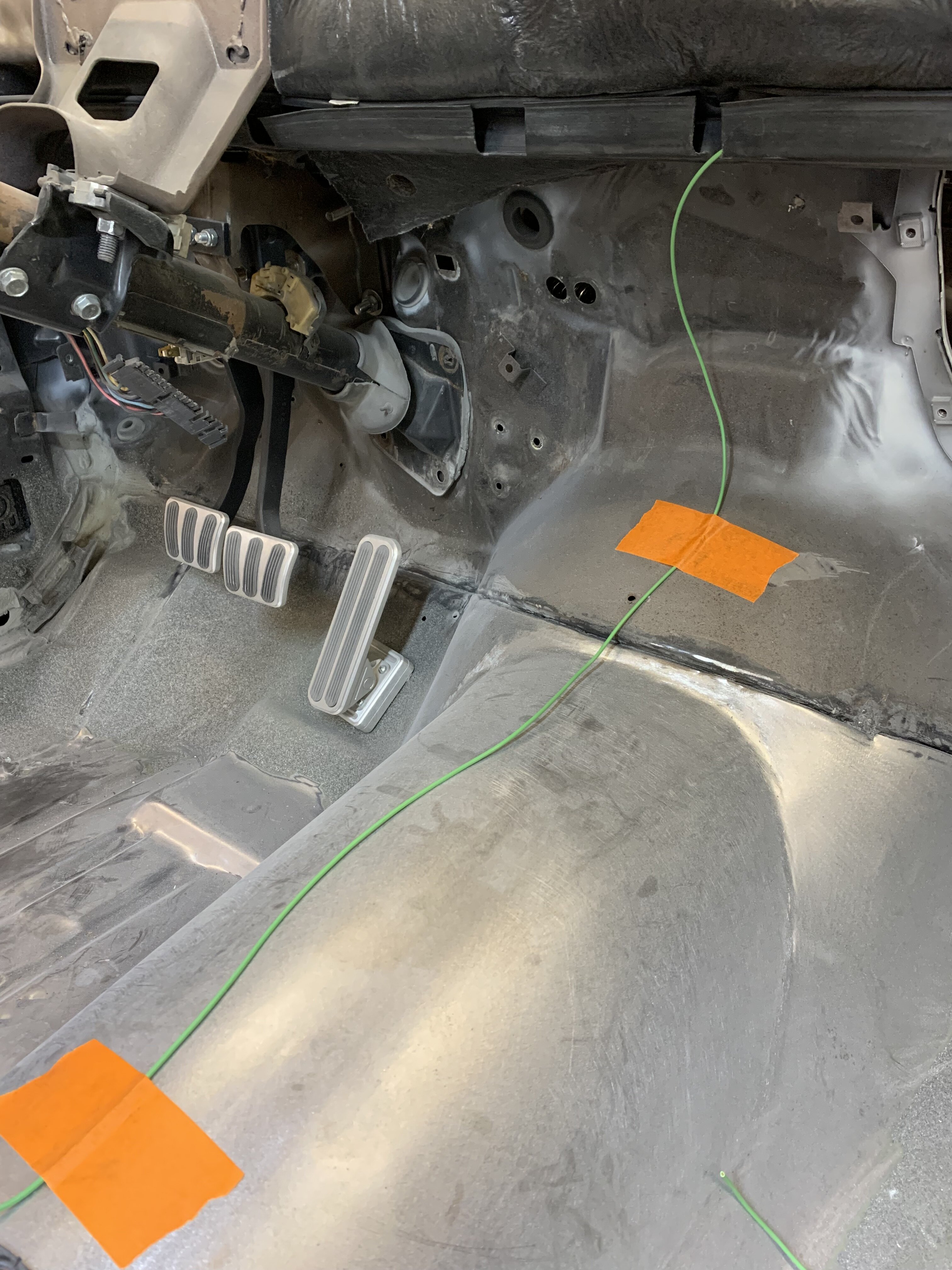

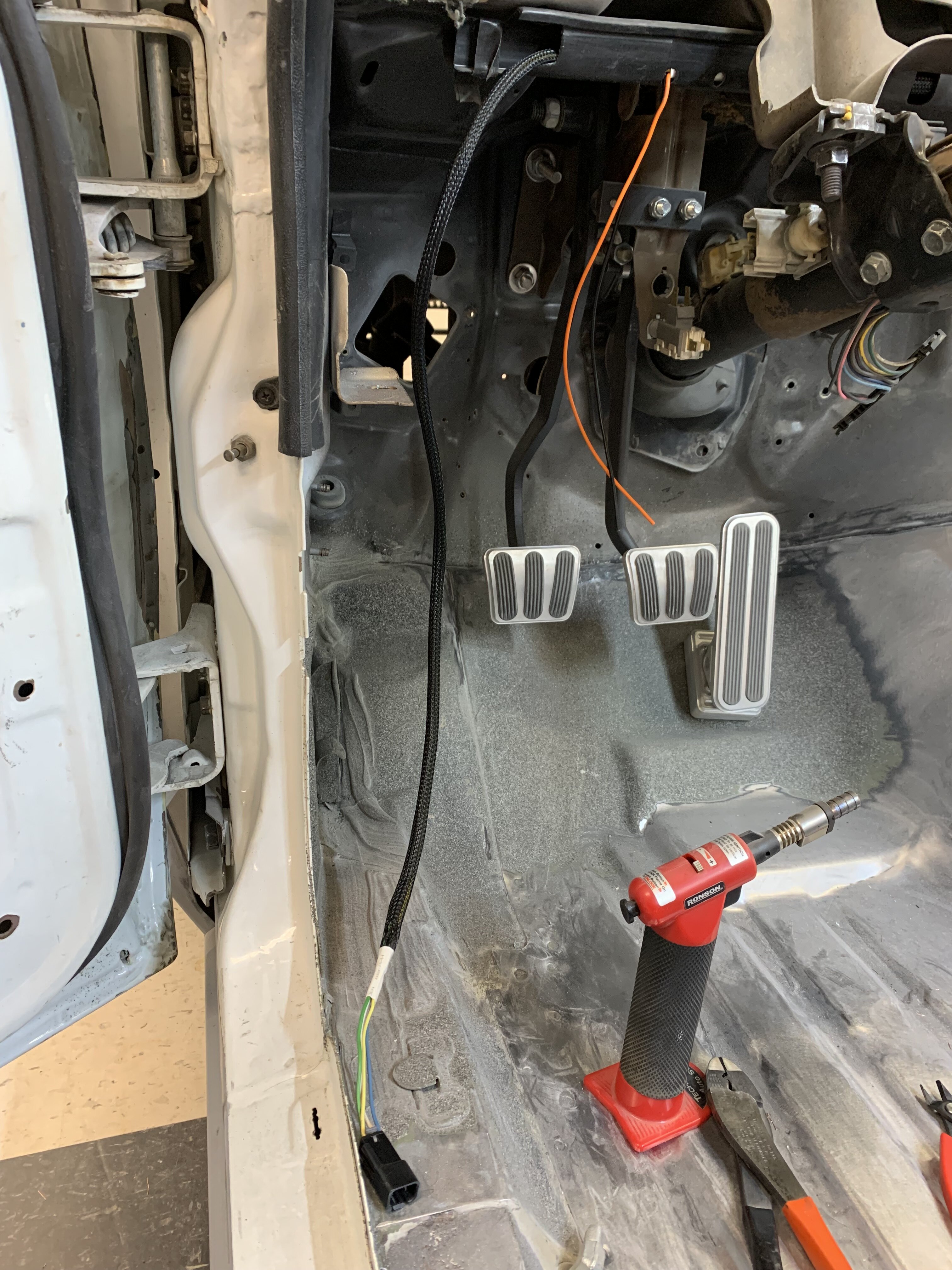

I needed to determine the length of each branch of the harness, so I started at the RH mirror and routed one of the wires along the path I had chosen back to roughly where the switch would be installed. I plan on mounting the switch in the center console I haven’t built yet, so I left myself some extra length so I’ll have some options when the time comes.

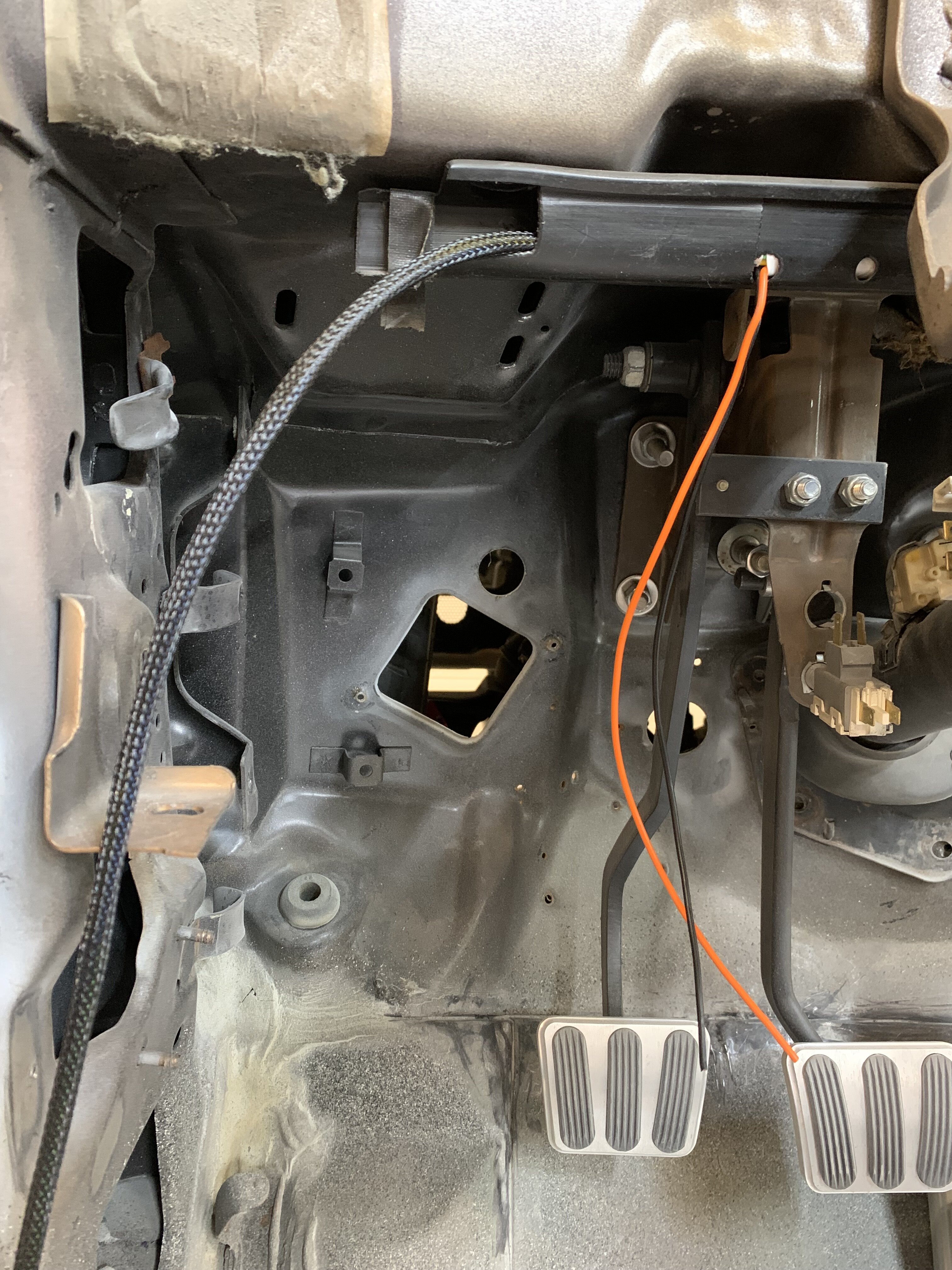

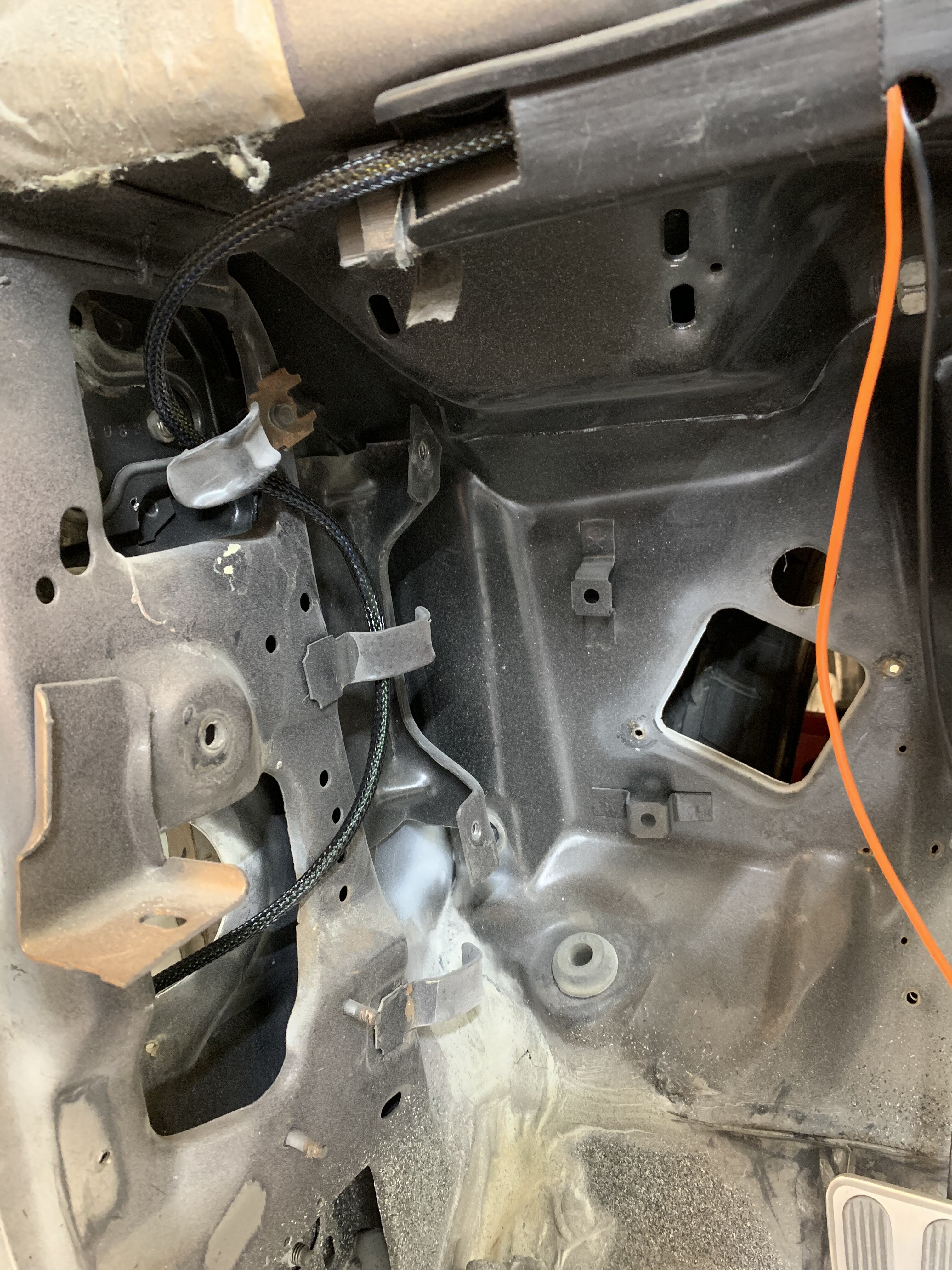

This is the proposed route. From the RH mirror…

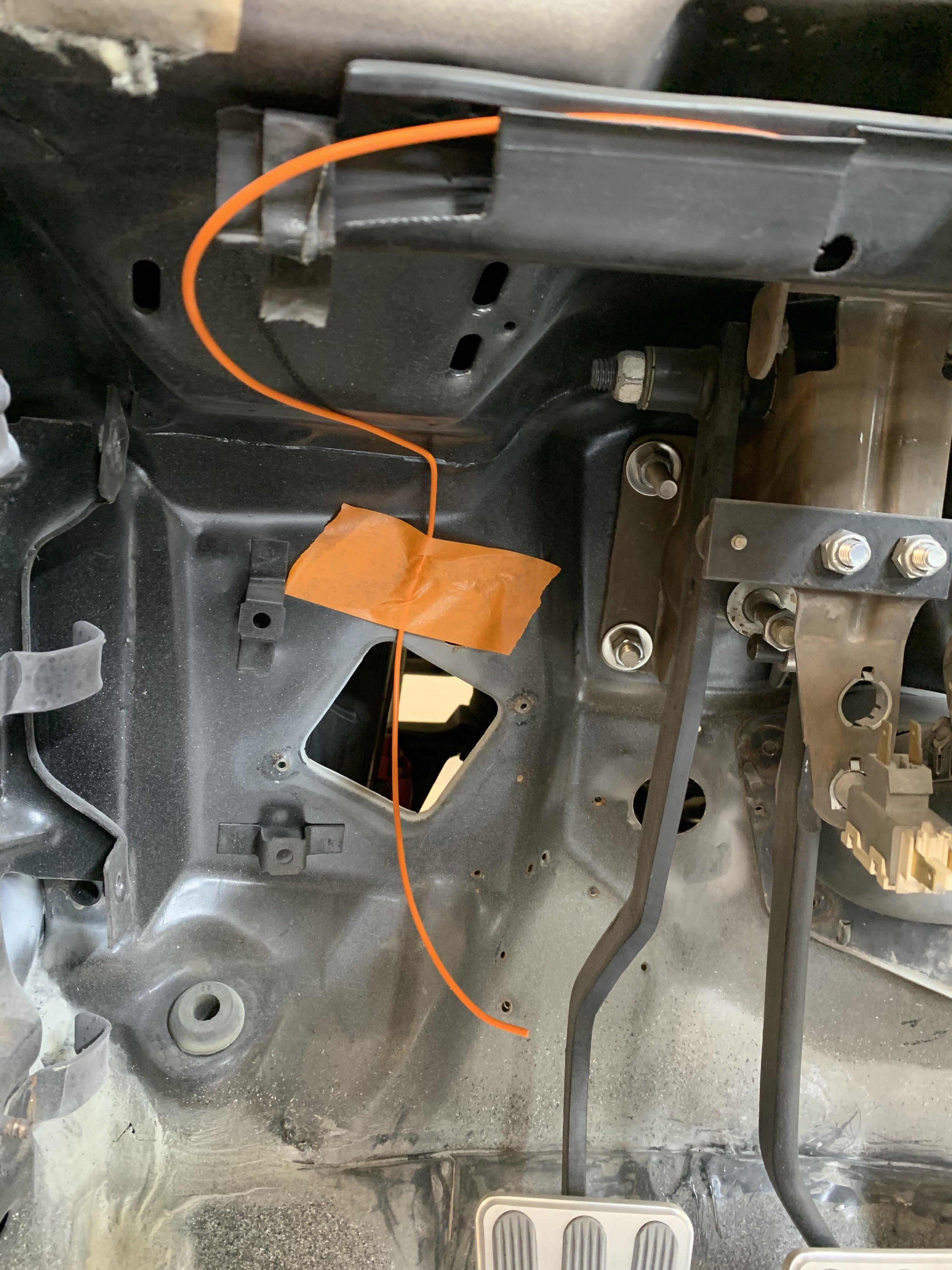

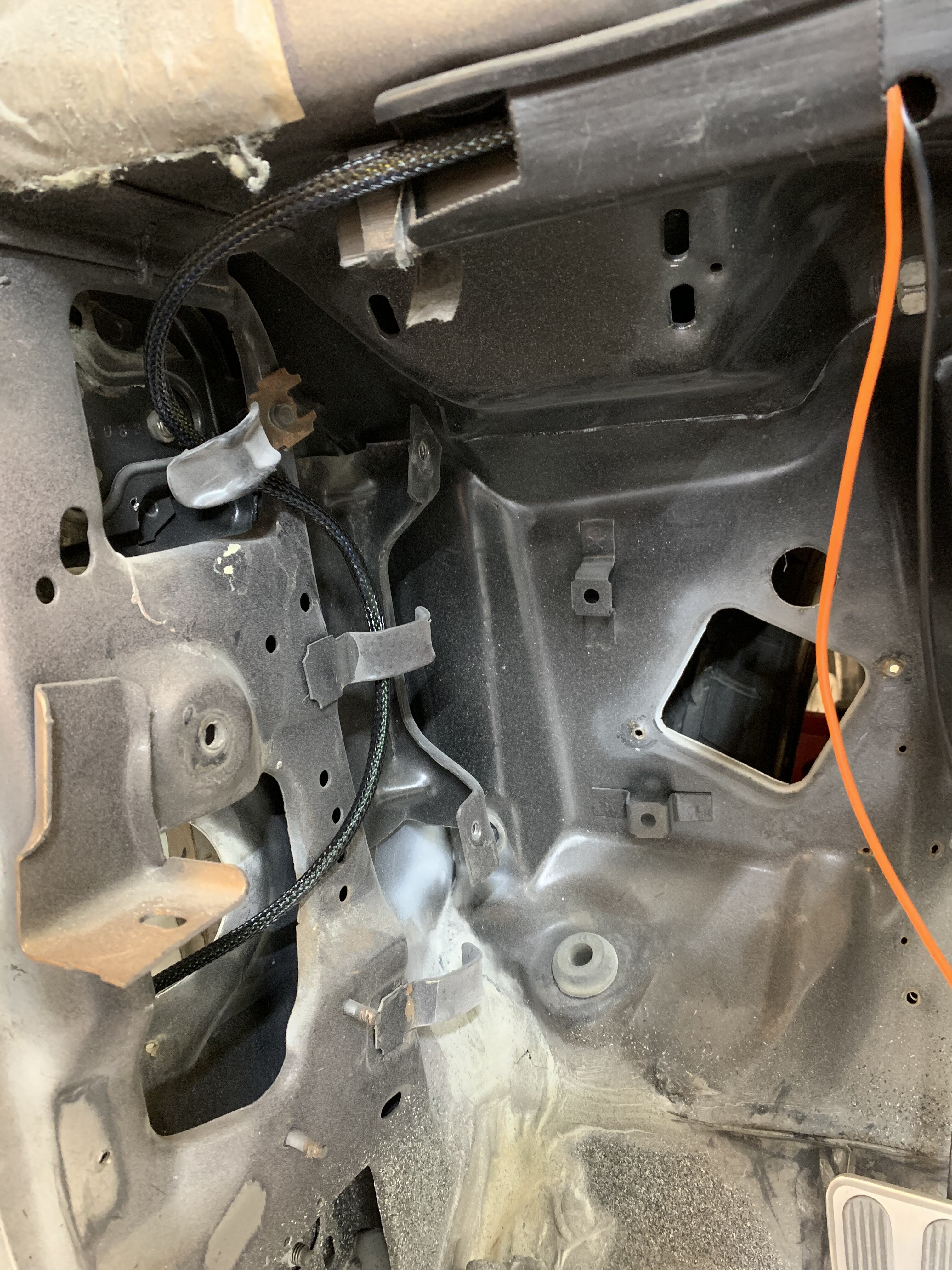

To this opening in the factory plastic conduit behind the dash:

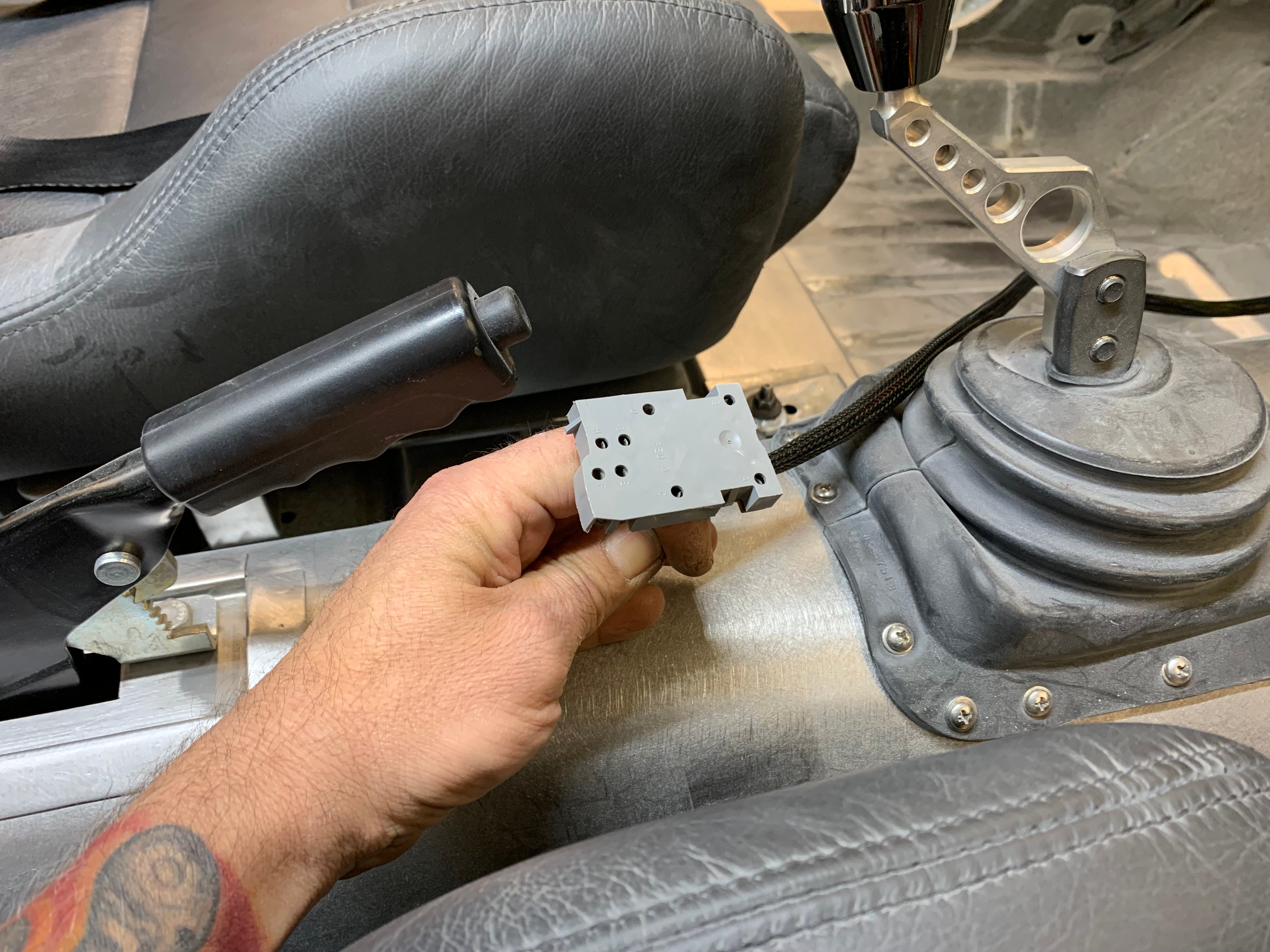

It’s tough to plan this far in advance of where everything is going to go, but I’m kind of thinking it might go somewhere in this vicinity right now:

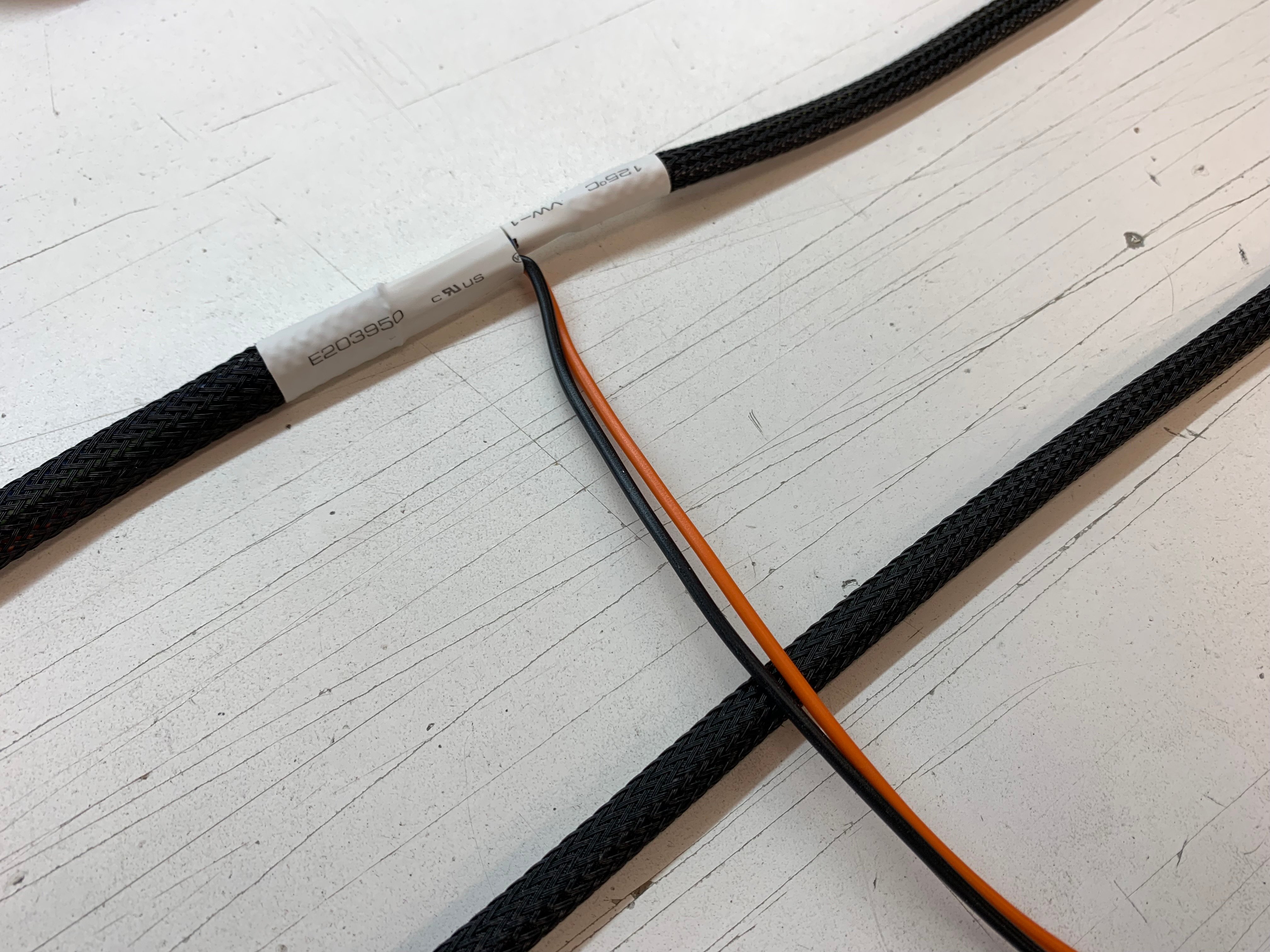

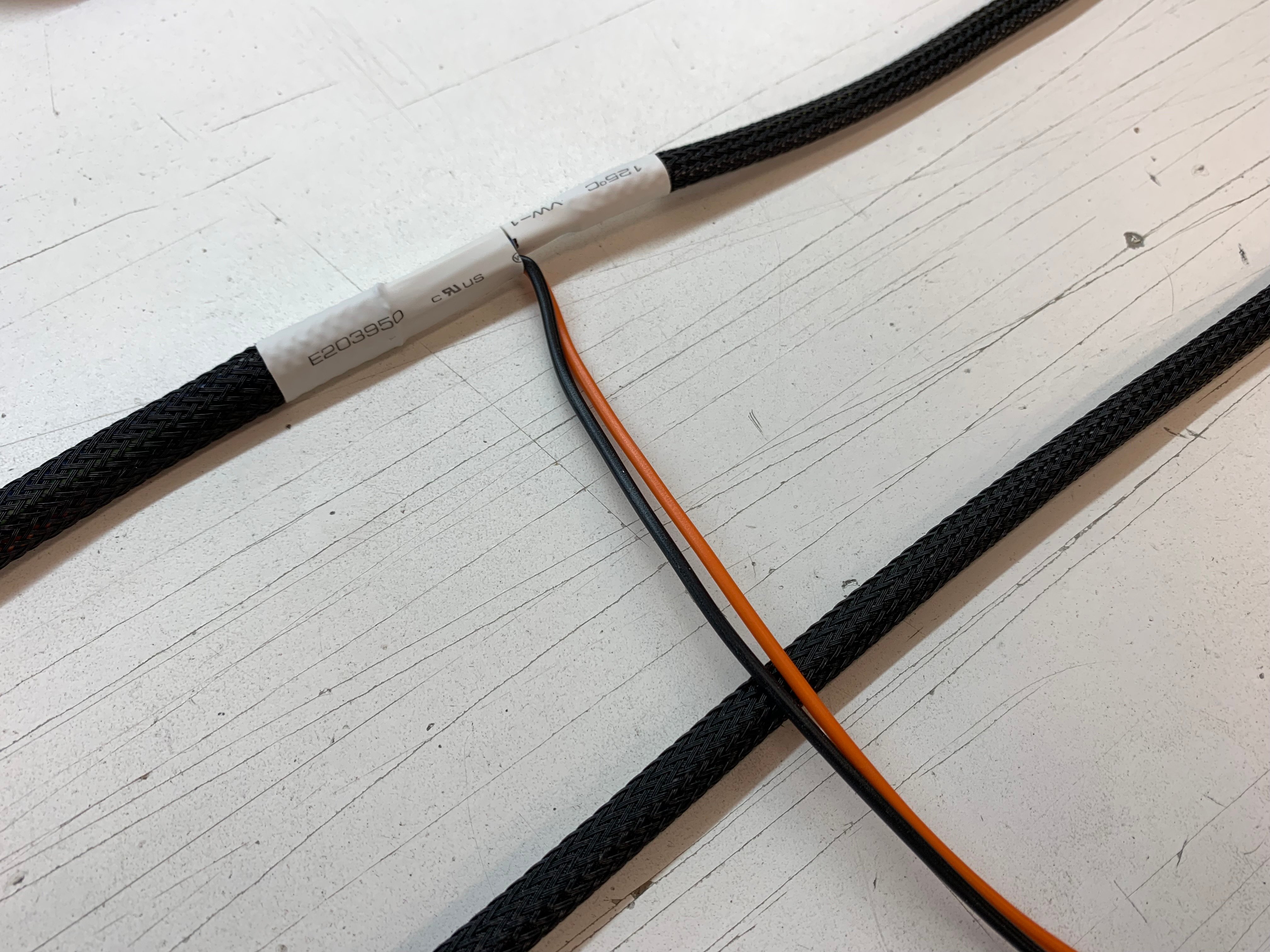

I repeated the process for the LH side, but with the addition of the two wires that will have to run to the fuse box, the power and ground. I was lucky enough to find some orange wire today that matches up to the factory power wire nicely.

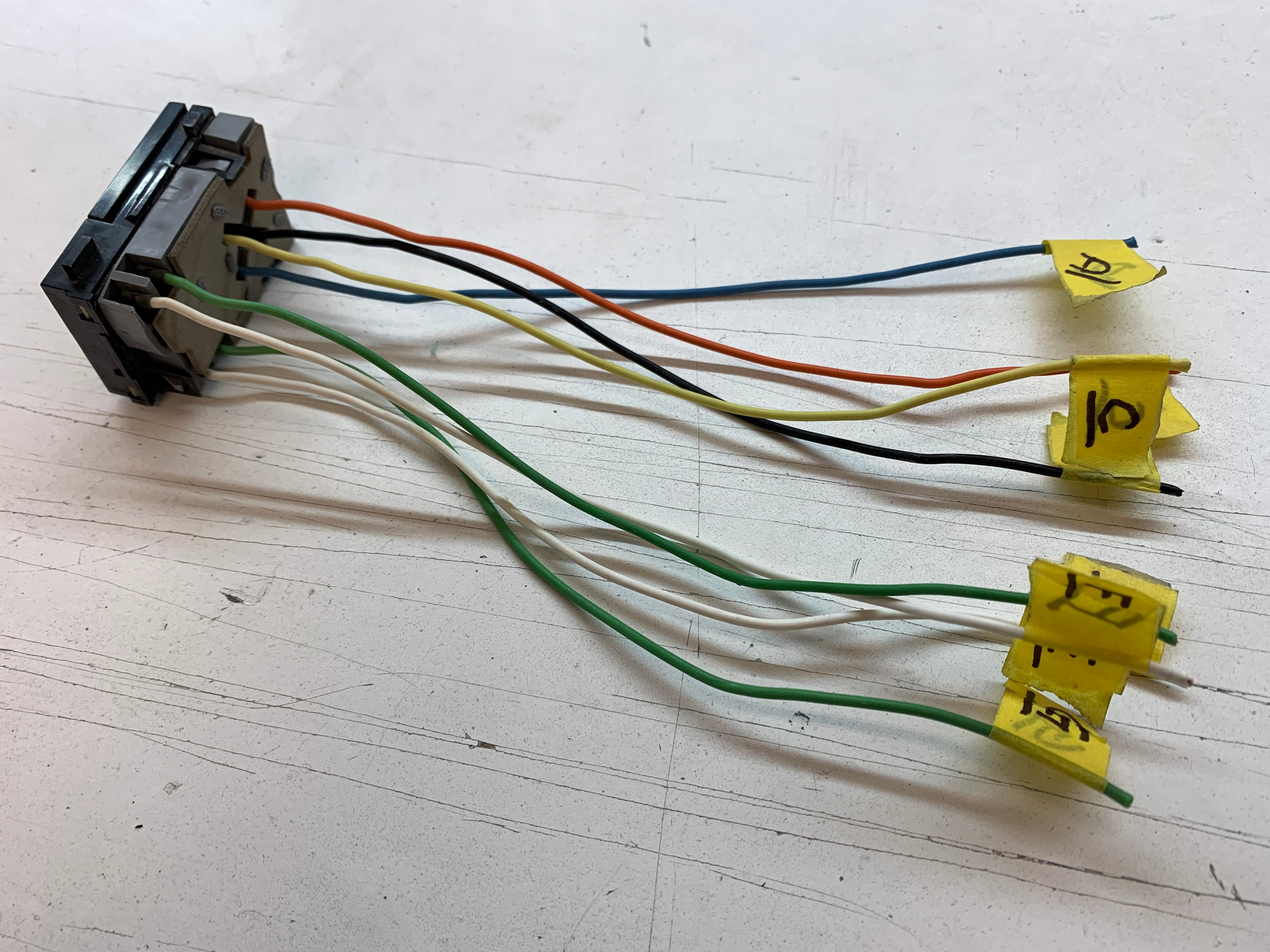

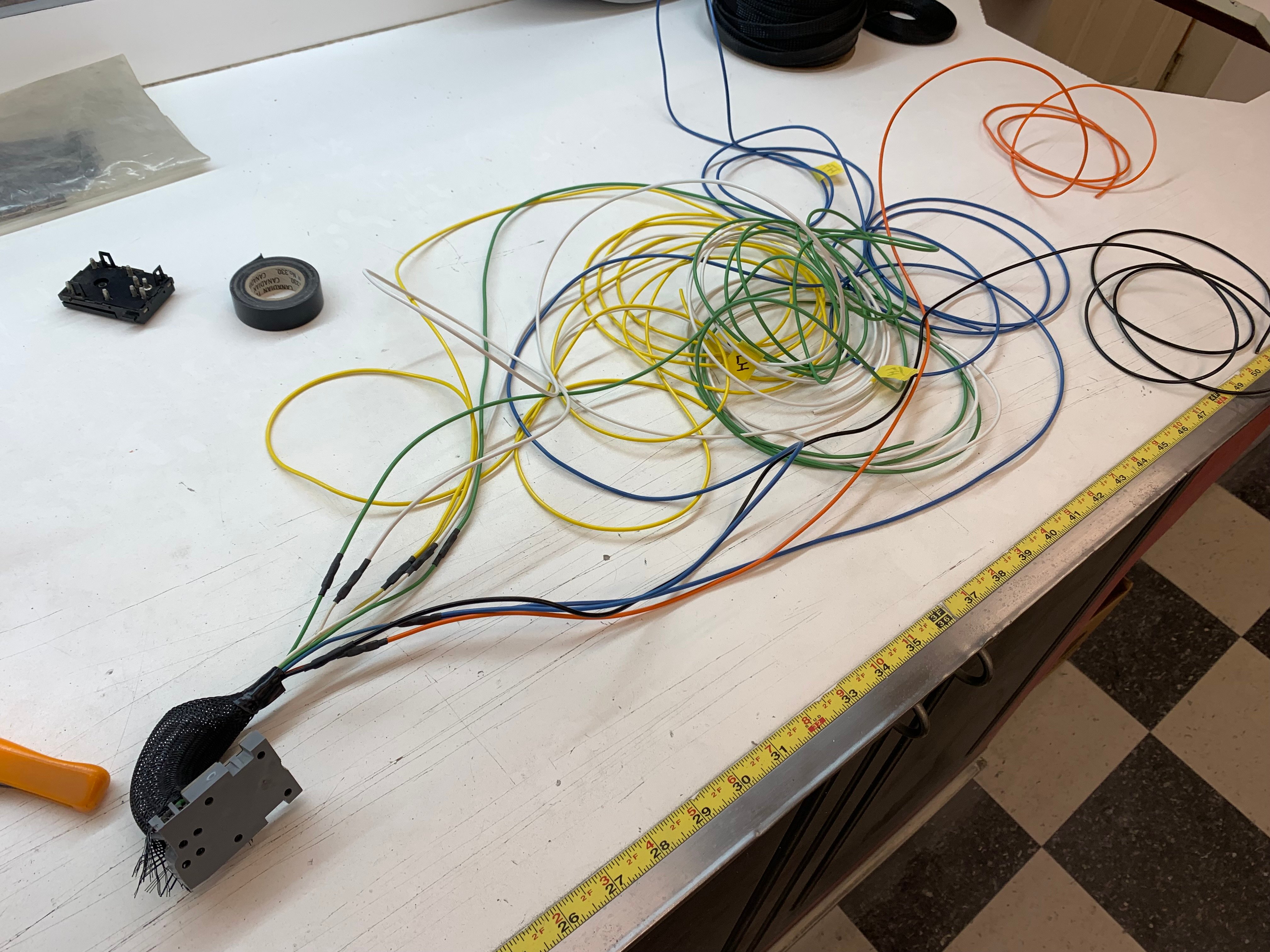

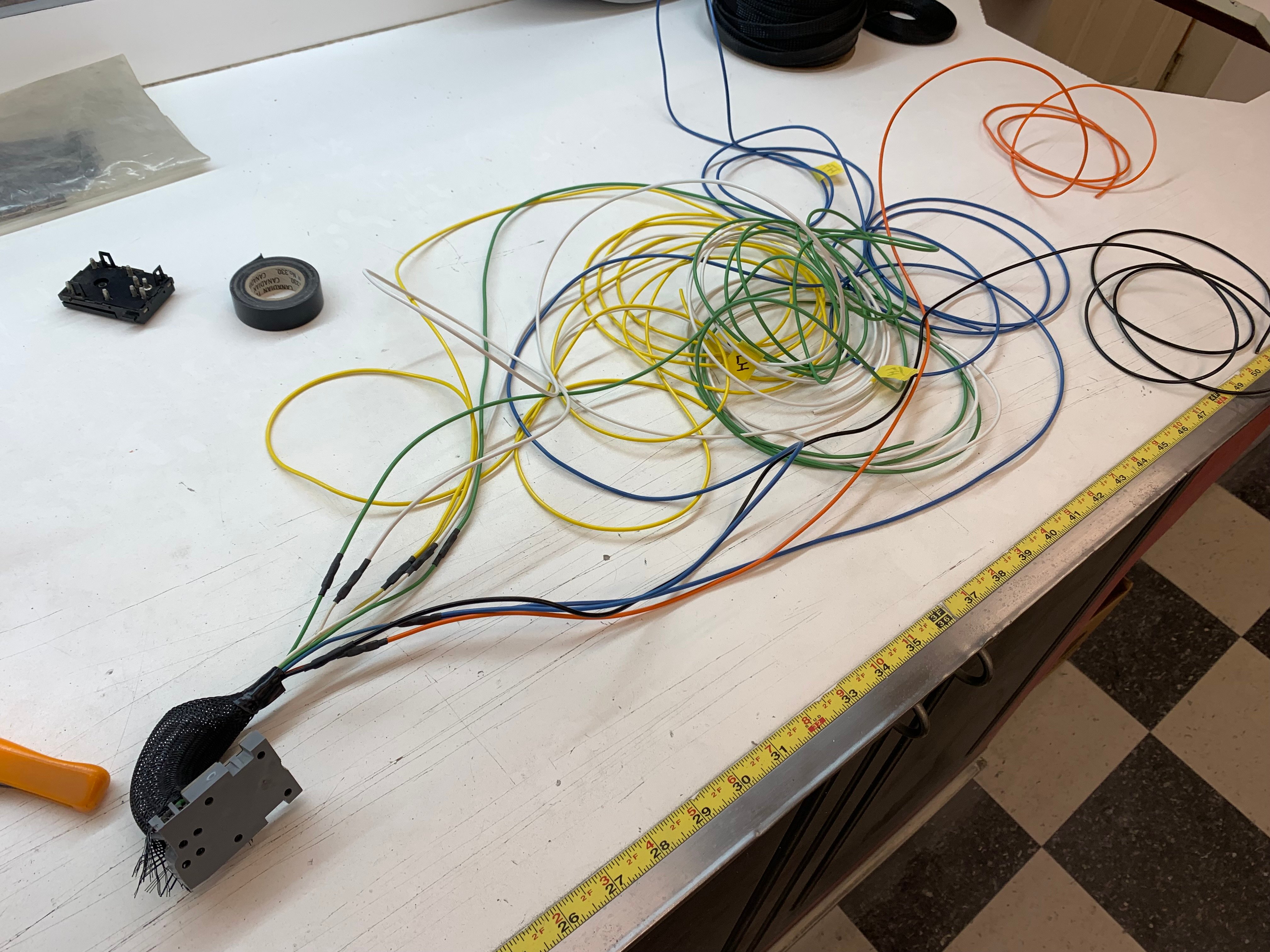

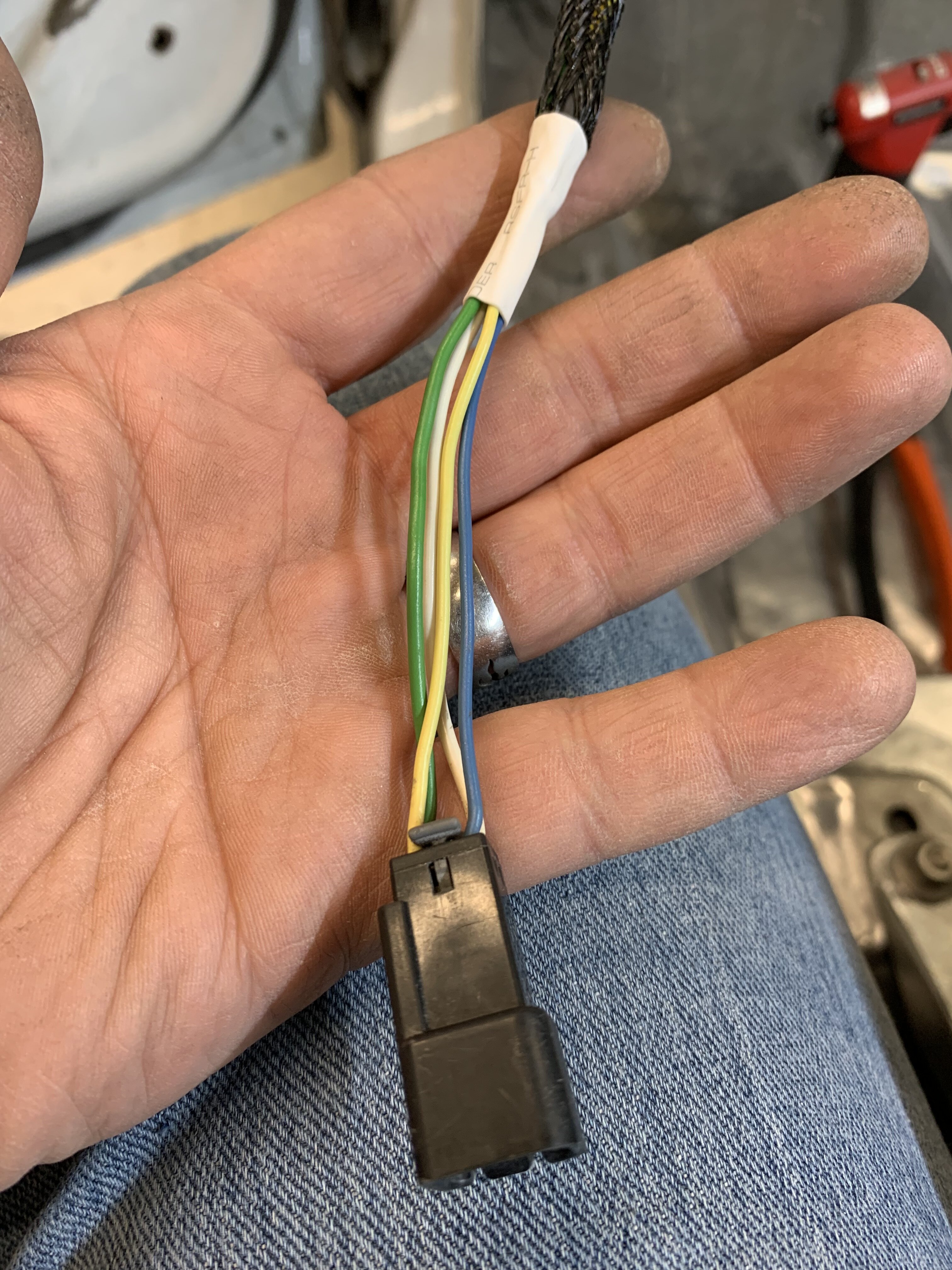

Once I had these lengths established, it was to the bench to start building the harness. Here are the 6 colors required, keep in mind that 2 of the wires are going to be spliced.

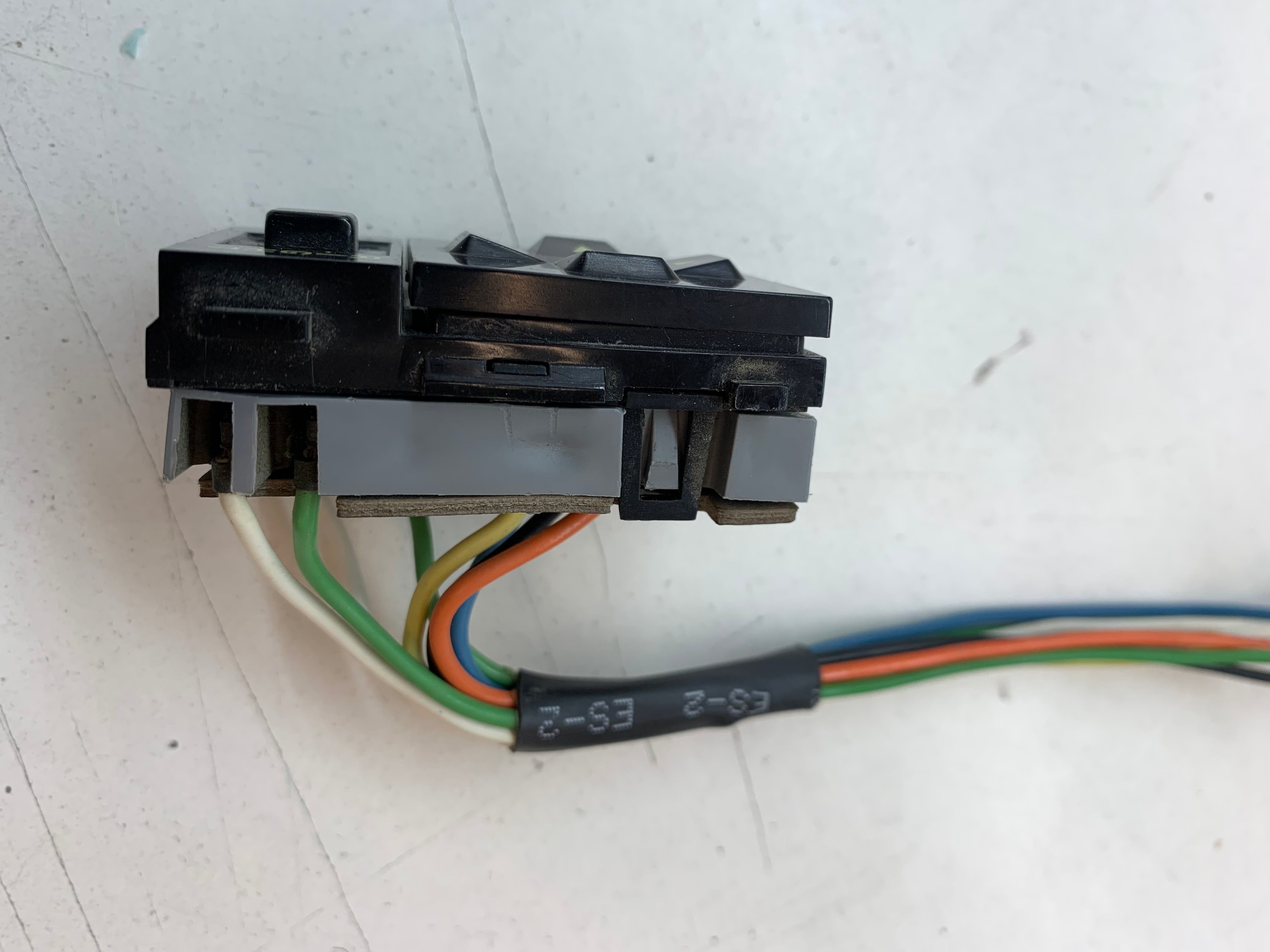

The switch, removed from the temporary harness and still labeled with the terminal letters:

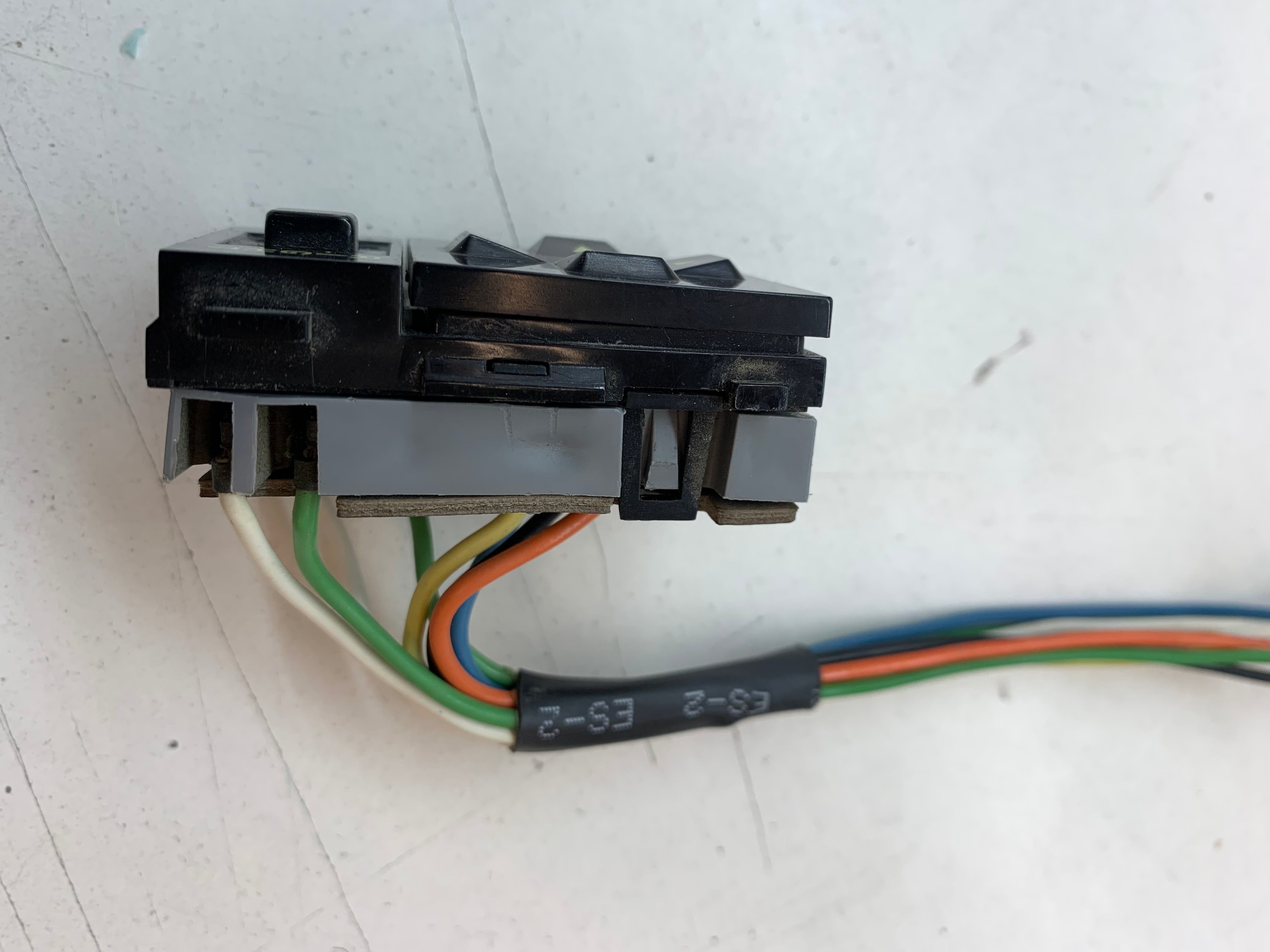

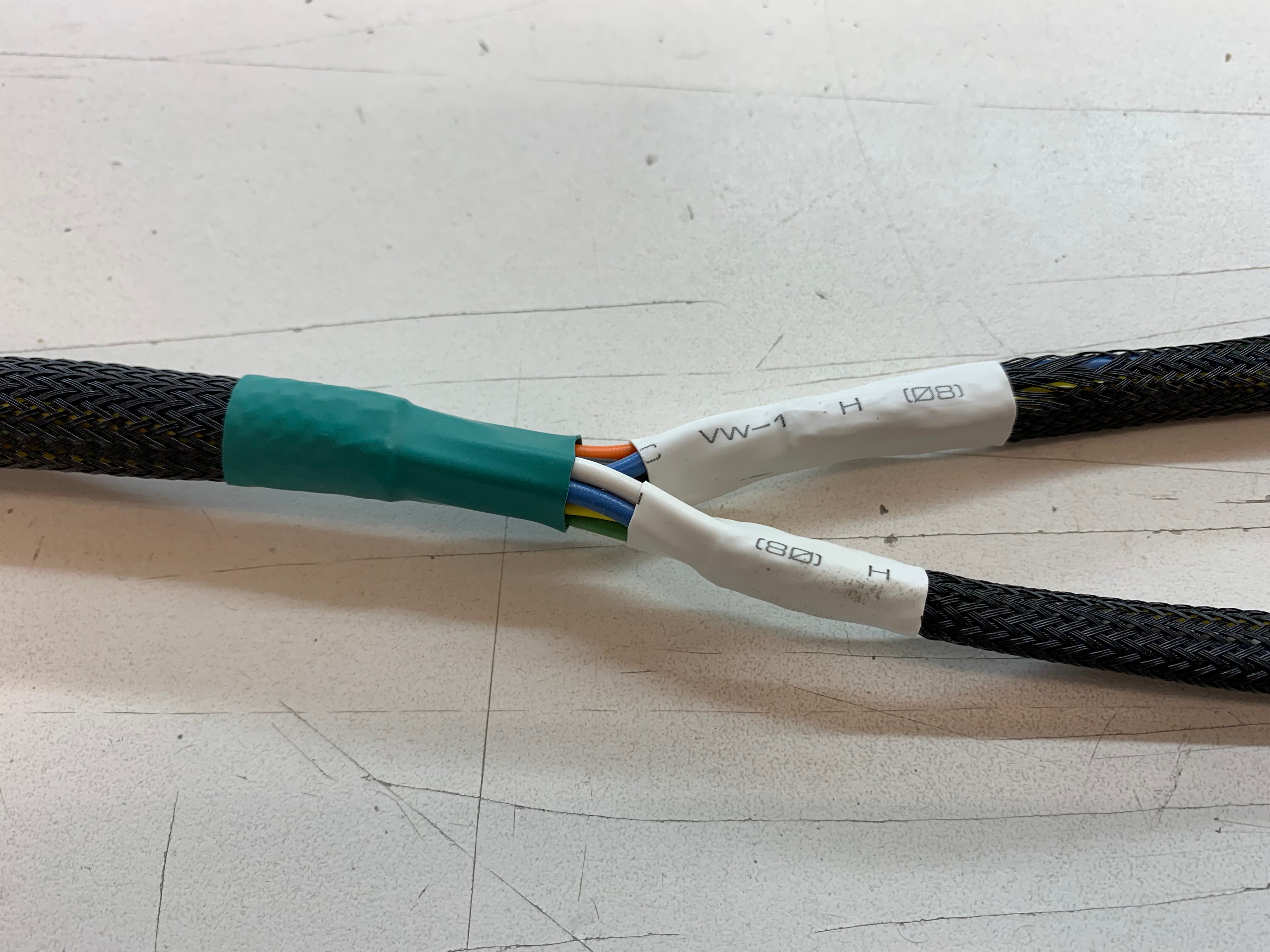

A small bit of shrink tube to hold the wires in the desired shape helps get them all pointed in the right direction.

Spaghetti anyone?

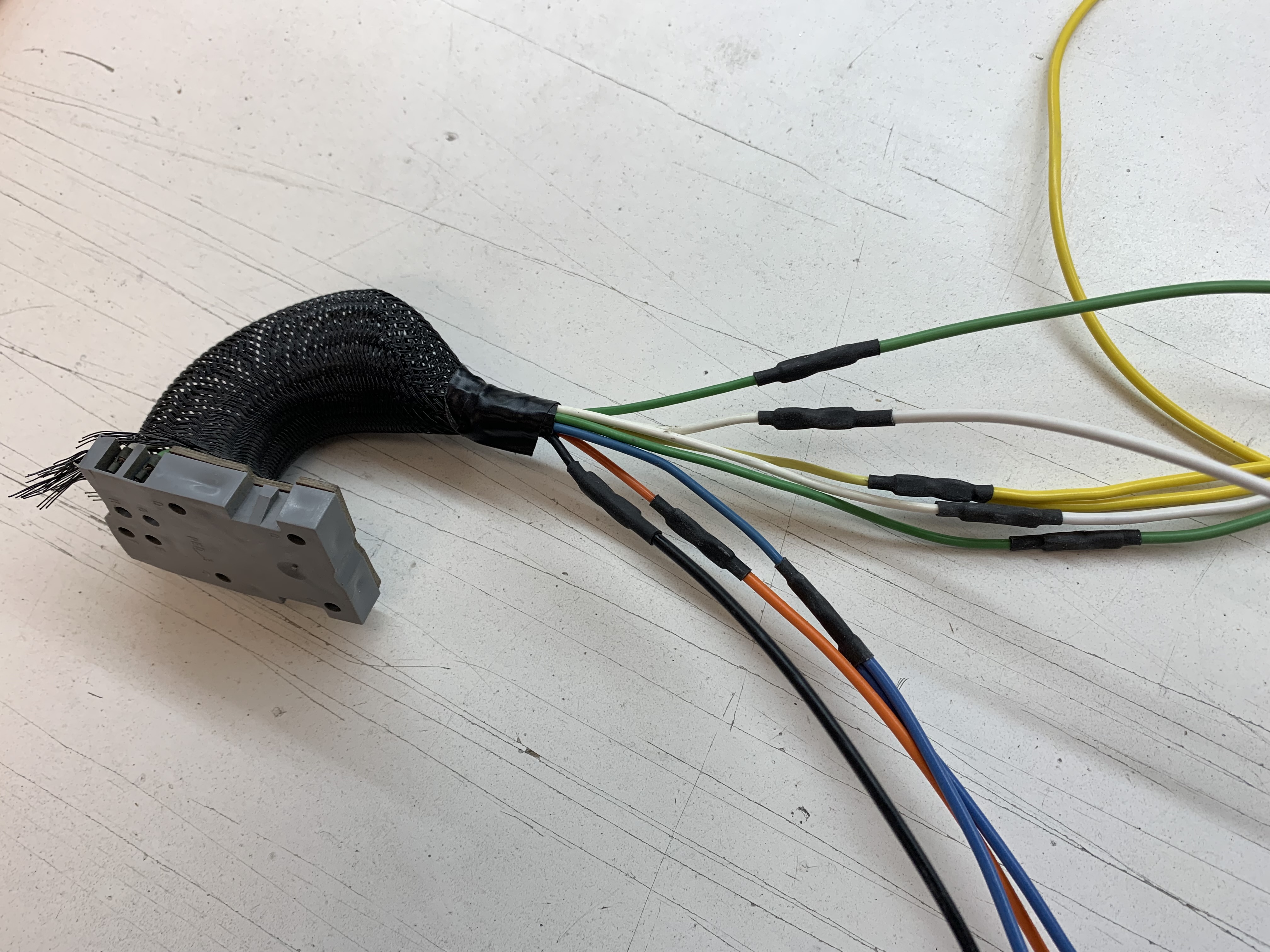

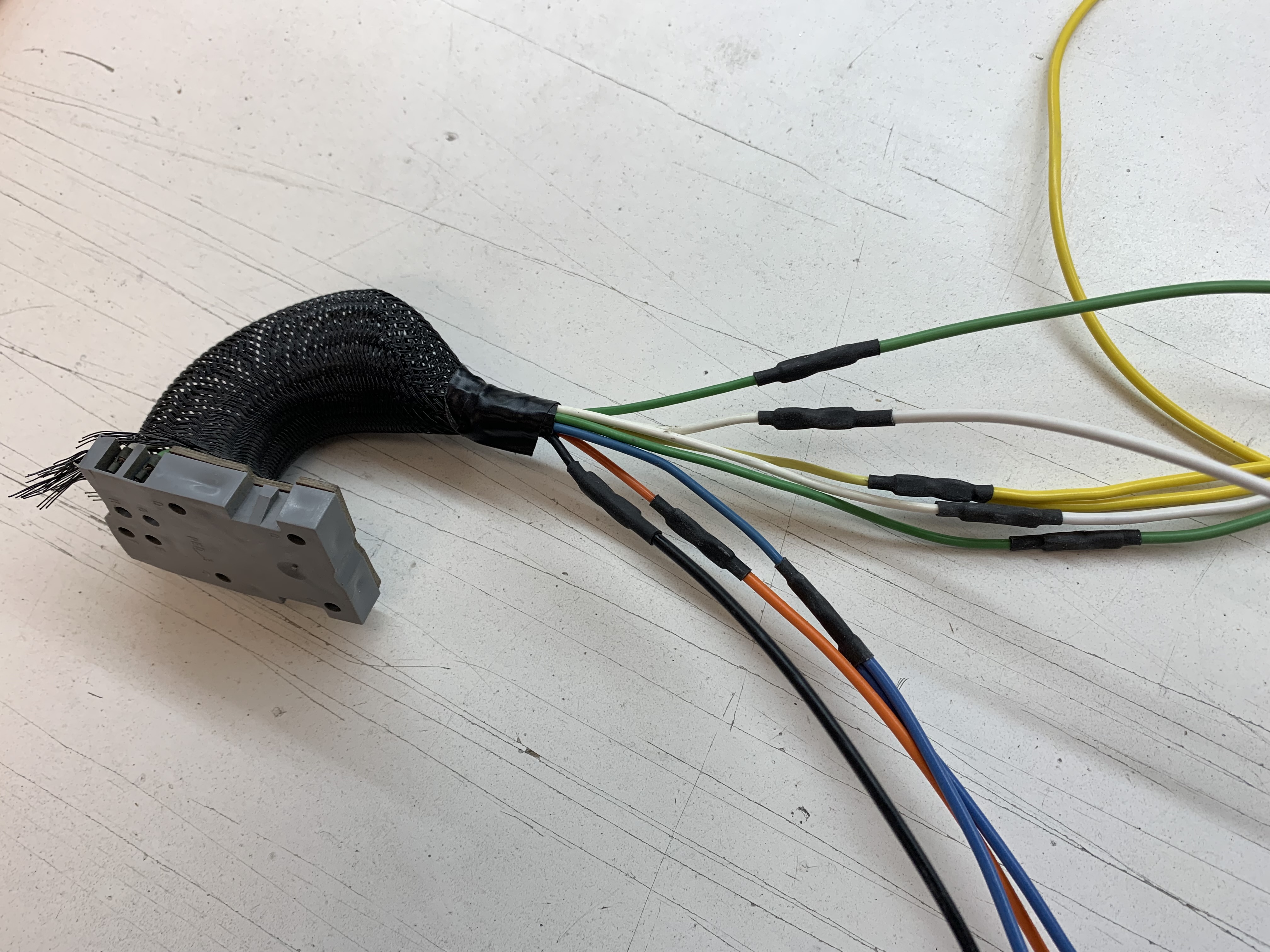

I’ve done a fair amount of automotive 12 volt wiring in my past, so I know a trick or two about how to cleanly build a tidy and efficient harness. Things like staggering your connections, using terminals without insulators and using shrink tube instead.

I used 2 sizes of non-slitted nylon braid conduit for this harness, 3/4” and 1/2”. The 3/4” was a nice size for the main run of the harness before it branched off. Each branch then stepped down to the 1/2” conduit. Rather than using crappy old electrical tape that inevitably peels and leaves a sticky mess behind, I use larger shrink tube to secure the conduit to the wire. Or in this case, to the previously installed piece of shrink tube.

After determining where the split into two branches had to be located, I continued on with creating the RH side first.

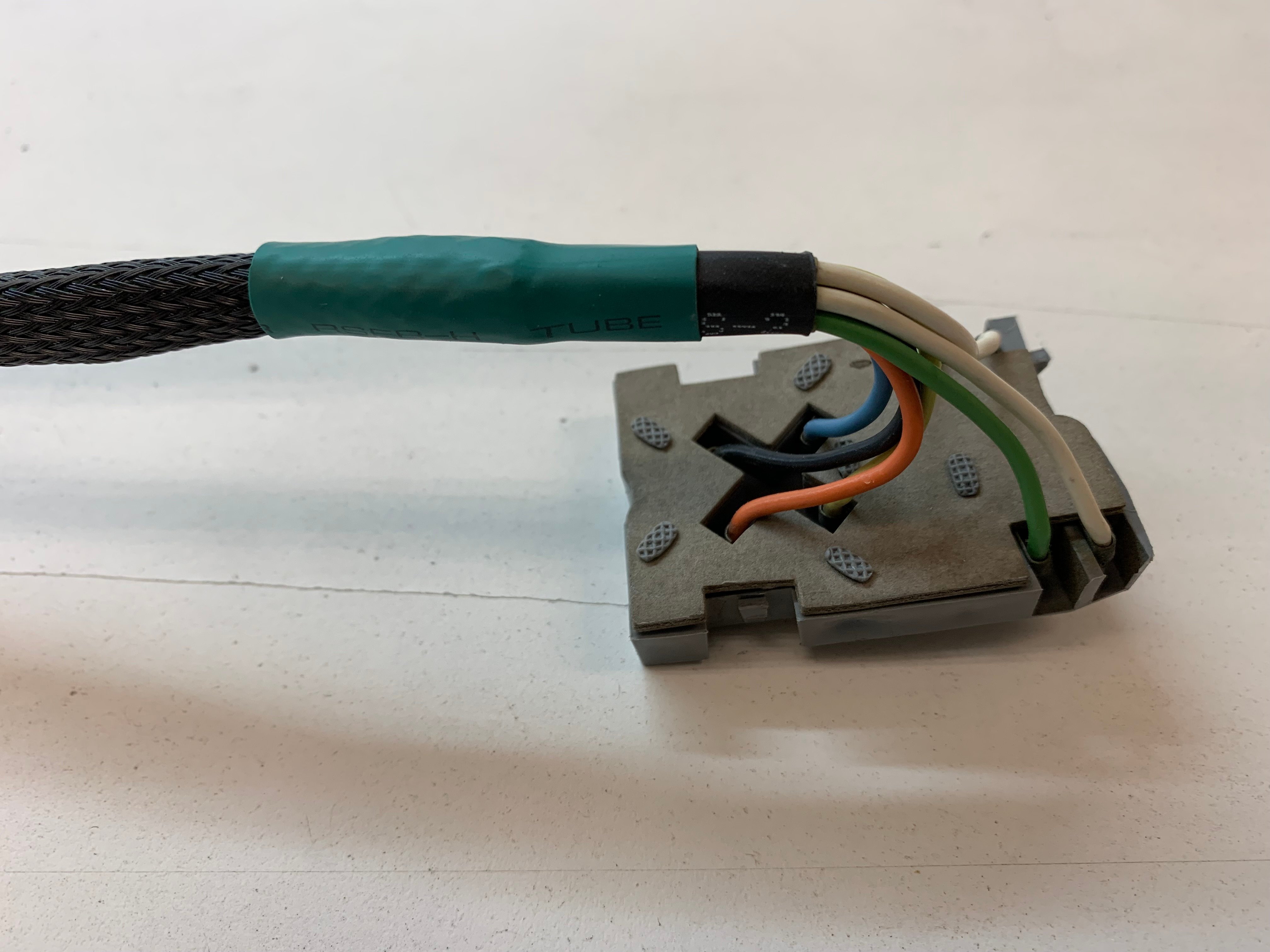

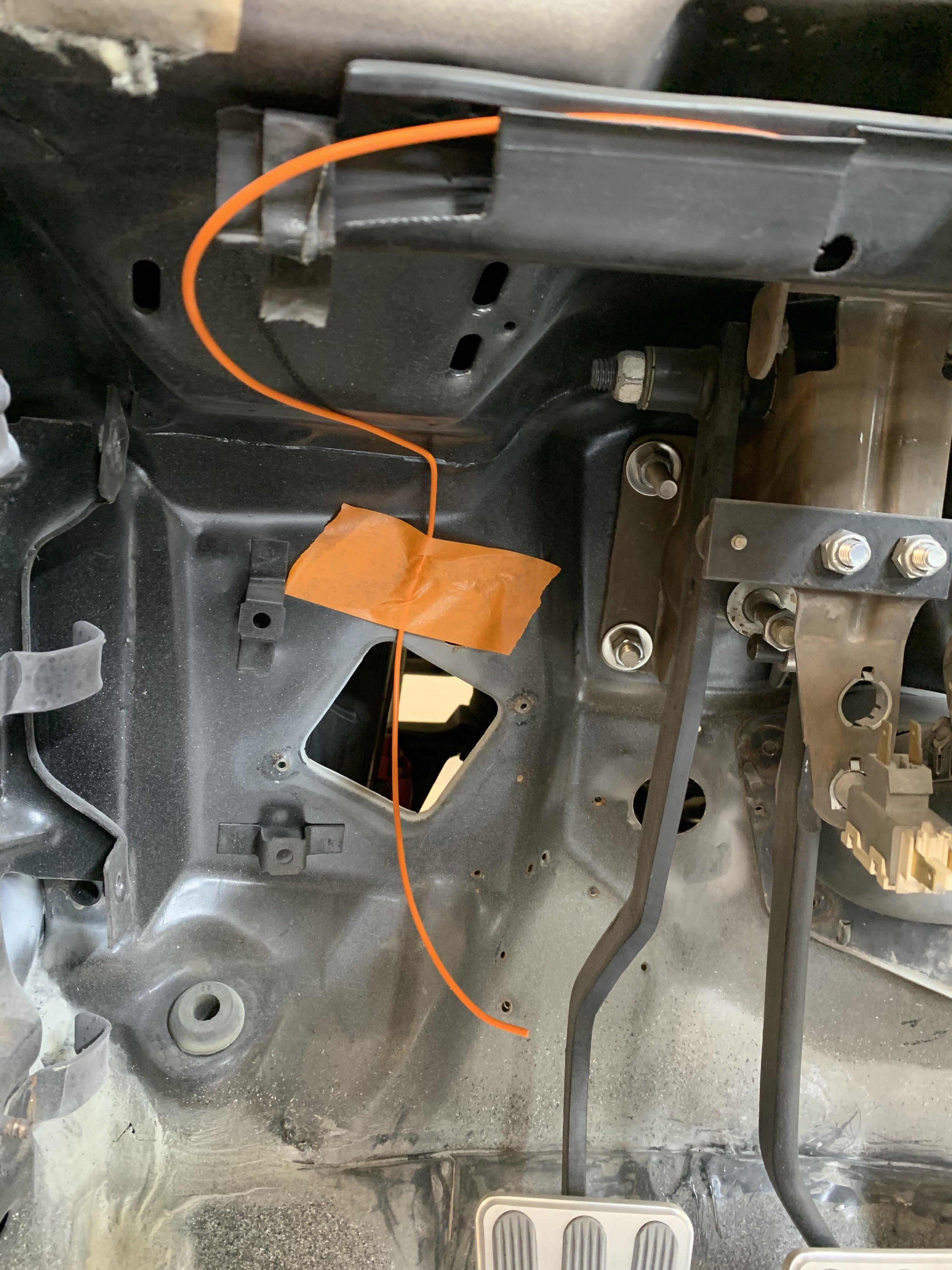

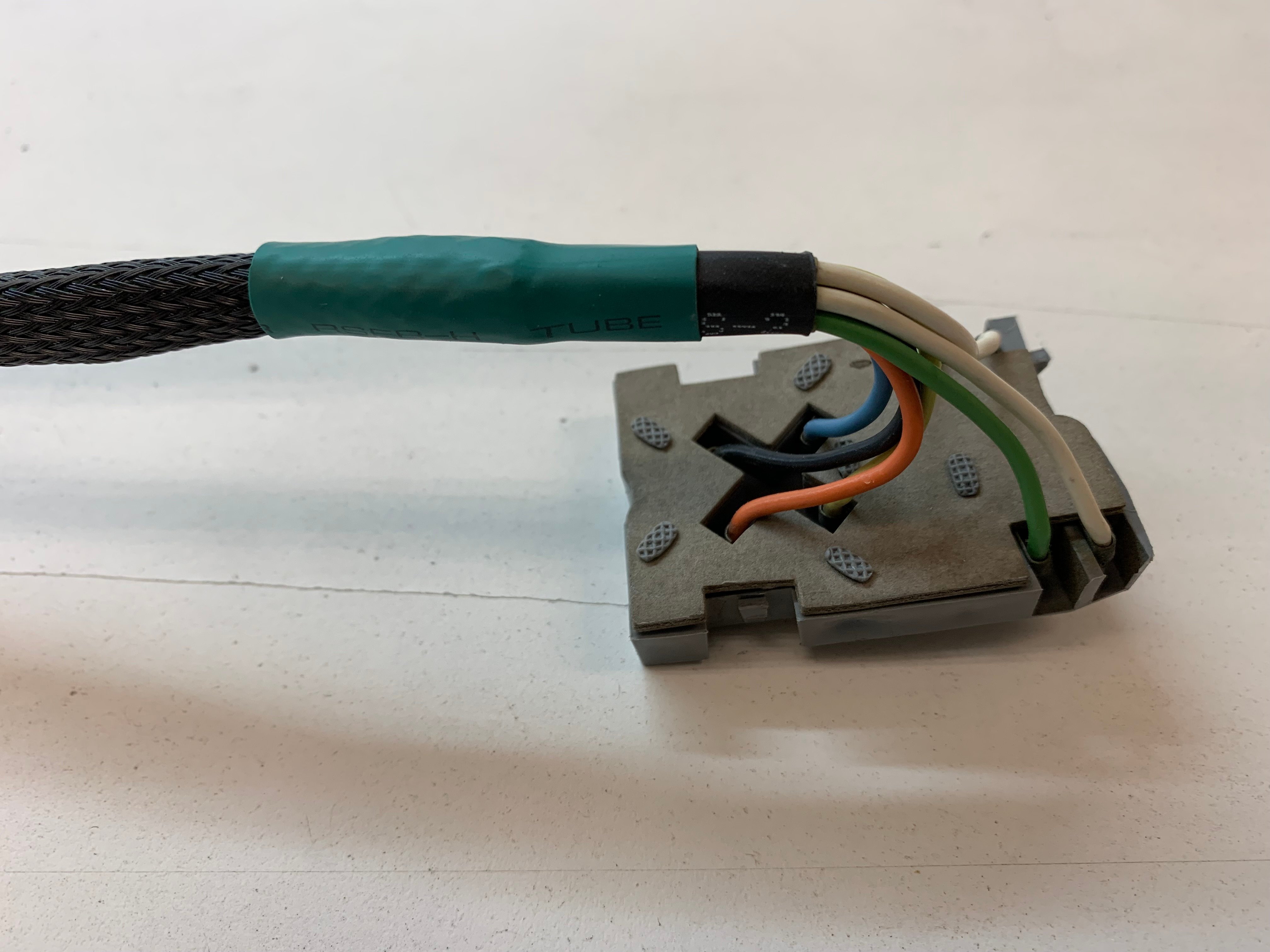

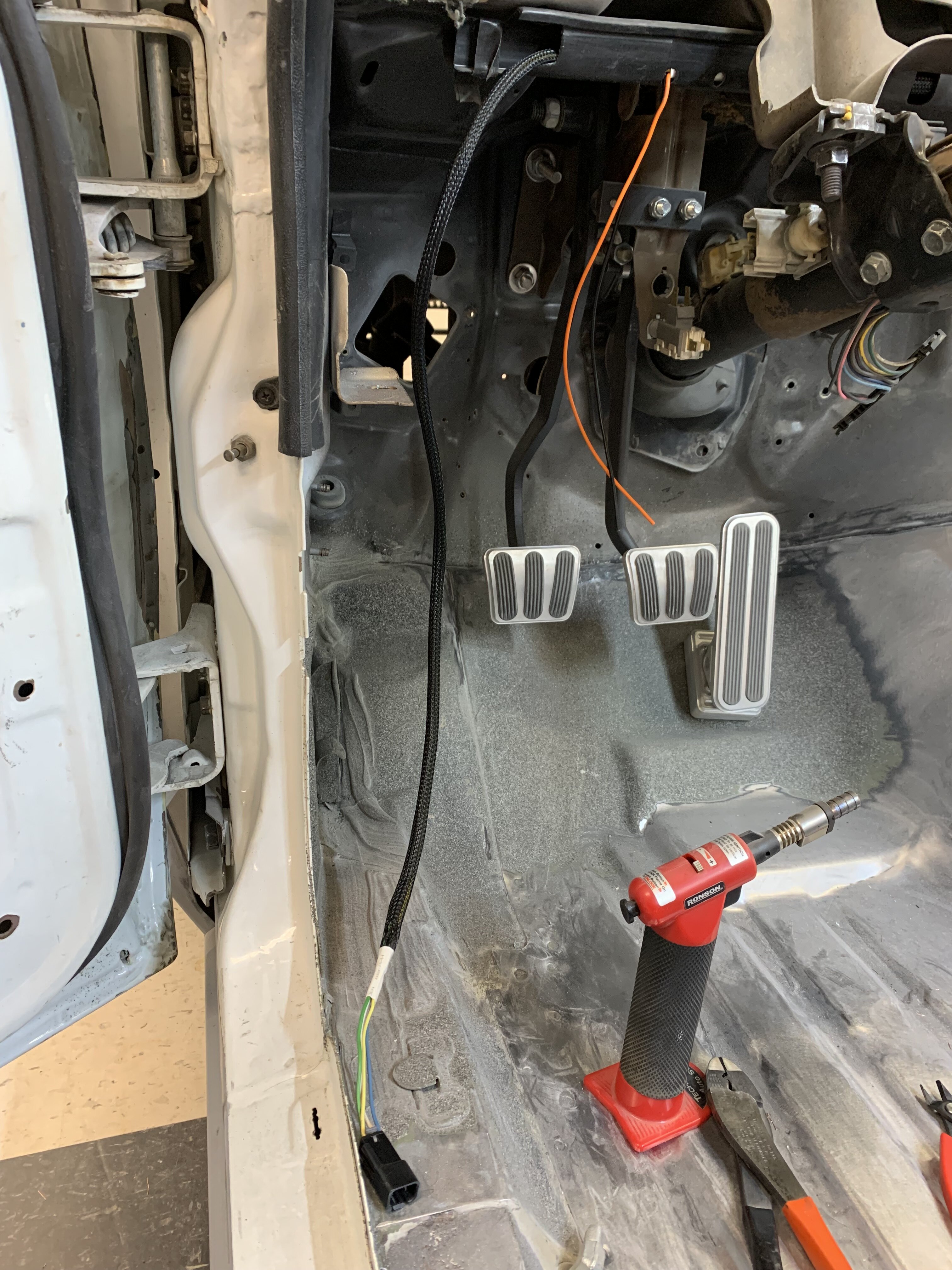

Then the LH side. The LH side has two extra wires run within it, the power and ground wires will drop out above the fuse box. Very convenient this way! Here is the split point…

…and where the power and ground wires drop out:

Continued >>>

After giving them time to dry and cure, I unmasked everything and mounted the mirrors back on the car. I’m getting more and more used to seeing them on there now and they’re looking more at home with every step.

The next thing I wanted to do was to test the function of the mirrors. The mirror motors, wiring pigtails, and switch were all used items purchased off of eBay. Up until this point I still didn’t know if they all worked or if I had a couple of complete duds despite the seller claiming they all worked when they were pulled.

So I set about making a temporary harness for testing, matching color for color until I realized that there were 4 wires per side for a total of 8 running to the switch, but only 6 wires coming out of the switch not including the power and ground. I figured 2 of the wires would have to be spliced together, but which 2?

And so began a couple of head scratching days of testing, research, pouring over wiring diagrams and schematics, as well as quizzing anyone I could think of who might understand how this was supposed to work. Despite multiple different combinations of wire connections to the switch, nothing seemed to work properly. Up would be down, left would be right, and things were off even side to side.

I finally reached out to the minds on this wonderful forum, and a couple individuals smarter than me got me pointed in the right direction. I’ll save you the gory details of my struggles, but you can read about it here if you haven’t already:

Power Mirror Wiring

Hey guys It’s not often that I get stumped and have to ask for help, but this particular one has me baffled. I’ve installed 3rd Gen F body mirror motors in a set of Monte SS housings, and am using the matching F body mirror switch to control them. The issue is, there are 4 wires going to...

gbodyforum.com

gbodyforum.com

Once I had everything functioning properly the way it should, I was breathing a whole lot easier. I wasn’t originally planning on making a permanent mirror harness just yet, but I figured I’d better build one while everything was still fresh in my head. So today I went to the parts store and stocked up on some wiring supplies I was short on.

I needed to determine the length of each branch of the harness, so I started at the RH mirror and routed one of the wires along the path I had chosen back to roughly where the switch would be installed. I plan on mounting the switch in the center console I haven’t built yet, so I left myself some extra length so I’ll have some options when the time comes.

This is the proposed route. From the RH mirror…

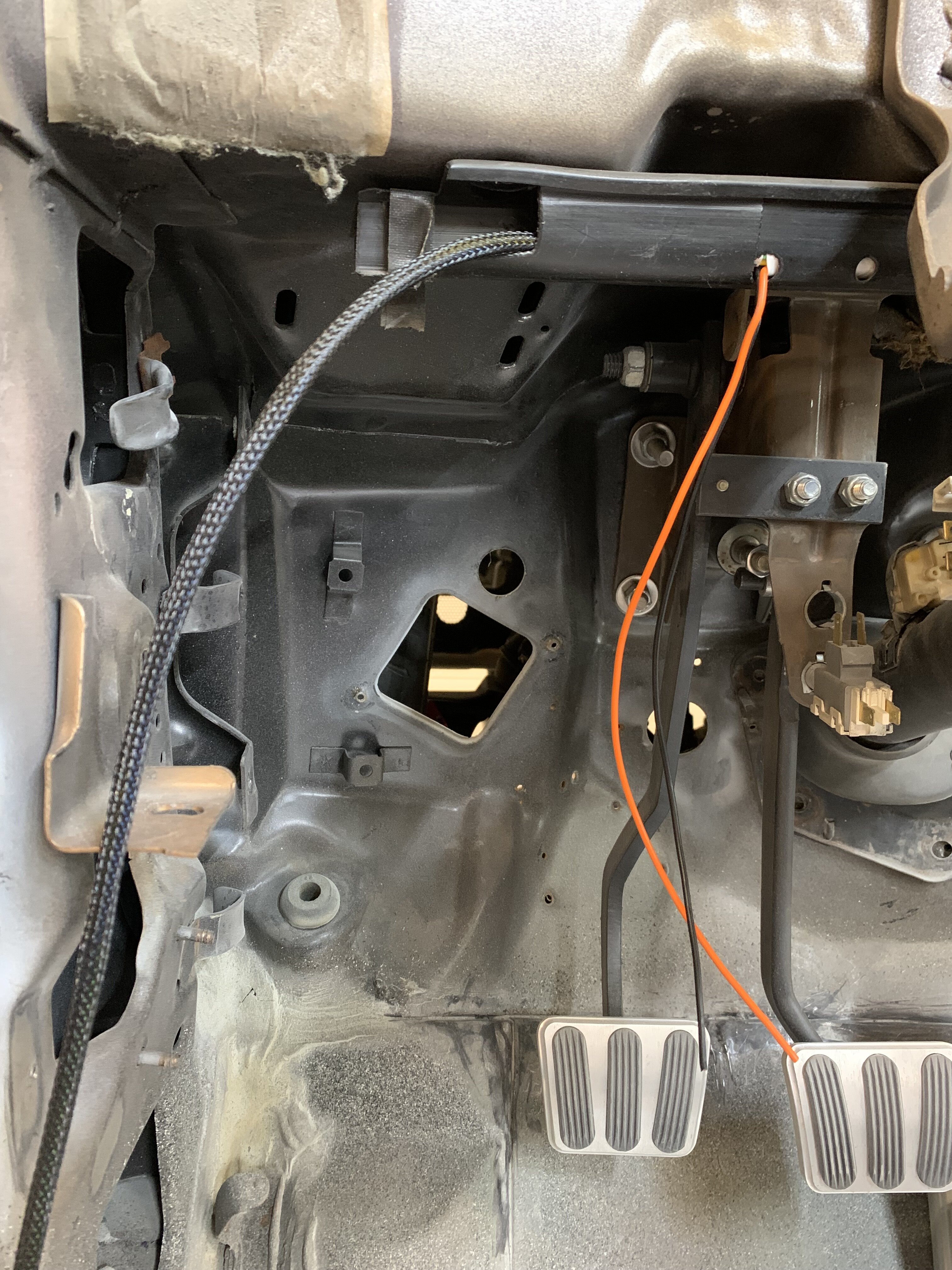

To this opening in the factory plastic conduit behind the dash:

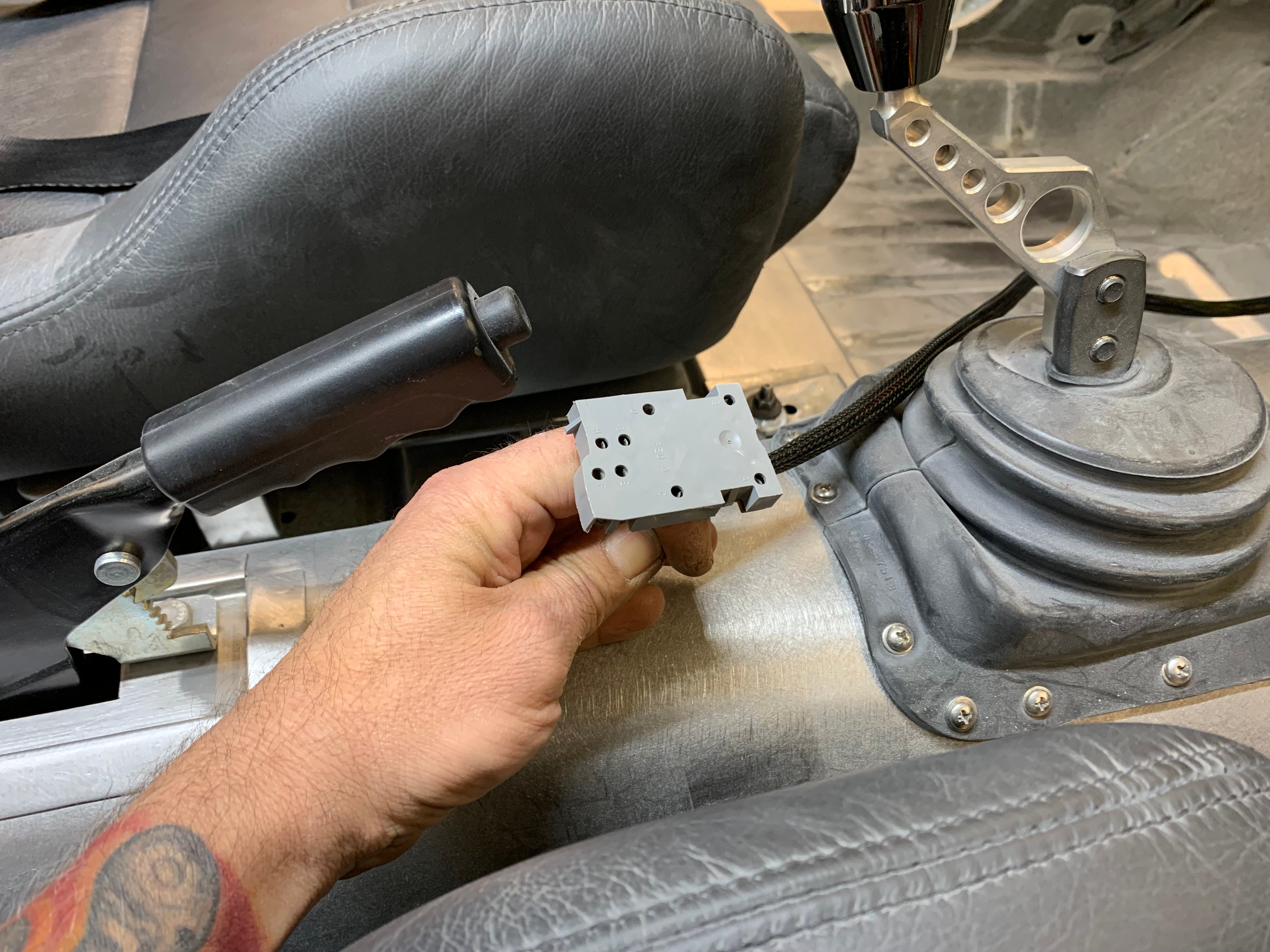

It’s tough to plan this far in advance of where everything is going to go, but I’m kind of thinking it might go somewhere in this vicinity right now:

I repeated the process for the LH side, but with the addition of the two wires that will have to run to the fuse box, the power and ground. I was lucky enough to find some orange wire today that matches up to the factory power wire nicely.

Once I had these lengths established, it was to the bench to start building the harness. Here are the 6 colors required, keep in mind that 2 of the wires are going to be spliced.

The switch, removed from the temporary harness and still labeled with the terminal letters:

A small bit of shrink tube to hold the wires in the desired shape helps get them all pointed in the right direction.

Spaghetti anyone?

I’ve done a fair amount of automotive 12 volt wiring in my past, so I know a trick or two about how to cleanly build a tidy and efficient harness. Things like staggering your connections, using terminals without insulators and using shrink tube instead.

I used 2 sizes of non-slitted nylon braid conduit for this harness, 3/4” and 1/2”. The 3/4” was a nice size for the main run of the harness before it branched off. Each branch then stepped down to the 1/2” conduit. Rather than using crappy old electrical tape that inevitably peels and leaves a sticky mess behind, I use larger shrink tube to secure the conduit to the wire. Or in this case, to the previously installed piece of shrink tube.

After determining where the split into two branches had to be located, I continued on with creating the RH side first.

Then the LH side. The LH side has two extra wires run within it, the power and ground wires will drop out above the fuse box. Very convenient this way! Here is the split point…

…and where the power and ground wires drop out:

Continued >>>

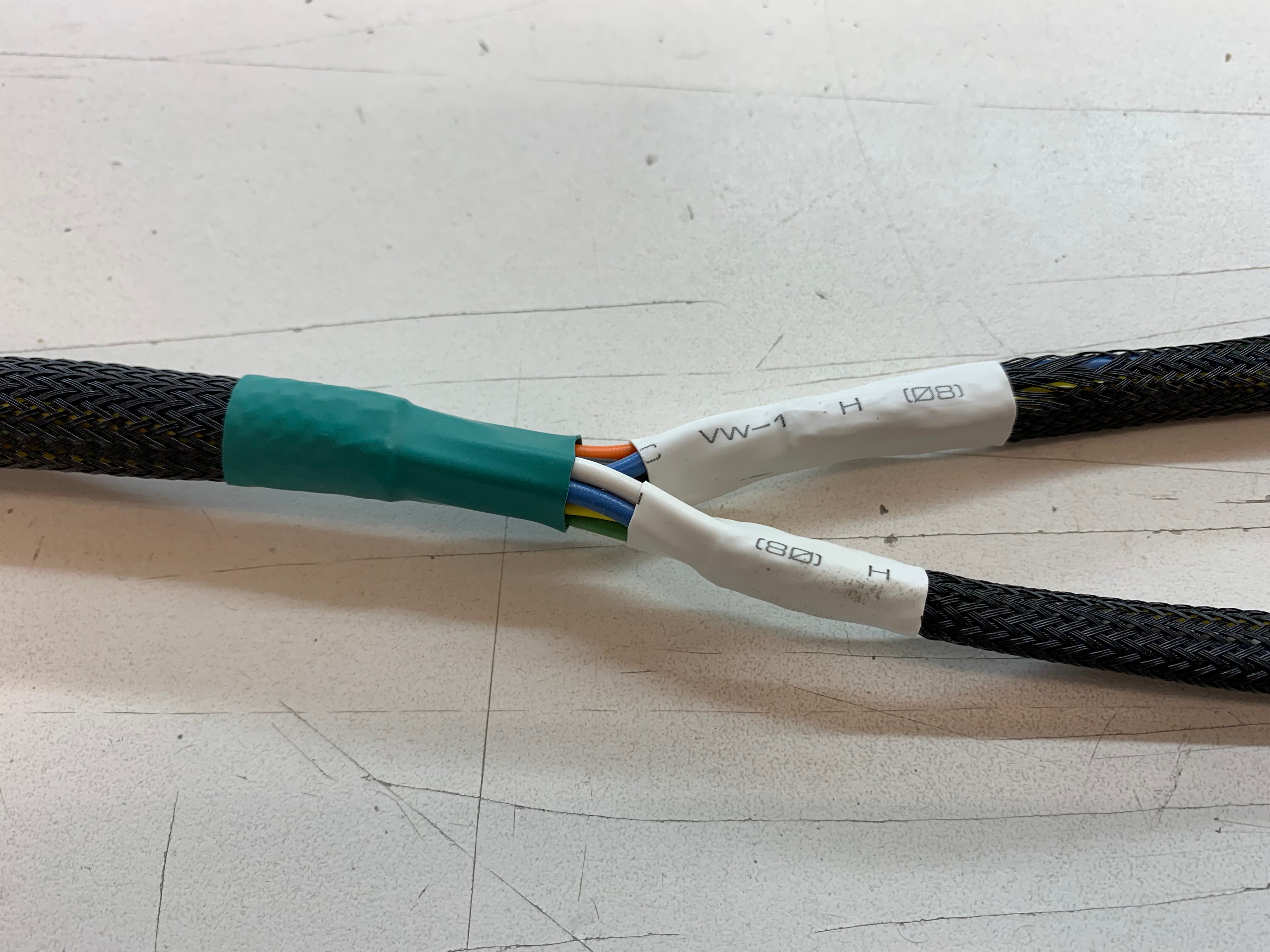

At this point, the harness was as completed as I could get it on the bench.

Time to install it in the car. Placed the switch roughly where I think it might go…

…then along the planned route and through the factory plastic conduit.

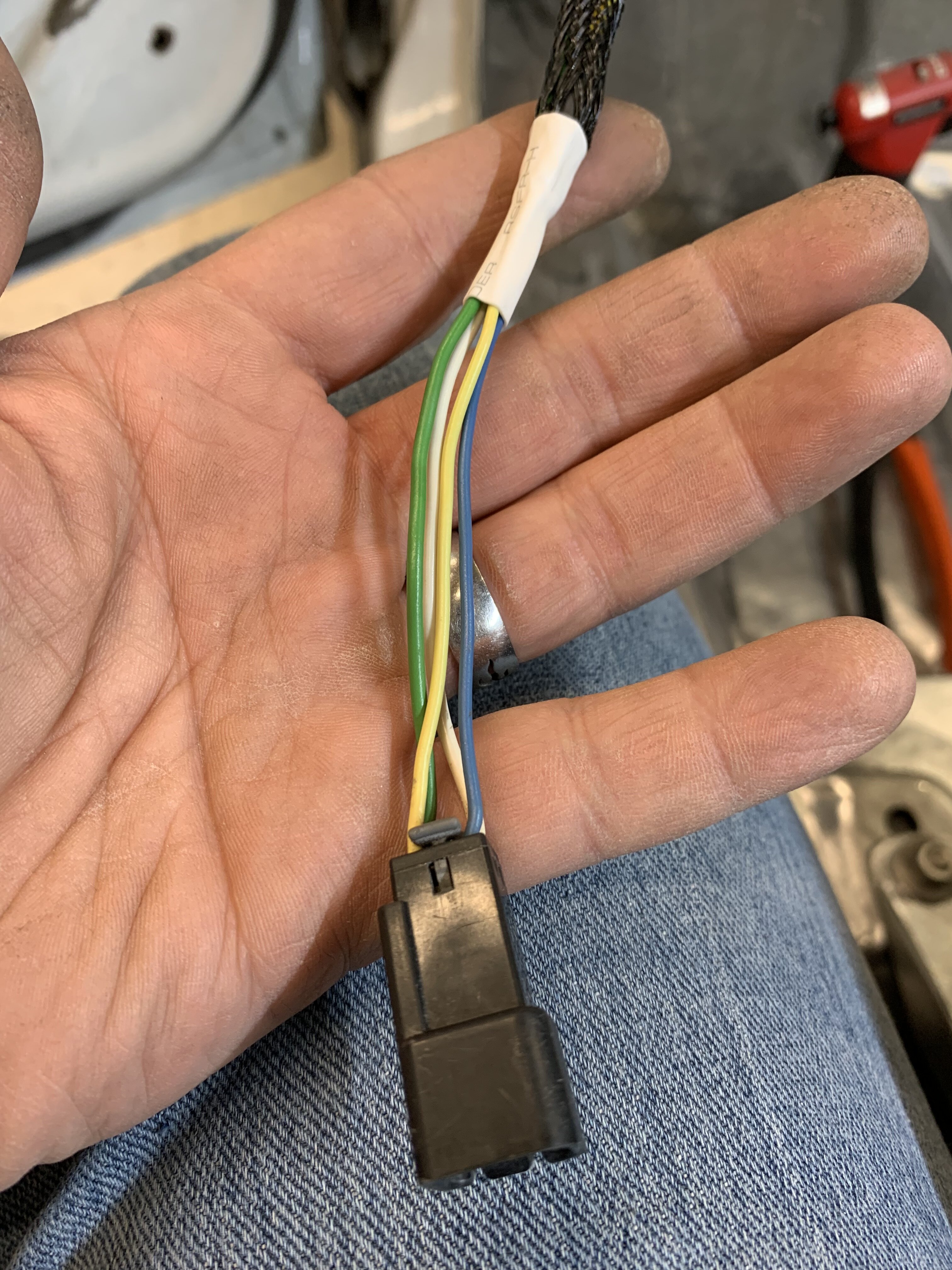

So far, so good. Now to attach the mirror plug ends. Same process as with the switch, stagger the connections, slide the conduit down over the connections and secure with shrink tube.

Clean and efficient.

Lather, rinse and repeat for the LH side:

Note the drop out of the power and ground wires towards the fuse box location:

And right back where we started, but on the LH side.

Harness nearly completed, now to test one last time. Install the switch onto the connector…

…and plug the power and ground leads into a cordless drill battery. 20 volts is good for the mirror motors isn’t it?

😅

And voilà, everything works perfectly just as it should!

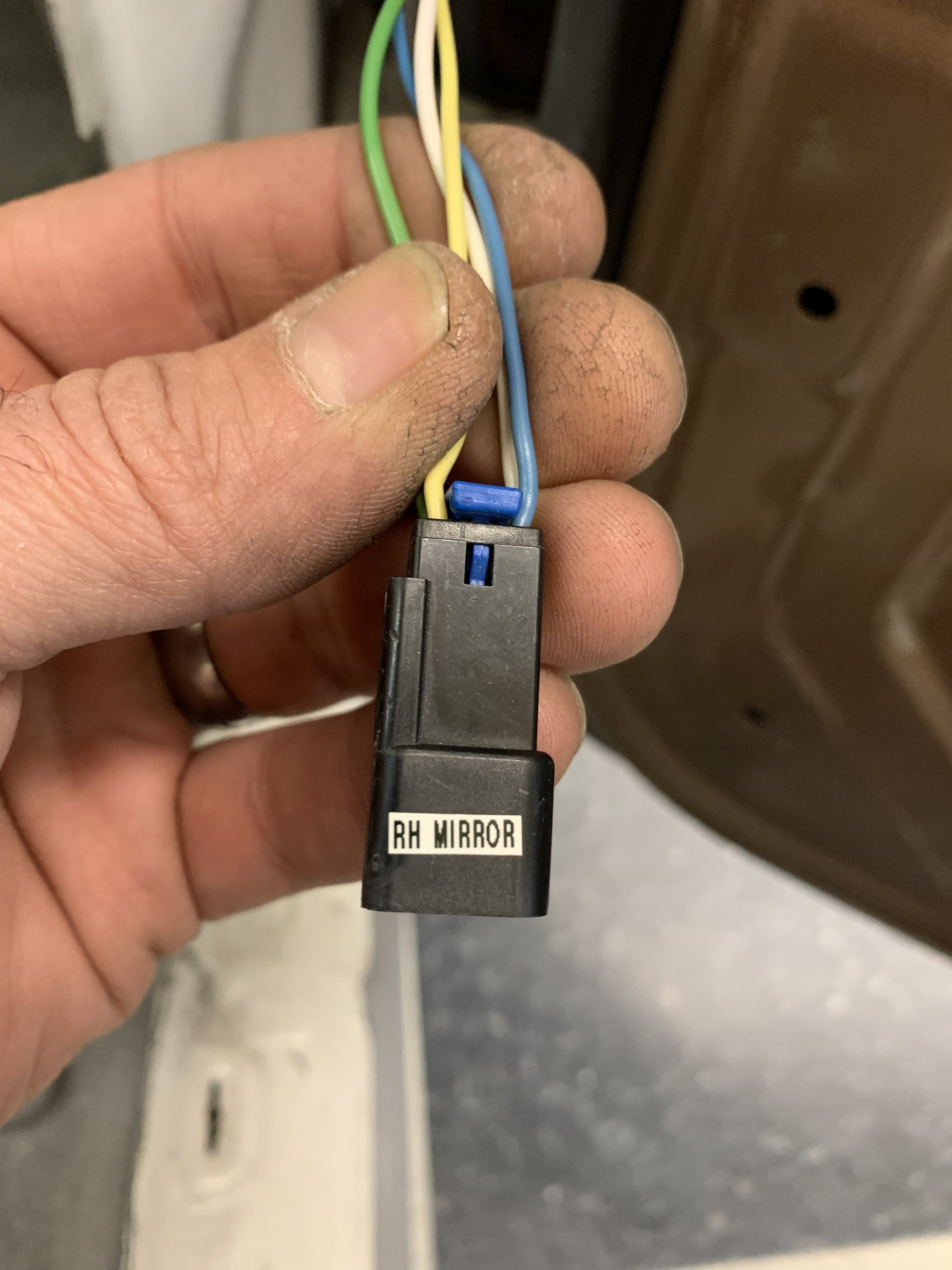

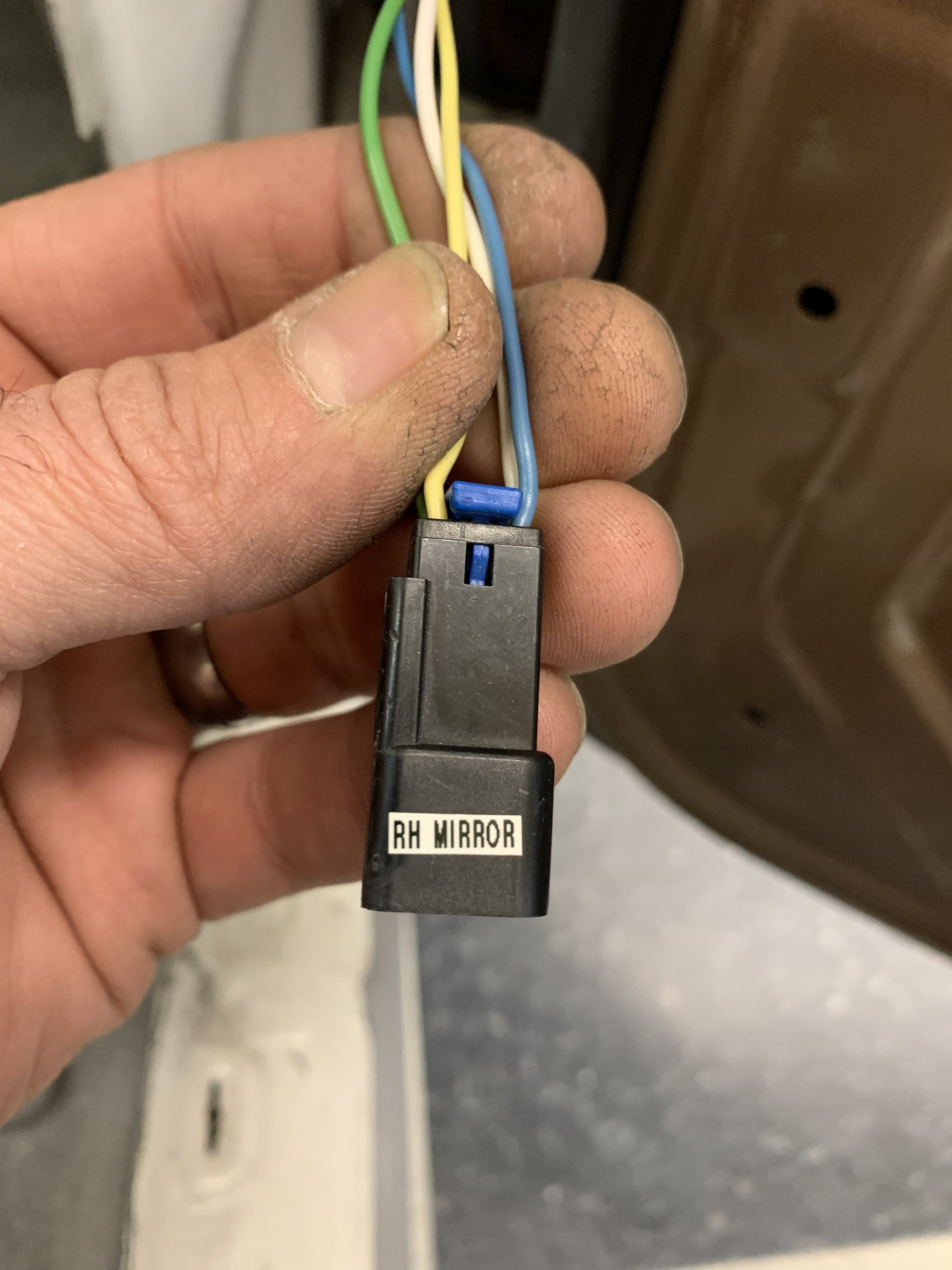

Done, right? Not quite. Because it might still be several years before I’m ready to wire the rest of the car and because my memory ain’t getting any better the older I get, I felt it prudent to label a few things. After playing around with the settings on my label maker, I was able to print out some tiny labels for each mirror plugs on the harness sides:

This’ll help me remember what this harness is for, and where the plugs go to. In addition to these, I also made one for the power and ground wires. Nothing worse than having mystery wires dangling underneath the dash that you have no idea what they’re for.

And that pretty much concludes all the work with the mirrors with the exception of the mirror to door gaskets. I’ve mentioned in the past that I’m having some 3D printed to taylor them to my specific application, but the final versions STILL aren’t done yet. I’ve been promised that they’ll be ready by Monday, so we’ll see. Once I have them in hand (and they’re right) I’ll do a post specifically on them.

Until then, onto the next item! (Hint, it’ll probably involve a little more bodywork and primer).

Thanks for following along.

D.

Time to install it in the car. Placed the switch roughly where I think it might go…

…then along the planned route and through the factory plastic conduit.

So far, so good. Now to attach the mirror plug ends. Same process as with the switch, stagger the connections, slide the conduit down over the connections and secure with shrink tube.

Clean and efficient.

Lather, rinse and repeat for the LH side:

Note the drop out of the power and ground wires towards the fuse box location:

And right back where we started, but on the LH side.

Harness nearly completed, now to test one last time. Install the switch onto the connector…

…and plug the power and ground leads into a cordless drill battery. 20 volts is good for the mirror motors isn’t it?

😅

And voilà, everything works perfectly just as it should!

Done, right? Not quite. Because it might still be several years before I’m ready to wire the rest of the car and because my memory ain’t getting any better the older I get, I felt it prudent to label a few things. After playing around with the settings on my label maker, I was able to print out some tiny labels for each mirror plugs on the harness sides:

This’ll help me remember what this harness is for, and where the plugs go to. In addition to these, I also made one for the power and ground wires. Nothing worse than having mystery wires dangling underneath the dash that you have no idea what they’re for.

And that pretty much concludes all the work with the mirrors with the exception of the mirror to door gaskets. I’ve mentioned in the past that I’m having some 3D printed to taylor them to my specific application, but the final versions STILL aren’t done yet. I’ve been promised that they’ll be ready by Monday, so we’ll see. Once I have them in hand (and they’re right) I’ll do a post specifically on them.

Until then, onto the next item! (Hint, it’ll probably involve a little more bodywork and primer).

Thanks for following along.

D.

Last edited:

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.