It would be nice if they had an "in car" app to Bluetooth your engine vitals to your phone, and if anything gets out of whack outside of your liking, it alerts you instantly.

BUILD THREAD The Mullet Maurader, The Epic of the LS swapped Buick

- Thread starter Northernregal

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Are you feeding the harness pressure signal with the stock 03-07 3 wire 5V oil pressure sensor? That standard part # looks like its right.

If you have a 1/8 pipe tap you can just break the top off that broken sensor and tap it for a old style mechanical gauge, or go to the cover by the oil filter housing on the pan.

I suppose having a regal you don't have the LS feeding the factory oil pressure dash gauge since Regals never had one.

Got lucky there! Just sucks cleaning

If you have a 1/8 pipe tap you can just break the top off that broken sensor and tap it for a old style mechanical gauge, or go to the cover by the oil filter housing on the pan.

I suppose having a regal you don't have the LS feeding the factory oil pressure dash gauge since Regals never had one.

Got lucky there! Just sucks cleaning

It would be nice if they had an "in car" app to Bluetooth your engine vitals to your phone, and if anything gets out of whack outside of your liking, it alerts you instantly.

I didn't have the ECM or dash set up for warnings. It will do it, I was just too excited to get it done. Safe to say it's set up now.

I have an ICT billet 16x1.5mm to 1/8npt adapter coming, going to use a 5v transducer and a mechanical dial gauge to be able to verify the transduce. Thinking about some mechanical gauges in the cab, just to be sure. None of the original gauges are even in the dash, it's all Holley digital dash, might have to set up a secondary log in the dash for weird stuff. The software is pretty accommodating for that.Are you feeding the harness pressure signal with the stock 03-07 3 wire 5V oil pressure sensor? That standard part # looks like its right.

If you have a 1/8 pipe tap you can just break the top off that broken sensor and tap it for a old style mechanical gauge, or go to the cover by the oil filter housing on the pan.

I suppose having a regal you don't have the LS feeding the factory oil pressure dash gauge since Regals never had one.

Got lucky there! Just sucks cleaning

Man, I don't even know all the tricks yet. Lol. It's way better than I hoped. 👍Oh and that gauge panel is awesome!!!!!

Pressure sensor and mechanical gauge installed today.

According to the OEM sender and the Holley ECU scaling, it had 34psi hot oil pressure.

According to the mechanical and the China Holley clone 100psi transducer, both agree on 49psi hot at idle, 65psi at 4000rpm and 74psi @ 6000. 👍 perfect.

This is with the 0.125" shim on a stock pump. As per Mike and his oil pump mods in the turbosaurus build.

Might switch back to 10W30 or maybe 5W30 on the next change, might just to try it out. We will see.

According to the OEM sender and the Holley ECU scaling, it had 34psi hot oil pressure.

According to the mechanical and the China Holley clone 100psi transducer, both agree on 49psi hot at idle, 65psi at 4000rpm and 74psi @ 6000. 👍 perfect.

This is with the 0.125" shim on a stock pump. As per Mike and his oil pump mods in the turbosaurus build.

Might switch back to 10W30 or maybe 5W30 on the next change, might just to try it out. We will see.

Decided to pull out all the datalogs from the ECU and check them out.

Poured through about 15 to discover someone needed to set his knock sensors up properly.😬

Made a few changes as per the Holley forum, and went for a drive.

I also discovered that I can pretty much fully tune from the dash, some parameters aren't available but for the majority of the things you need to tune it's all there. Even the big fuel and tuning maps.

So I did a little tweaking and discovered that with proper timing it's a beast. Holy smokes.

Also drives really nice on the highway, I have all four corners set for 4 clicks on compression and rebound, pretty close to the Viking recommended settings.

Little highway speed action here.

.

This is with garage "eyeballed" caster and toe. Pretty damn good, so far nothing but good things to say about the UMI Stage 4 suspension setup. Wow it just transformed this car and my alignment isn't even done yet. I can't imagine what it will be like on a closed course with good rubber.

Did a couple really good pulls to get the fuel tables and timing sorted out. Not enough traction to launch hard but it pulls really well. Can't wait to get on the strip and find out how fast it is.

Also made it home with no explosion of any major fluids! One day in a row. 😀

Poured through about 15 to discover someone needed to set his knock sensors up properly.😬

Made a few changes as per the Holley forum, and went for a drive.

I also discovered that I can pretty much fully tune from the dash, some parameters aren't available but for the majority of the things you need to tune it's all there. Even the big fuel and tuning maps.

So I did a little tweaking and discovered that with proper timing it's a beast. Holy smokes.

Also drives really nice on the highway, I have all four corners set for 4 clicks on compression and rebound, pretty close to the Viking recommended settings.

Little highway speed action here.

This is with garage "eyeballed" caster and toe. Pretty damn good, so far nothing but good things to say about the UMI Stage 4 suspension setup. Wow it just transformed this car and my alignment isn't even done yet. I can't imagine what it will be like on a closed course with good rubber.

Did a couple really good pulls to get the fuel tables and timing sorted out. Not enough traction to launch hard but it pulls really well. Can't wait to get on the strip and find out how fast it is.

Also made it home with no explosion of any major fluids! One day in a row. 😀

Been a couple weeks so an update is due.....

Last time i drove the car, about 2 weeks ago I noticed that it didn't want to back up anymore. It goes into each gear, on jack stands it reverses and everything forward is good even while driving and made some weird clunking noises when in reverse. I noticed that the engine braking in 1st is not what it was before this so I did my research and concluded that it was either worn reverse band or a crappy servo/ servo pin. I also wanted to check the modulator adjustment as it is a full manual conversion and has a vacuum modulator just like a TH400. It is set up for full kill shifts, max pressure and max flow at every adjustment I could make in the shift kit, but to be honest I didn't die when it shifted and I didn't feel like it was "Full Kill" mode.

So up on stands she went and the pan came off. It wasn't a glitter bomb but there was some clutch material in the bottom. Not so bad...

I got the valve body out and the reverse servo out. It seemed a bit crooked, maybe a bit jammed in but I wasn't really sure. Either way I disassembled the servo and checked the pin length.

So the general fix on the interwebs for a weak reverse is to lengthen the reverse servo pin, or replace. GM makes a fancy tool to determine what pin you need as they make and sell several to accommodate this issue. So I measured up and ordered a longer pin as a hail mary shot in the dark at a fix, at worst I could lengthen with the TIG welder....

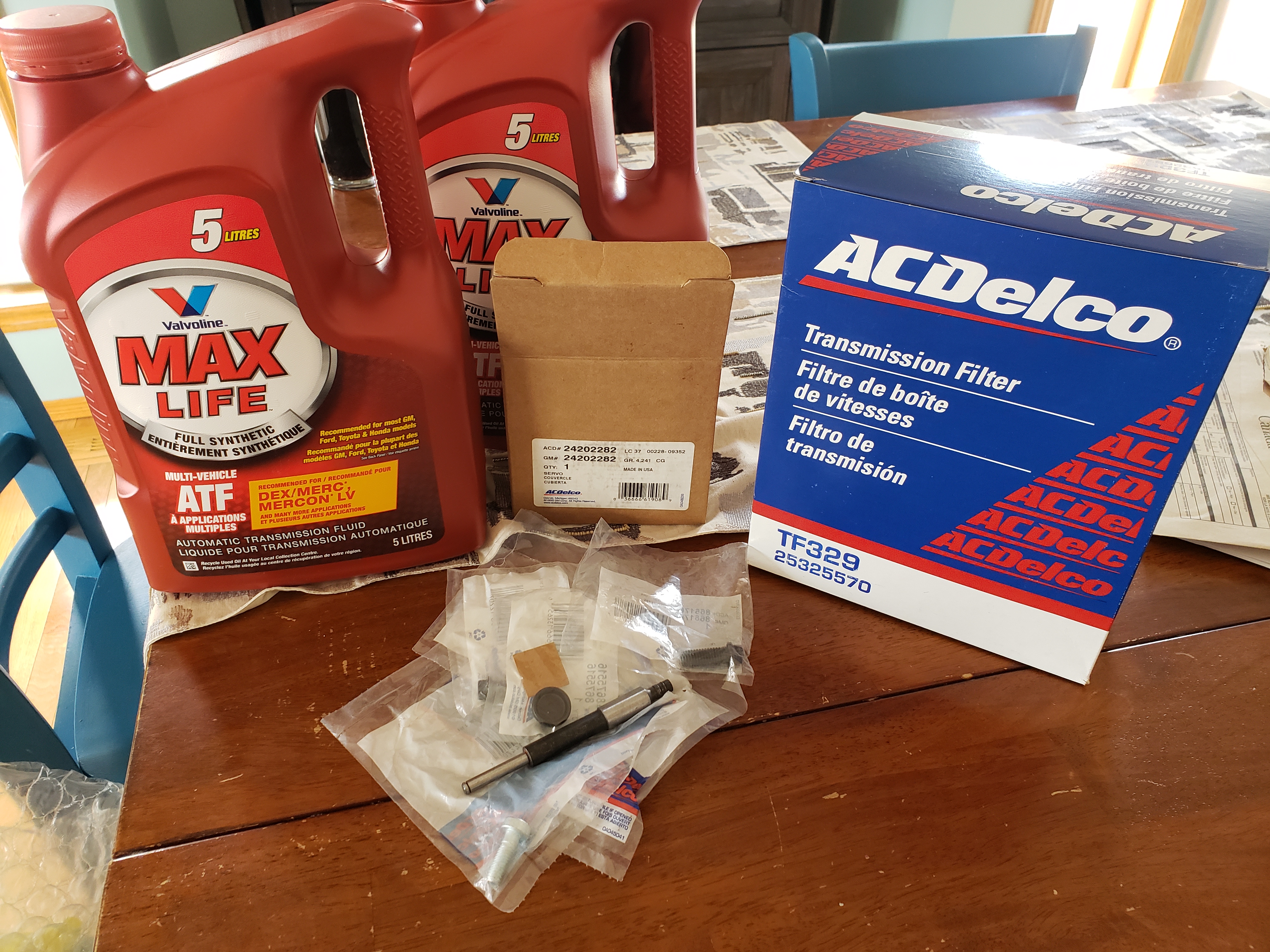

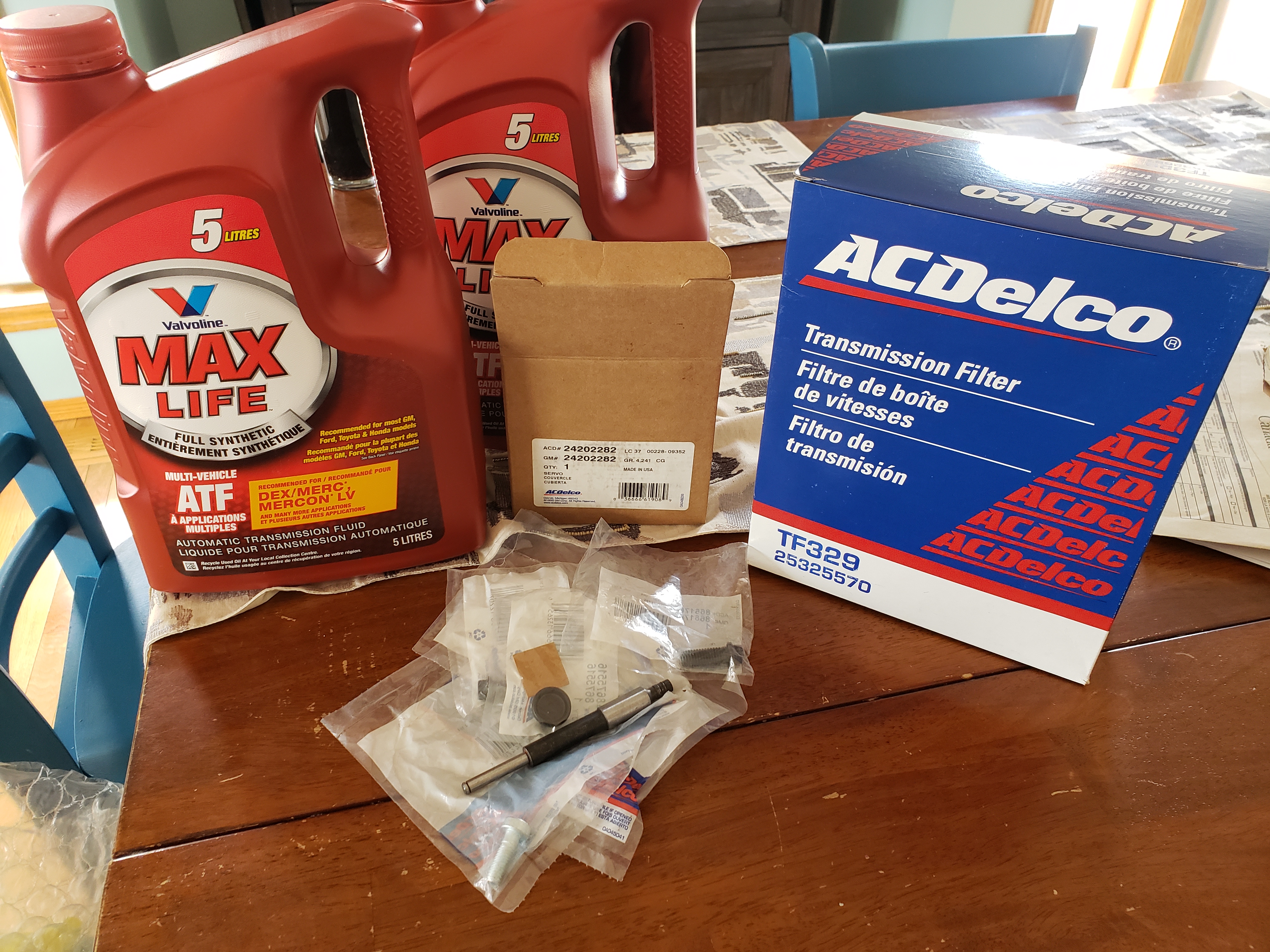

Rockauto made record time in getting parts here, ordered on Sunday night and arrived today! Hell ya! Stopped by the Wally world and got some trans fluid.

Got a few extra things as my spidey sense is tingling and I feel like she is going to be coming apart in the near future. So some extra check balls and a couple center support/overdrive clutch bolts.

Got right to it tonight, this is the reverse servo pin I had....

And the replacement.

So it all went back in, its a minor annoyance to drop the transmission pan, as the Holley Crossmember needs to be unbolted and moved forward to get the rear most 3 pan bolts. Took a couple hours and some minor cursing. I discovered that the TCC servo had popped out of its spot in the valve body so that got put in properly while I was at it and calibrated the dipstick (something I learned in my googling about the problem)

Got the fluid topped back up and decided to install a fresh filter, it was already open...

I fired it up to check the fluid and check reverse. BAM! Fixed! Right in to reverse, engine got a load and moved on its own at idle. Nice!

So I cycled the gears, put it in neutral, checked and topped up the fluid, checked fluids again and put it back in reverse. Nothing.... WTF?!?

It clunks like its going into reverse, has a little bit of pressure to back up if you rev it a bit, and makes the weird clunking noises in the trans if its in reverse.

So, sticking reverse servo? Band can't be shot as it went in fine with the first try. I haven't calibrated the transducer I am using on the trans but it shows:

60psi warm idle in park

190psi warm idle 1st gear

280psi warm reverse at idle.

All within spec.

I am going to double check the linkage for the shifter but I suspect its still good as well.

I'll take it for a drive as soon as I can to see if the 1st reverse holdback is still weak and check the gears and running pressures. But so far I can't find this issue on the google. 🙁

Anyone know 4L80E's? Keeping in mind there are no electronics to blame here, it is full manual.

Last time i drove the car, about 2 weeks ago I noticed that it didn't want to back up anymore. It goes into each gear, on jack stands it reverses and everything forward is good even while driving and made some weird clunking noises when in reverse. I noticed that the engine braking in 1st is not what it was before this so I did my research and concluded that it was either worn reverse band or a crappy servo/ servo pin. I also wanted to check the modulator adjustment as it is a full manual conversion and has a vacuum modulator just like a TH400. It is set up for full kill shifts, max pressure and max flow at every adjustment I could make in the shift kit, but to be honest I didn't die when it shifted and I didn't feel like it was "Full Kill" mode.

So up on stands she went and the pan came off. It wasn't a glitter bomb but there was some clutch material in the bottom. Not so bad...

I got the valve body out and the reverse servo out. It seemed a bit crooked, maybe a bit jammed in but I wasn't really sure. Either way I disassembled the servo and checked the pin length.

So the general fix on the interwebs for a weak reverse is to lengthen the reverse servo pin, or replace. GM makes a fancy tool to determine what pin you need as they make and sell several to accommodate this issue. So I measured up and ordered a longer pin as a hail mary shot in the dark at a fix, at worst I could lengthen with the TIG welder....

Rockauto made record time in getting parts here, ordered on Sunday night and arrived today! Hell ya! Stopped by the Wally world and got some trans fluid.

Got a few extra things as my spidey sense is tingling and I feel like she is going to be coming apart in the near future. So some extra check balls and a couple center support/overdrive clutch bolts.

Got right to it tonight, this is the reverse servo pin I had....

And the replacement.

So it all went back in, its a minor annoyance to drop the transmission pan, as the Holley Crossmember needs to be unbolted and moved forward to get the rear most 3 pan bolts. Took a couple hours and some minor cursing. I discovered that the TCC servo had popped out of its spot in the valve body so that got put in properly while I was at it and calibrated the dipstick (something I learned in my googling about the problem)

Got the fluid topped back up and decided to install a fresh filter, it was already open...

I fired it up to check the fluid and check reverse. BAM! Fixed! Right in to reverse, engine got a load and moved on its own at idle. Nice!

So I cycled the gears, put it in neutral, checked and topped up the fluid, checked fluids again and put it back in reverse. Nothing.... WTF?!?

It clunks like its going into reverse, has a little bit of pressure to back up if you rev it a bit, and makes the weird clunking noises in the trans if its in reverse.

So, sticking reverse servo? Band can't be shot as it went in fine with the first try. I haven't calibrated the transducer I am using on the trans but it shows:

60psi warm idle in park

190psi warm idle 1st gear

280psi warm reverse at idle.

All within spec.

I am going to double check the linkage for the shifter but I suspect its still good as well.

I'll take it for a drive as soon as I can to see if the 1st reverse holdback is still weak and check the gears and running pressures. But so far I can't find this issue on the google. 🙁

Anyone know 4L80E's? Keeping in mind there are no electronics to blame here, it is full manual.

- Status

- Not open for further replies.

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.