Not sure what scaled correctly means. I just have the regular sensor installed. I have not done anything else to it.And you're sure it's overheating? Has your sensor been scaled correctly? Or do you have another in the other head running a mechanical guage?

Twin turbo ls overheating issue

- Thread starter johnnunez29

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

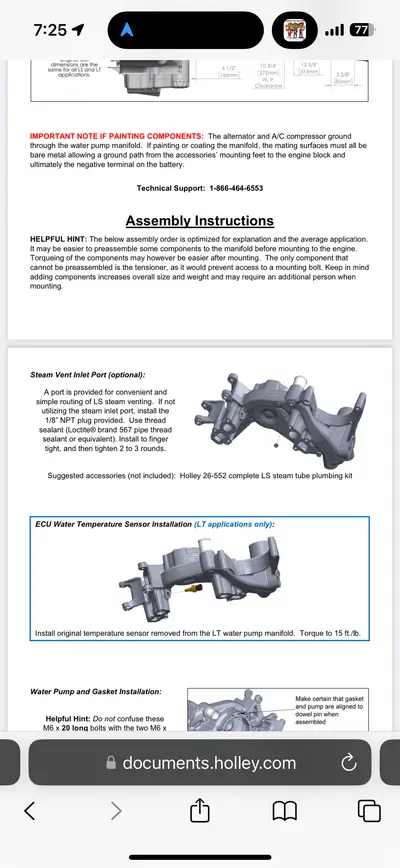

Maybe not a good design?I was going to mention that as well. The steam line is not supposed to go into the water pump. I'll poke around for the article and repost here if I can find it.

Attachments

Scaled means that even if the sensor you're using is working properly, the scale (range) that it uses, may be different than what the program in the Terminator is setup for. You can easily adjust the program so it matches whatever sensor you are running.Not sure what scaled correctly means. I just have the regular sensor installed. I have not done anything else to it.

I know many have done it that way before. But when I was looking into my LS swap, I had foundation article about not doing that for some reason. I think I amounted to water pressure, flow, or something along those lines.Maybe not a good design?

Gonna look into thatScaled means that even if the sensor you're using is working properly, the scale (range) that it uses, may be different than what the program in the Terminator is setup for. You can easily adjust the program so it matches whatever sensor you are running.

I know many have done it that way before. But when I was looking into my LS swap, I had foundation article about not doing that for some reason. I think I amounted to water pressure, flow, or something along those lines.

Air moves much better when it’s rising in a liquid. The factory steam port lines most generally end at a higher point than they start - for that reason.

But that can be difficult to accomplish on many swap situations. I have mine exiting at the top of the water pump via a fitting that I drilled and tapped the water pump for. It works, but it is not ideal.

But that can be difficult to accomplish on many swap situations. I have mine exiting at the top of the water pump via a fitting that I drilled and tapped the water pump for. It works, but it is not ideal.

I believe it’s a little lower than rads port. I’m going to run car with funnel and the steam vent into the funnel to confirm fluid is coming out.Air moves much better when it’s rising in a liquid. The factory steam port lines most generally end at a higher point than they start - for that reason.

But that can be difficult to accomplish on many swap situations. I have mine exiting at the top of the water pump via a fitting that I drilled and tapped the water pump for. It works, but it is not ideal.

Just to confirm. How hot is HOT? I’ve been turning off at 220 topsI believe it’s a little lower than rads port. I’m going to run car with funnel and the steam vent into the funnel to confirm fluid is coming out.

Just to confirm. How hot is HOT? I’ve been turning off at 220 tops

Some questions : ‘heating up’ - what does that mean EXACTLY? For reference, 215 is not hot and 225 is starting to get warm and 235 is close to hot. How much run time on this? Has it been driven at highway speeds for more than 3 minutes? What is the timing, AFR and rpm at idle? What ECU?

I answered that in previous posts. I'd let it get close to 230 before shutting it down. And that is with the radiator cap installed. Verify that the thermostat is opening via heat gun on the radiator pipes and watching the coolant temp on the 3.5" handheld. Once you shut the motor off - do not touch it until the coolant temp is down to less than 110-120 degrees and less than 100 is even better. Then check the coolant level and see if it took any in - lather rinse repeat until the level in the radiator at sub 120 degrees is the same on every check.Wrapping the pipes will help. But I’m with Shawn, be sure it’s over heating before you get crazy throwing parts at it. Use a heat gun on the pipes. Make sure your rad hoses are getting pressurized (hard). When warming up verify when the t-stat opens via heat gun and gauges. And let it get to 225-230 before shutting it down. You won’t hurt a thing letting it get to high 230’s, but high 220’s is normal operation for some applications.

During this process, if you cannot tell when the thermostat opens via temperature readings on every warmup and cooldown cycle, then you have an issue causing the overheat condition.

I re-read all of this thread as it seems that you still have the issue and we are repeating some of the same info. I did more than just glance at your engine bay photo. You need a turbo blanket unless you don't mind having your inner fender and coolant reservoir getting melted. Wrapping the headers and bellows pipes helps as well, but wrapping those headers is a pita unless you remove them. You'll find that most guys running up and forward headers are running them without any inner fenders, and there is a reason for that - the inner fenders stop air flow from exiting the engine compartment. But I LOVE THEM - STREET CAR BROTHER!!!!

Thank you! Will try all this. The turbo blanket I was told by turbo manufacturer not to install. According to them this could over heat the internals and cause damage . Wrapping the pipes and stuff is ok. The coolant reservoir is temp, unfortunately I have nowhere to put one so I will need to buy another in aluminum and modify itI answered that in previous posts. I'd let it get close to 230 before shutting it down. And that is with the radiator cap installed. Verify that the thermostat is opening via heat gun on the radiator pipes and watching the coolant temp on the 3.5" handheld. Once you shut the motor off - do not touch it until the coolant temp is down to less than 110-120 degrees and less than 100 is even better. Then check the coolant level and see if it took any in - lather rinse repeat until the level in the radiator at sub 120 degrees is the same on every check.

During this process, if you cannot tell when the thermostat opens via temperature readings on every warmup and cooldown cycle, then you have an issue causing the overheat condition.

I re-read all of this thread as it seems that you still have the issue and we are repeating some of the same info. I did more than just glance at your engine bay photo. You need a turbo blanket unless you don't mind having your inner fender and coolant reservoir getting melted. Wrapping the headers and bellows pipes helps as well, but wrapping those headers is a pita unless you remove them. You'll find that most guys running up and forward headers are running them without any inner fenders, and there is a reason for that - the inner fenders stop air flow from exiting the engine compartment. But I LOVE THEM - STREET CAR BROTHER!!!!

Heat soak is the issue. A blanket will move the heat out the downpipe. The turbo will reach temps that are never seen in a factory application.Thank you! Will try all this. The turbo blanket I was told by turbo manufacturer not to install. According to them this could over heat the internals and cause damage . Wrapping the pipes and stuff is ok. The coolant reservoir is temp, unfortunately I have nowhere to put one so I will need to buy another in aluminum and modify it

I don’t know what turbo you have, but I’ve never heard of anyone indicating that a turbo blanket will hurt. I’ll agree that one isn’t needed if you have an open engine bay, but you don’t. I’ve melted 3 inner fenders in error - changing them sucks if you want you engine bay to look nice.

Similar threads

- Replies

- 1

- Views

- 203

- Replies

- 6

- Views

- 255

- Replies

- 3

- Views

- 426

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.