And finally, in a response to an earlier request for pictures.................................................

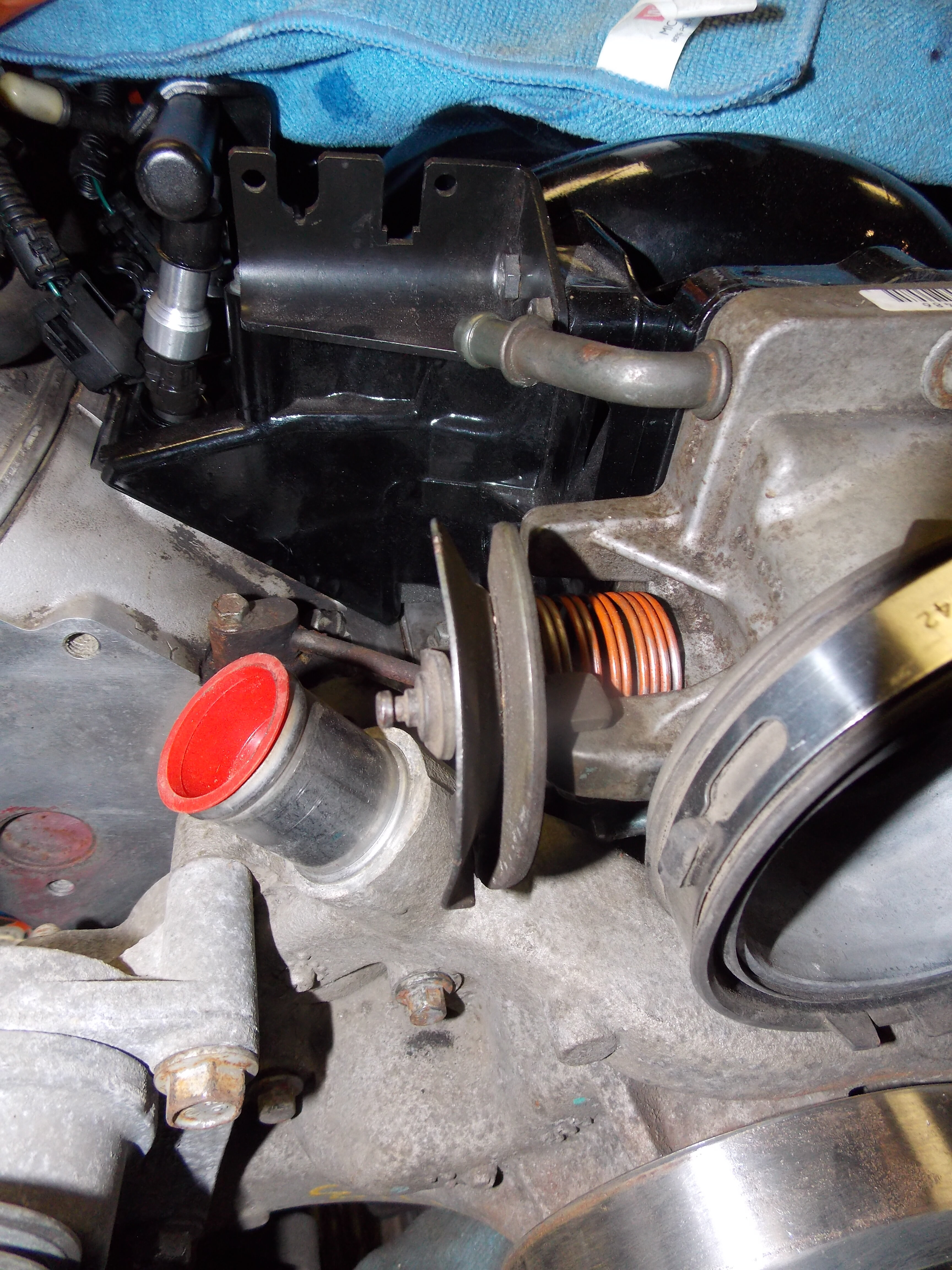

So these are a pair of shots of the replacement pump that I had hoped to use on my Orpan LS project. This particular model is the truck version. and, clearly shown, the return pipe. At this point the test fit of this pump was already declared a failure and it has been removed from the front of the engine. The culprit is the return nipple because, sitting as it does at the 12 O'clock position, any attempt to move the V-sheave for throttle body butterfly actuator shaft causes the pivot pin for the cruise control to crash directly into the tube.

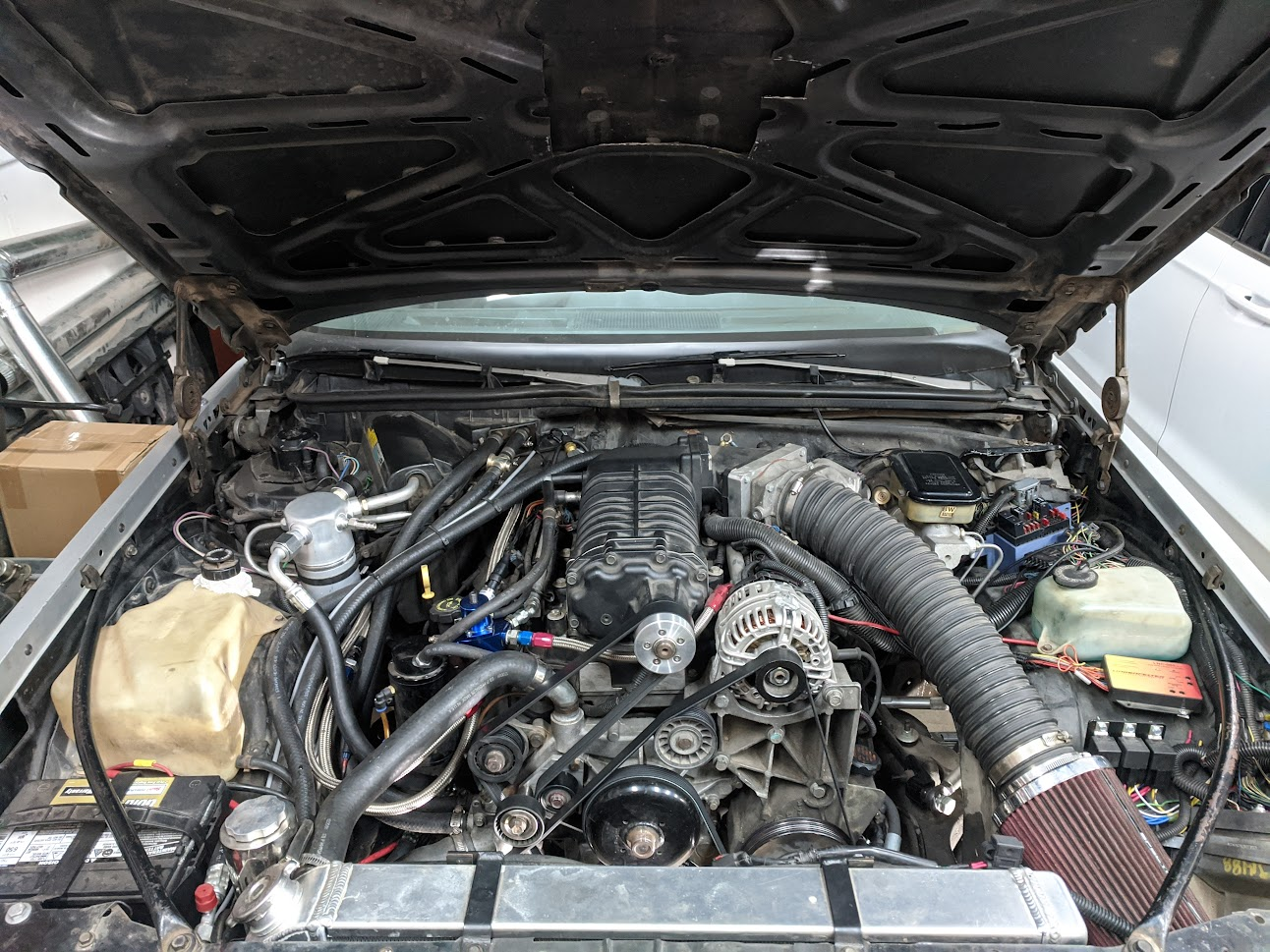

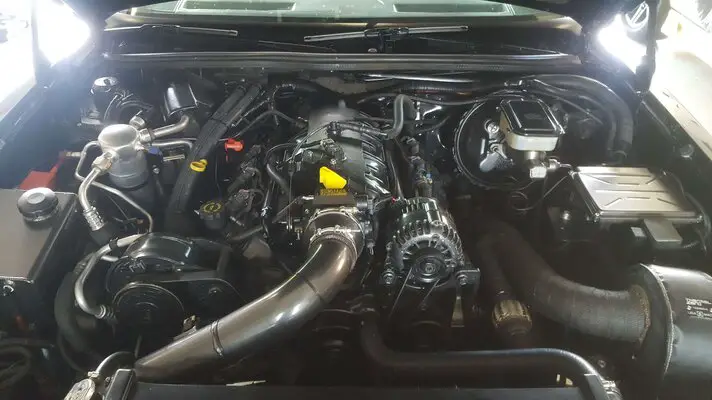

This is my chosen alternative, the 2007-2013 Sierra 1500 version of the water pump. Instead of being located at 12 O'clock, the return tube is laid over and moved slightly to rest at around the 10.30-11.00 O'clock position. In that position, there is enough clearance room between the throttle body and the return that they can and do get along. There is a small nipple on the bottom of the throttle body that wants to come kissing close but I think with a little butane persuasion it can be deflected just enough to be able to put a hose or a block off cap on it.

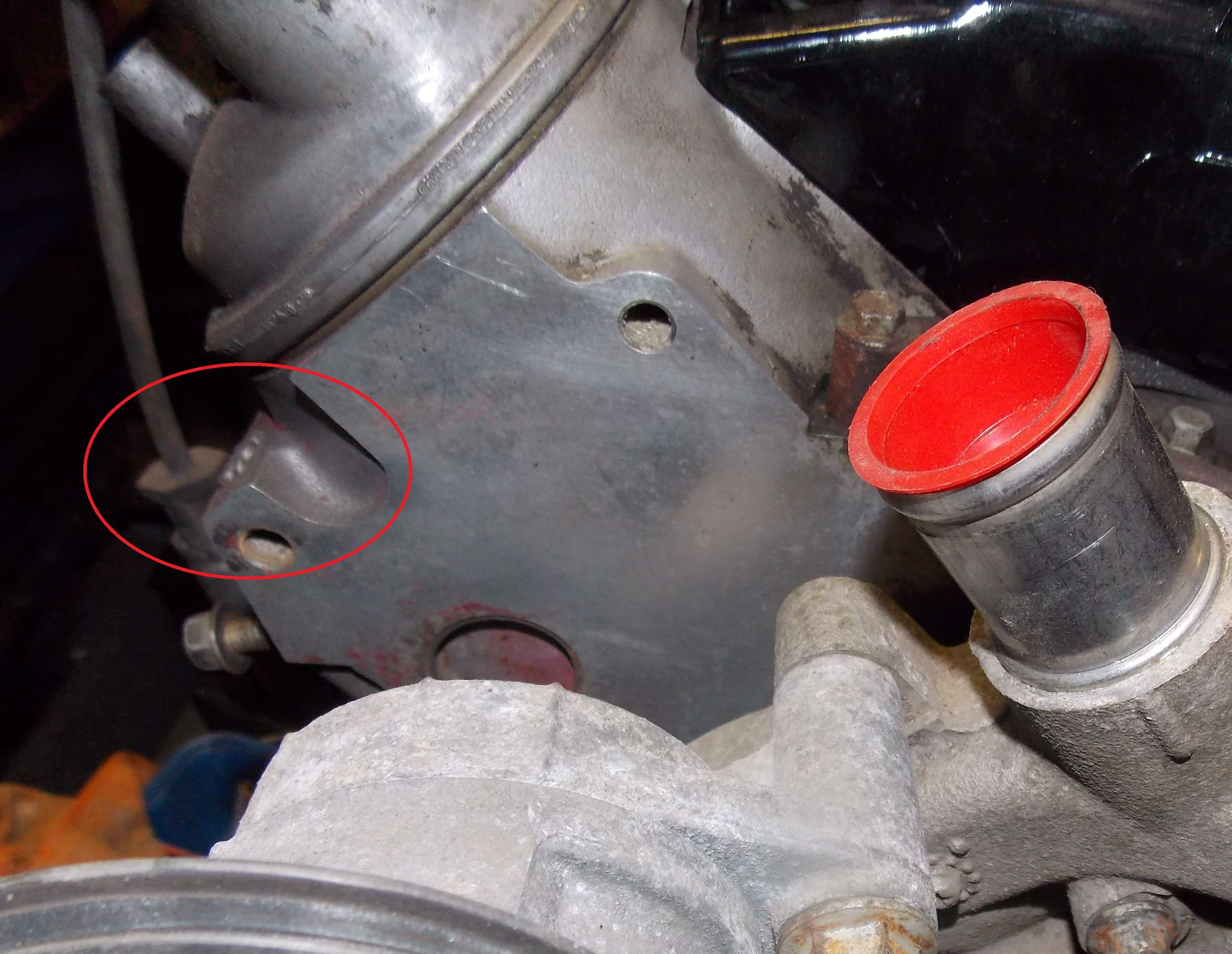

In this detail shot you can get a better perspective in regard to the desired relationship between the return nipple and the pivot pin for the cruise control. No touchy-no feely.

And a second detail shot. This one shows the mounting bracketry on the LS-6 manifold for the throttle cable, cruise control cable, how they line up with the throttle body, and how the change in the location of the return line on the Sierra version pump puts everything into a place of its own with no arguments over location. The cute red caps are hydraulic block off items and are great for keeping debris and escaping fasteners from trying to hide.

The principal difference between this one and the F-Body version is that the return line on the F-Body is located at about the 2 O'clock position as seen from the front, and points straight out from the pump body.

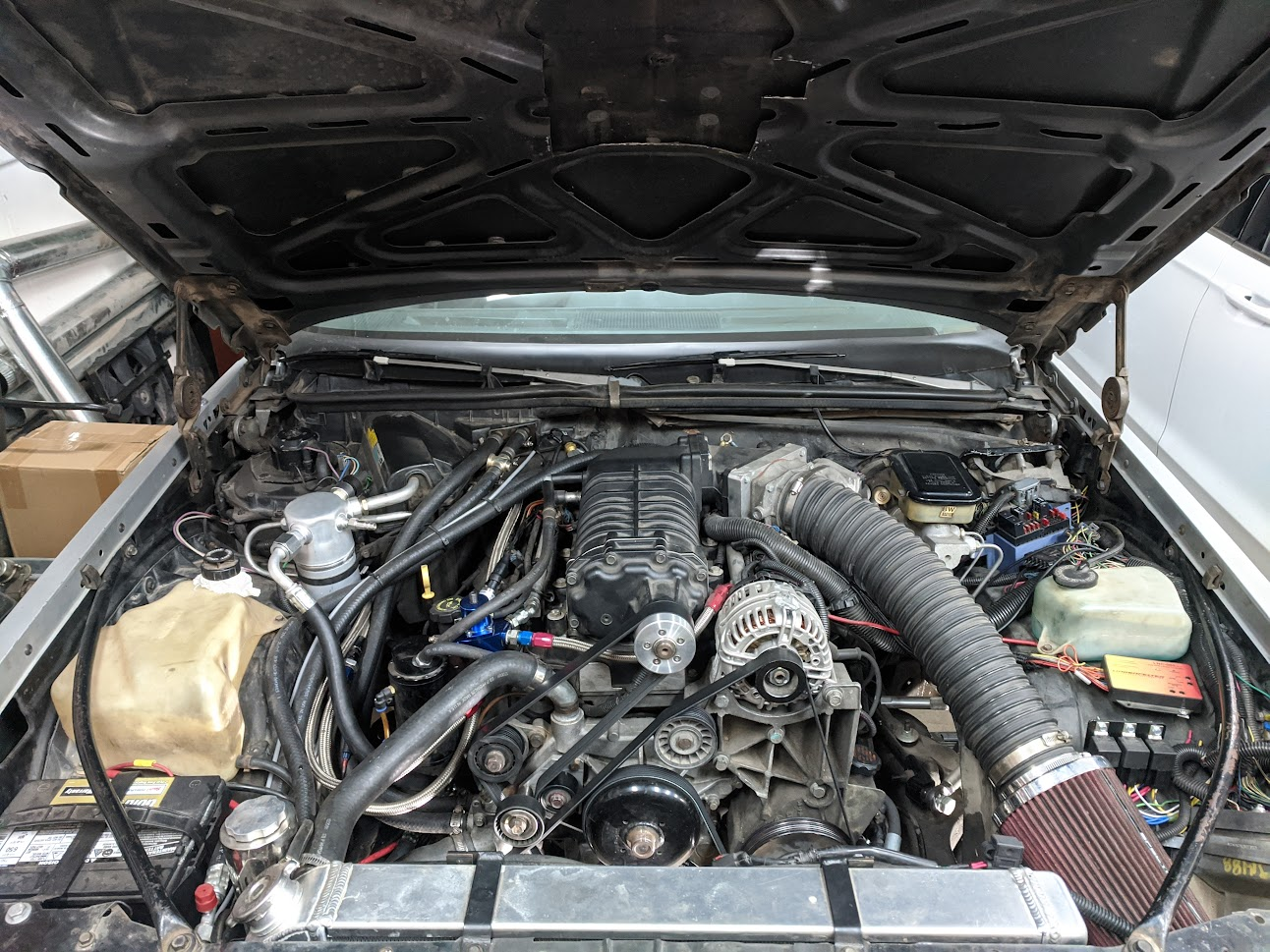

The sierra version that is shown on my engine in these pictures is a "gently used" item from the shelves at my local yard. I was in the area and managed to dodge the rain drops long enough to wander into the counter sales room and ask if, per chance, Jr. had one on the shelf. He did, so I scored that one and will be returning the other one; straight swap, no shuck or jive. For those who might question the use of a previously owned part, it's ultimate fate will depend on my my budget. For now it is a place marker for the process of mocking up the front fascade. I still have to score the driver's side brackets for the alternator and the power steering pump and they may have to come from E-Gay at some point. As I noted previously, the price for a new Sierra version pump is over 3 Bills with the sales tax. The F-Body is closer to 4 !!!!

This Sierra version pump spins nice, not loose, not tight. The pump body needs to be wire brushed and cleaned. I already have new pump to block gaskets waiting for it as well as a new t-stat housing assembly. Apparently the neck and the stat are all one piece for these (Surprise, surprise, surprise!!!!) but the cost to me for a new one is actually quite reasonable. If it turns out that the mystery O-ring is actually a replacement for the existing corpse in the neck casting then I may just extract the old fogie and stuff in the new one; keep the new piece for final assembly. All the idlers on their brackets both bolt up and line up so that is a bonus.

So, and summarily, thanks to all who posted and offered their thoughts. The next step in this chain is to introduce the stock exhaust manifolds to my air driven die grinder for the purpose of shaving off all the casting flash that is left between the tubes. Getting that all cleaned out will make it easier to handle them and keep from getting slashed along the way.

Nick