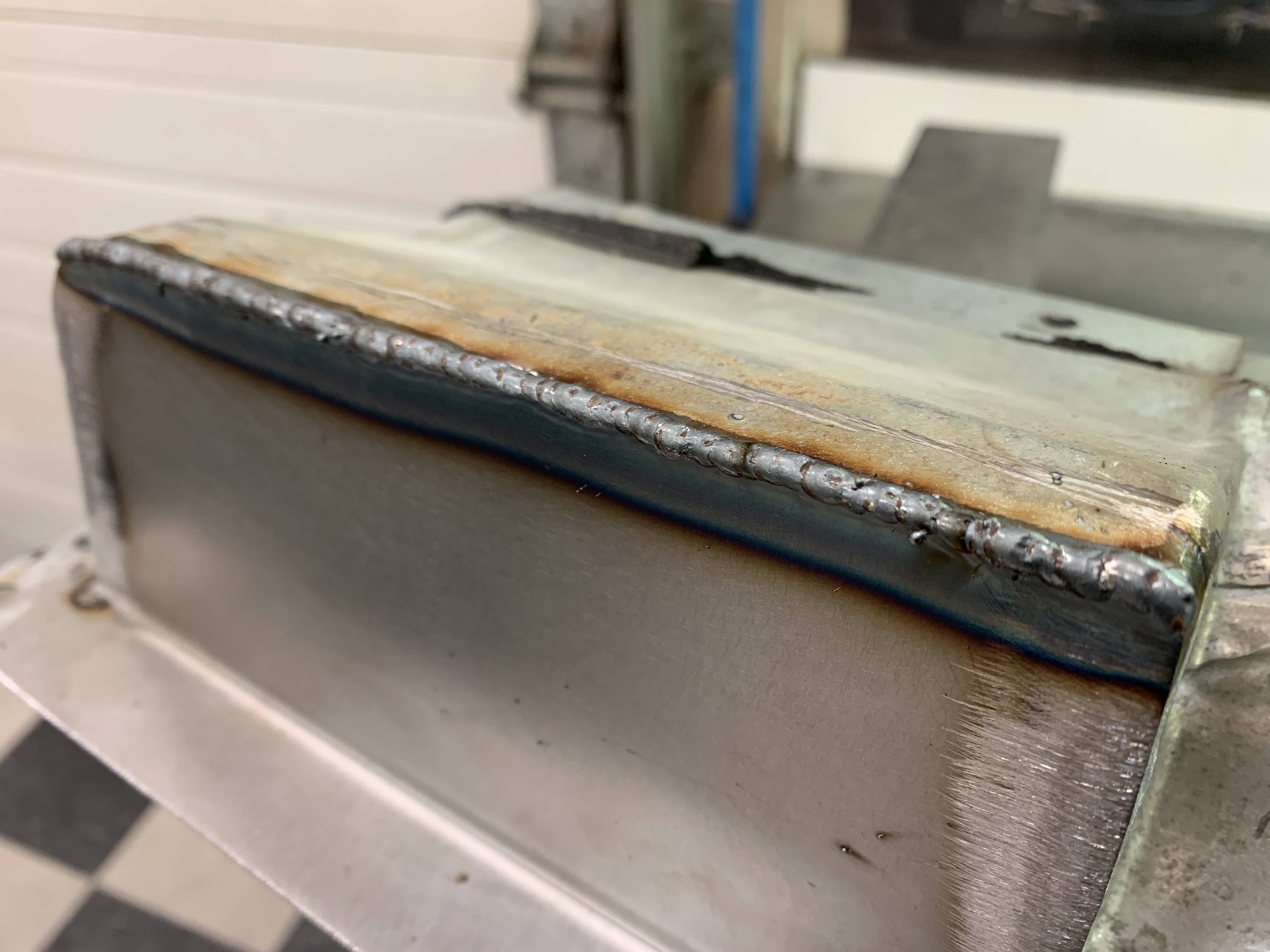

I was stick welding heavy plate steel for several years before I got my hands on a wire-fed MIG machine. I even stick welded several pieces of custom outdoor furniture out of 16ga rectangular tube. I can lay down a pretty mean bead with a stick welder.

When I started working with the MIG on 20ga-22ga sheet, my biggest hang-up was timing. I had to break the habit of striking an arc arc and pausing to let it penetrate. If you do that with thin sheet, you'll blow holes before you even realize what's happening.

The key, for me, was learning how to spot weld quickly and deliberately. Know where the arc is going, get into the trigger, and get out again quickly. Once I figured that out, stitching panels together got a whole lot easier. Now, I just need more practice. But that's OK, because the practice is fun. The tedious part is dressing the welds down to smooth out the body panels.