The old Doug Nash 4+1 started getting hard to shift last year and at first I thought it was the clutch.

I thought about it all winter and realised that I didnt want to pull the transmission until I checked into it further.

So I looked at excess play in the clutch linkage to start.The holes in the Z Bar for the clutch pedal and clutch fork pushrods were showing signs of wear.

I took the Z Bar out and took it and both pushrods to my favorite machine shop for Jim George to have a look at.

He decided on a course of action to fix my problem. Jim thought that a heim joint on the clutch fork pushrod would be a good idea,and I just happened to have one as they are what I use as sway bar endlinks.

Jim made a new clutch fork pushrod from some Grade 8 fine thread rod,with the heim joint on one end and a 1/2 inch ball bearing silver soldered on the other end.The ball bearing is there to prevent the pushrod from wearing a hole in the fork where it seats.

On the pedal end he made a bushing and spot welded it so it cant come out.

All this removed the excess play,which was really bad.

I got it back together yesterday and went for a short drive and so far it is shifting much better,although a slight adjustment is needed.

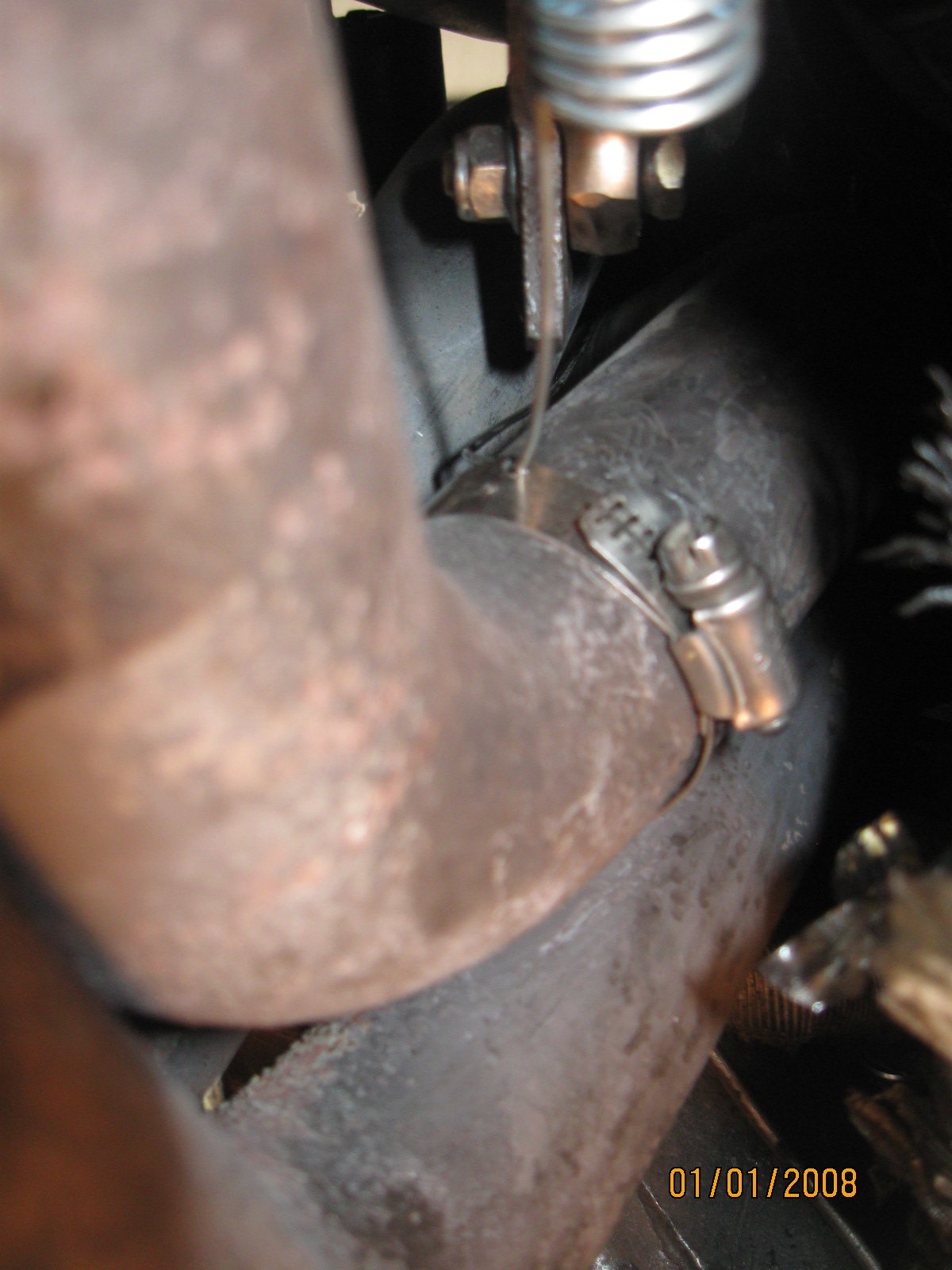

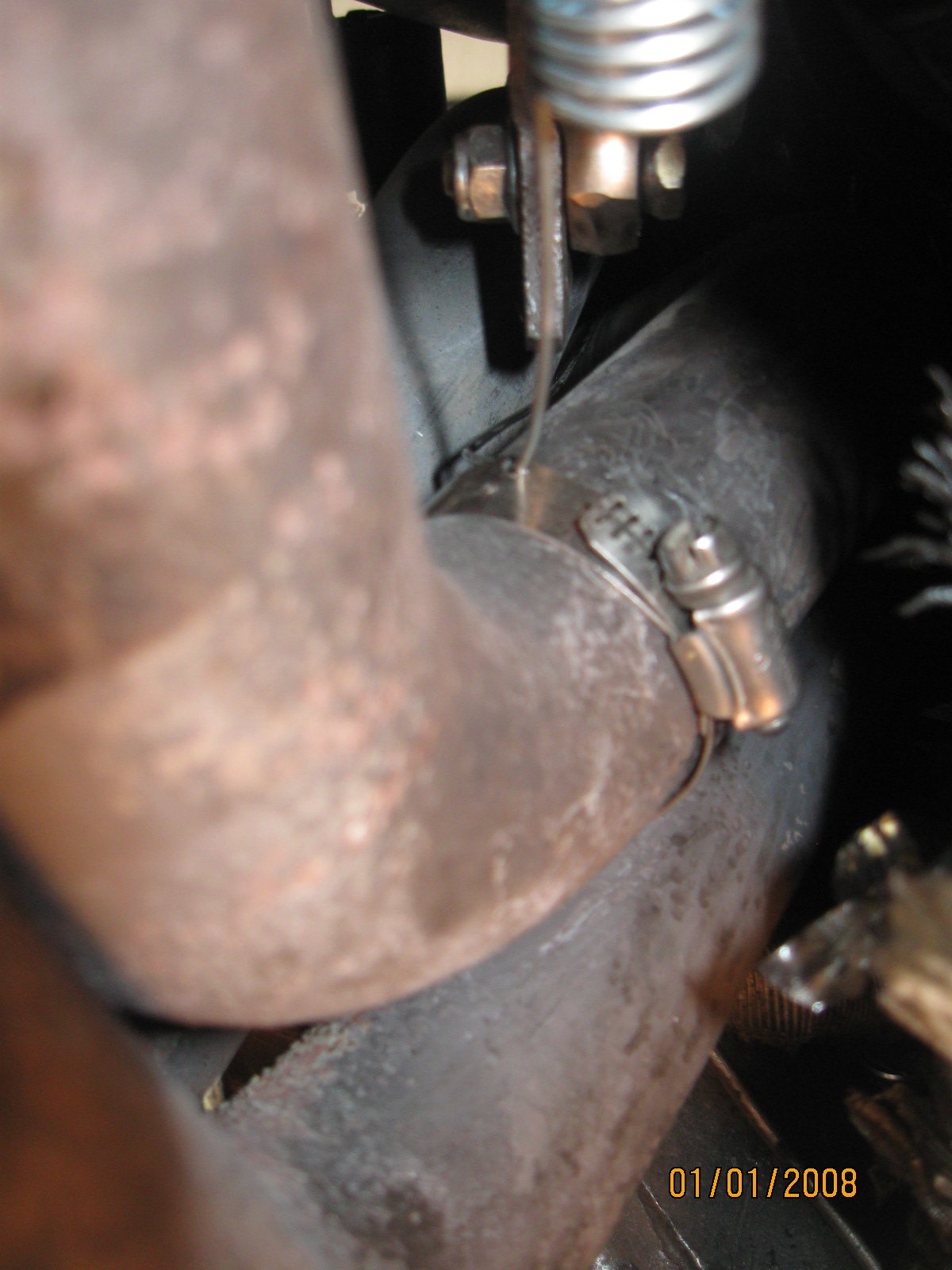

I also hooked up a return spring to the clutch fork,as it was just MacGyvered from before I bought it.

I had read about someone using a hose clamp on a header tube as a secure point.I got a universal return spring and a hose clamp and now I have a return spring hooked up.The fork had a hole on the topside which was in the wrong location so I drilled a new hole on the bottom for it.

Heres some pictures.

The first two show the way too much play.

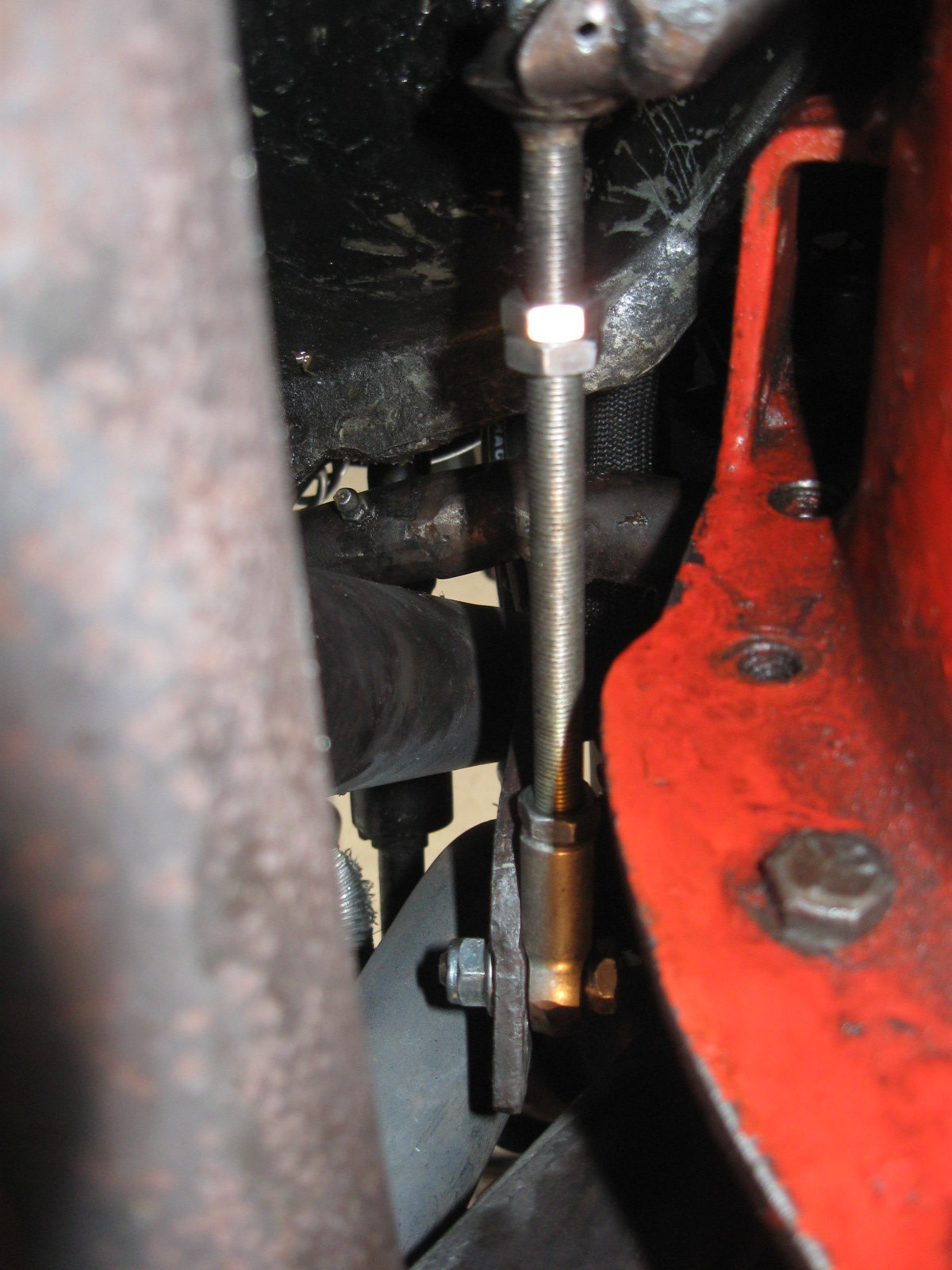

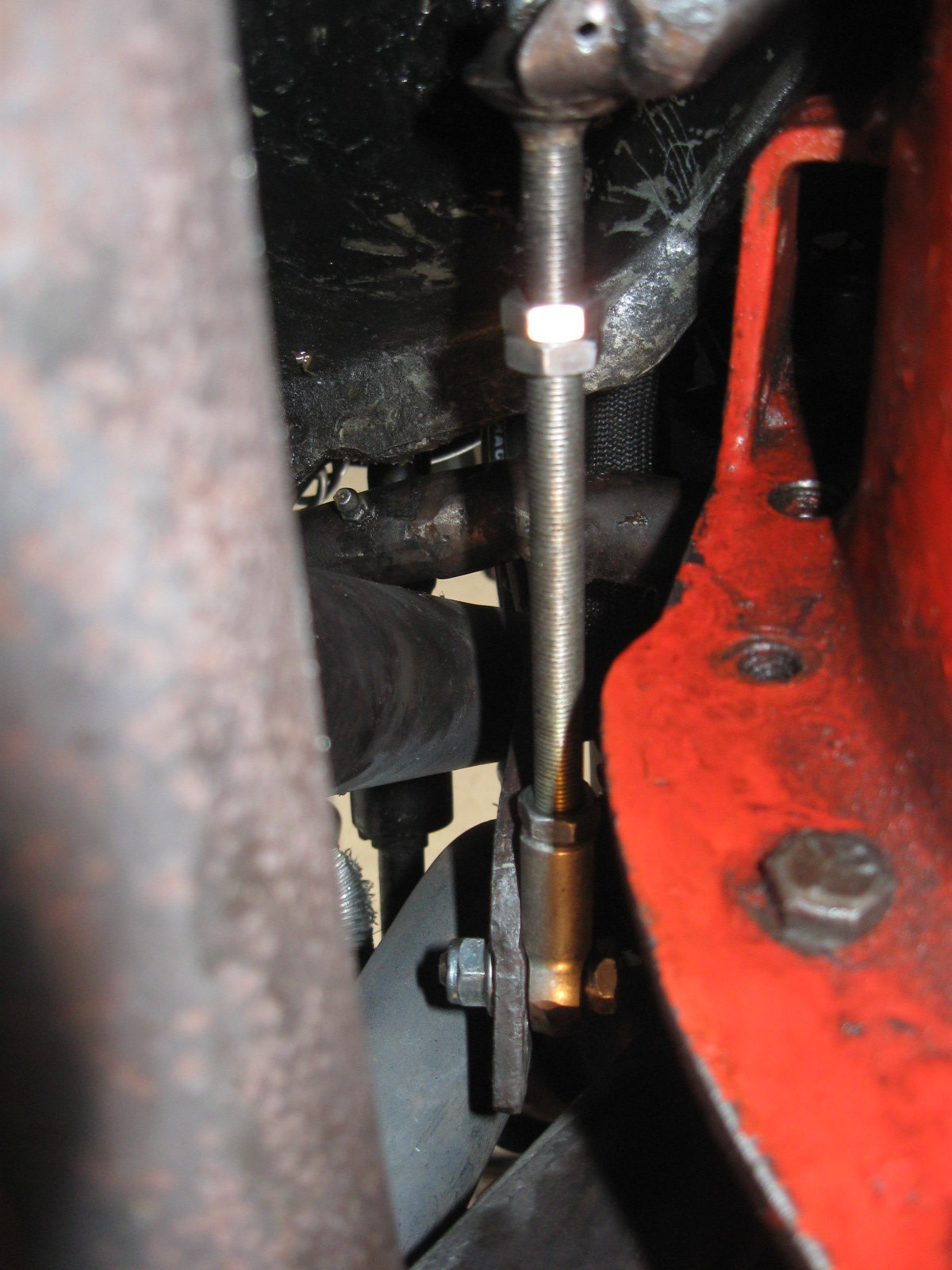

Now here it is all fixed up

Here it is installed.

Guy

I thought about it all winter and realised that I didnt want to pull the transmission until I checked into it further.

So I looked at excess play in the clutch linkage to start.The holes in the Z Bar for the clutch pedal and clutch fork pushrods were showing signs of wear.

I took the Z Bar out and took it and both pushrods to my favorite machine shop for Jim George to have a look at.

He decided on a course of action to fix my problem. Jim thought that a heim joint on the clutch fork pushrod would be a good idea,and I just happened to have one as they are what I use as sway bar endlinks.

Jim made a new clutch fork pushrod from some Grade 8 fine thread rod,with the heim joint on one end and a 1/2 inch ball bearing silver soldered on the other end.The ball bearing is there to prevent the pushrod from wearing a hole in the fork where it seats.

On the pedal end he made a bushing and spot welded it so it cant come out.

All this removed the excess play,which was really bad.

I got it back together yesterday and went for a short drive and so far it is shifting much better,although a slight adjustment is needed.

I also hooked up a return spring to the clutch fork,as it was just MacGyvered from before I bought it.

I had read about someone using a hose clamp on a header tube as a secure point.I got a universal return spring and a hose clamp and now I have a return spring hooked up.The fork had a hole on the topside which was in the wrong location so I drilled a new hole on the bottom for it.

Heres some pictures.

The first two show the way too much play.

Now here it is all fixed up

Here it is installed.

Guy

Last edited: