We went for our drive today,and everything worked real good until we were almost home.

While slowing down and downshifting for construction,the clutch pedal went hard to the floor.

I was able to drive home using the starter and starting in gear a couple of times.

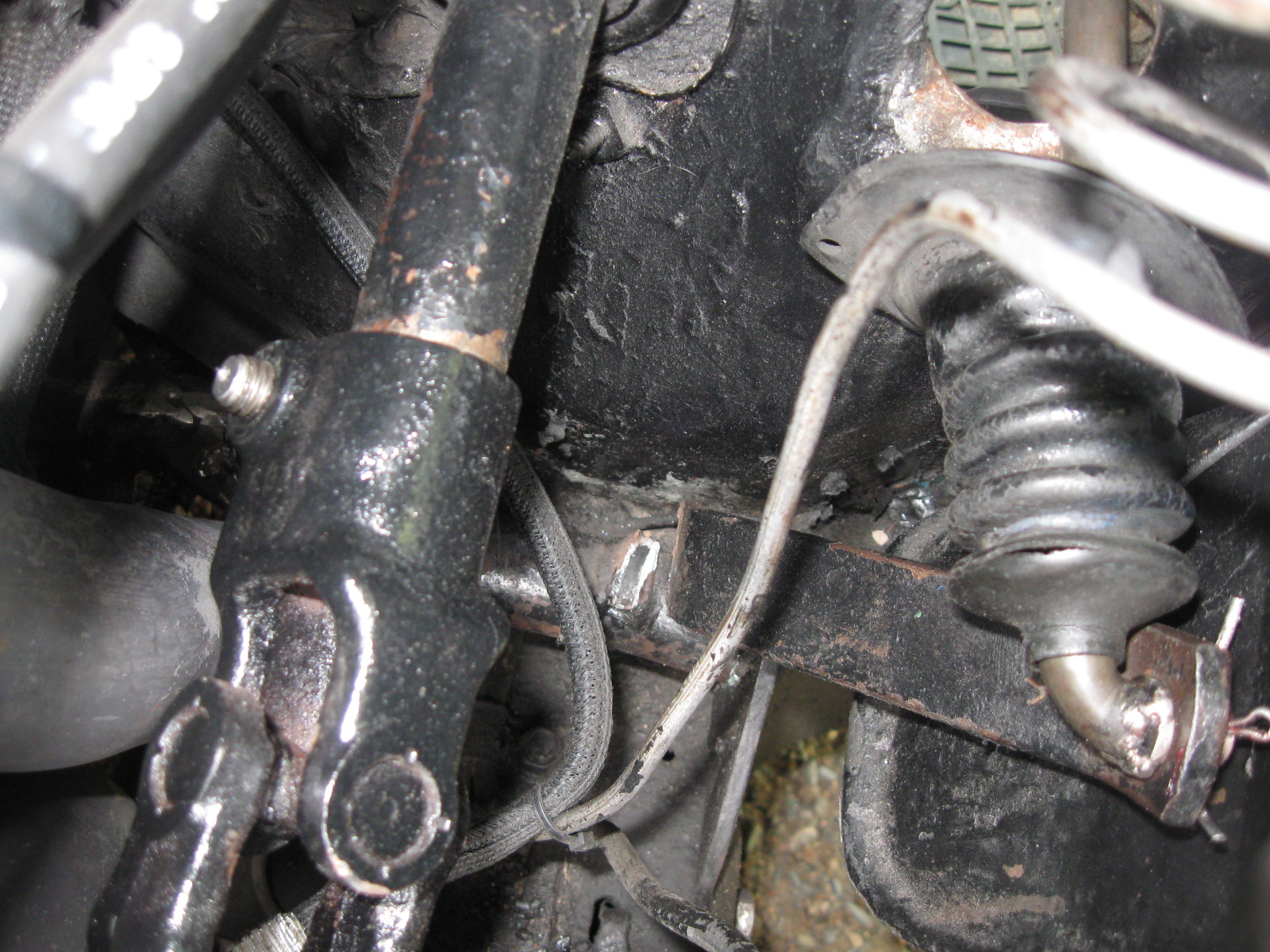

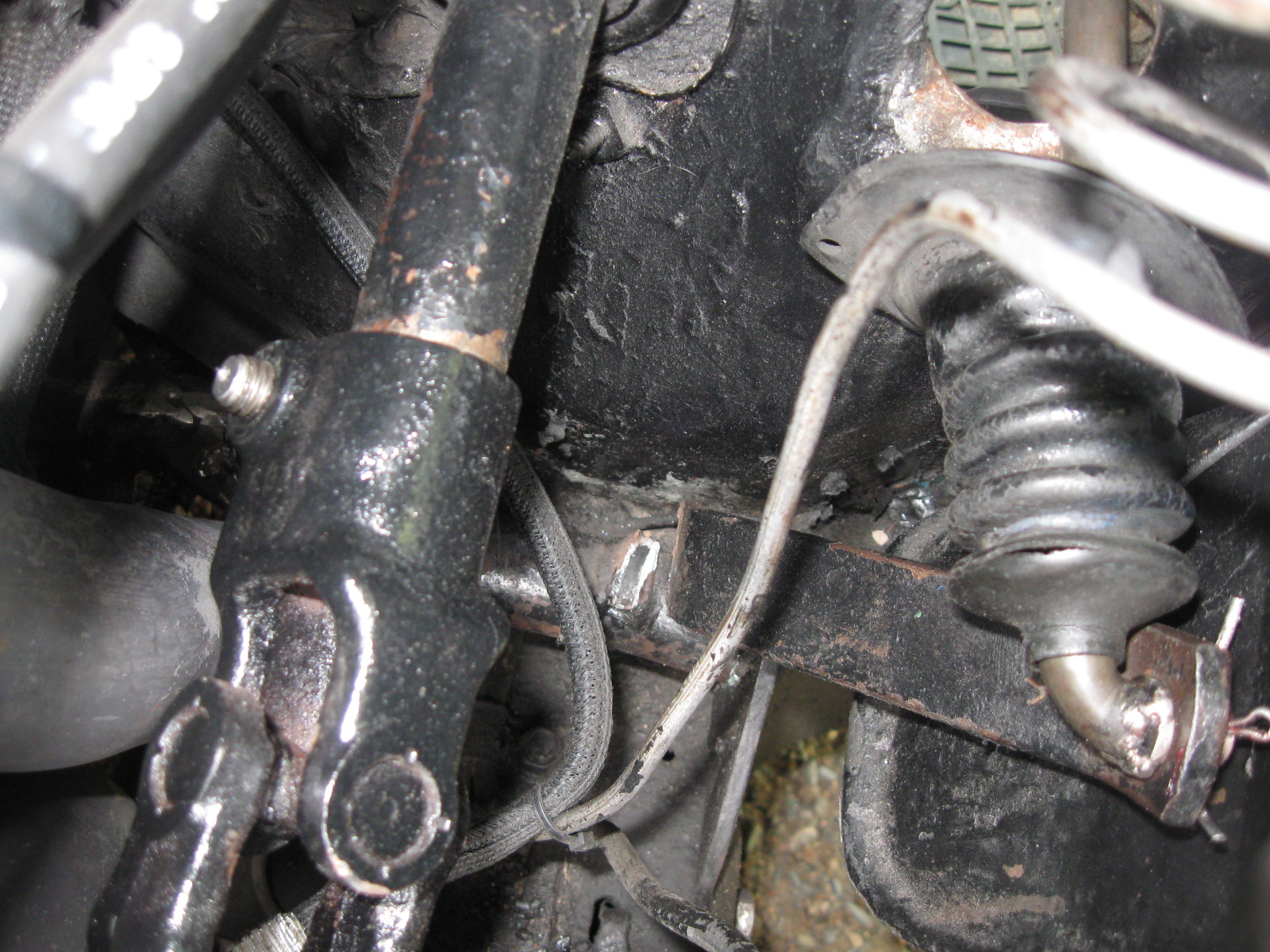

The bracket that goes from the clutch pedal pushrod to the Z Bar broke off at the weld..

Not too big a problem,my buddy Mark is going to give me a hand to fix it up tomorrow.

Guy

While slowing down and downshifting for construction,the clutch pedal went hard to the floor.

I was able to drive home using the starter and starting in gear a couple of times.

The bracket that goes from the clutch pedal pushrod to the Z Bar broke off at the weld..

Not too big a problem,my buddy Mark is going to give me a hand to fix it up tomorrow.

Guy