I did quite a bit of research on different hx configurations. At the end of the day, the bumper bar and cover won’t allow many of the options. I was close on doing one behind the grille and one on each side of the front frame horns like you mentioned. Based on the space available, the total frontal area didn’t match what I’ve got now. Ducting the air and mounting would be trickier too, so i took the easy way outDid you ever think of going with a different hx set up with them both at the ends of the bumper with ducting or air dams to force the air to them? Even could be mounted to the ends of the inner bar.

BUILD THREAD Project Over The Top - Malibu T-Top Conversion

- Thread starter superbon54

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

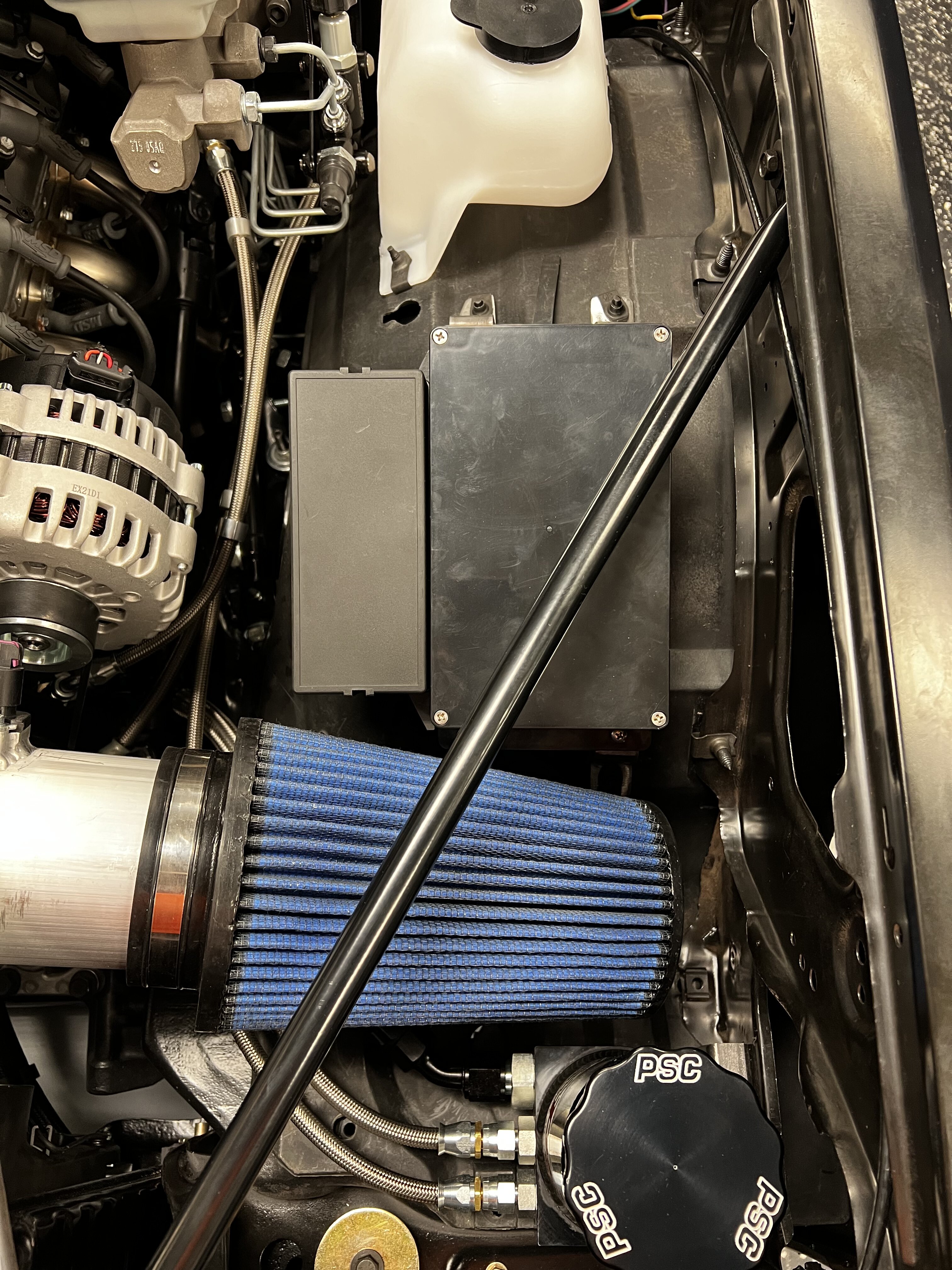

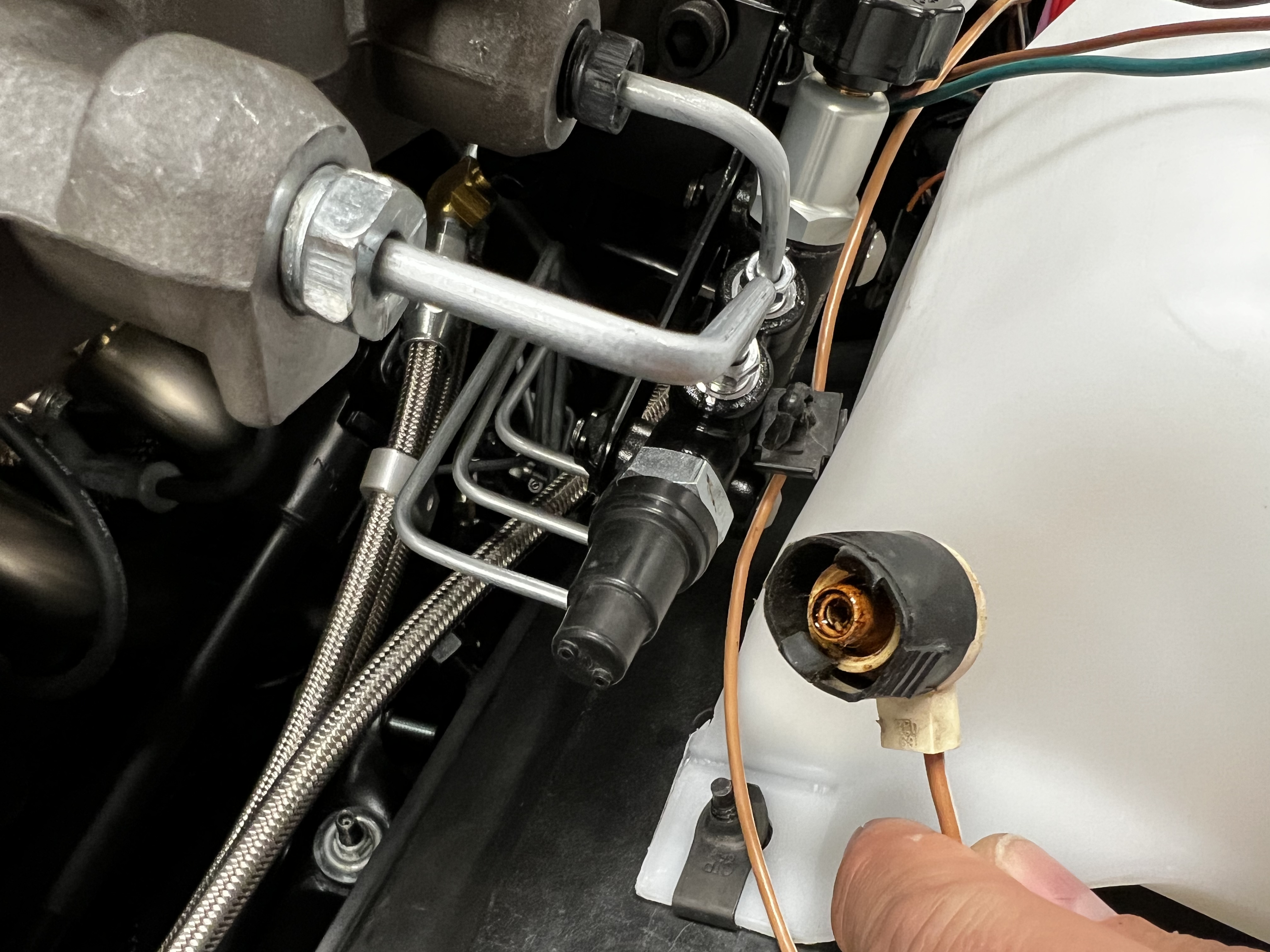

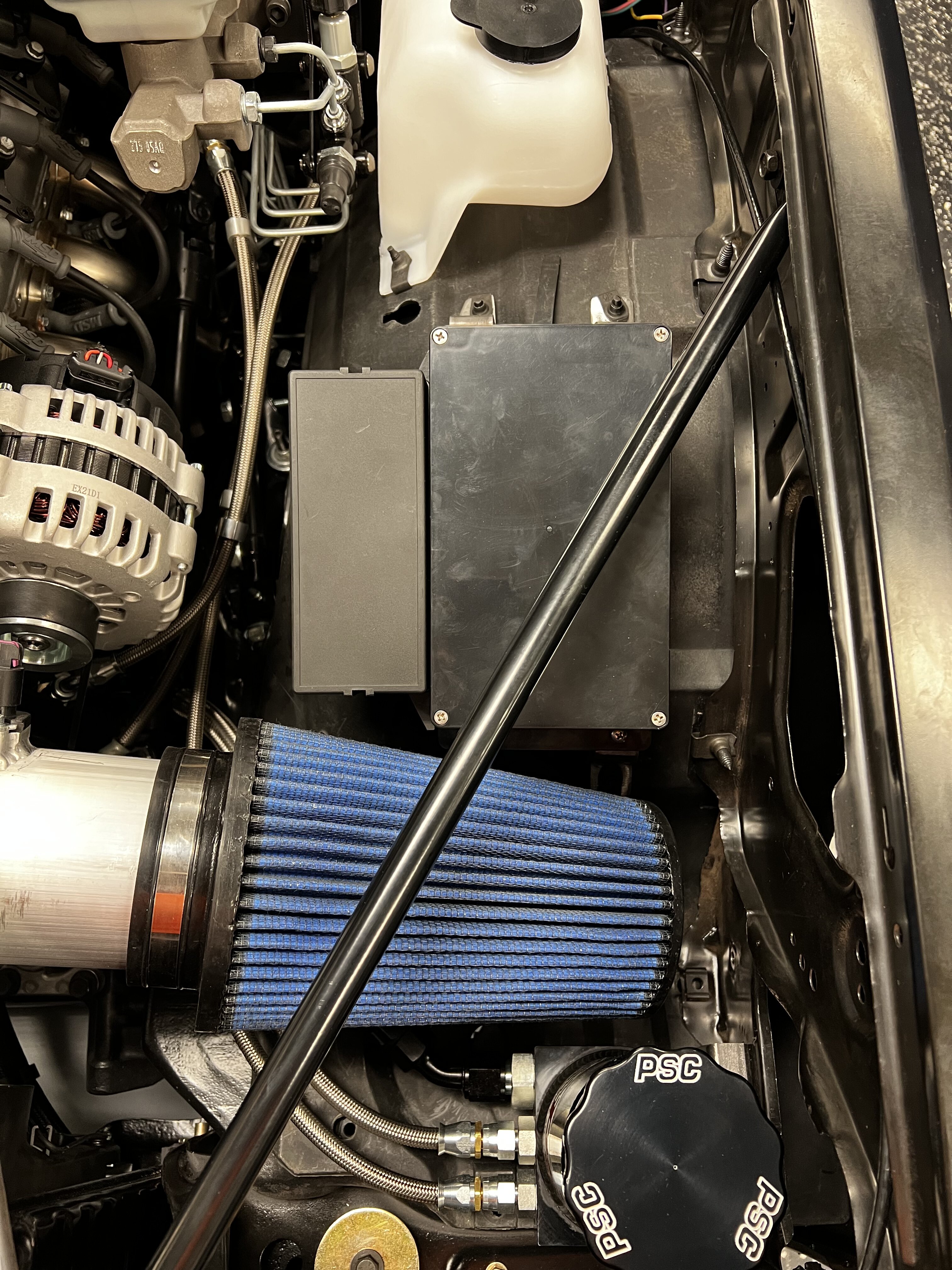

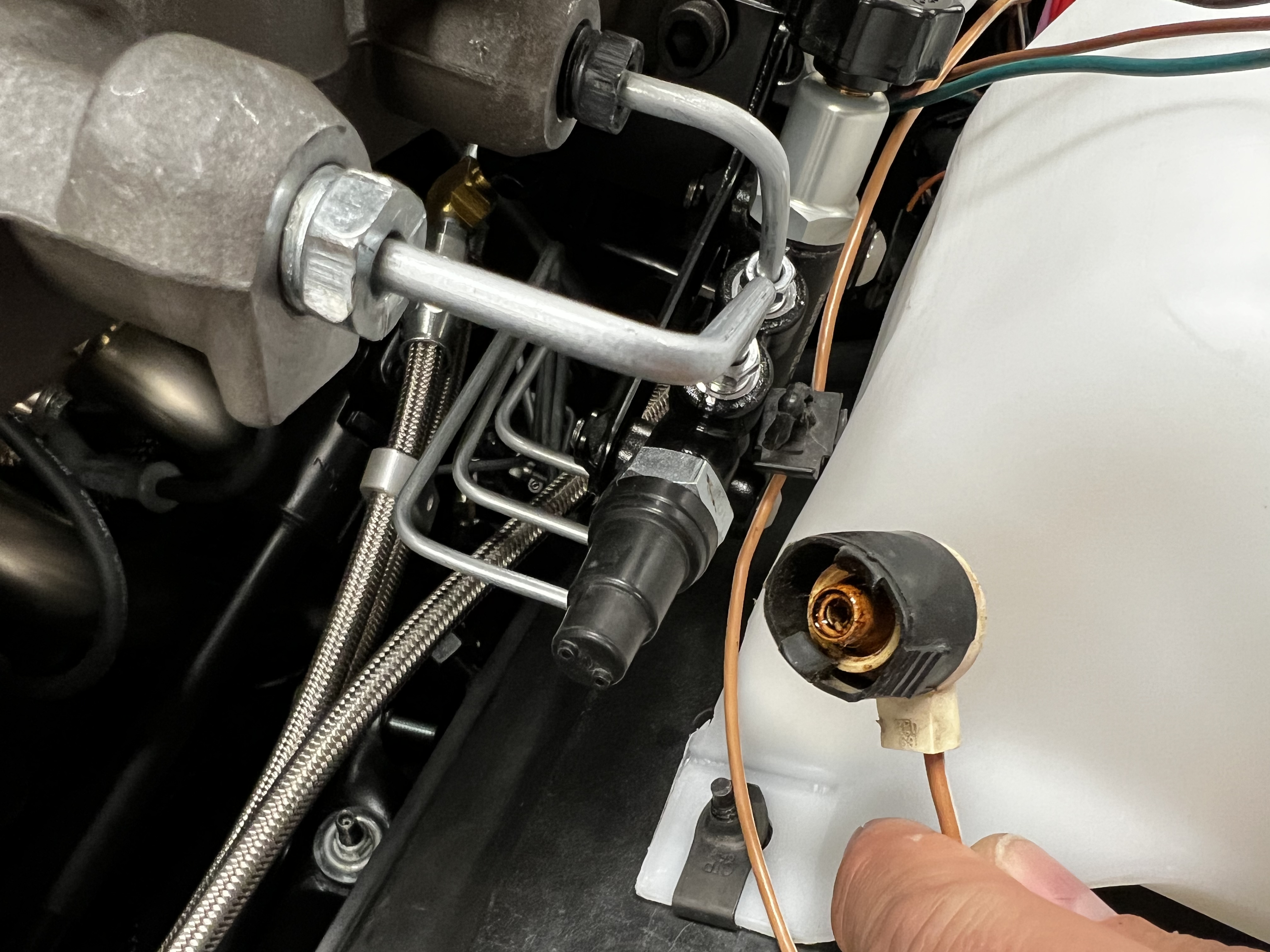

In between thanksgiving festivities and decorating for Christmas, I was able to knock out a few things. I fabricated mounts and installed the oil cooler. I’m going to fabricate some ducting for it, but that’ll come after all body parts and the splitter are installed. I also mocked up the hx pump and hogged out the core support to make way for the upper hose. Fun fact - my 7 year old cut the bracket out using the plasma cutter and did most of the welding. Not bad for a beginner!!

I also fabricated brackets for my under-hood electrical distribution, fuses and relays.

I’m waiting for 3 more fittings to complete the hx plumbing, so I’ll tear everything down and paint the cure support, brackets and widgets that need it before final installation.

Moving onto electrical, I could use a little help from the commentariat. The factory under-hood harness is from an 85 or 86 El Camino. First the brake wire. I’m assuming I can crimp a spade and connect the other side of the Wilwood switch to ground?

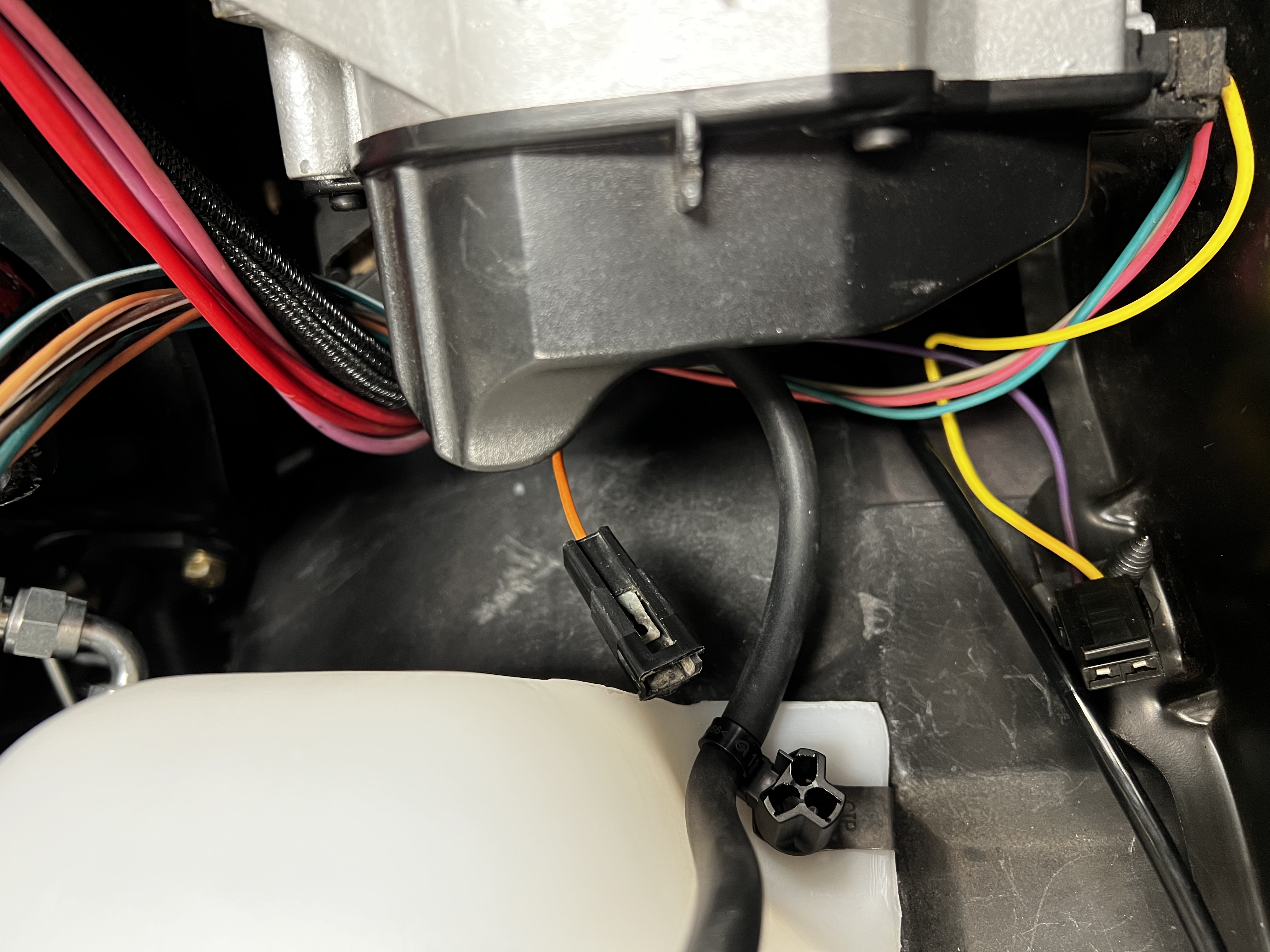

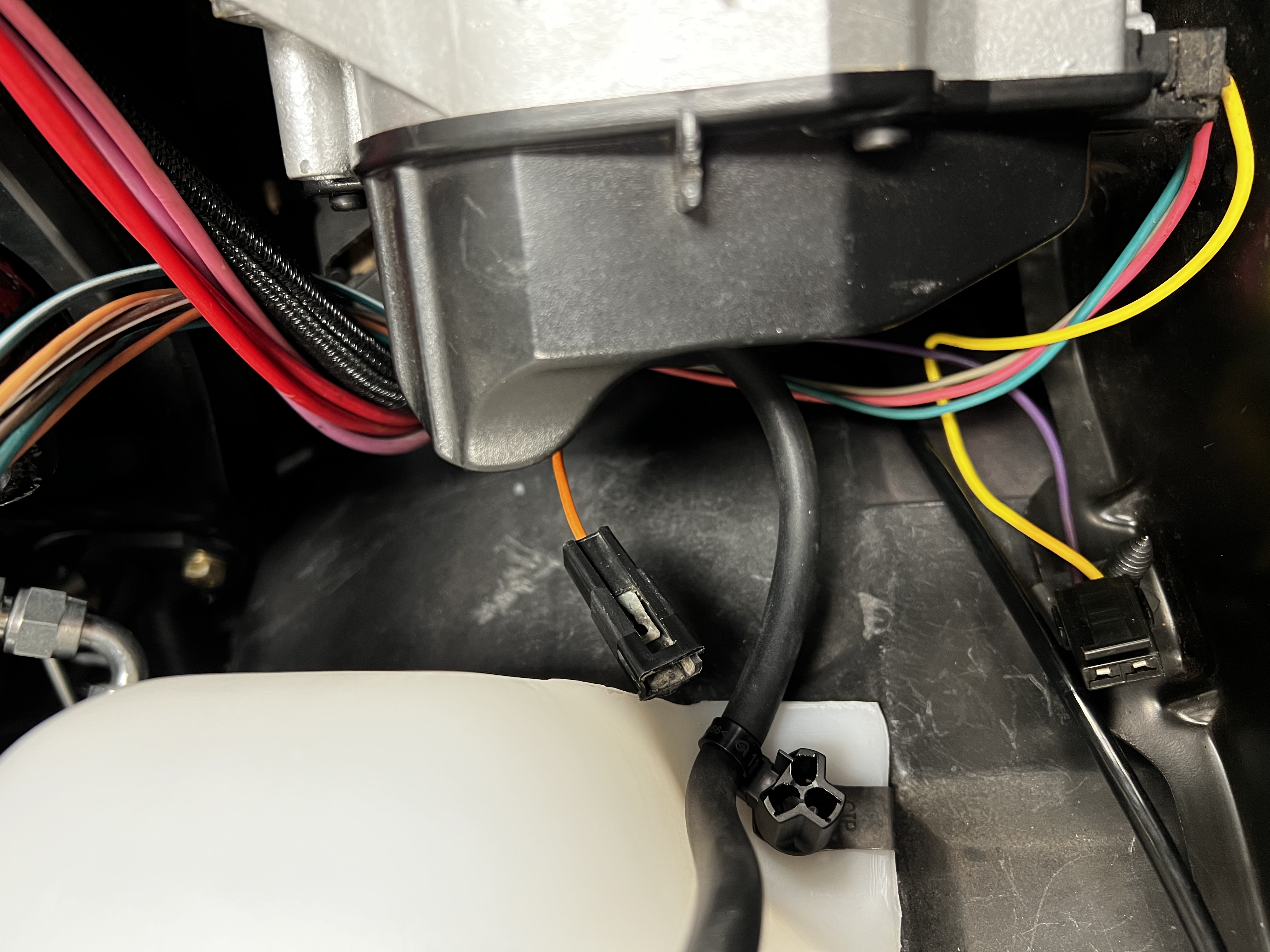

Next are connectors near the wiper motor. I don’t know what either of these do? Factory cruise or washer fluid level maybe?

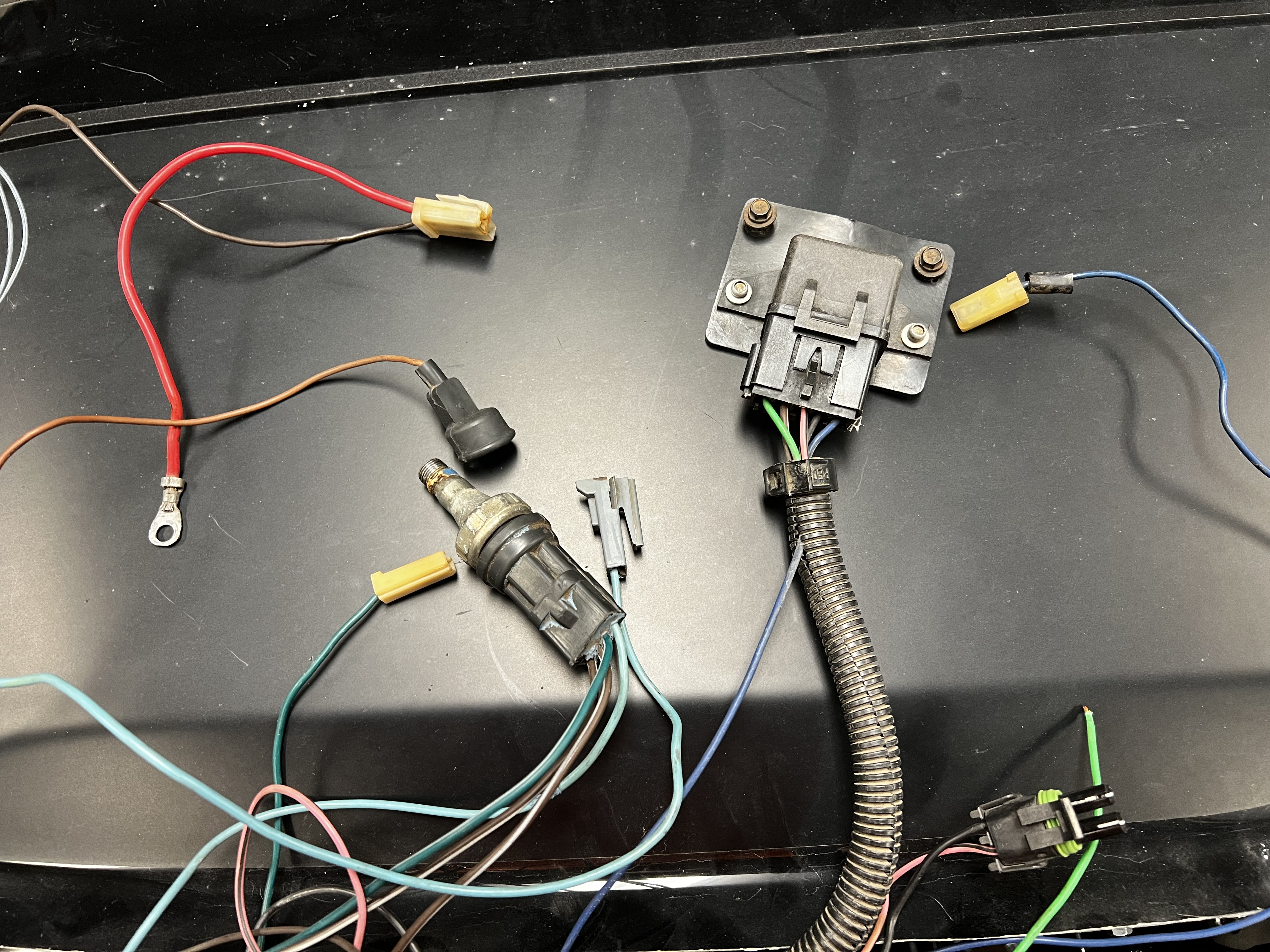

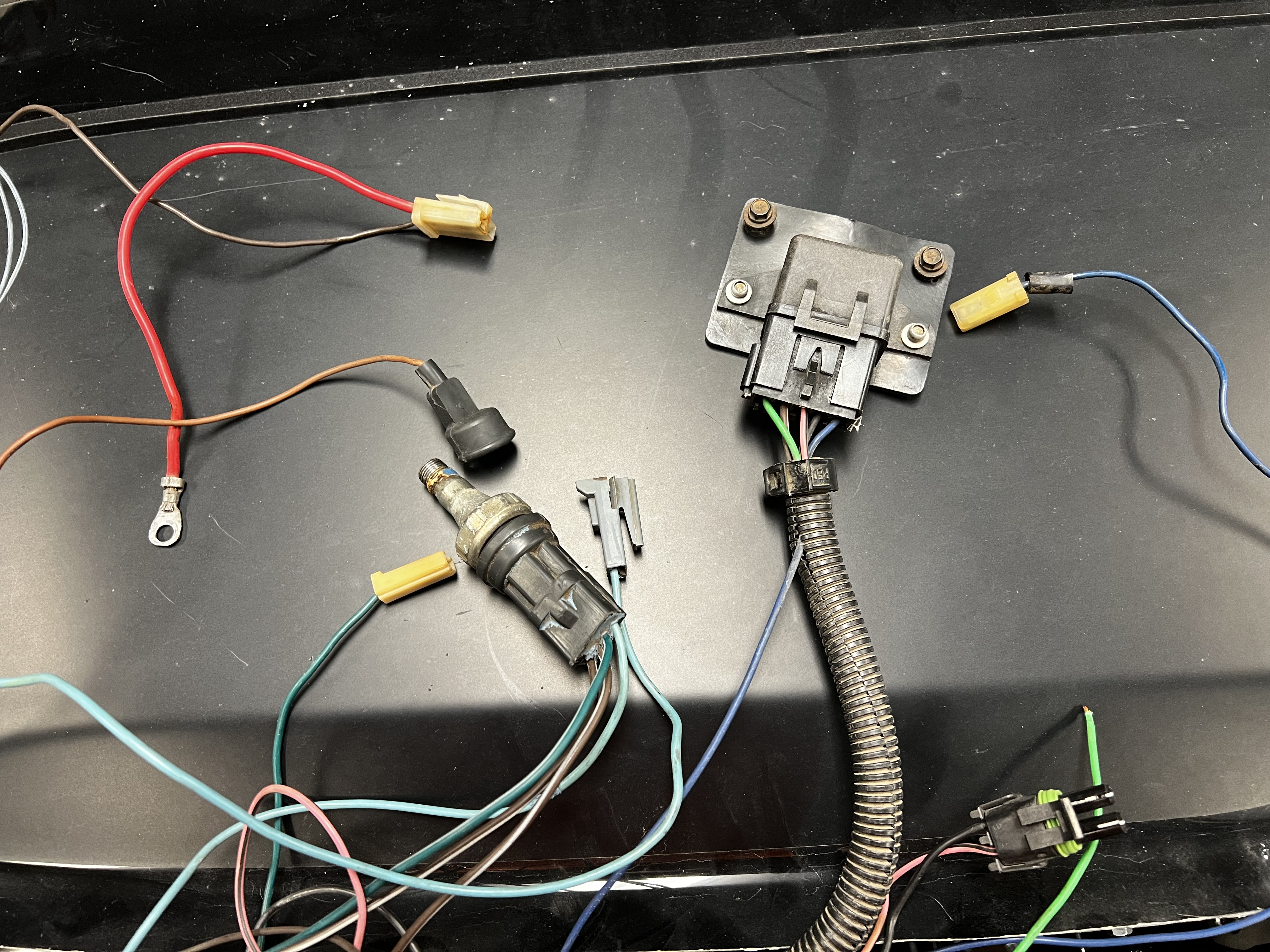

Finally some engine wiring. I assume the brown wire on the alternator connector is for the volt gauge? I know the oil sender and am assuming the blue or green is water temp, but not sure what the other is. As for the light blue, green and tan wires and the relay and weather pack connector, I assume they are all emissions related?

I have a speartech harness for the engine and it has flying leads that I’ll plug into the DD RTX gauges, so I don’t need any of the factory wiring for those.

I also fabricated brackets for my under-hood electrical distribution, fuses and relays.

I’m waiting for 3 more fittings to complete the hx plumbing, so I’ll tear everything down and paint the cure support, brackets and widgets that need it before final installation.

Moving onto electrical, I could use a little help from the commentariat. The factory under-hood harness is from an 85 or 86 El Camino. First the brake wire. I’m assuming I can crimp a spade and connect the other side of the Wilwood switch to ground?

Next are connectors near the wiper motor. I don’t know what either of these do? Factory cruise or washer fluid level maybe?

Finally some engine wiring. I assume the brown wire on the alternator connector is for the volt gauge? I know the oil sender and am assuming the blue or green is water temp, but not sure what the other is. As for the light blue, green and tan wires and the relay and weather pack connector, I assume they are all emissions related?

I have a speartech harness for the engine and it has flying leads that I’ll plug into the DD RTX gauges, so I don’t need any of the factory wiring for those.

I'll hit the easy first, the single orange is to power the OE under hood light. The brown wire will either go right to the VOLT light or to the resisitor wire in gauge cars. For the oil switch you have in the pic is for a gauge set up so the green/white wire will go to the amber CHOKE light, light blue is/was for the carb's electric choke, the two brown wires will have one go to the CHOKE fuse & the other goes to the CCC IDLE SPEED CONTROL. That single green is the temp wire & single tan is for the oil pressure gauge sender. Now the purple & yellow wire plug should be part of the pulse wiper system. I have no idea what that single blue wire is for.

Awesome thanks! I found a pic of where the purple/yellow connector should go. If it’s not on my wiper motor it looks like rock auto has some remaned ones in stock. Much of the engine wiring won’t be needed, I’ll have to decide if I cut it off or just tuck all out of sight somewhere. I’ll also have to snoop around for what the blue wire is used for.I'll hit the easy first, the single orange is to power the OE under hood light. The brown wire will either go right to the VOLT light or to the resisitor wire in gauge cars. For the oil switch you have in the pic is for a gauge set up so the green/white wire will go to the amber CHOKE light, light blue is/was for the carb's electric choke, the two brown wires will have one go to the CHOKE fuse & the other goes to the CCC IDLE SPEED CONTROL. That single green is the temp wire & single tan is for the oil pressure gauge sender. Now the purple & yellow wire plug should be part of the pulse wiper system. I have no idea what that single blue wire is for.

I didn’t have much time this week, but was able to disassemble and prep parts to spray today. I cheated masking the front of the core support since nobody will see the tape line once the header panel is on. All my AN fittings came in, so when I install everything I can plumb it up too.

You are killin it. And nice garage setup also. I don't know how some of you guys keep it so clean!

Many thanks!! Your build, along with a few others, motivate me to keep pushing my build forward.You are killin it. And nice garage setup also. I don't know how some of you guys keep it so clean!

As far as the garage goes, I saved my pennies for many years flipping cars to build it. My dad is a pack rat and he’s got a really nice shop you can’t even walk through, which I can’t stand. Its also my motivation to keep mine clean and uncluttered. But like all garages, I could use an extra 1,000 sqft or 3

wow incredible. when i 1st looked at your pi in my post i accepted it as a BU but later thought i never seen t top 1 and dug around cuz i didn't recognize the nose as a BU either then couldn't find a 2 dr after 82. now knowing its a 79 makes sense, nice choice in parts the quad lights look much better can't wait to see it done.I've always had a soft spot for the Malibus, and growing up in the 80s, thought t-tops were the coolest thing someone could have on a car. Our neighbor had a t-top cutlass, and I was always a little jealous our 'Bu didn't even have that option. Fast forwarding some years, I started building my current Malibu project and at some point got the bright idea to graft on a t-top roof and live out that childhood dream.

Before cutting up the car, I did some research and learned while the bottom 90% of the A pillars are the same between, the B pillars are completely different and that there are two different B pillar designs on the t-top cars. When it's done, I want the car to look completely stock, so I knew that I would have to do some custom fab work to make it all fit. The donor roof came from a 1986 Monte Carlo.

This picture shows my clean, 1979 tub, braced and ready to go under the knife.

View attachment 73936

I started by cutting the A pillars roughly half way down and took a sawzall to the entire roof right in front of the B pillar. No turning back now!!

View attachment 73937

Next, I cut the front face off the B pillar, leaving the quarter window frame intact. I also cut the inner roof structure back to fit the cross brace on the t-top roof and notched the remaining roof skin to reach the inner structure to weld it together.

View attachment 73938

At this point, I was able to test fit the donor roof section into place. I was starting to feel better, like I might actually be able to pull this off.

View attachment 73939

I tacked the A pillars into place and went to town fully welding the donor B pillar to what was left in the Malibu. I measured 100 times for each weld to ensure the roof was square and that all dimensions were correct to the templates I created before I cut the roof off the Monte. The bracing lined up almost exactly between the two, and the biggest challenge was matching up the inner structure of the B pillars. The factory Malibu pillar ends about an inch further back than the Monte, meaning the Monte B pillar is more upright than the Malibu. The seatbelt mount was put in the correct position for a Monte to allow less customization required on interior parts. The picture below shows the inside after welded, along with my garage pal. He's now old enough to understand what tools are what (and how to get beer out of the fridge) so he makes a great gofer, and loves to spend time in the garage.

View attachment 73941

I was going to weld the two halves of the A pillars together, but could not for the life of me get either one of them straight, using the windshield and side trim as a guide. I decided to spring for new A pillars, and found that the front header panel was reproduced as well. Mine didn't have any holes, but did look a little crusty even after being dipped. I drilled out what felt like 200 spot welds, most of which in the header, to remove the components and welded the new ones in. I was amazed how much seam sealer was used to cover questionable welds at the base of the A pillars. The header had a spot weld every inch or so, and the base of the A pillar had maybe a half dozen total holding it to the firewall, some of which popped off without drilling out. I put in some extra welds both on the outside and inside for good measure. For aftermarket parts, I was actually impressed with the fit. Only the A pillars needed the fender hole oblonged to align properly, and that may be because they aren't actually meant for the car. View attachment 73942

View attachment 73943

View attachment 73944

With the structural work done, I changed focus to working on the frame. The tub will be going in to be acid dipped this winter, and when it returns, I will have the cosmetic work completed. I will pay someone to do that, as it's above my abilities and available time. The bottom of the B pillar skin will need to come in about 1/4" to match the character line found on the Malibu. The steel around the quarter window will be finished, removing the drip rail and closing off clean to the window. The roof transition is different between the two, so I will use the sharp crease found on the t-top roof all the way to the C pillar.

In all, the conversion isn't too difficult. The key, as with most in-depth projects is to take your time and wear out the tape measure before welding things together. It's always easier than taking it back apart and redoing it!!

wow incredible. when i 1st looked at your pi in my post i accepted it as a BU but later thought i never seen t top 1 and dug around cuz i didn't recognize the nose as a BU either then couldn't find a 2 dr after 82. now knowing its a 79 makes sense, nice choice in parts the quad lights look much better can't wait to see it done.

Thanks man! I’m trying to make it look factory with mostly factory parts, but obviously not actually be anything that ever came out of a GM plant.

Thanks man! I’m trying to make it look factory with mostly factory parts, but obviously not actually be anything that ever came out of a GM plant.

Last edited:

yeah that's awesome. always liked seeing the 68-72 novas & 73-74 novas mixed and matched, i'm waiting to see a 55 chev nose on a 57' lolThan

Thanks man! I’m trying to make it look factory with mostly factory parts, but obviously not actually be anything that ever came out of a GM plant.

- Status

- Not open for further replies.

Similar threads

- Replies

- 5

- Views

- 825

- Replies

- 25

- Views

- 2K

- Replies

- 15

- Views

- 1K

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.