What did you do to your non-G body project today? [2023]

- Thread starter Wraith

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

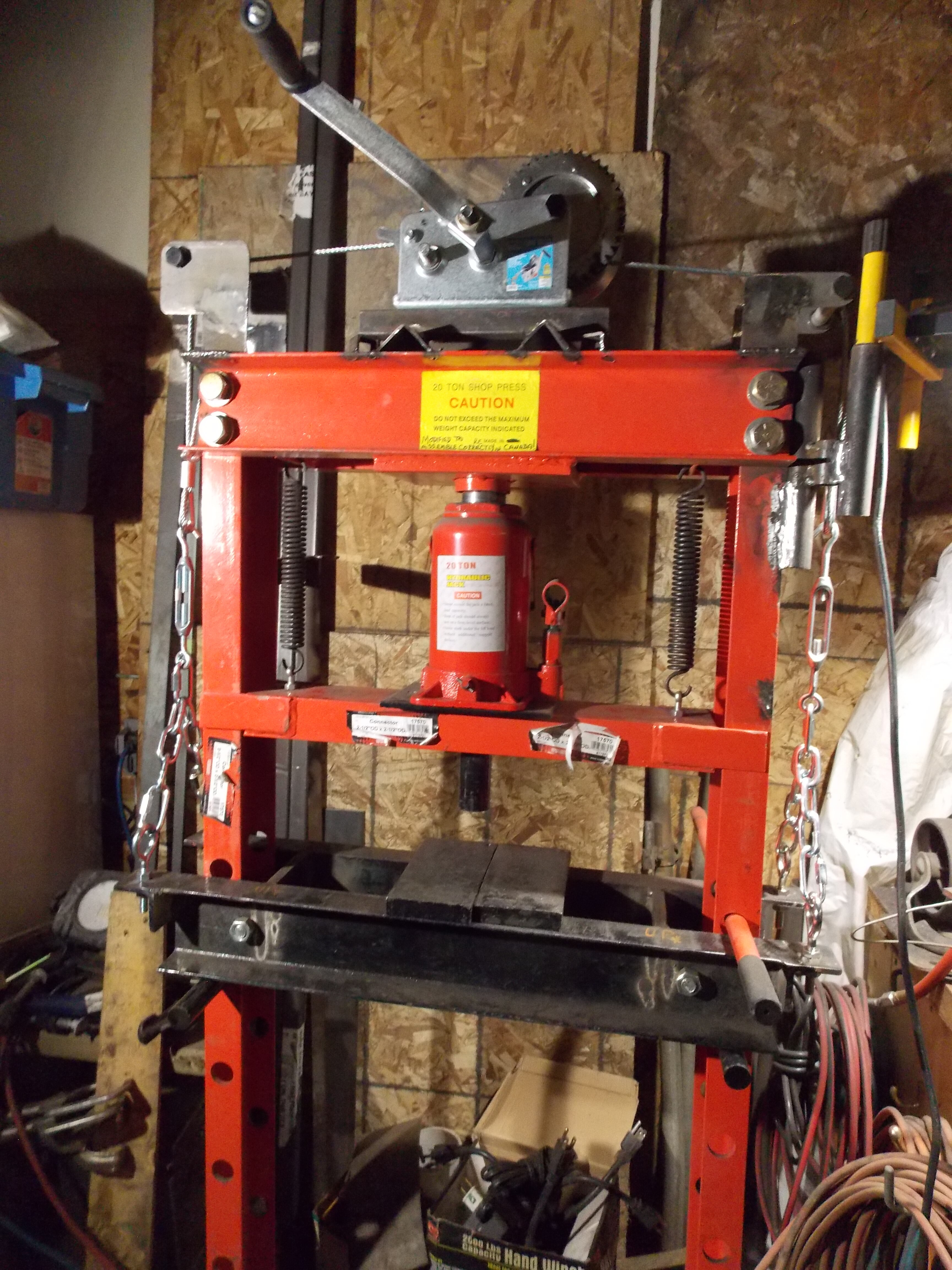

So, whether a non G-Body project or a shop project, this is the finished product.

As mentioned at some point or other in past, the goal was to dream up, design, fabricate and assemble a working lifting winch that could be attached to top head frame of my hydraulic press and make moving the adjustable press deck closer or further away from the press ram a who lot easier.

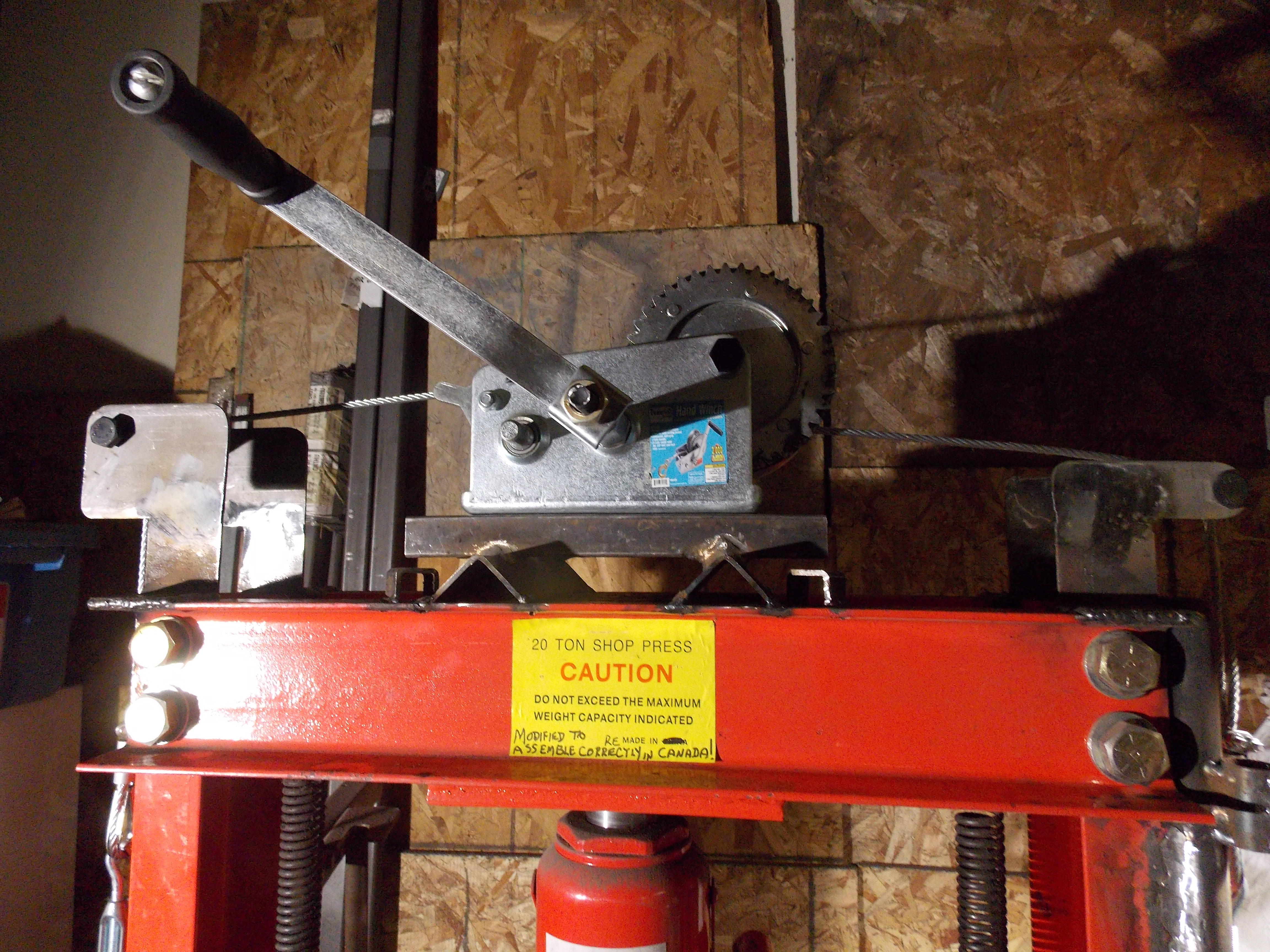

For the detail minded, these two shots show how the cable loops over the end roller and drops down to the turnbuckle that is itself attached to the chain yoke that is, in turn, attached to the moving press deck by means of eyebolts that were bolted to extensions made from 1/4 x 2 angle that were drilled and then welded to the ends of the channels from which the deck was made. Once the initial tension on the lifting cable is set, it is the turnbuckle that is used to fine tune that tension and equalize it from side to side so that the deck rises and falls straight, not off kilter or c*ck-eyed.

Up close and personal with the winch and its cable. The main problem with the winch is that it was designed to take up or release its cable but able to do it only in one direction. My problem was that I needed to have the cable leave the reel in two directions at once, both in unwind and rewind mode plus have the cable wind onto the reel smoothly and in alignment with the direction it was facing.

The solution, which you can't see because the shot of it came out too dark for any detail to be seen, was to spot weld two nuts on the center sleeve of the reel, at 180 degrees separation from each other. To make life simpler when it came time to lace in the cable, the shoulders of the nuts were chamfered/relieved to allow the cable to both enter the throat of the nut and exit it at a softer angle.

The over cable length was then guesstimated using a tape and adding a few more inches jis. The cable was then laced through the first nut to about half way, but so it pointed in one direction, then the other end was also laced throught its nut but only after the cable was wound partially around the sleeve to get the cable to face in the opposing direction. What I got from all this is what you see on the reel, a single length of cable that comes and goes in two directions at once.

The only no so big tweak that had to happen to the right side was that I had to reposition the section of pipe that holds/supports my pivoting work light. Gave me the opportunity to abstract it further away from the head frame and change the angular relationship of that tube to give me more swing on the light and better focus and placement to see what's going on either on the press or on the adjacent drill/welding deck.

And it actually works!!

Further modification??

Yeah, yeah, sure, sure, I can already hear the muttering from the cheap seats; leave well enough alone already. And for the most part that will be the case. What still might have to happen is the fabrication and fitting of a partition or inner wall to the reel that would permanently bisect it into two half reels. This would keep the two sides divorced and prevent the cable from trying to wind over itself instead of staying geographically apart while leaving and returning to the reel. The initial take up of the cable was mostly a fight to keep the two halves from doing just that. Right now the cable is coming and going linearly for the most part but any service to it, such as resetting the ends due to stretch, will be a battle because any slack that has to be put into the cable causes it to want to "snap" back at the reel and snarl up. Watch your face and fingers when that happens.

Oh, the label??

Well it used to say where the press was made, which country of origin didn't impress me all that much, so it got edited and rewritten to read where the press was remanufactured and modified. Where? Here IN Canada!! of Course.

Nick

Update, upgrade, who said anything about that. LIke I noted, buy it wash it, polish it clean it, do an end to nut and bolt on it to make sure they are all there and tight. and flip the bugger to someone who wants that kind of project. This isn't about adding to the stable, this is about adding to your wallet.Nick, not my cup of tea. I hate 50's cars. They look cool, but ride like crap. You need to pour tons of money into them just to catch up to late 60's early 70's handling. Engine upgrade is mandatory. In my salad days, I had a 1959 Ranchero, hi-po 289, three speed manual trans. What a POS. It wasn't even old and it was falling apart. Endless headaches.

Nick

That's what he said..........................................., this is about adding to your wallet.

" And it actually works!!" Nick, I have to admit, that is genius. The hardest part of working with my press, is adjusting the stupid rack. It weighs a ton! And getting the rods in place while holding it all steady is maddening. Well done!!!!!!!!!!!!!

but not what SHE said.....That's what he said...........................................

heading outside to finally change the waterpump on my auction 07 Silvado (it's a Silvado because the E and R are missing 😁 ) . I'll probably get as far as removing it today and knocking the back cover off to inspect the impeller, then install tomorrow

Nick that's what I had in mind when you started talking about it a few posts back. Yup cable attached in 2 places on that reel to wind in and out at the same time will work. Nice.

Me and my woman did a day date in the Z06, drove out to lunch here. Excellent food.

Similar threads

- Replies

- 92

- Views

- 8K

- Replies

- 9

- Views

- 601

- Replies

- 1

- Views

- 468

- Replies

- 67

- Views

- 5K

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.