17 year old tires ?!? hope you're using them as rollers only! 😱😲Scored full set of 5 H2 rims n tires granted date code is 2007🤦🏻♂️ but for $450 and 20 minutes from my place I jumped on it.

View attachment 245968

And good place to store them

View attachment 245967

What did you do to your non-G Body project today [2024 edition]

- Thread starter pagrunt

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Yep, been sitting in his barn for a while.17 year old tires ?!? hope you're using them as rollers only! 😱😲

Rollers? For the most part, might drive on them for a little bit definitely not going to abuse them.

Probably get some cooper AT3 XLT or Cooper Strongholds around new years

liquidh8

Comic Book Super Hero

Rear Main seal on the father-in-laws 05 1500 Chevy, along with a diff oil change and RF wheel bearing/hub.

So glad I have a trans jack! This is a Gray 1000, air over hydraulic 2 stage.

Got the Father-in-Law scraping some gastkets.

Just a tray of bolts and tools, cheap old HF cart.

Transfer case will get news seals as well.

Real main seal is in.

So glad I have a trans jack! This is a Gray 1000, air over hydraulic 2 stage.

Got the Father-in-Law scraping some gastkets.

Just a tray of bolts and tools, cheap old HF cart.

Transfer case will get news seals as well.

Real main seal is in.

Just to complicate my shop time, I now have several projects running at once. The foot peg relocation project for my HD bagger is an ongoing exercise to which I apply a few minutes here and a few minutes there to keep things moving along.

I did turn stone mason for just long enough that I was able to successfully split a large granite panel down into two sections. For those who equate "rock" with music, granite is a fairly hard substance that gets used for countertops in kitchen reno's. It used to be the prinicipal substance for outer walls on commercial buildings and this particular slab, prior to my acquisition, spent the first 60 years of its life being one of fifty or so slabs that together made up a set of stairs for a local church. Issues with the elderly having problems with keeping their footing on the stuff led the church council to have it all replaced and they auctioned off the slabs to defer some of the costs. So I scored a slab about 4' x 3' in size that weighs somewhere west of 200 lbs.

It's been sitting on a double wide furniture dolly while other things got done but this last few weeks with Bay One open I finally elected to take a run at it and see if I could cut it to size.

First tip: Quarries and Stone suppliers use very heavy saws to cut this stufrf; there is a Reason for that. The very old school masons and cutters were able to use hammers and chisels to cut stone only because what they were working with was soft. Granite is not soft. How hard is it??? Hard enough that it took the edge completely off a steel chisel, all the way from keen to square.

Tried phoning around but no one around here seems to carry stone cutting wheels for mini-grinders, and I did so not want to unship my 7" from its case because it is both old and made from Aluminum meaning heavy! A fast shuffle through my mini grinder case and i found two masonry wheels, used/new that I had picked up for dressing edges on the concrete stair project a few years back. It took killing both of them but I finally got my revenge when I once again took a hammer and that poor abused chisel to the cut that I had managed to make in the surface of the granite and after one or two good shots with the hammer, heard the sound of the granite change to a dull clunk and then the split appeared and ran completely from one side to the other. WAH-HOO!!

Finished it off with a little bit of edge dressing using the stump that remained of the second wheel and then used a pair of pry bars to shift the larger piece over on the pallet to center it on the dollies again. Put the sack of pre-mix concrete and the smaller section back on top of the bigger one and put it back in the pocket ahead of the Monte. Now being shorter it fits better and leaves more room for other things to be placed along side it.

Second Tip: Furniture dollies are down right handy if you need to move heavy things around in a garage. Just about everything I need to be portable is sitting on a furniture dolly and if I can't buy one, I can always buy the casters and make one from lengths of fascia board. You can even use them for engine dollies if you do some judicious re-inforcement of the basic frame.

Finally, got that mess cleaned up and put away, swept the floor and brought the S-10 back in for round two. Rear brakes are about ready to be rebuilt and it looks like the winter salt has managed to chew its way through an exhaust pipe, plus the usual nicks and dings to be dealt with.

Nick

I did turn stone mason for just long enough that I was able to successfully split a large granite panel down into two sections. For those who equate "rock" with music, granite is a fairly hard substance that gets used for countertops in kitchen reno's. It used to be the prinicipal substance for outer walls on commercial buildings and this particular slab, prior to my acquisition, spent the first 60 years of its life being one of fifty or so slabs that together made up a set of stairs for a local church. Issues with the elderly having problems with keeping their footing on the stuff led the church council to have it all replaced and they auctioned off the slabs to defer some of the costs. So I scored a slab about 4' x 3' in size that weighs somewhere west of 200 lbs.

It's been sitting on a double wide furniture dolly while other things got done but this last few weeks with Bay One open I finally elected to take a run at it and see if I could cut it to size.

First tip: Quarries and Stone suppliers use very heavy saws to cut this stufrf; there is a Reason for that. The very old school masons and cutters were able to use hammers and chisels to cut stone only because what they were working with was soft. Granite is not soft. How hard is it??? Hard enough that it took the edge completely off a steel chisel, all the way from keen to square.

Tried phoning around but no one around here seems to carry stone cutting wheels for mini-grinders, and I did so not want to unship my 7" from its case because it is both old and made from Aluminum meaning heavy! A fast shuffle through my mini grinder case and i found two masonry wheels, used/new that I had picked up for dressing edges on the concrete stair project a few years back. It took killing both of them but I finally got my revenge when I once again took a hammer and that poor abused chisel to the cut that I had managed to make in the surface of the granite and after one or two good shots with the hammer, heard the sound of the granite change to a dull clunk and then the split appeared and ran completely from one side to the other. WAH-HOO!!

Finished it off with a little bit of edge dressing using the stump that remained of the second wheel and then used a pair of pry bars to shift the larger piece over on the pallet to center it on the dollies again. Put the sack of pre-mix concrete and the smaller section back on top of the bigger one and put it back in the pocket ahead of the Monte. Now being shorter it fits better and leaves more room for other things to be placed along side it.

Second Tip: Furniture dollies are down right handy if you need to move heavy things around in a garage. Just about everything I need to be portable is sitting on a furniture dolly and if I can't buy one, I can always buy the casters and make one from lengths of fascia board. You can even use them for engine dollies if you do some judicious re-inforcement of the basic frame.

Finally, got that mess cleaned up and put away, swept the floor and brought the S-10 back in for round two. Rear brakes are about ready to be rebuilt and it looks like the winter salt has managed to chew its way through an exhaust pipe, plus the usual nicks and dings to be dealt with.

Nick

Had an interesting fing in the bathroom sink's aerator what was the cause for it's replacement. Some how I got a seed in it & was growing something that ended up choking the water flow. After trips to three big box stores I found the right one at the local mom & pop hardware store. Should of took pics but somethings don't need to be out there. Lucky it only stayed in the aerator.

Went down to the yard with intention of getting some other things done today but fixed the gas powered compressor instead. In process after that I looked at my 68’ Cutlass I’m parting out. Looking off to the side where it’s sitting was a hood , no big deal. Thing is it looked like a possible upside down Roadrunner hood due to the cowl opening. Well I found the hood to the Cutlass! Immediately I knew what I wanted to do with it. Just have to find the grills for the sides( all ready found dozens) and the rear cowl grill. I can’t seem to figure out how it is listed to find it. For right now it’s going into storage.

Last edited:

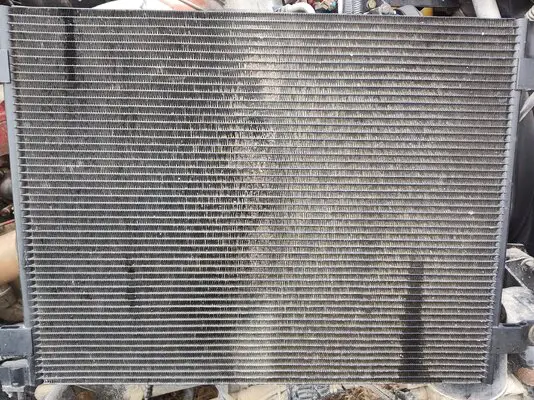

It's harvest season, and it's been extremely dry in Ohio, as of Friday 87 of 88 counties were in some sort of drought conditions.

Makes for extremely dusty with very fine particles while harvesting. Usually for harvest doesn't start till October.

Yesterday Uncle said AC was struggling in his combine and semi.. didn't get anything pictures of the combine. It was just as bad.

Spent 2-2.5hrs pressure washing the combine and 2 hours on the semi..

Generally it gets like this after harvest not 2-3 weeks in.

Pressure washer I used? 5.5gpm at 2800psi I scored off FB marketplace.

Should freeze him out now that everything is clean lol

Makes for extremely dusty with very fine particles while harvesting. Usually for harvest doesn't start till October.

Yesterday Uncle said AC was struggling in his combine and semi.. didn't get anything pictures of the combine. It was just as bad.

Spent 2-2.5hrs pressure washing the combine and 2 hours on the semi..

Generally it gets like this after harvest not 2-3 weeks in.

Pressure washer I used? 5.5gpm at 2800psi I scored off FB marketplace.

Should freeze him out now that everything is clean lol

Attachments

Used to have that with construction and farm equipment radiators here in New England. Runs off the equipment like a river of mud. Ran a radiator repair shop so understand completely.It's harvest season, and it's been extremely dry in Ohio, as of Friday 87 of 88 counties were in some sort of drought conditions.

Makes for extremely dusty with very fine particles while harvesting. Usually for harvest doesn't start till October.

Yesterday Uncle said AC was struggling in his combine and semi.. didn't get anything pictures of the combine. It was just as bad.

Spent 2-2.5hrs pressure washing the combine and 2 hours on the semi..

Generally it gets like this after harvest not 2-3 weeks in.

Pressure washer I used? 5.5gpm at 2800psi I scored off FB marketplace.

Should freeze him out now that everything is clean lol

liquidh8

Comic Book Super Hero

Hung out this weekend at a local car show with my youngest daughter. On Friday we pulled the 32 Ford in the shop for some repairs and upgrades. I swapped out the valve cover gaskets with the quality steel core deals from Felpro. I also swapped the old accel locked advance distributor with no vacuum advance, for a ready to run small cap dizzy with vacuum advance. New MSD plug wires and ignition coil, also ultrasonic cleaned the NGK plugs. After that we washed and vacuumed 1 year of crap off and out of it.

Then Saturday, cruised to get some brunch, then hit the car show. No trophy, but we did win the 50/50, which was more than a trophies cost, and the day with one of my daughters as we know, is priceless.

Then Saturday, cruised to get some brunch, then hit the car show. No trophy, but we did win the 50/50, which was more than a trophies cost, and the day with one of my daughters as we know, is priceless.

Got into the exhaust pipe and found that the road salt had literally eaten holes in it multiple places all the way to the connection under the truck box just ahead of the kickup over the rear end. Turns out that I now need to fabricate a complete new unit.

Since that whole exhaust system never did see a parts counter to begin with, recreating it is a simple exercise involving a lot of pre-bent exhaust Ells that get trimmed for length and then fitted to each other in a specific sequence. Yeah, yeah, why not use mandrel bends and go pretty? Too much work and too little time and who is going to see it? For my little truck I have found this method to be easiest and most practical since I only get about 4 years out of my exhaust pipes due to the corrosive crap that gets sprayed on our roads every winter. Only minor glitch with the ells is that I needed 22.5 degree bends for one section and all the store had was 20 degree. You'd think that 2 degrees isn't much but it forced me to pie cut that bend and tweak the bend to a greater angle to get the alignment right. There is not that much free space under the truck box and that makes getting things right the first time saves the frustration of a redo.

With the brakes I did get as far as spraying them down with CFC free green Label Brake Cleaner. The drums are close to done. Not sure why or how but they have a lot of small black spots showing on the brake surface. Smooth to the touch, almost look like it was contamination in the metal during the foundering process. I did get almost 10 years and several shoe changes out of them so they did pay for themselves. I'd kind of like to see if they could be turned but finding a shop that not only has a machine but someone who genuinely knows how to use it.......................................... . Major exercise in futility, if you find a shop then they don't want to do the machining unless they get to do the shoe work too.

. Major exercise in futility, if you find a shop then they don't want to do the machining unless they get to do the shoe work too.

After all that there is still the acne in the passenger side of the box, still thinking that might have happened due to an adverse reaction between two of the layers of material that I shot on that side last year. If I can get it down to metal and Rust Mort it, then I will have to shoot Epoxy or similar to seal the surface before I dare shoot anything else. Only way I can see to isolate the layers and keep them from engaging in some kind of chemical warfare.

Nick

Since that whole exhaust system never did see a parts counter to begin with, recreating it is a simple exercise involving a lot of pre-bent exhaust Ells that get trimmed for length and then fitted to each other in a specific sequence. Yeah, yeah, why not use mandrel bends and go pretty? Too much work and too little time and who is going to see it? For my little truck I have found this method to be easiest and most practical since I only get about 4 years out of my exhaust pipes due to the corrosive crap that gets sprayed on our roads every winter. Only minor glitch with the ells is that I needed 22.5 degree bends for one section and all the store had was 20 degree. You'd think that 2 degrees isn't much but it forced me to pie cut that bend and tweak the bend to a greater angle to get the alignment right. There is not that much free space under the truck box and that makes getting things right the first time saves the frustration of a redo.

With the brakes I did get as far as spraying them down with CFC free green Label Brake Cleaner. The drums are close to done. Not sure why or how but they have a lot of small black spots showing on the brake surface. Smooth to the touch, almost look like it was contamination in the metal during the foundering process. I did get almost 10 years and several shoe changes out of them so they did pay for themselves. I'd kind of like to see if they could be turned but finding a shop that not only has a machine but someone who genuinely knows how to use it..........................................

. Major exercise in futility, if you find a shop then they don't want to do the machining unless they get to do the shoe work too.

. Major exercise in futility, if you find a shop then they don't want to do the machining unless they get to do the shoe work too.After all that there is still the acne in the passenger side of the box, still thinking that might have happened due to an adverse reaction between two of the layers of material that I shot on that side last year. If I can get it down to metal and Rust Mort it, then I will have to shoot Epoxy or similar to seal the surface before I dare shoot anything else. Only way I can see to isolate the layers and keep them from engaging in some kind of chemical warfare.

Nick

Similar threads

- Replies

- 3

- Views

- 259

- Replies

- 17

- Views

- 1K

- Replies

- 9

- Views

- 1K

- Replies

- 966

- Views

- 58K

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.