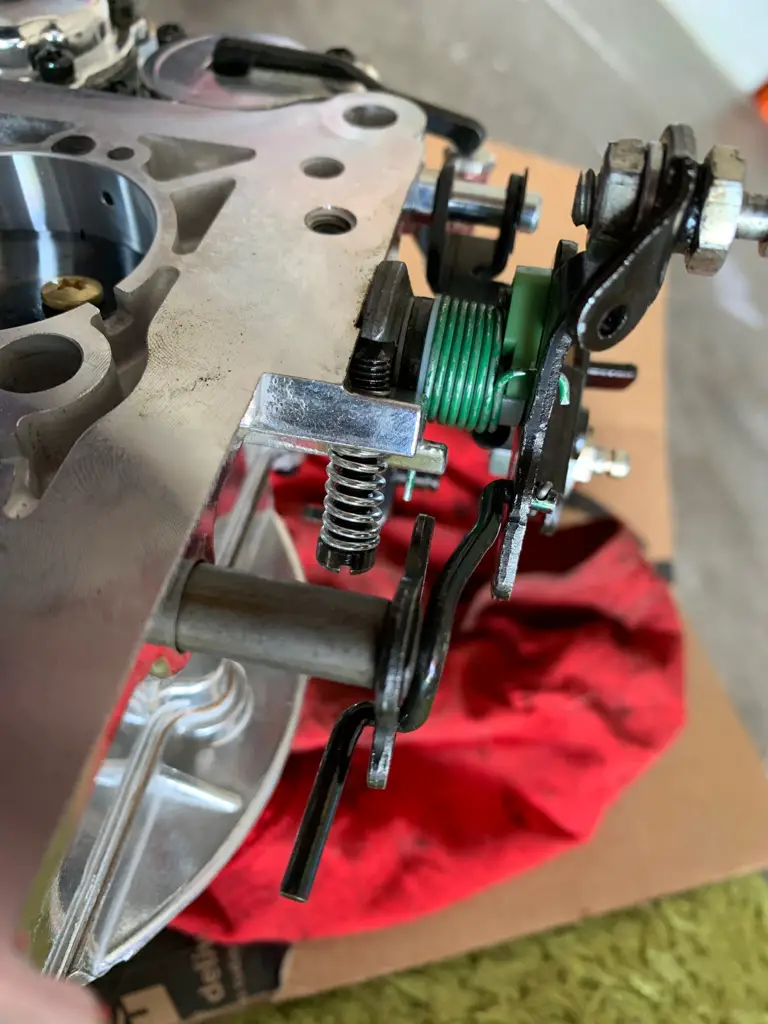

Transfer slots are now square it was my fast idle screw adjustment that apparent controlled that

Sent from my iPhone using Tapatalk

Like I said, leave it around 40 and run the full 16 degrees of vacuum advance. I am around 48 degrees total with my 9 to 1 Olds 350 and may add a couple more on my Mallory breakerless either by bumping the base timing 2 degrees or adding another couple degrees of vacuum advance or both. I had 22 base, 14 mechanical and a 30 degree vacuum can. No pinging but had bucking at low speeds. Switching to a 20 degree can, fixed it. I did notice lazier part throttle.Since I have to have such high initial timing would it be worth my while to just lock out the mechanical advance and leave the vacuum advance alone?

Sent from my iPhone using Tapatalk

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.