1982 Monte E85 Blow Thru Procharged SBC Build *PICS and VIDS ADDED***RUNNING***

- Thread starter wingnutks

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Lol hell yea manAre you going to run it on the dyno with the Procharger?

Got the main hoop bent up last night.

Also things are escalating lol

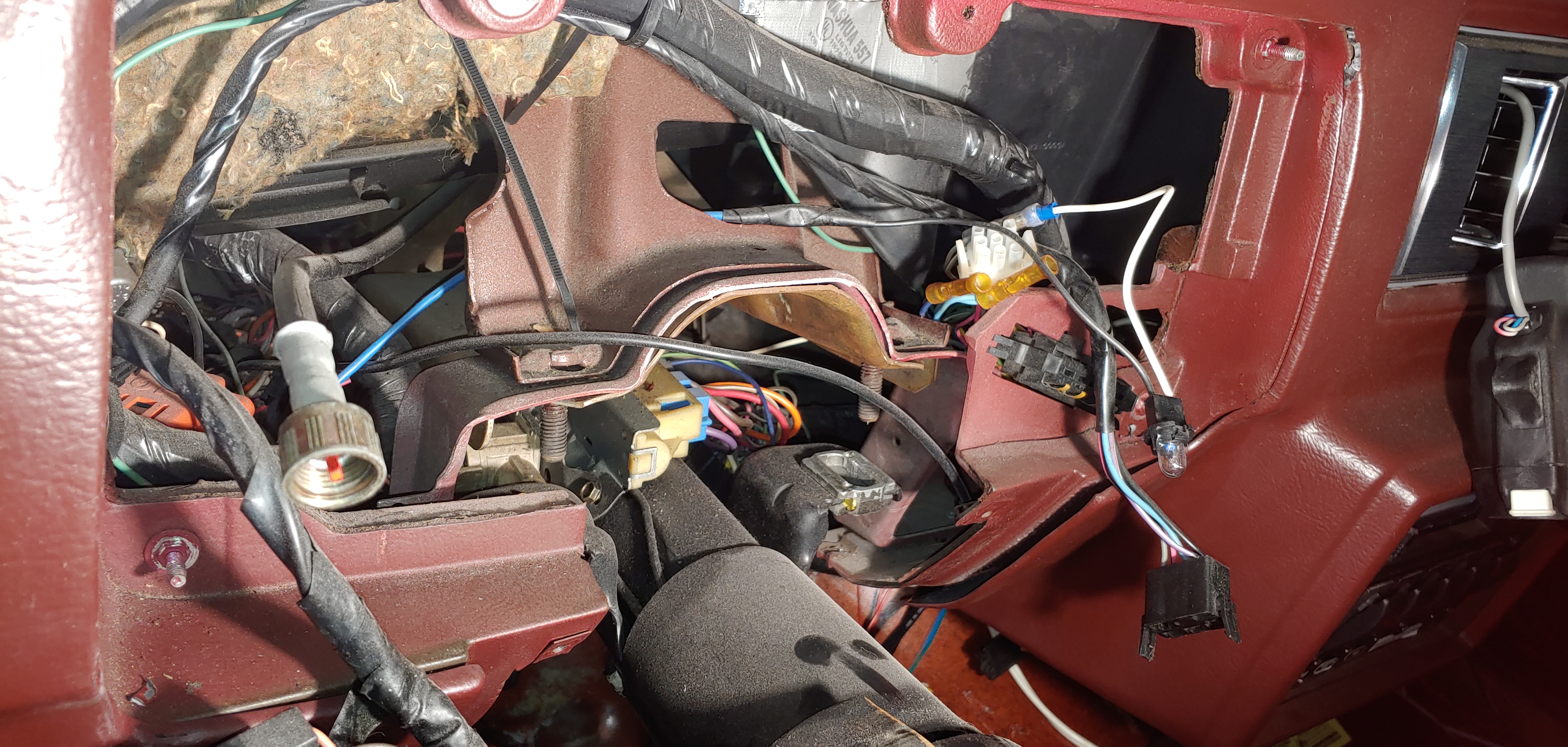

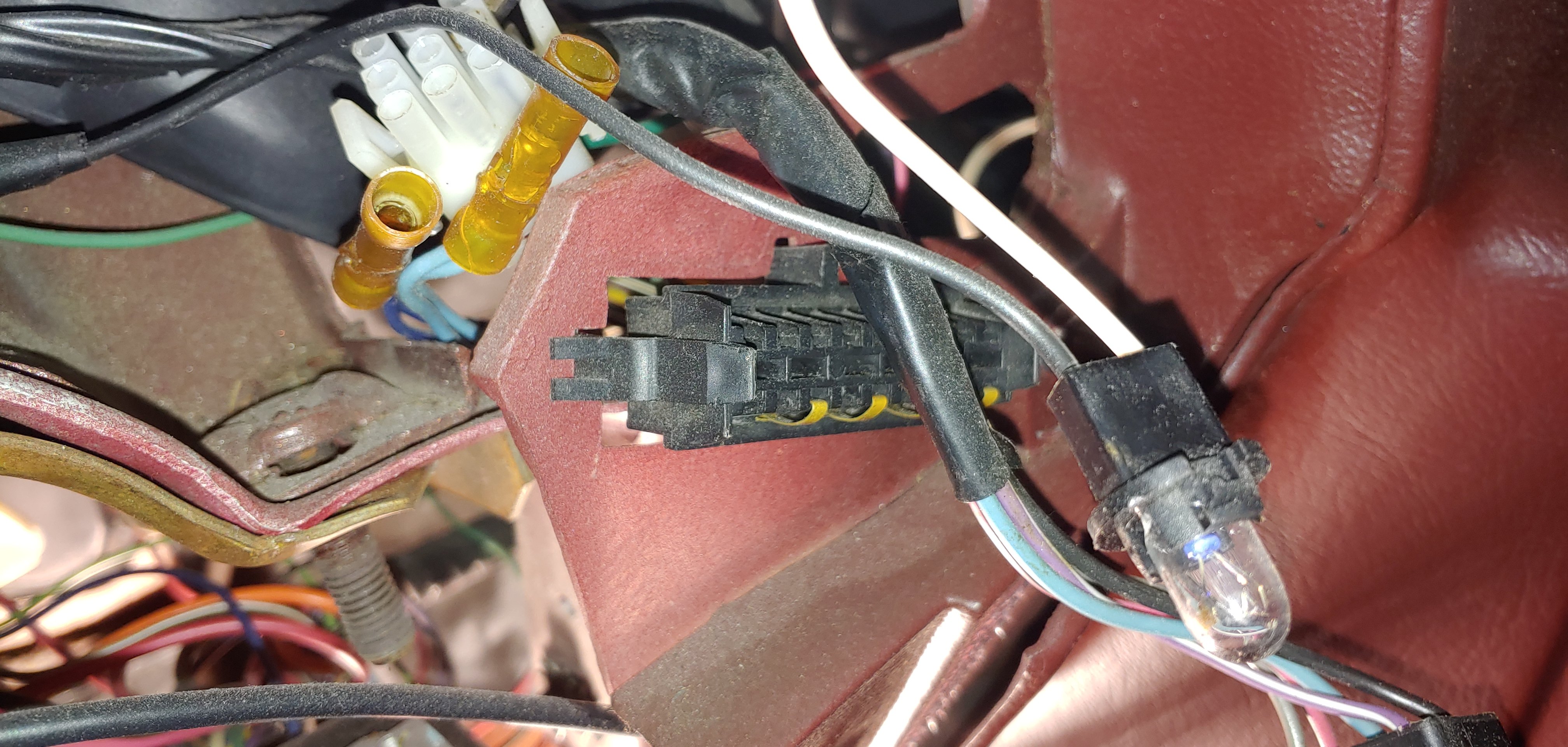

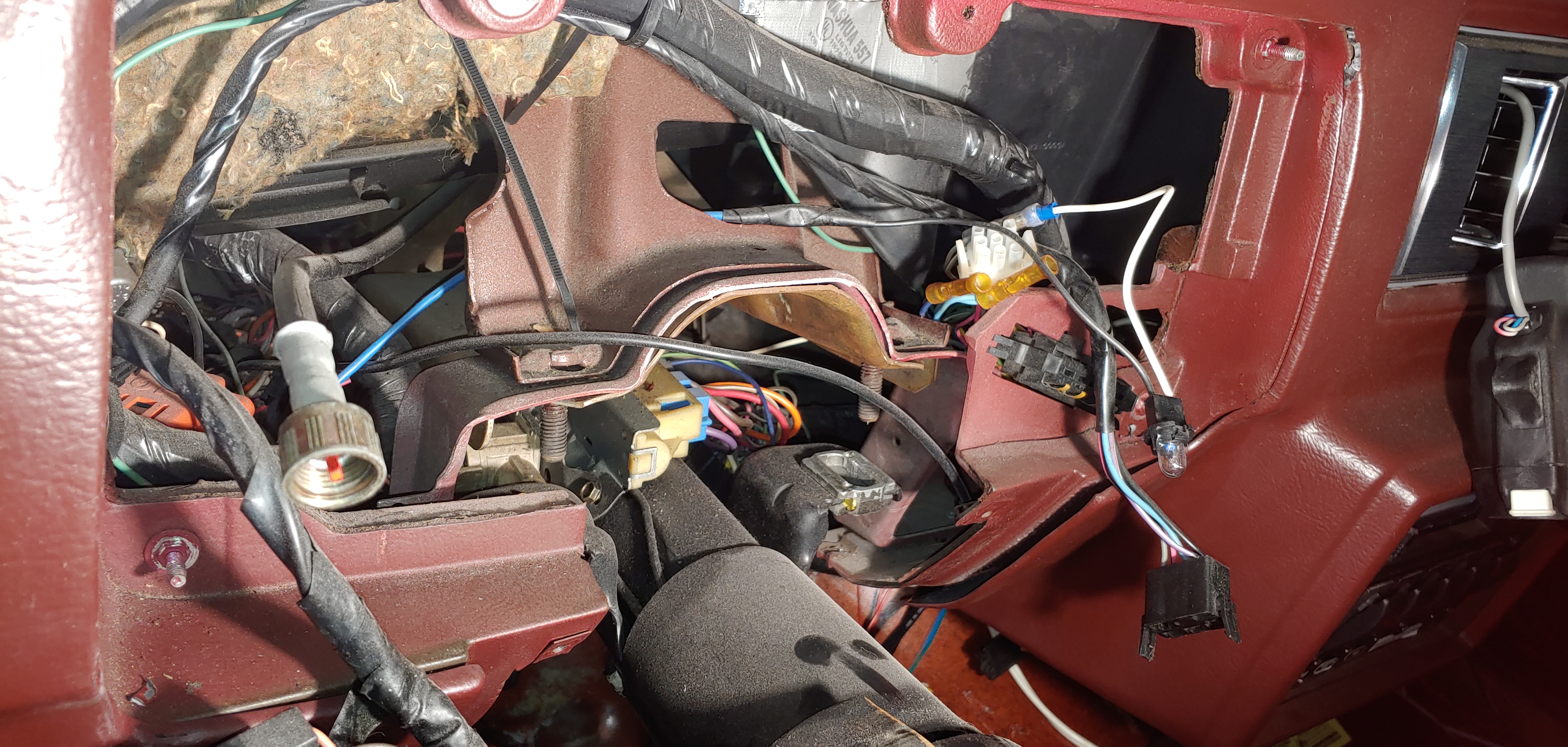

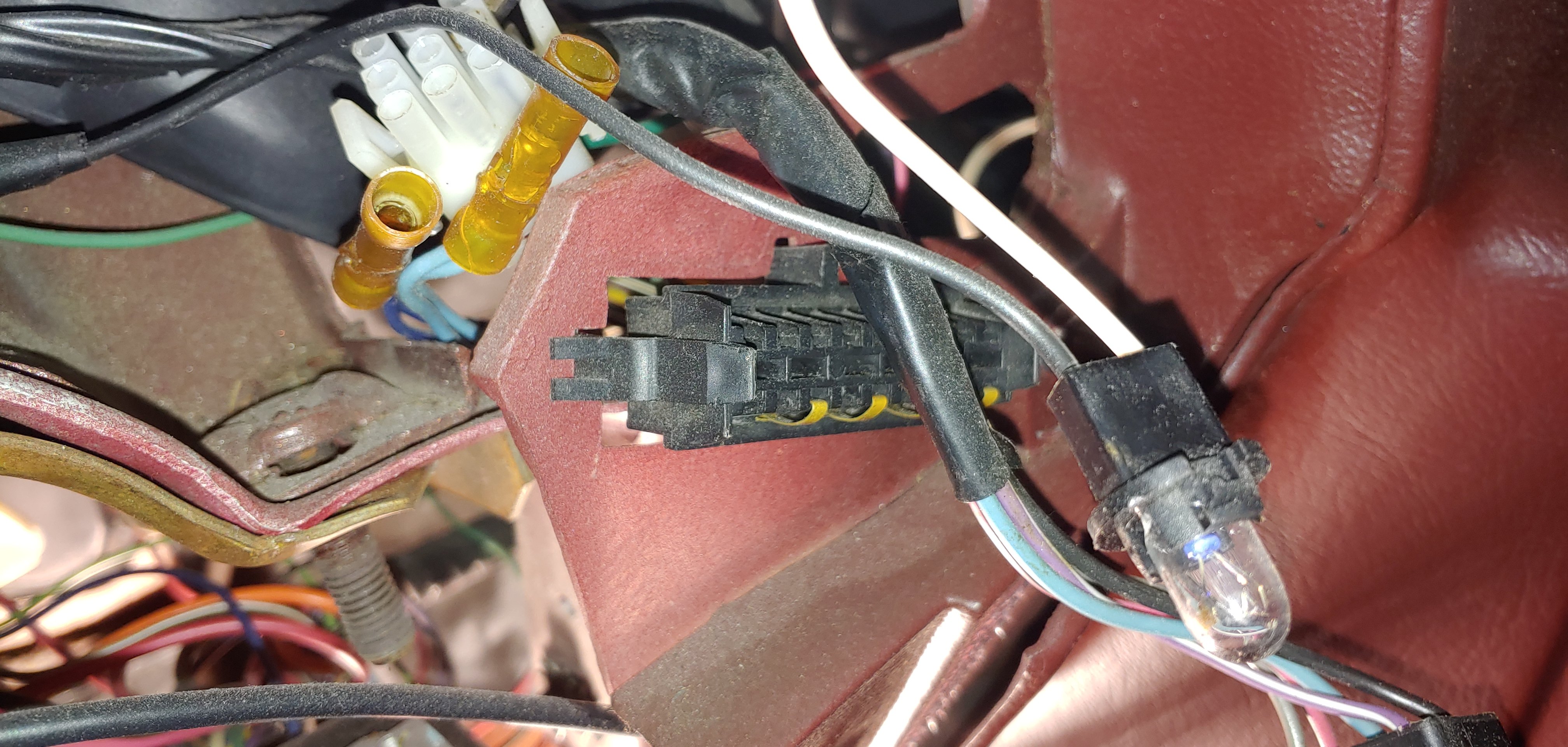

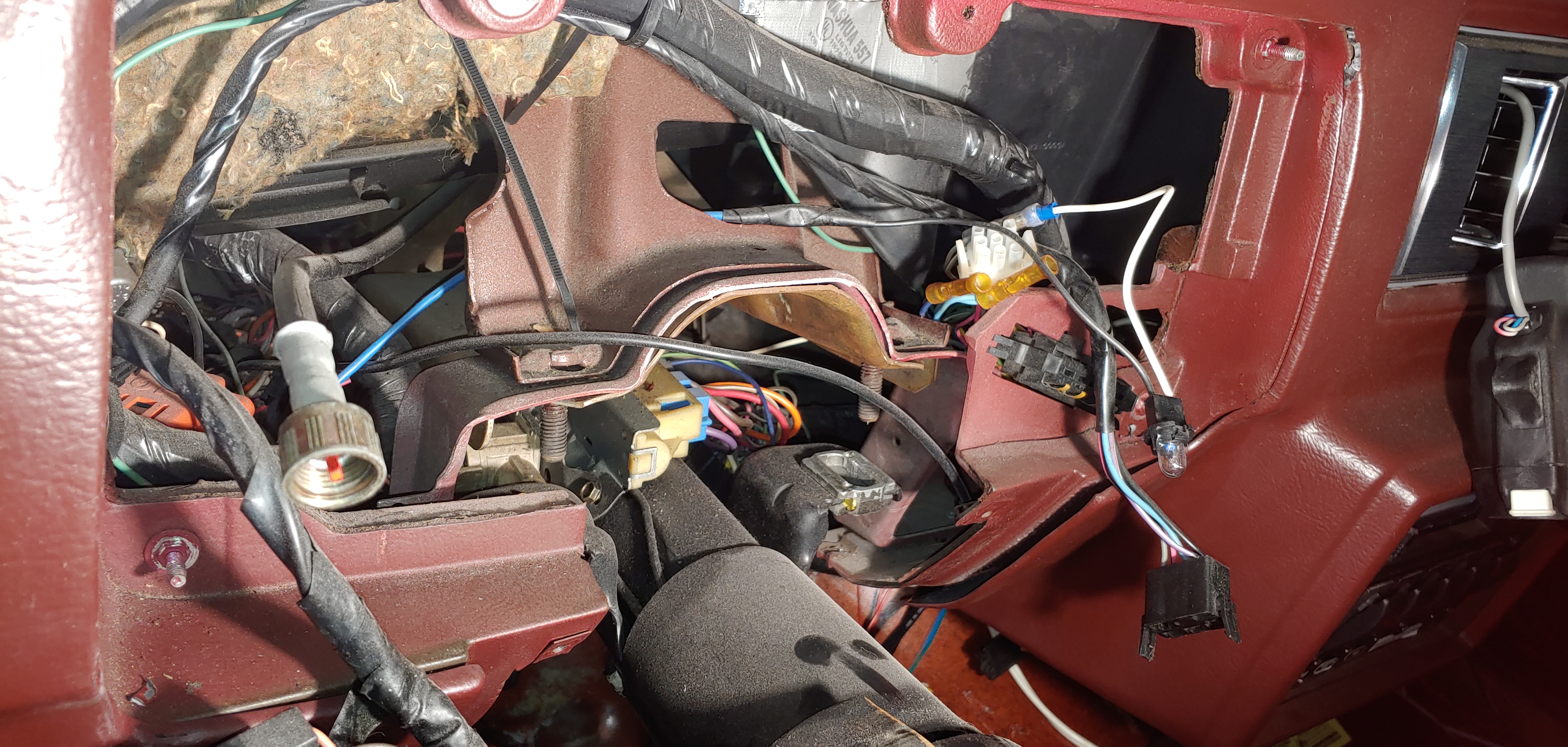

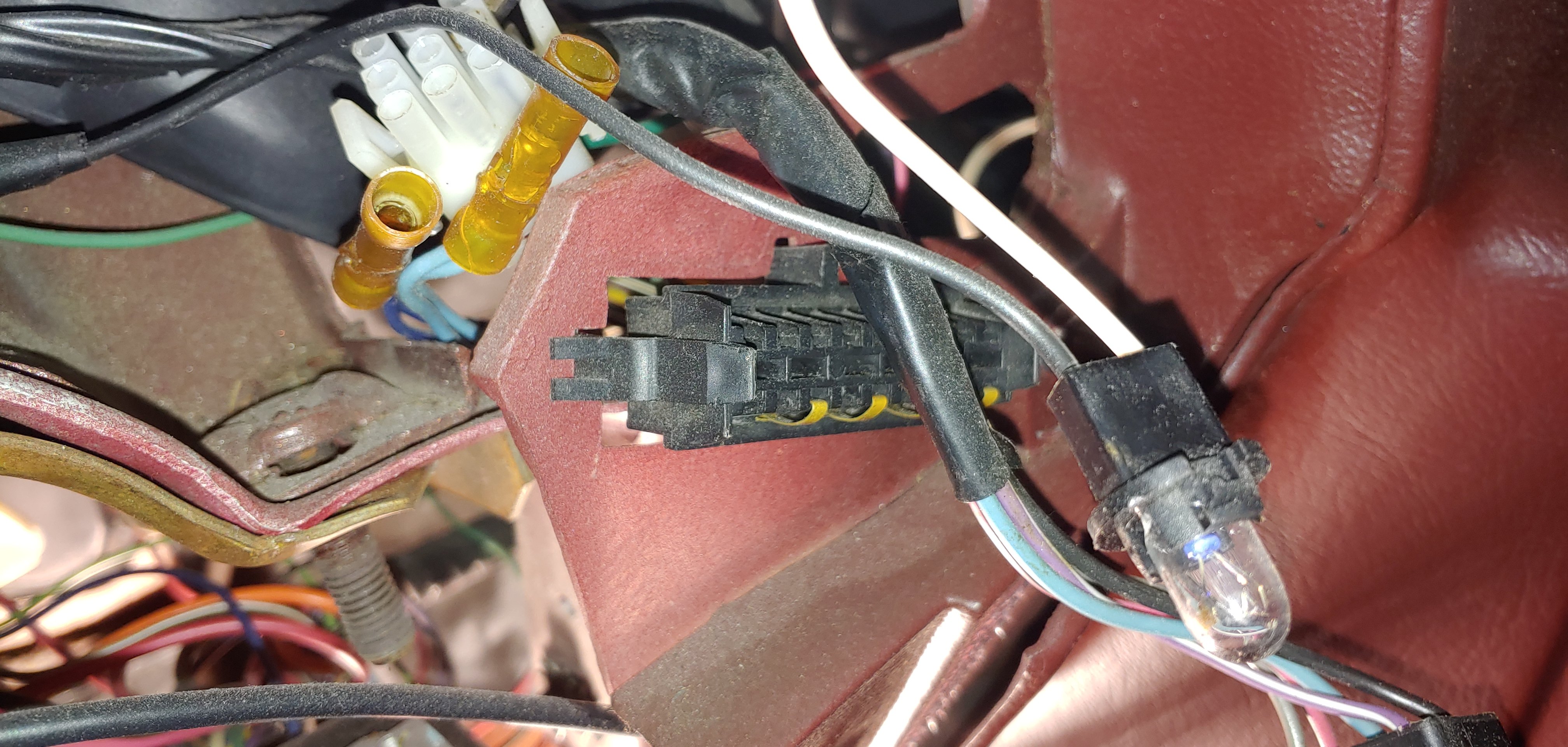

What is this plug to the bottom right of the gauge cluster?

Also things are escalating lol

What is this plug to the bottom right of the gauge cluster?

If you're refering to the one clipped in is the cluster/circuit board plug, the one hanging is the rear defroster plug.What is this plug to the bottom right of the gauge cluster?

Last edited by a moderator:

Yes, the plug that is clipped to the dash metal work aligns with the circuit board of the instrument cluster when you install it back into place.If you're refering to the one clipped in is the cluster/circuit board plug, the one hanging is the rear defroster plug.

Will you be reinstalling the original cluster?, or going with something aftermarket? Original gauge clusters are wired slightly different than warning light clusters. Check schematics for pin position if changing to a different cluster.

I didn't know what it was for because I have all aftermarket gauges so nothing uses that plugYes, the plug that is clipped to the dash metal work aligns with the circuit board of the instrument cluster when you install it back into place.

Will you be reinstalling the original cluster?, or going with something aftermarket? Original gauge clusters are wired slightly different than warning light clusters. Check schematics for pin position if changing to a different cluster.

Your turn signal and high beam indicators are in that along with the fuel gauge and volt meter. It's also a good source for dash panel lights power and ground that will work with the dimmer switch.

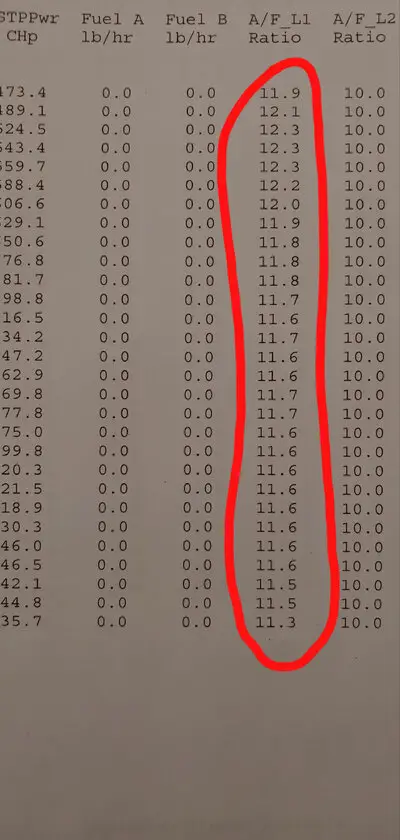

Dynod the motor today. Broke in fine. Oil. Pressure was good. ~75 at WOT.

On 4.75" pulley it made 830 @ 6700

On 3.70" pulley it made 917 @ 6300.

We stopped the pull early because the boost just stopped climbing... Think the blower was starting to get out of its inefficiency.

With the 4.75" pulley 2° of timing was good to go from 795 to 830. Definitely conservative on timing.

It's the first motor I have ever built so I am glad it started and came home in one piece. Also pumped that the cam. I specd did exactly what I wanted it to do.

Also not sure it matters but headers were 1-3/4 dyno headers. 1-7/8 header will be going on in the car.

The carb did perfect!

On 4.75" pulley it made 830 @ 6700

On 3.70" pulley it made 917 @ 6300.

We stopped the pull early because the boost just stopped climbing... Think the blower was starting to get out of its inefficiency.

With the 4.75" pulley 2° of timing was good to go from 795 to 830. Definitely conservative on timing.

It's the first motor I have ever built so I am glad it started and came home in one piece. Also pumped that the cam. I specd did exactly what I wanted it to do.

Also not sure it matters but headers were 1-3/4 dyno headers. 1-7/8 header will be going on in the car.

The carb did perfect!

Attachments

Pretty awesome! You are definitely getting to the limit of what the D1SC can do for you.

How about a video and some of the tune specs?

Was this on E, if yes then what? I.e. pump, E70, E85, E98...

What are you using to control the timing, i.e. launch, boost retard?

(You've probably already told us, but perhaps the dyno setup was different).

I'd about guarantee that the 1 3/4 headers weren't helping, but for that matter you could be running 2 to 2 1/4" - you're in the big block zone of header sizing. But the power loss was minimal - you're in the zone where an additional 20-30hp is not much of adifference. Your past the point of needing to make power IMHO - now you need to become a traction specialist lol.

Lastly - HOLY SCHMOLY - congratualtions - that making some steam!!!!!!

Was this on E, if yes then what? I.e. pump, E70, E85, E98...

What are you using to control the timing, i.e. launch, boost retard?

(You've probably already told us, but perhaps the dyno setup was different).

I'd about guarantee that the 1 3/4 headers weren't helping, but for that matter you could be running 2 to 2 1/4" - you're in the big block zone of header sizing. But the power loss was minimal - you're in the zone where an additional 20-30hp is not much of adifference. Your past the point of needing to make power IMHO - now you need to become a traction specialist lol.

Lastly - HOLY SCHMOLY - congratualtions - that making some steam!!!!!!

- Status

- Not open for further replies.

Similar threads

- Replies

- 0

- Views

- 116

- Replies

- 3

- Views

- 411

- Replies

- 0

- Views

- 63

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.