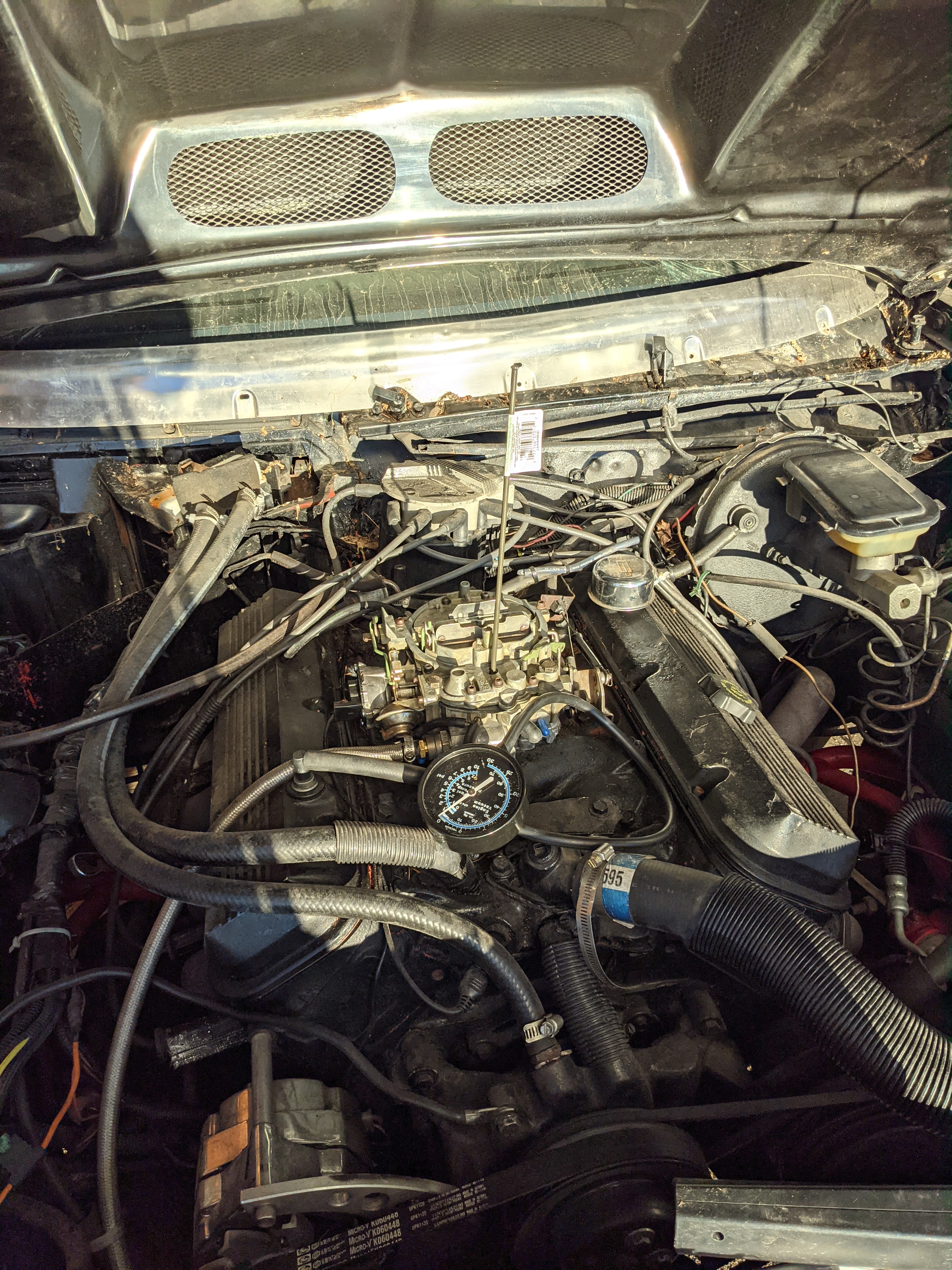

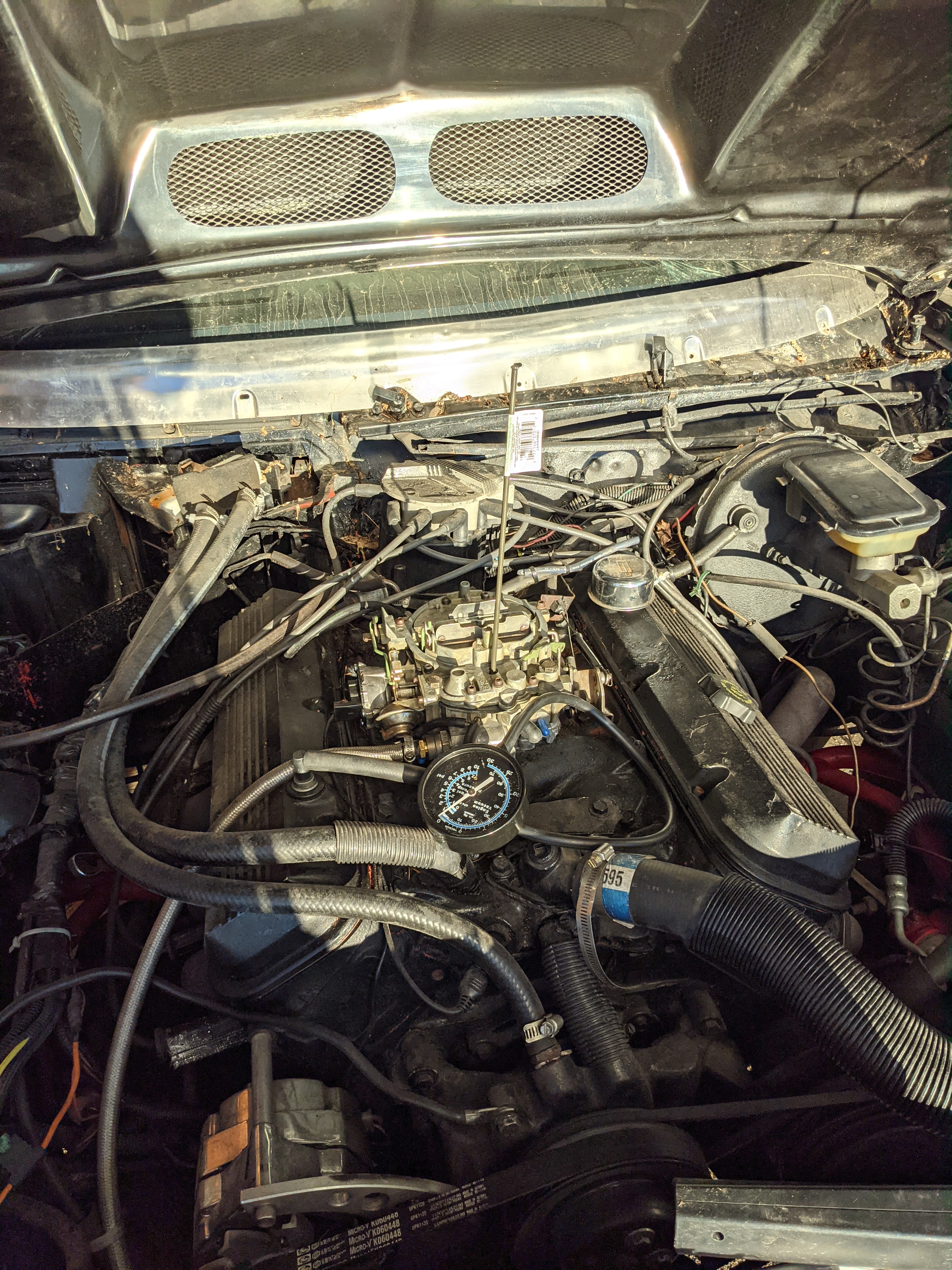

It was just out of gas thank God. That means the chainsaw premix I dumped in it to get it to the gas station when I first started it has also run its course. Now there's 6 gallons with Stabil in the tank. Once I got some temperature in the thing it wouldn't rev past an idle without pooping out the carb and intake, so I went to O'reilly and got a chunk of brake line and made an APT tool.

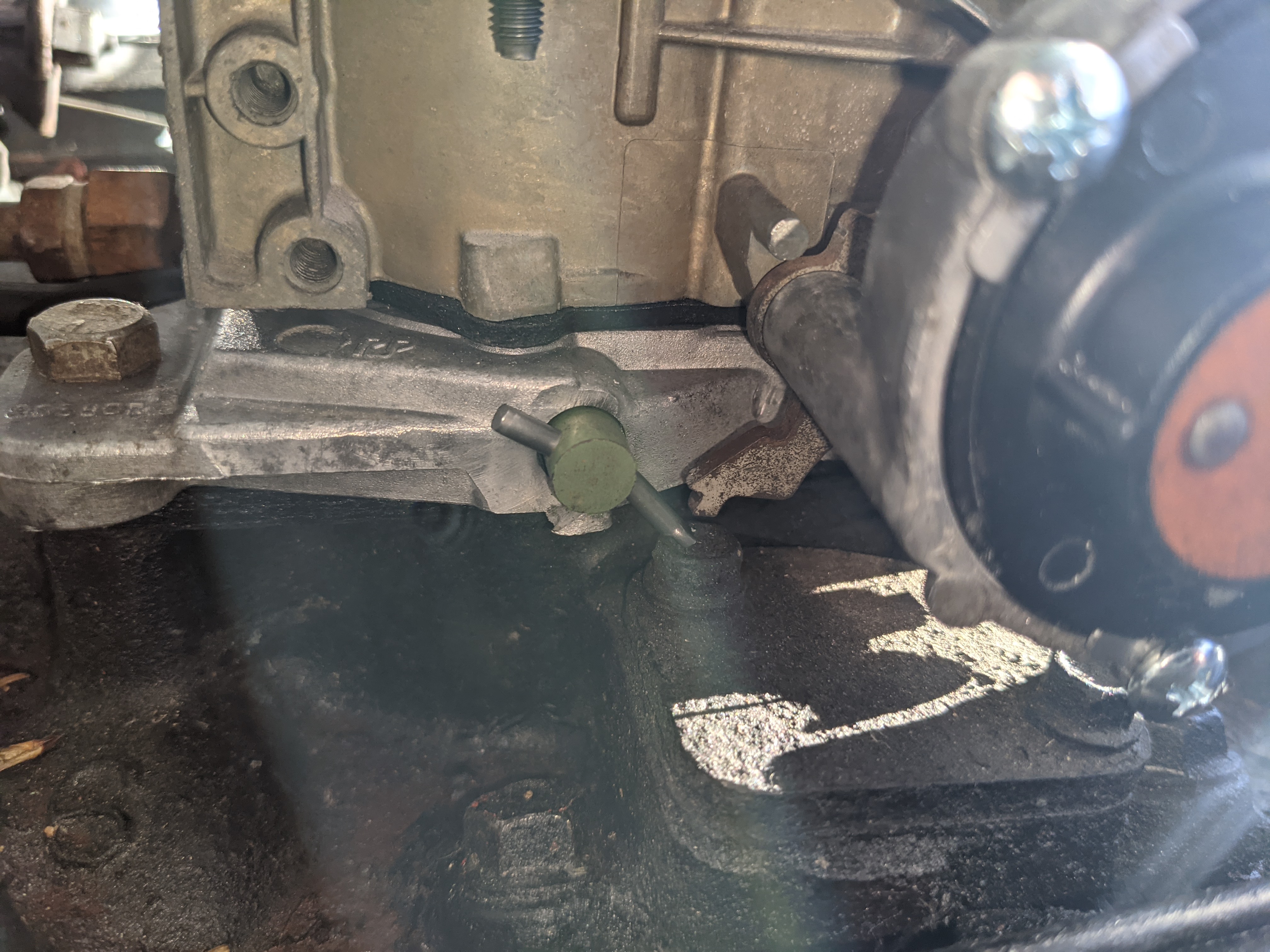

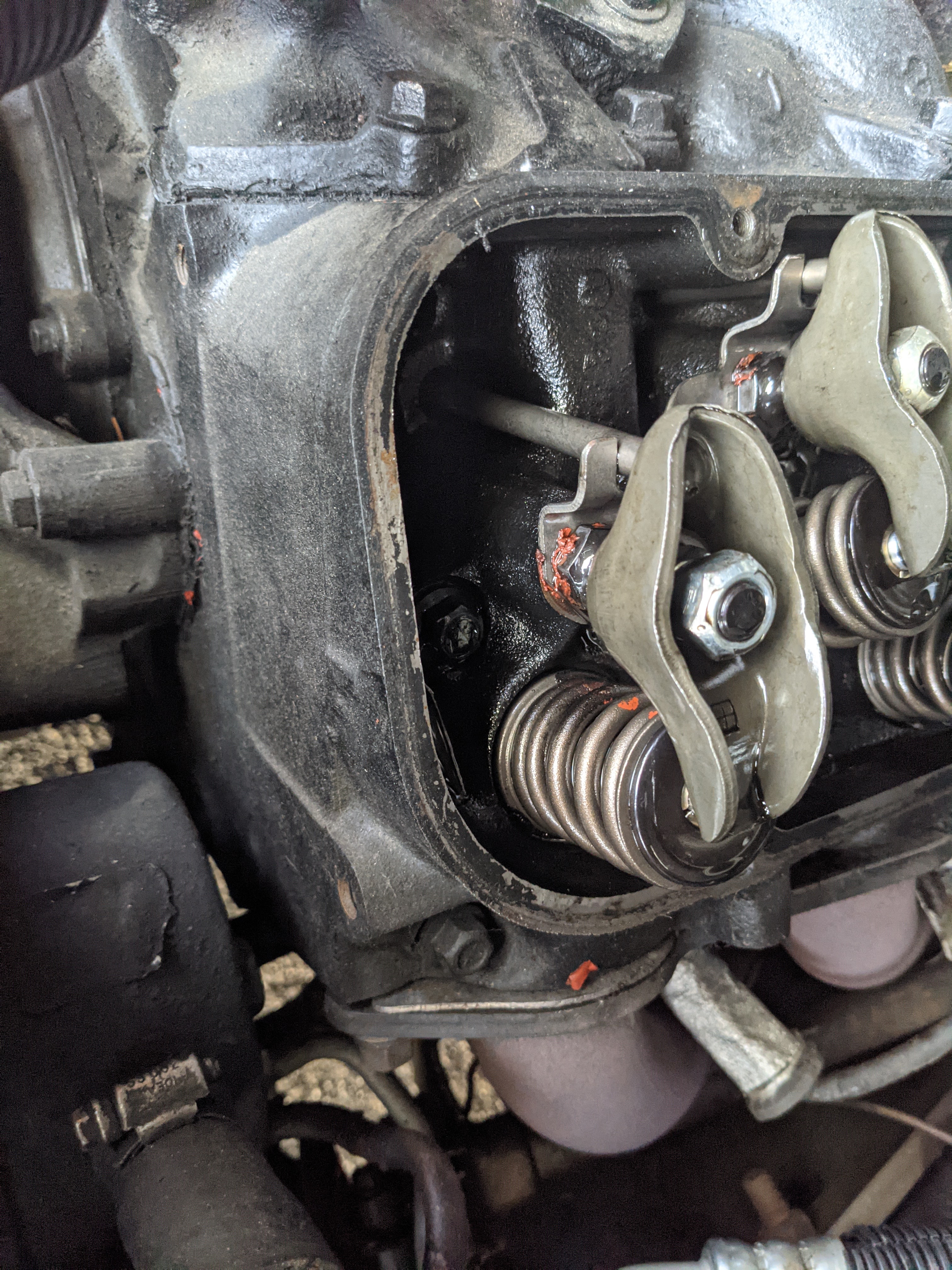

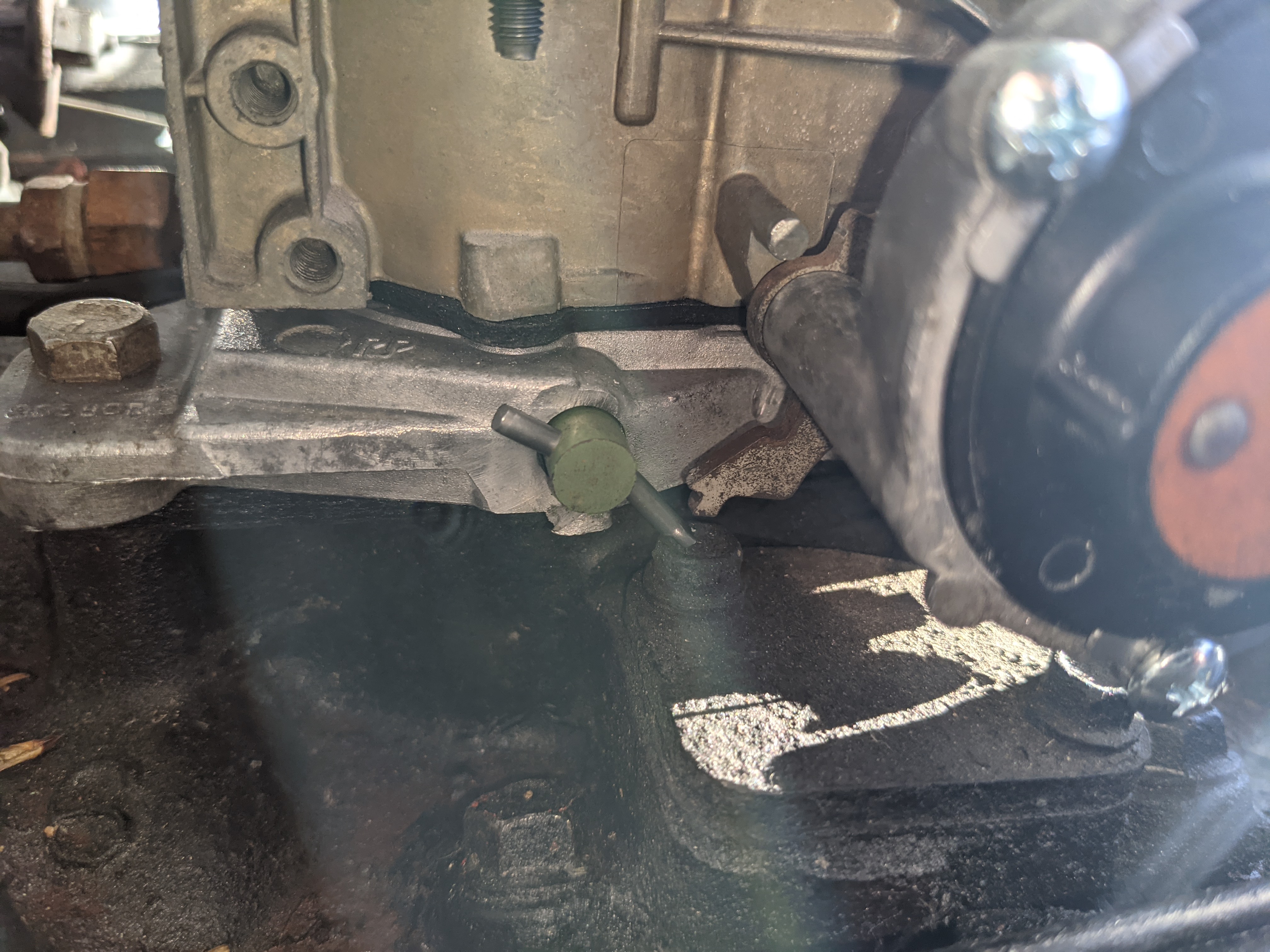

Fits like it was made for it and the sticker helps me count turns. The 2 1/4 turns I started at is clearly not where it was before. That's what I get for milking a carb rebuild for 11 months. My only saving grace so far has been my ability to find what I had before in my old posts. So the car was previously idling at 13-14" and now it's been 16-17" today. I pulled the timing back to the 15 degree mark at idle but the car got hot before I remembered to check total timing once it revved out cleanly. Idle screws still pretty damned unresponsive, I can turn them all in and the damn thing still runs. I'd have to believe 16" of vacuum is enough to suck the needles down into the jets to lean it out enough so that the wife won't b*tch when I walk in the house reeking like exhaust. I think I need to get a wideband involved now to make efficient, useful progress. For now it runs well enough to putt putt around and drive itself on the trailer which is what really lit the fire to get this done. If anyone has a starting schematic for this car it would be much appreciated. It's pretty ghetto that I'm still striking a yellow wire against the positive battery post to fire this thing up every time. I think if I road tripped it as is to Freiburger and Finnegan they'd be proud. One more thing, shouldn't this linkage be bent up to get caught in the choke linkage to prevent the secondaries from opening when the choke is on? I ask because I suspect that is what I need to wire together to tune the primaries at WOT.

Fits like it was made for it and the sticker helps me count turns. The 2 1/4 turns I started at is clearly not where it was before. That's what I get for milking a carb rebuild for 11 months. My only saving grace so far has been my ability to find what I had before in my old posts. So the car was previously idling at 13-14" and now it's been 16-17" today. I pulled the timing back to the 15 degree mark at idle but the car got hot before I remembered to check total timing once it revved out cleanly. Idle screws still pretty damned unresponsive, I can turn them all in and the damn thing still runs. I'd have to believe 16" of vacuum is enough to suck the needles down into the jets to lean it out enough so that the wife won't b*tch when I walk in the house reeking like exhaust. I think I need to get a wideband involved now to make efficient, useful progress. For now it runs well enough to putt putt around and drive itself on the trailer which is what really lit the fire to get this done. If anyone has a starting schematic for this car it would be much appreciated. It's pretty ghetto that I'm still striking a yellow wire against the positive battery post to fire this thing up every time. I think if I road tripped it as is to Freiburger and Finnegan they'd be proud. One more thing, shouldn't this linkage be bent up to get caught in the choke linkage to prevent the secondaries from opening when the choke is on? I ask because I suspect that is what I need to wire together to tune the primaries at WOT.