Round 2-

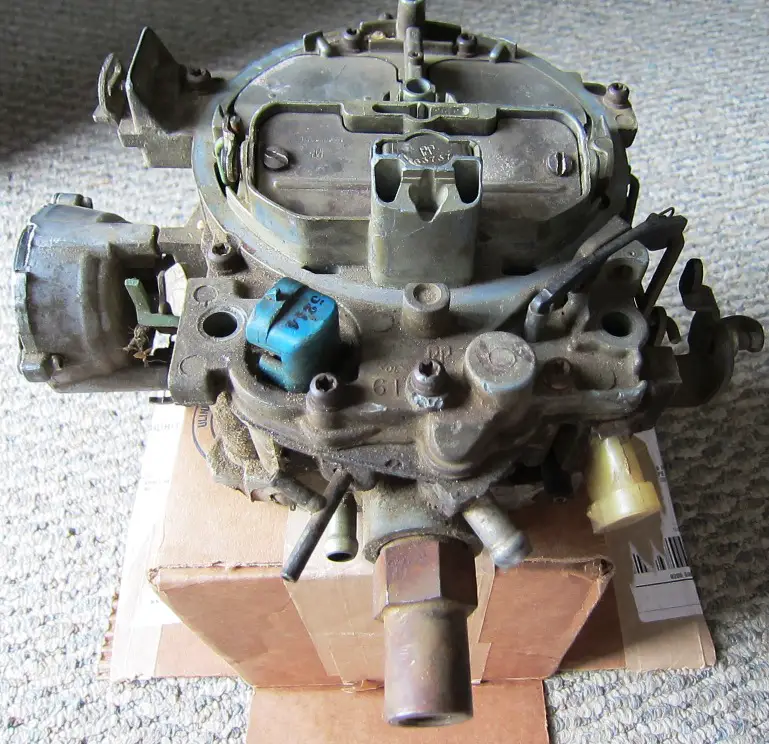

I checked my stash and I am fresh out of spare used 85 442 carbs. However, there's one under the hood of the 85. The original one that came on it. It is basically stock as it came from the factory, with the exception of sometime back around 25 years ago I had to replace the TPS on it (with an ACDelco replacment) as it started getting flittery on me causing some drivability problems. Otherwise it is stock. Still has all the plugs, caps and anti-tamper crap still on it. 60K miles on the car, so there it is.

So off it came. OMFG I think the fuel filter nut was never going to pop off but finally I got it. Even with a flare wrench I think I started to round that puppy. Got plenty of fuel tubes though, so no worries.

Disassembly went far smoother with this one than last time. The lean stop screw came out smooth as silk. No issues. Fairly clean throughout, but there was a tad of orange tinting in the fuel bowl from that yesteryear crappy unleaded fuel.

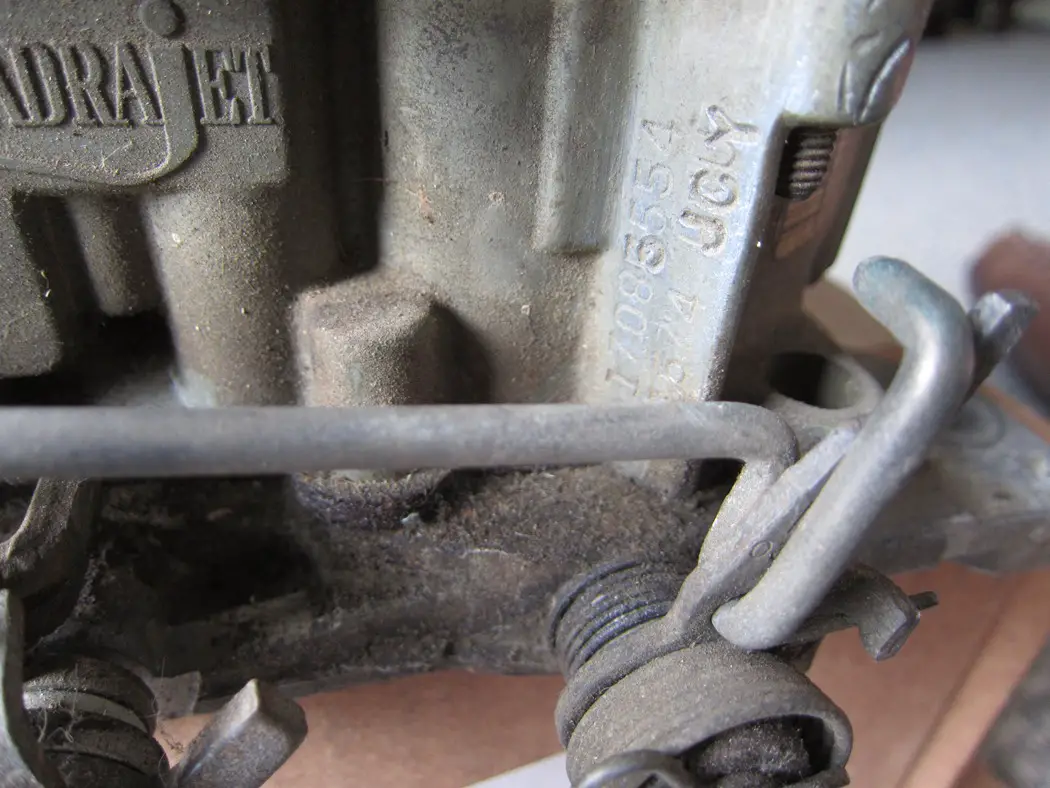

This one was built the same day as the NOS 84

H/O carb I got on the shelf. No surprise. Day 158 (June 6) of 1984. When it actually got restamped is anyone's guess. My car was built in February 85, so I'm guessing when they assembled the engine they whipped out the hand stamps and had a party? I dunno. You can see the ham-handed-ness on the restamp. But, that's GM for you.

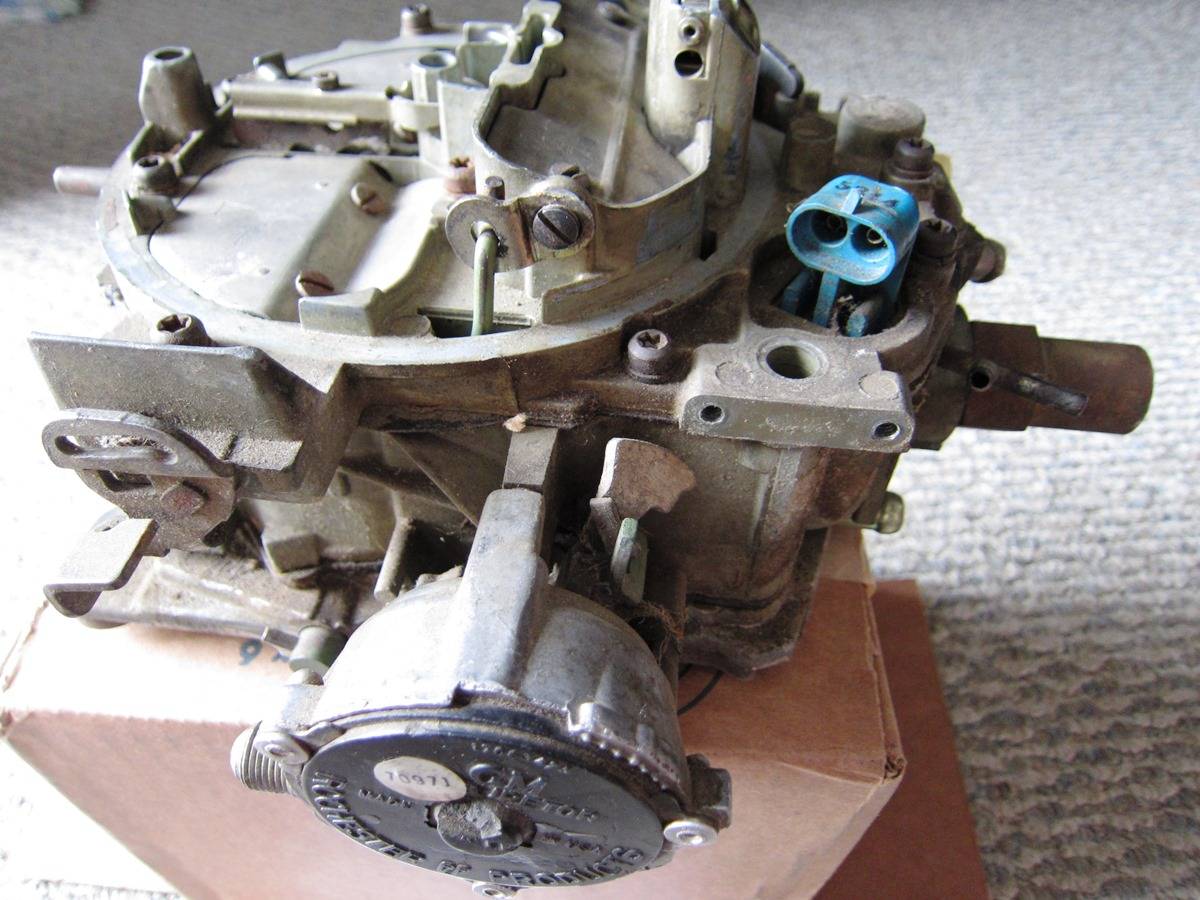

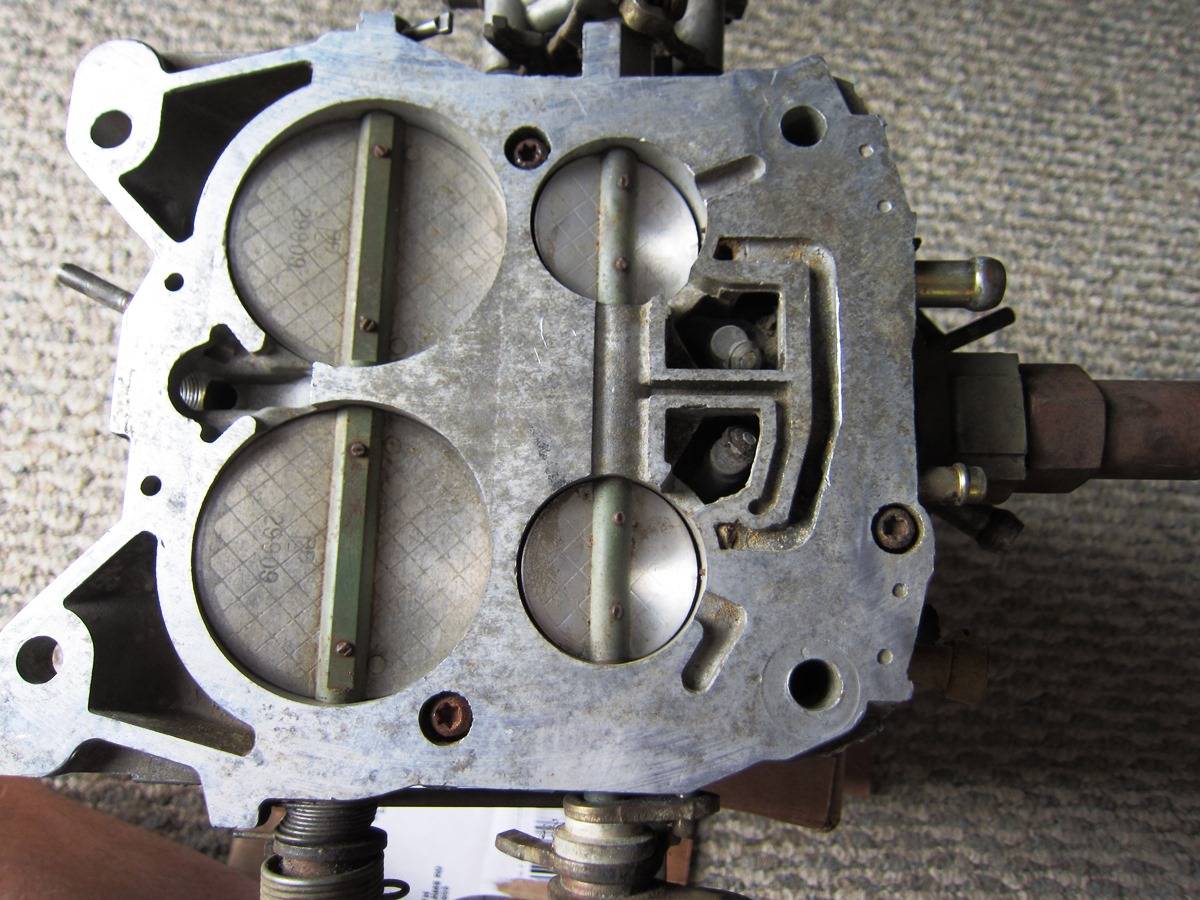

When I flipped over the top and started disassembly of that, I noticed something odd that I never noticed before. Keep in mind, I know this carb. It's been with me and the car since it was built. But this is the oddest SOB I've ever come across. I have a VIN 9 carb, but a VIN Y air flap tabbie. Yup, you heard right. I went and got the other 5554 carb top from the fugged up one (Round 1 carb) and did a comparison pic. It can't be a VIN Y top because the VIN Y is a 2-point adjust carb, meaning no rich stop provision is drilled/threaded into the lid. BUT... this one got an extra long tab for the air valves.

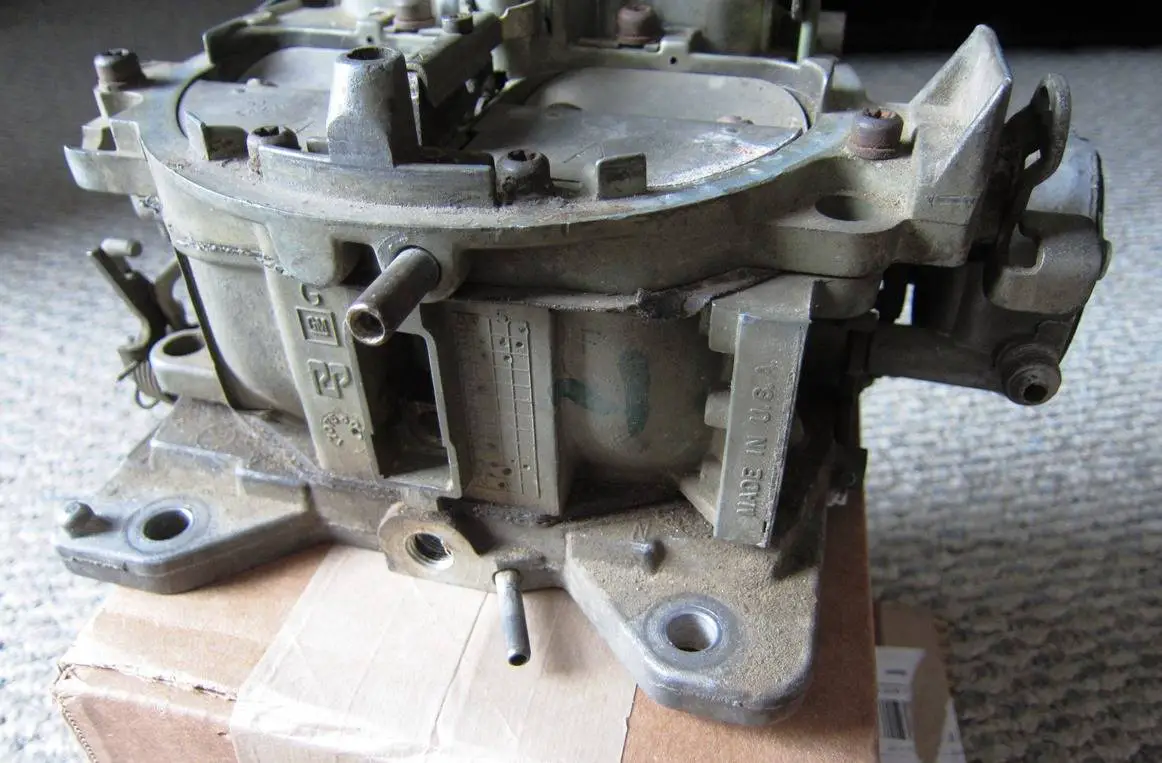

Secondary hanger is a J, which is weird, but the secondary rods are DA as expected, and primary rods/jets are 57U/75, which was also expected.

I sh*t you not, I've never seen a VIN 9 carb with a tab on the secondaries. Another example of 80s GM quality.

Also, when I pulled the carb top off, one of the accelerator well tubes on the secondary was laying in the bowl. I wriggled the other one a bit and it came out easy. WTF GM???? Can't make things last 40 years??

🙂

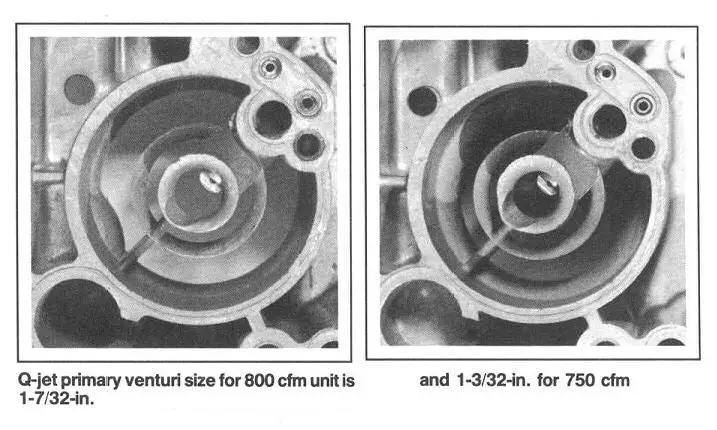

For anyone interested, the accelerator well tubes act like secondary pump in a way to get the secondaries going to help cover any fuel starvation as the secondaries open up. There's a discharge port just above the front of the secondary air flaps. Fuel is drawn through the tubes and into the secondaries through those ports JUST AS the secondary air flaps start to open up as rpms increase. The positioning of the air flaps form the venturi area in the right spot to start sucking some fuel into the secondaries before the main secondary jet system starts supplying the majority of the fuel. The accelerator wells are supposed to cover that lag time. Without it, you can run into a never ending stumble when the secondaries open. Some race car guys fill the ports with solder and redrill them so they end up discharging just under the air flap. I guess the idea is to get them to pull in even sooner. If you're using an E-jet, you're likely not going to be looking for HP though.

Comparison with 2 VIN 9 air horns off 17085554 carbs. Identical except for the tab on my original carb. Note too, that both carbs have a rich stop provision, although the one on the left, which is the one off my car, has the air bleed valve and rich stop and plugs already removed. Kinda hard to tell on this pic, but where the arrows are, you can see the difference in the air valve rotation limiting tab. I mean WTF.

So it appears I'm going to have to fix what Rochester screwed up. I carefully measured the non-tabbed stop on the spare VIN 9 carb and it came in at 5/32" on the far side from the back, and it is cut at a slight angle to end up without any tab sticking out on the outer section. So it's effectively an angle. Using a super-calibrated black thin sharpie, I made my mark. You can barely see the mark, but it's there. Dremel cutoff wheel made quick work out of it. Boom. Fixed that for you, GM. Now it looks like the other one. So if you have a Y carb or any other carb that needs a tab filed/cut off, that's where you make the mark. Now I have fully opening secondary air flaps. WTF!!

I got 3 of the 4 shafts out. I've still got to grind down the primary choke shaft screws and pull that shaft, but that will wait until tomorrow. The bowl is empty and stripped of everything I can get out of it. The throttle body is almost bare...still have to cut the metering screw caps and grind them out so I can get the adjuster tool in there (not going to chisel the throttle body) and I think the only thing left on the air horn besides the choke shaft is removing the TPS adjuster screw cap. I already drilled a little hole in it, but need to put a sheetmetal screw in there and pop it out and remove the screw.

The throttle blade, secondary air flaps and the choke blade are all held on with tiny, staked screws. YOU MUST use a Dremel or air grinder, or something similar to cut down the the tips of the screws coming out of the bottom side. If you do not, you seriously run the risk of busting off the screws inside the shaft and they are made of hardened steel. A real PITA if you don't grind them down first. Be careful doing this as that green stuff all over the shafts is a teflon coating that you cannot duplicate! At least not cheaply. You can damage that teflon rather easily and corrosion could set in. Throttle blades use a tiny 3-48 screw, with a T8 size fillister like screw head, while the secondary air flaps and choke blade uses 6-32 straight blade screws. It's a good idea to get some taps in those sizes as well just to clean up the threads. You will have to buy new screws for this. But don't just buy any old screw as you need hardened ones. Unfortunately, I can't find any original T8 3-48 screws, so straight blade screws it will be. A little dab of loctite, or you can stake them if you wish, but either way, you don't want those puppies to come loose and get sucked into your engine!! NO BUENO!

In case anyone was wondering, the little air bleed valve cover on top of the carb is held on by tiny rivets. These need to come out when rebuilding your carb if still there. A 7/64" drill bit is perfect for this. Says 0.110" drill bit in the literature, but that's if you're miking it. A 0.129" is called out for the choke rivets but that drill bit works out to be a 5/32". Also, the internal choke screw heads take a T20 for the mounting screw, and for the center shaft screw, it's a T15. This is not even spelled out in the literature.

Additionally, you will need to remove the intermediate choke shaft seal (as well as the choke housing shaft seal) rubber bit. It may appear to be brass, and while that part is, don't go prying on it. Just the rubber bits need to come out. See pic.

That's all for now. Never know what you'll find working on stuff.