Finally, the day arrived when my carburetor returned back to me in better condition than when it was sent. I was expecting to like it, but I wasn't expecting the level of detail I got. Granted, the guy is a retired GM engineer and knows carburetors inside and out, but he tends to shy away from the CCC style, but he is knowledgeable about them.

His name is Harold Demes, from Vail, AZ. His email addy is [email protected] if you wish to inquire about his services. I can tell you from experience, it took about a month and a half from when I sent mine out until I got it back.

Cost to send it to him via FedEx was around $35.

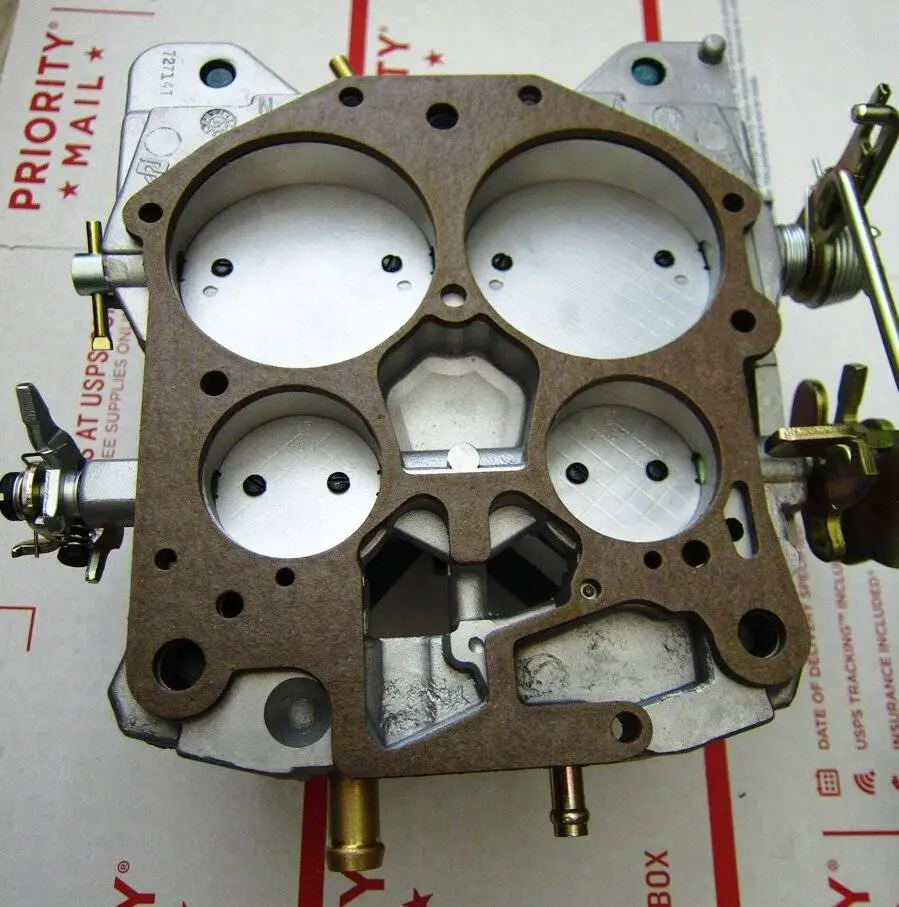

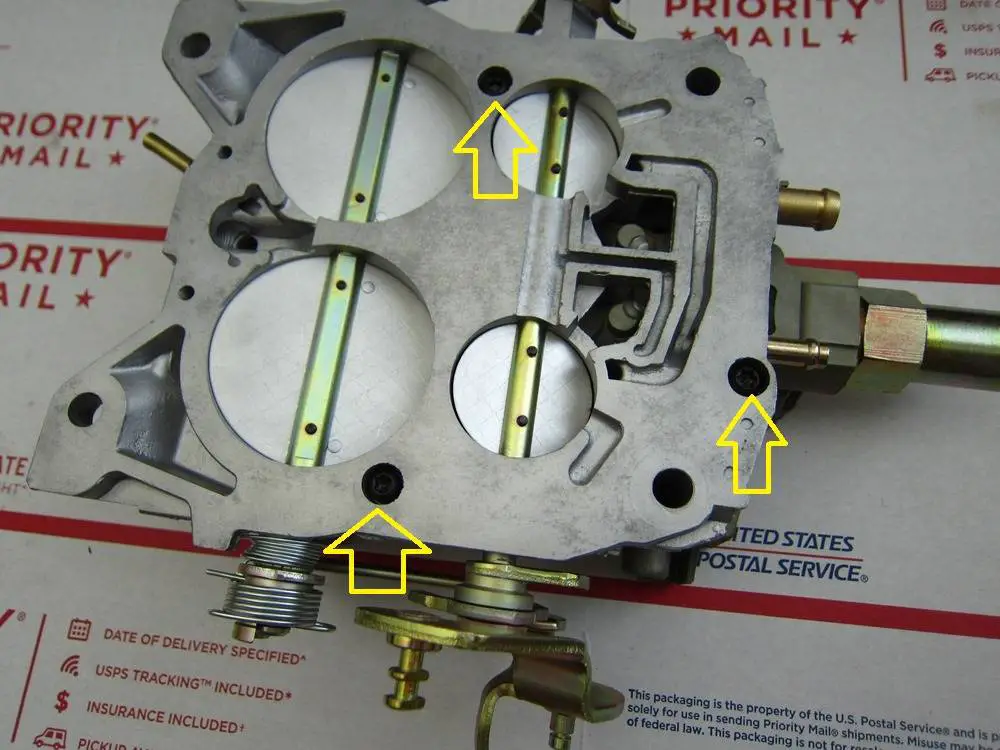

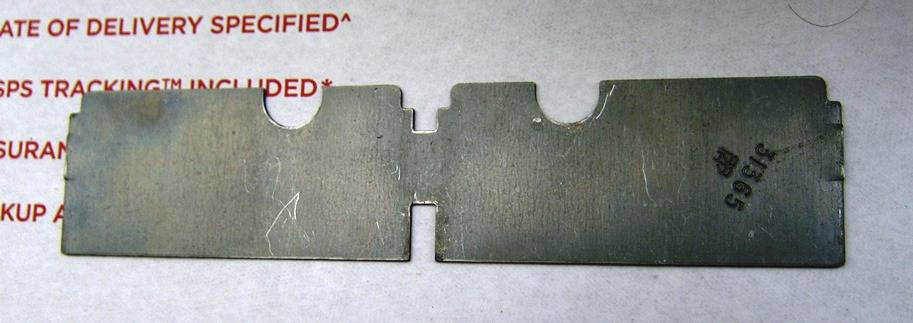

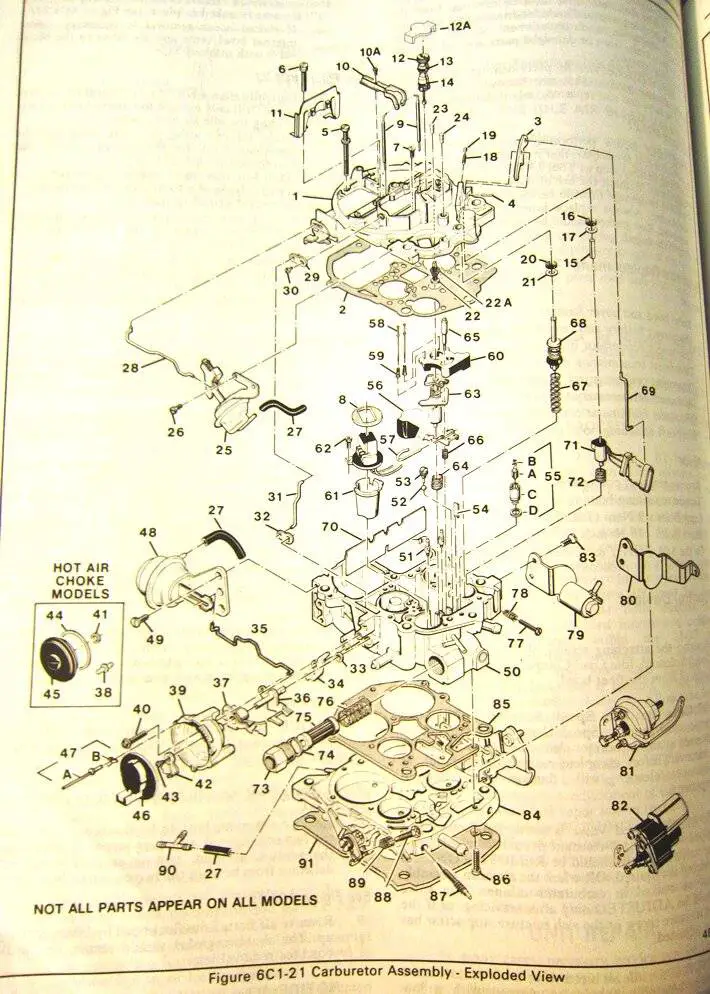

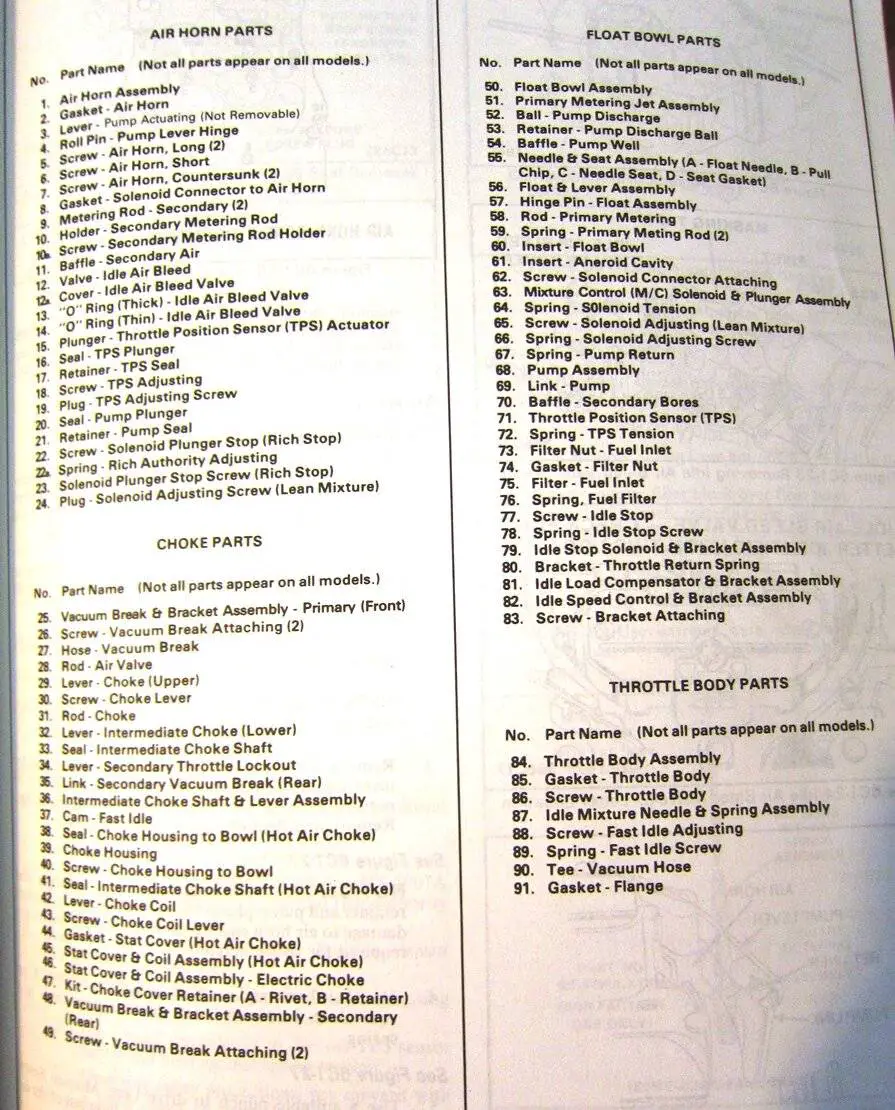

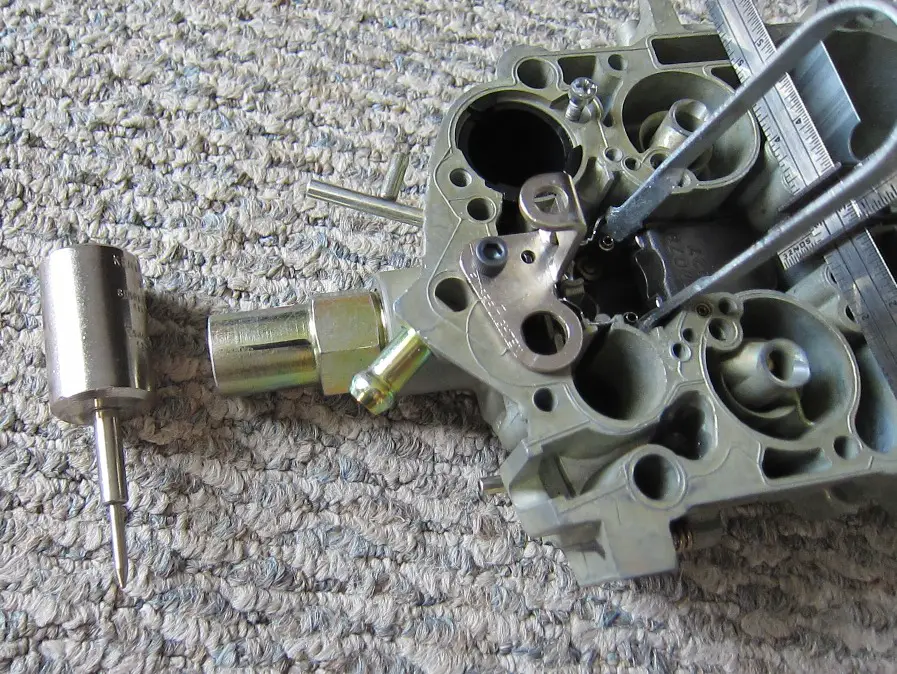

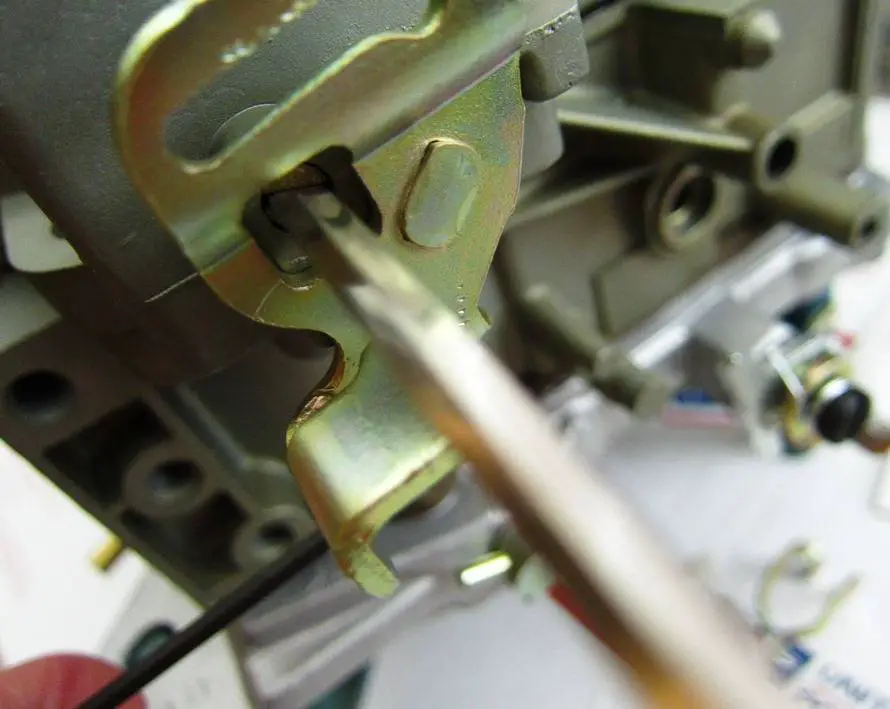

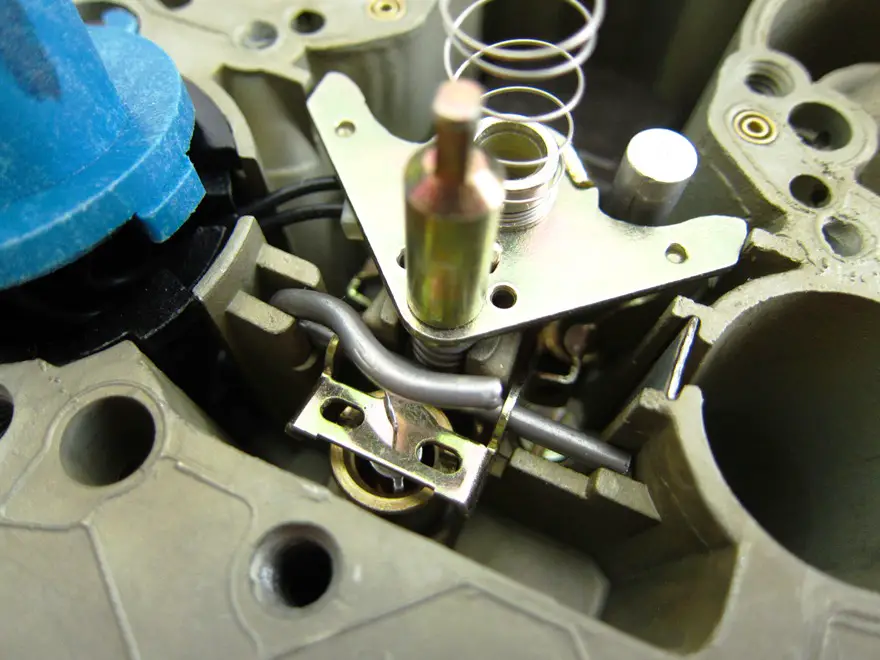

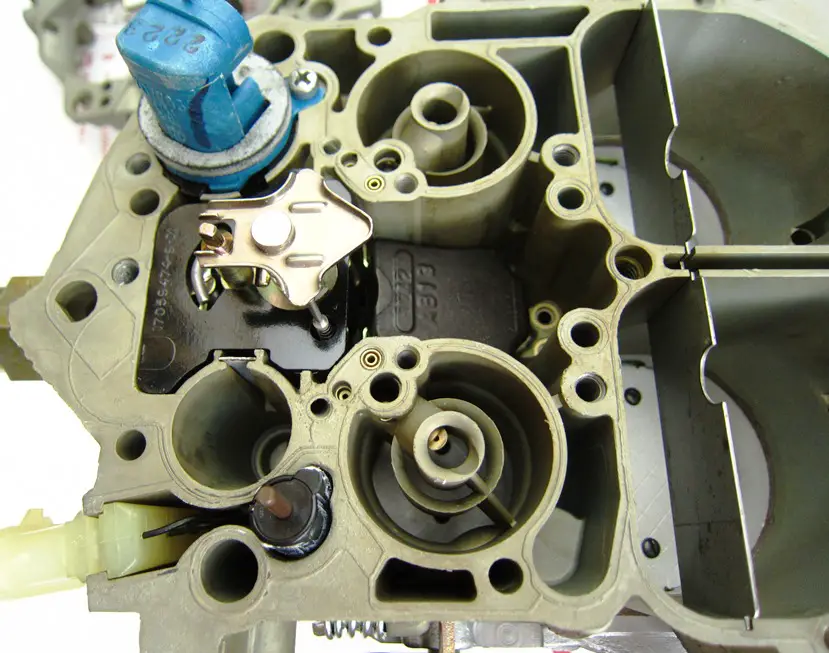

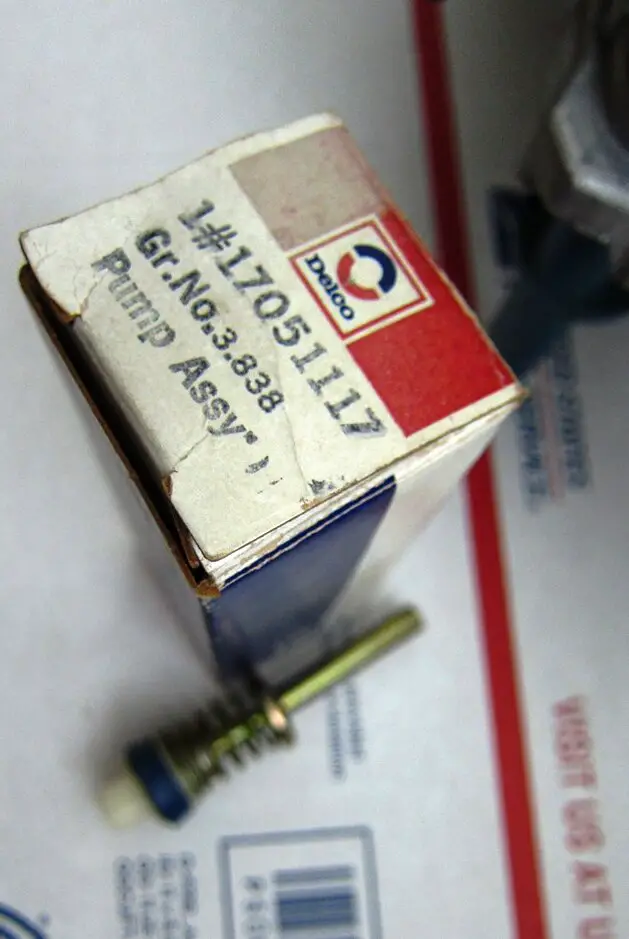

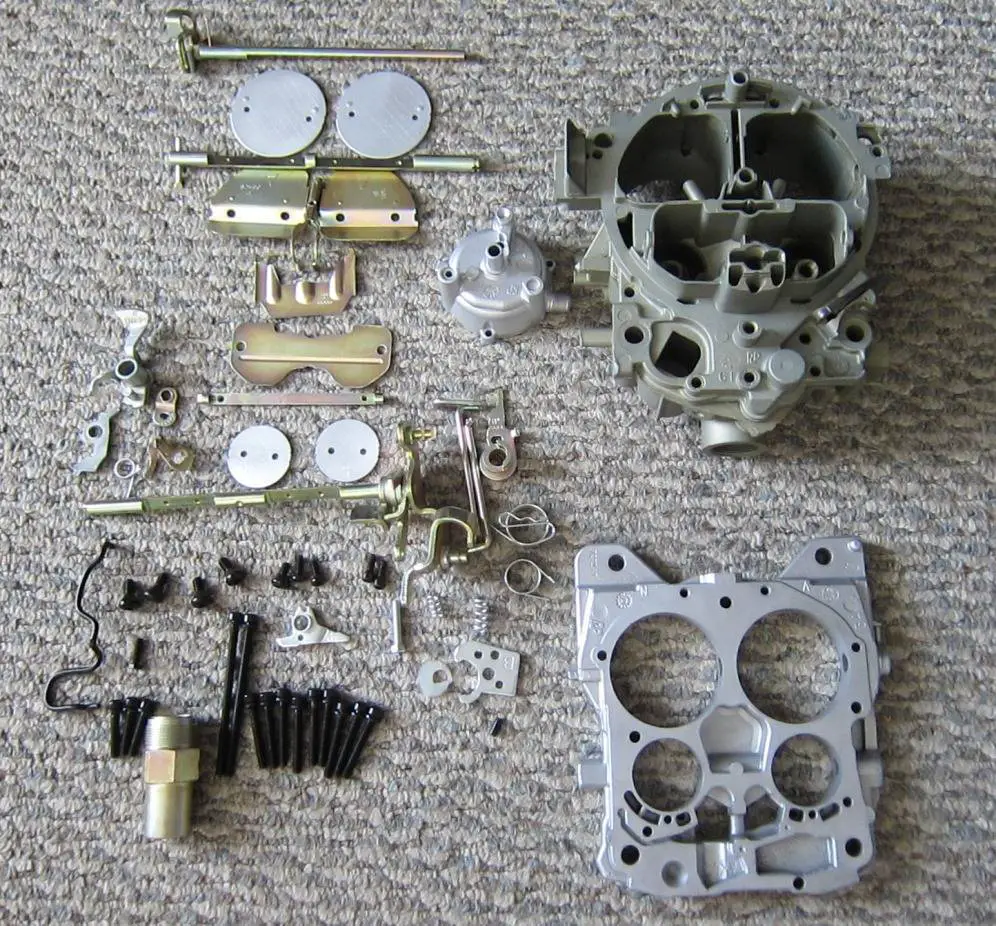

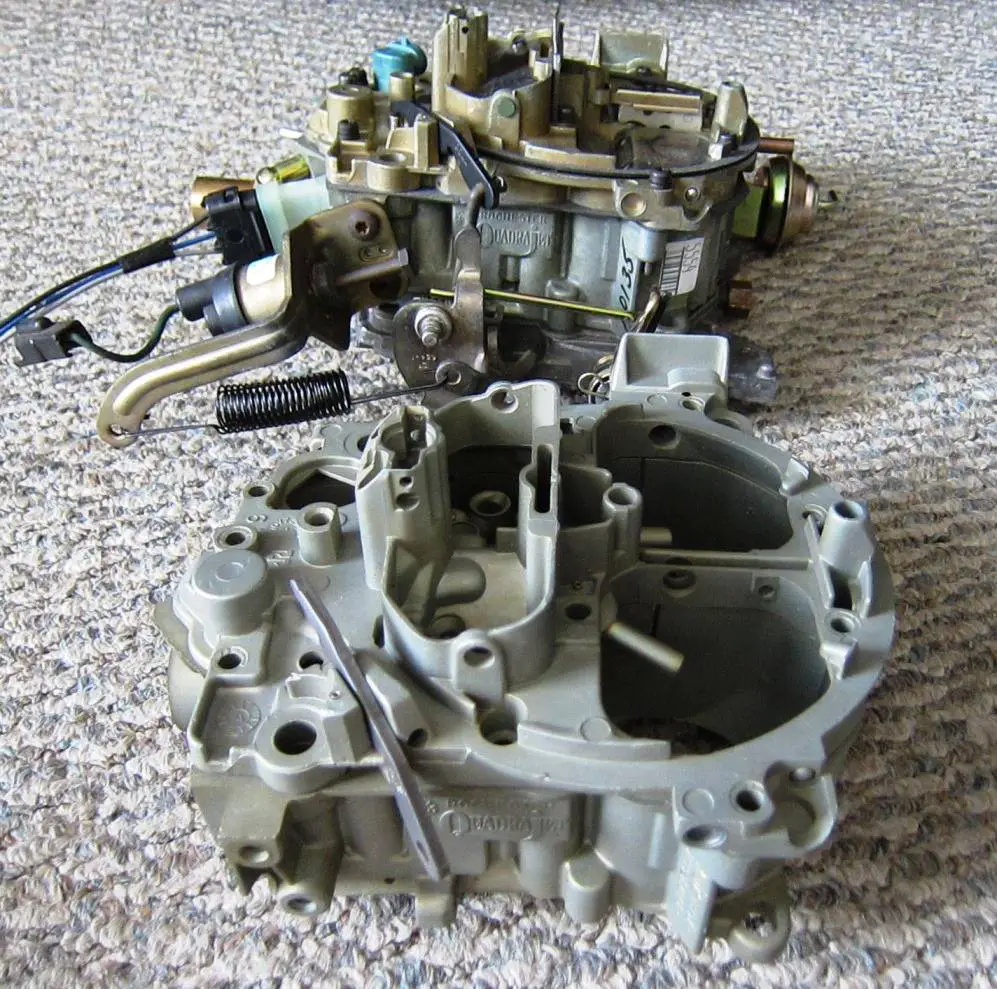

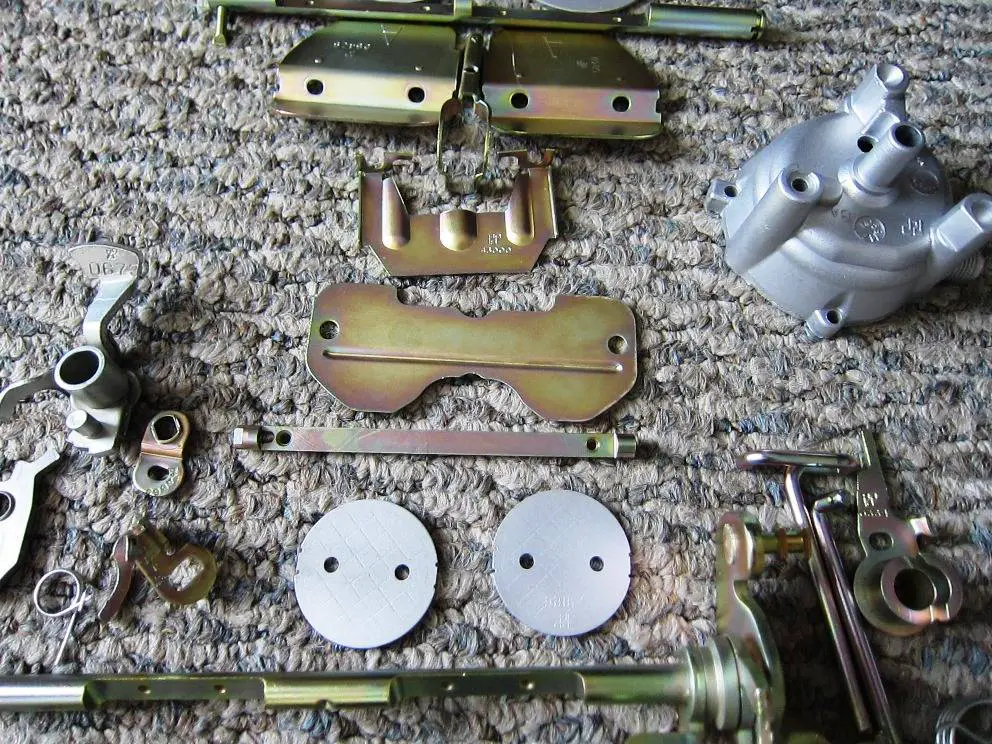

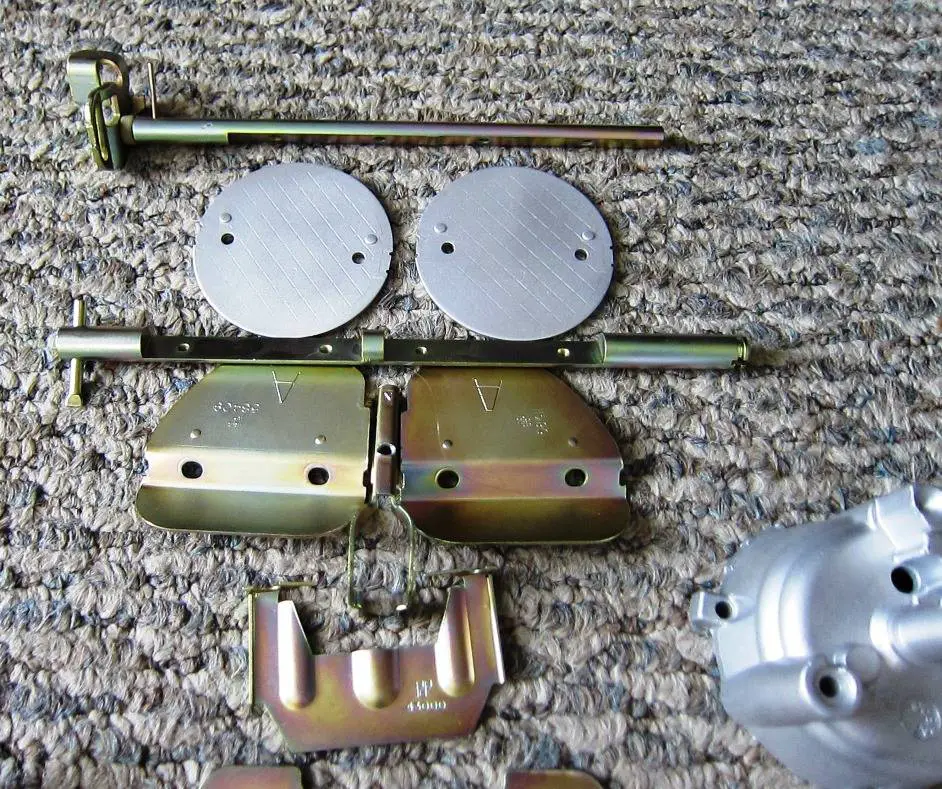

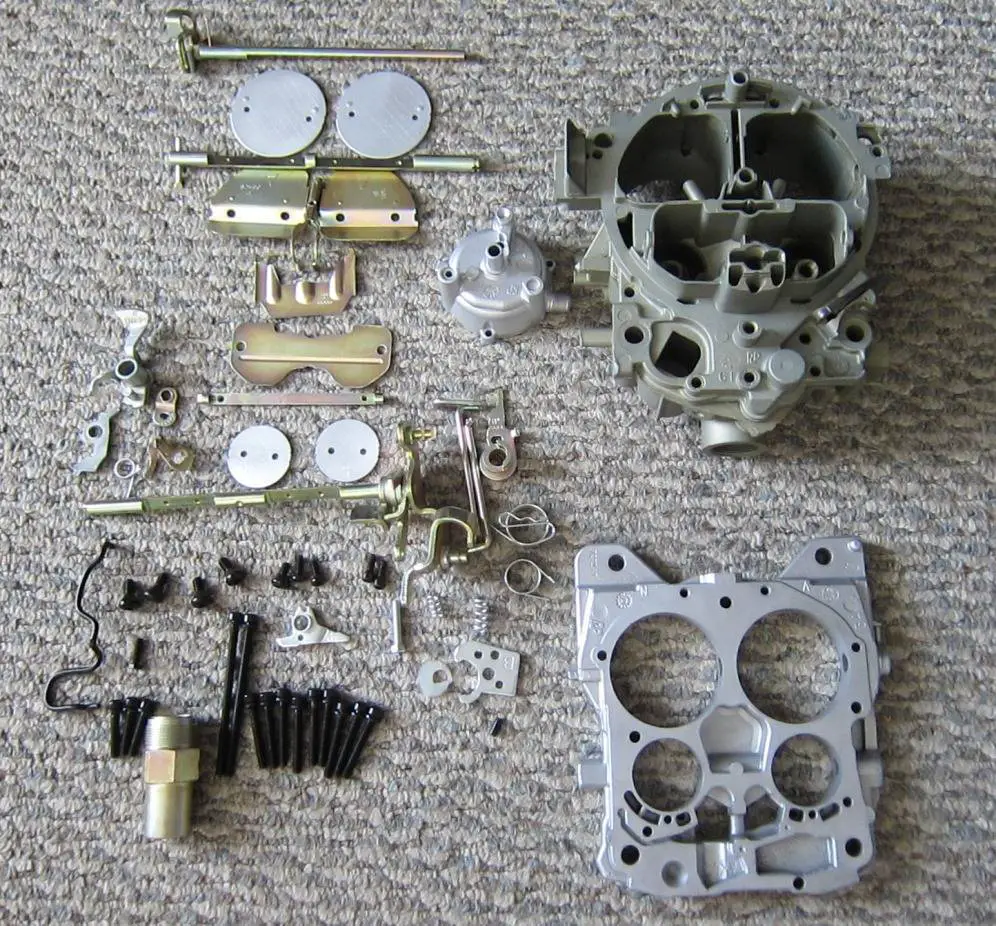

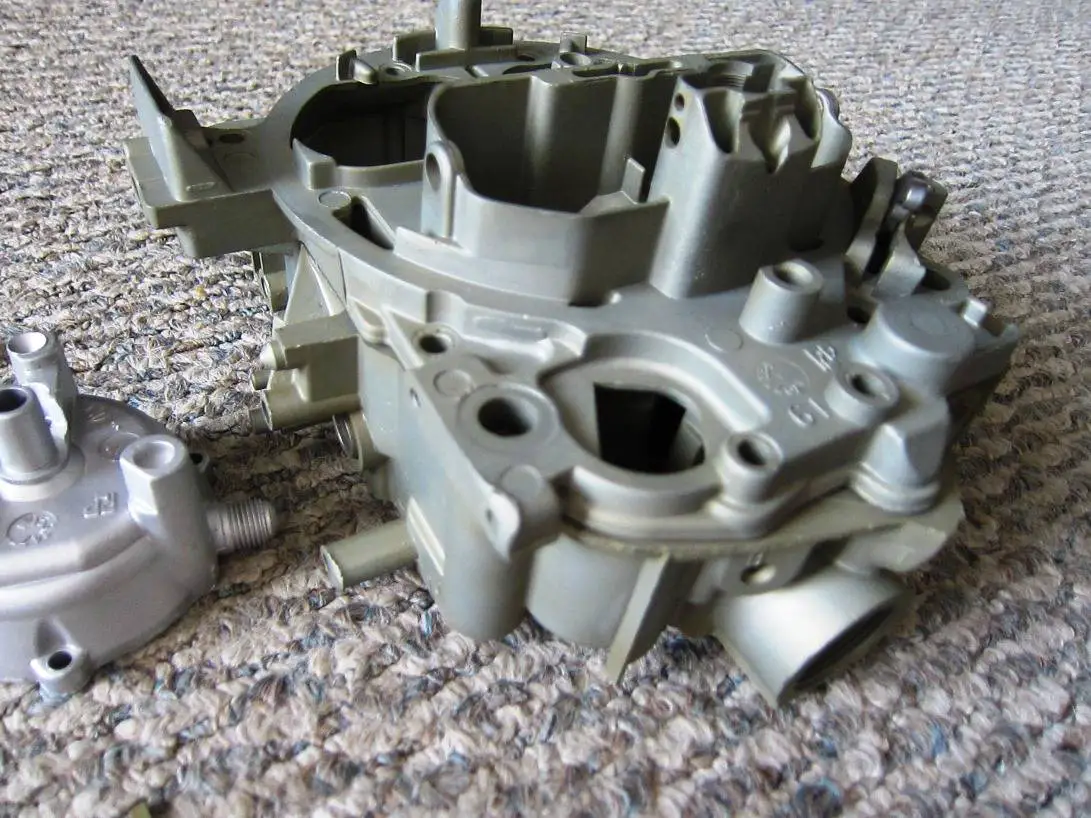

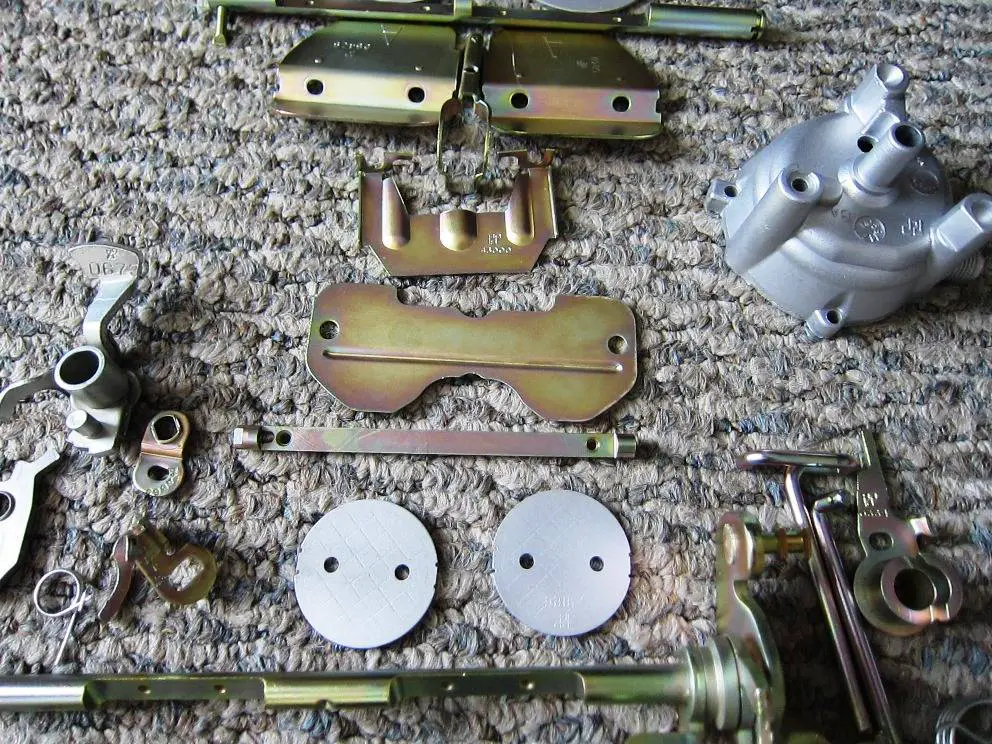

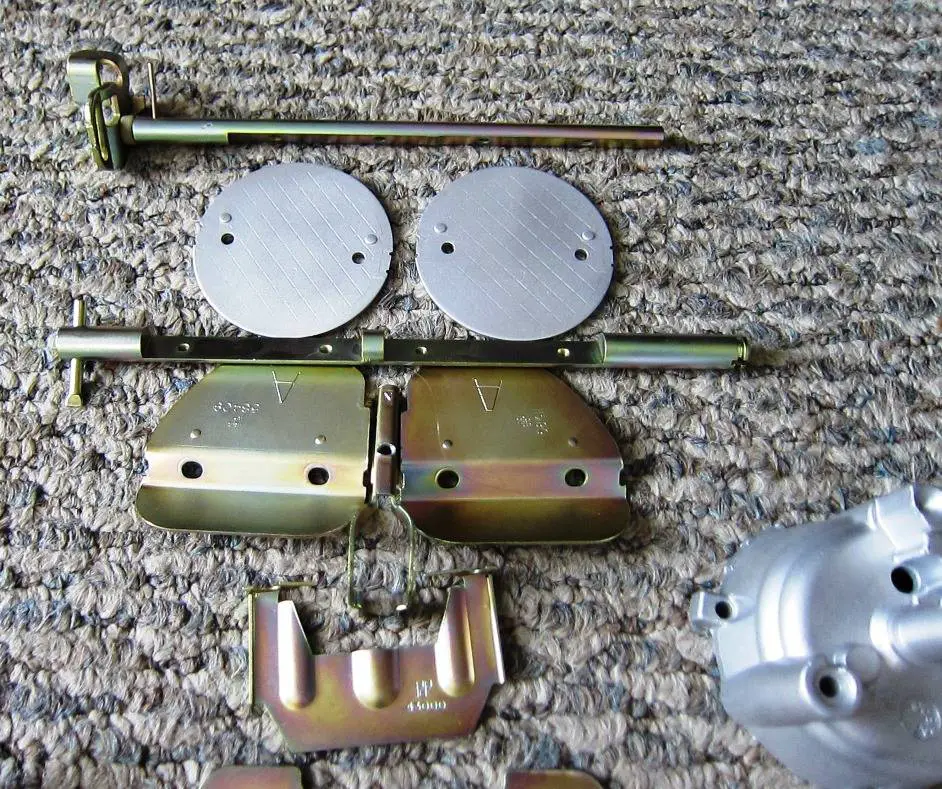

I stripped the carb down to parade rest. I only included things that were crucial to the replating/refinishing and cleaning procedures he was going to use. No electronics made it to him, or primary guts or secondary rods.

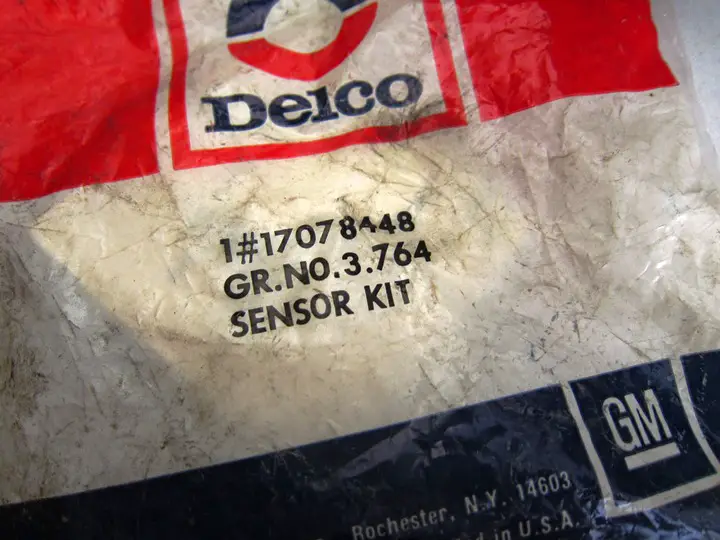

His price to clean/refinish/replate the stuff I sent him was $100, and he charged $50 to rebush the primaries. I had a standing order to do the secondaries if he deemed necessary, but he didn't believe it needed it. Not many do, and this one was no exception. A flat $20 return trip. Total cost with turnaround was $205. Your price may vary, that's up to him. So if you're interested, contact him. MANY many people with Quadrajets are pleased with his services. And now I am too. I'm not sure what he'd charge to do a complete top to bottom restoration, but again, he likes doing the older, non-CCC carbs the best.

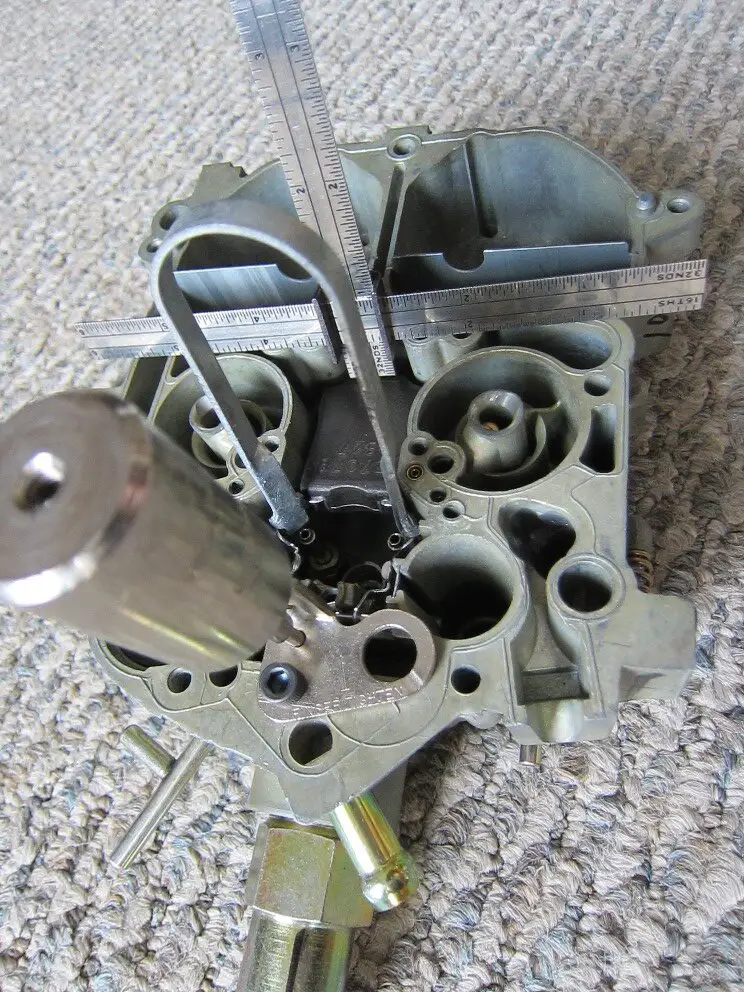

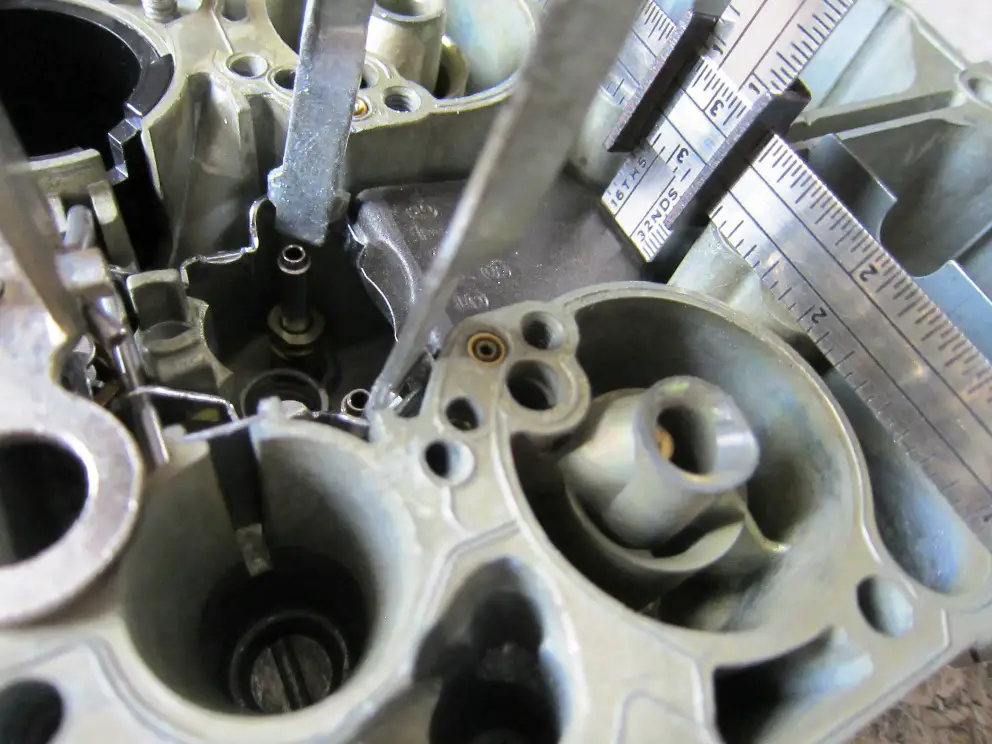

I have the skills, tools and parts to do mine myself, so why not? If I had all the cool plating stuff, I'd do that myself too, but I don't.

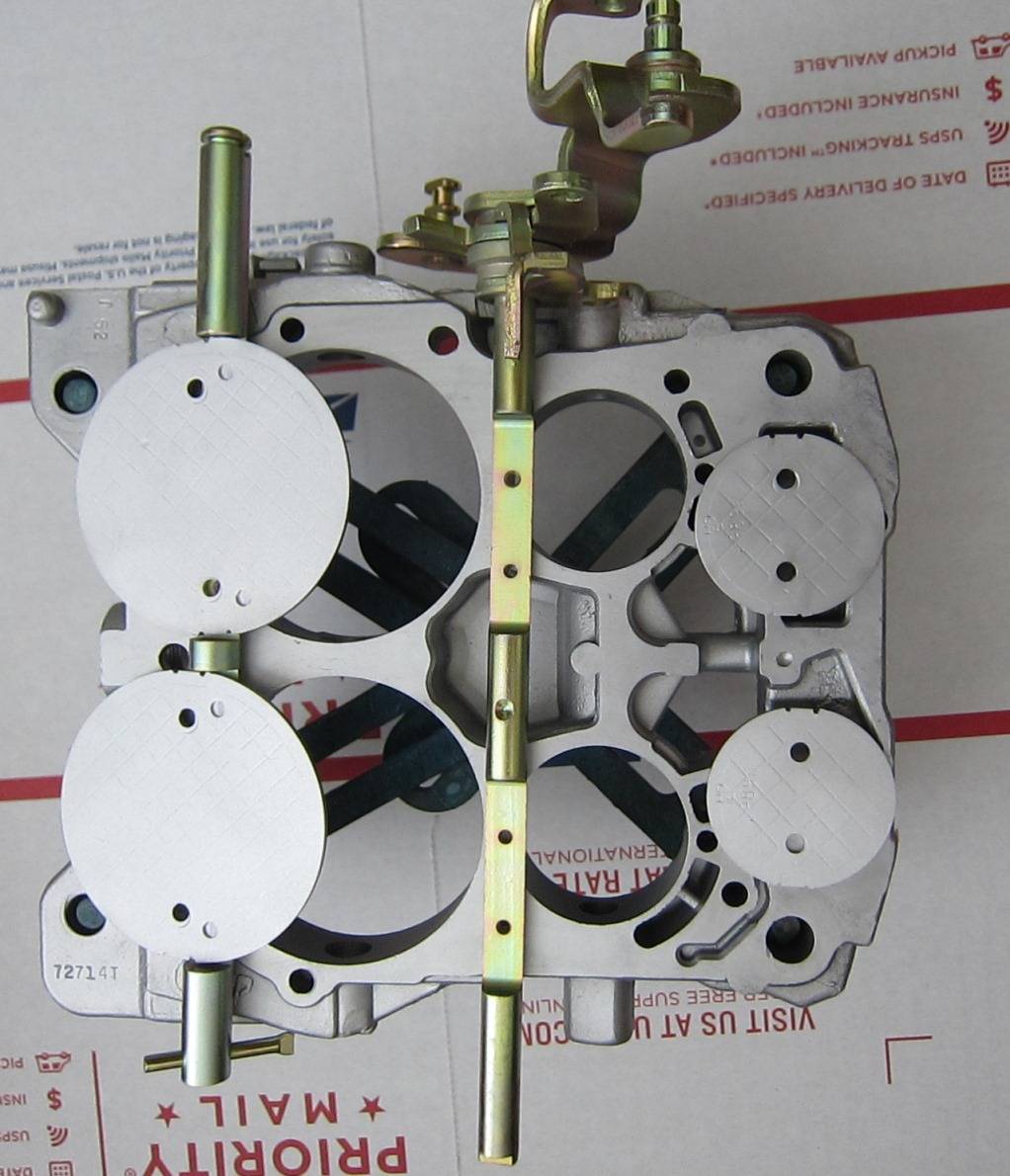

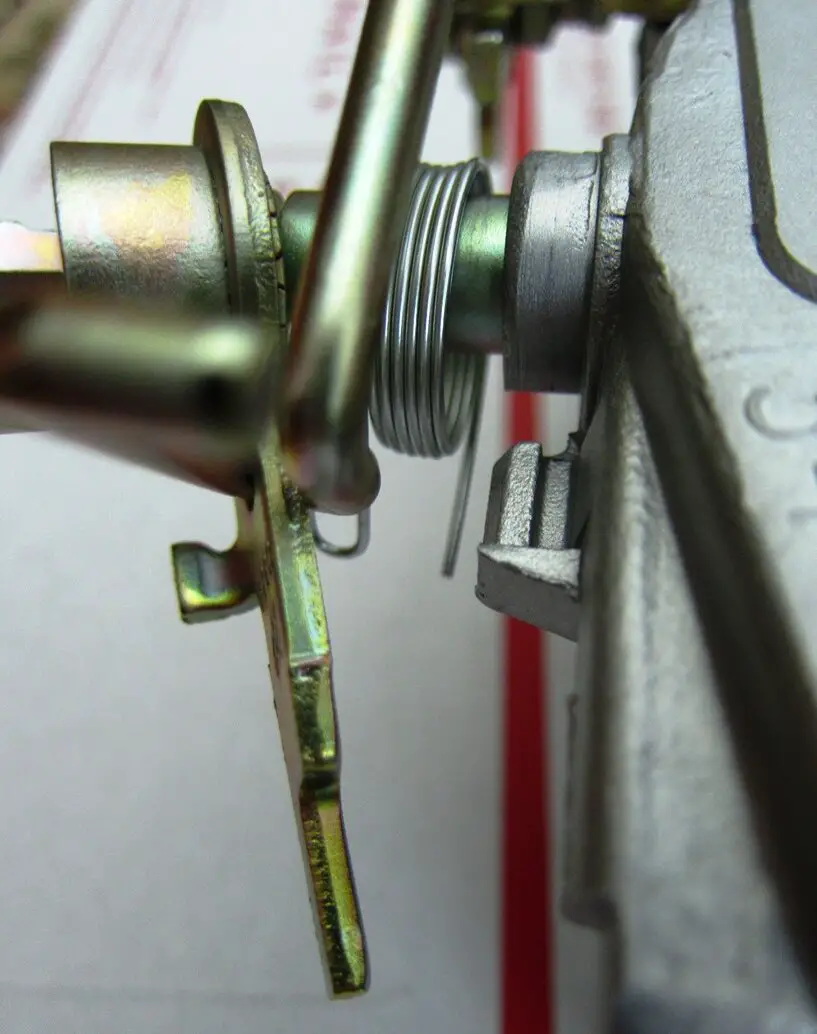

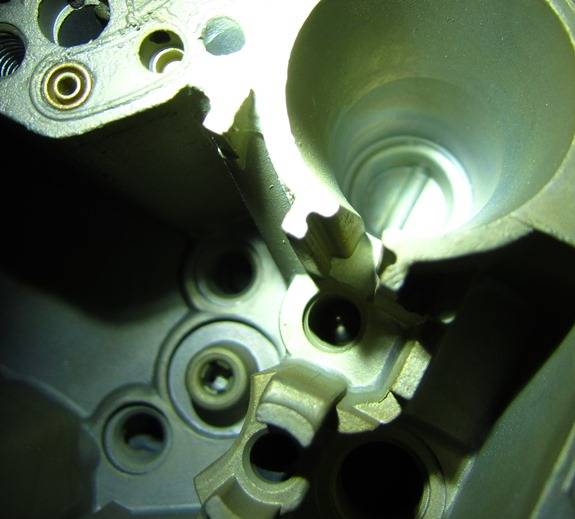

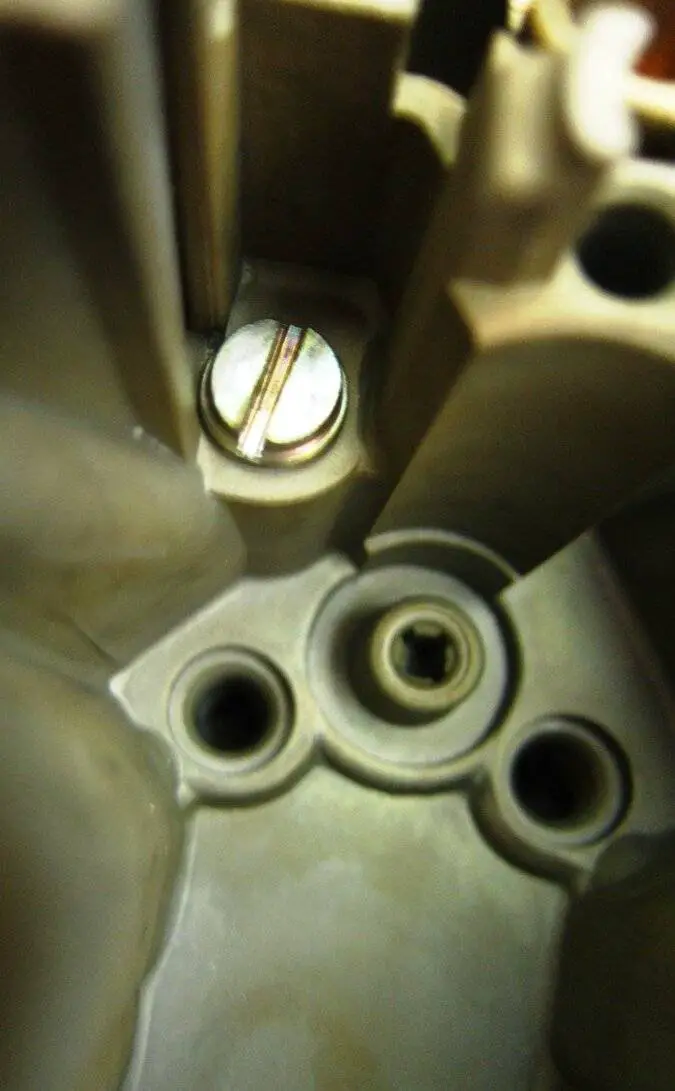

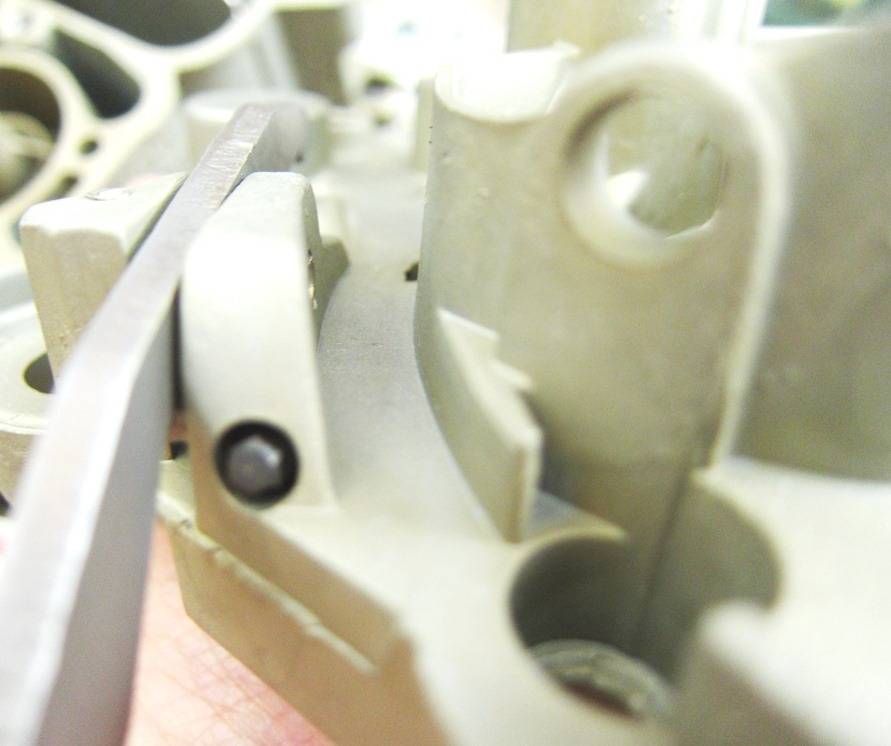

As received.

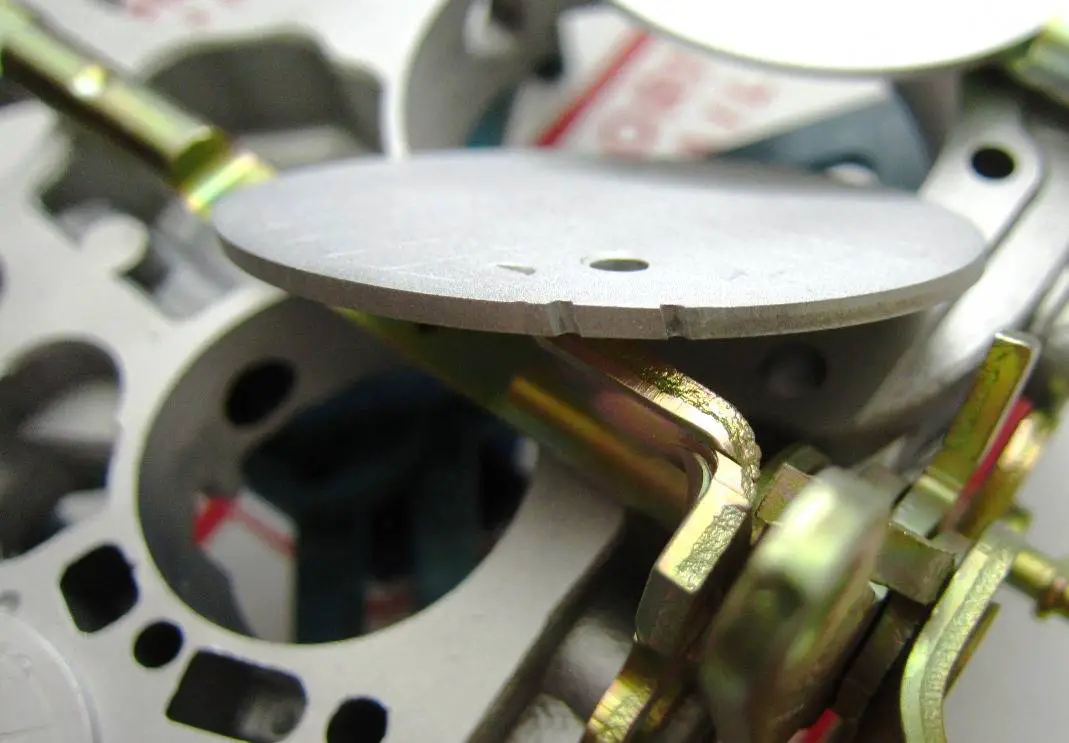

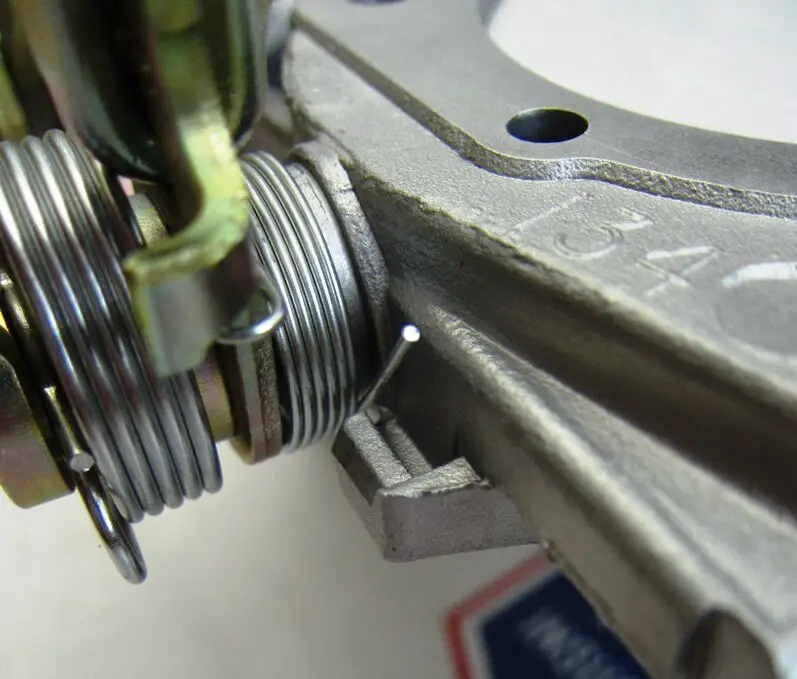

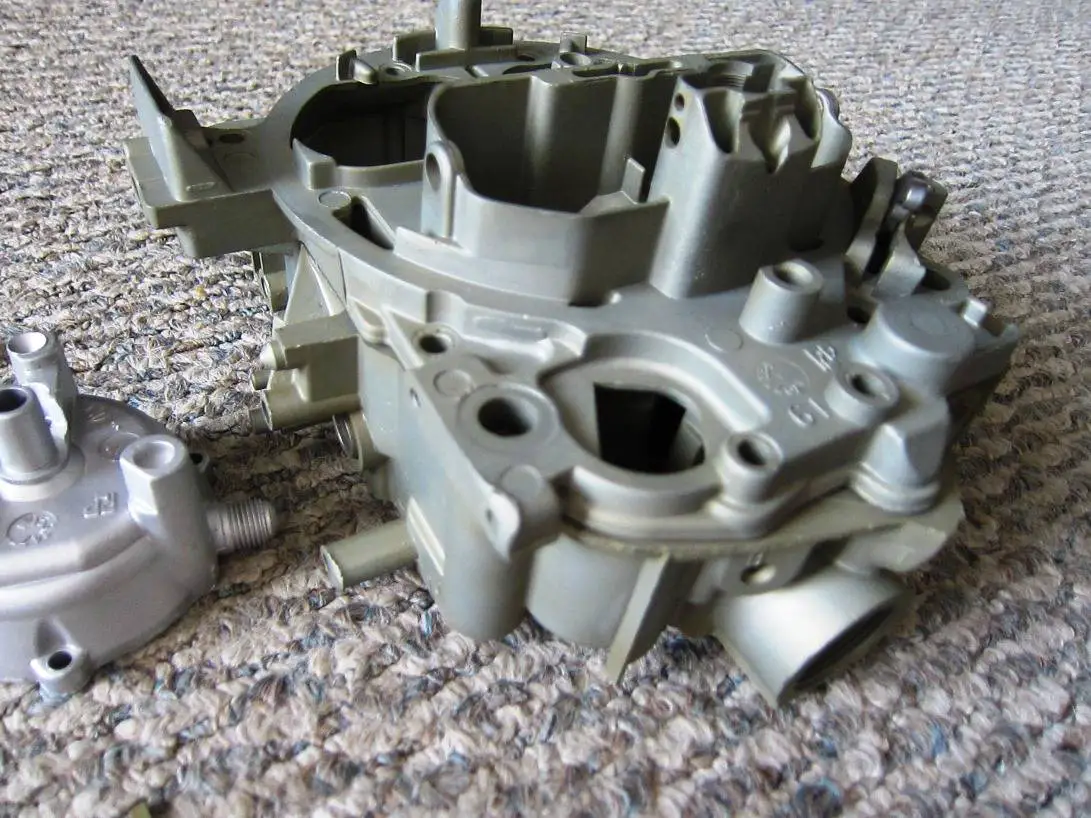

Looks pretty good overall.

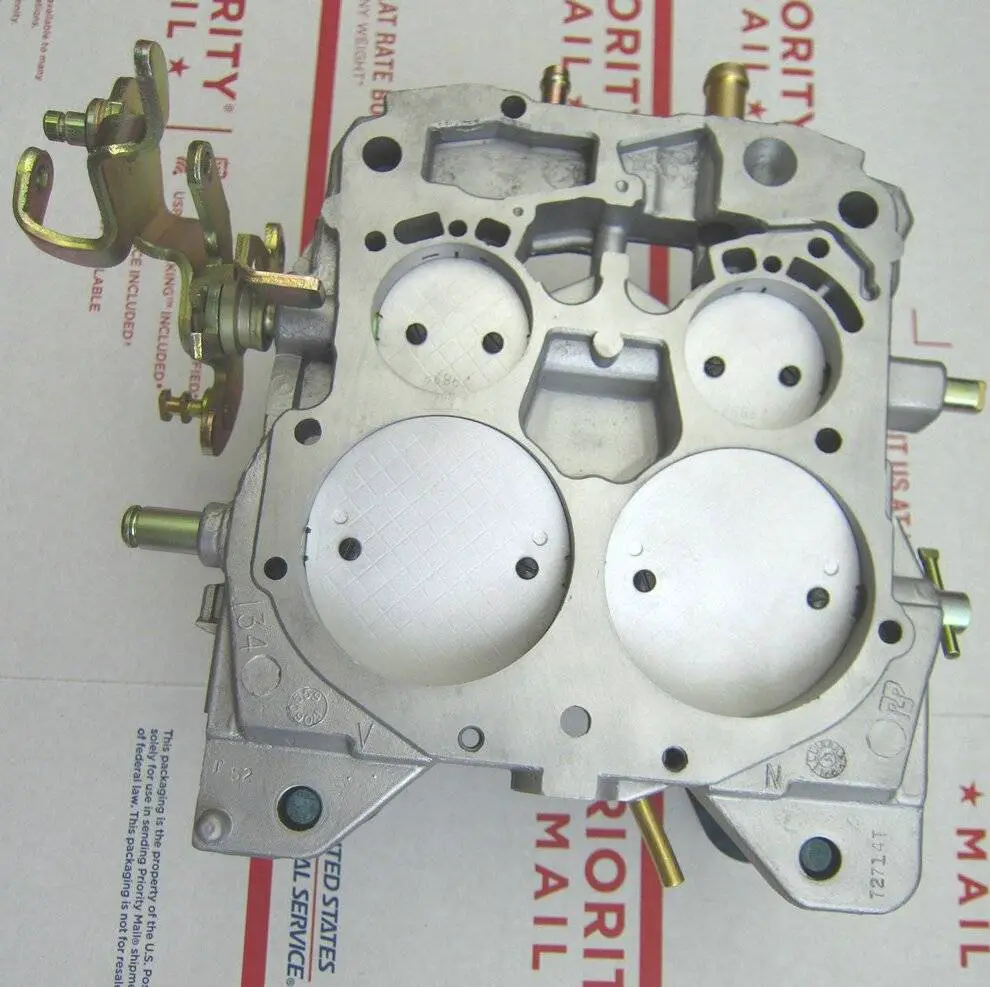

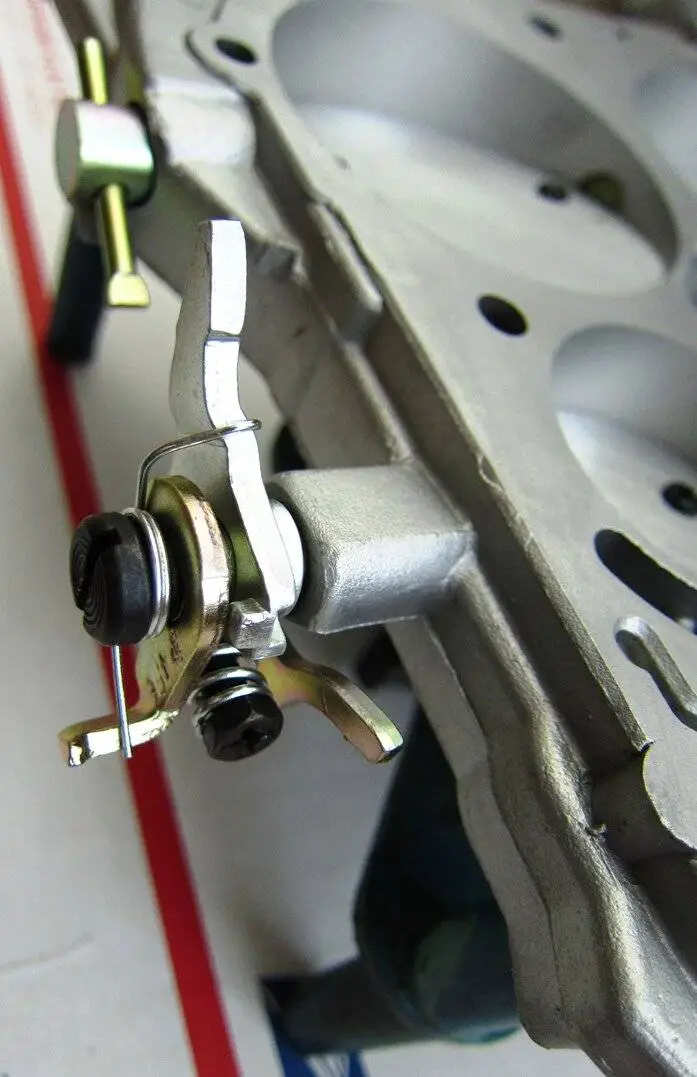

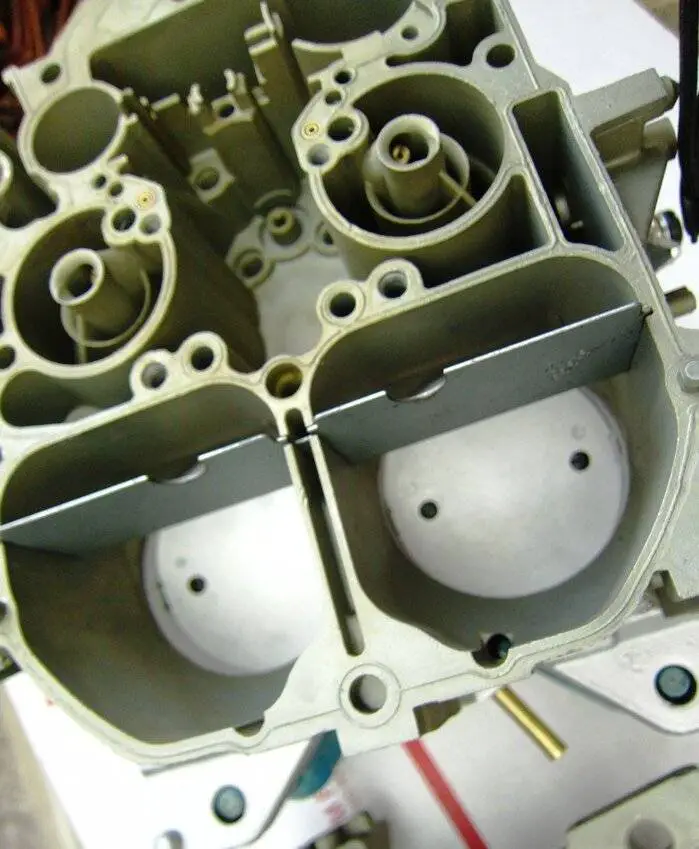

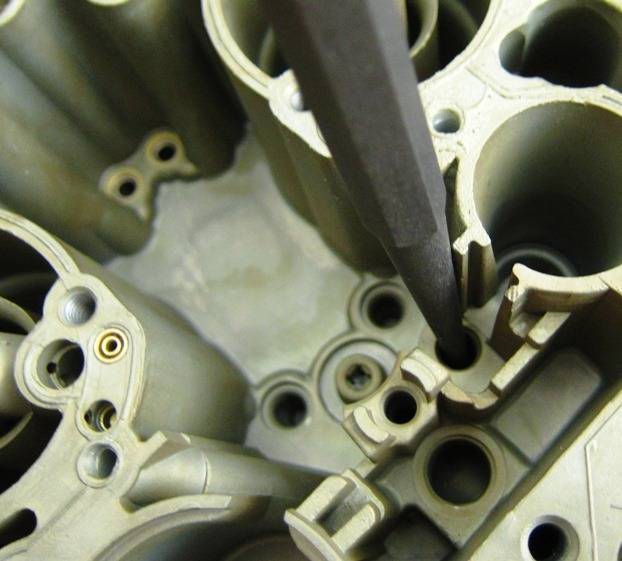

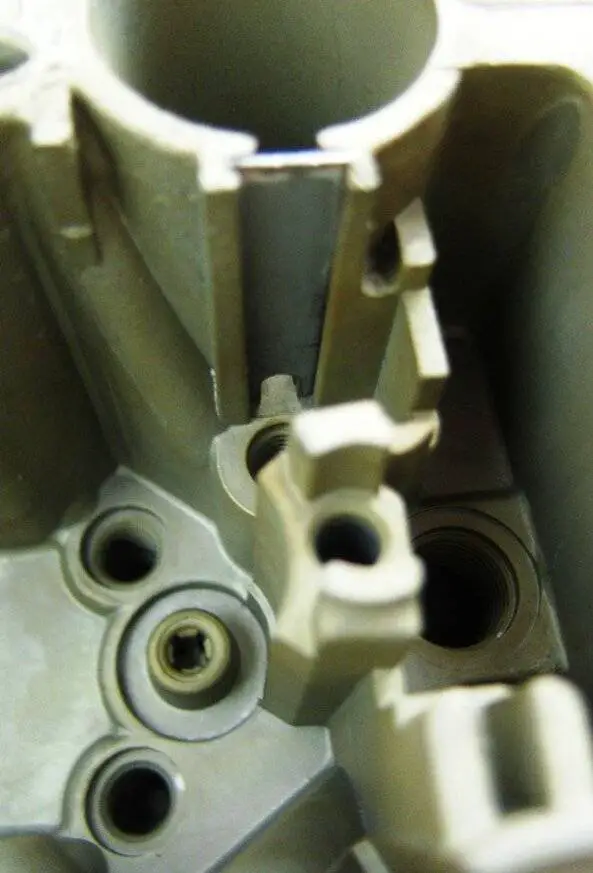

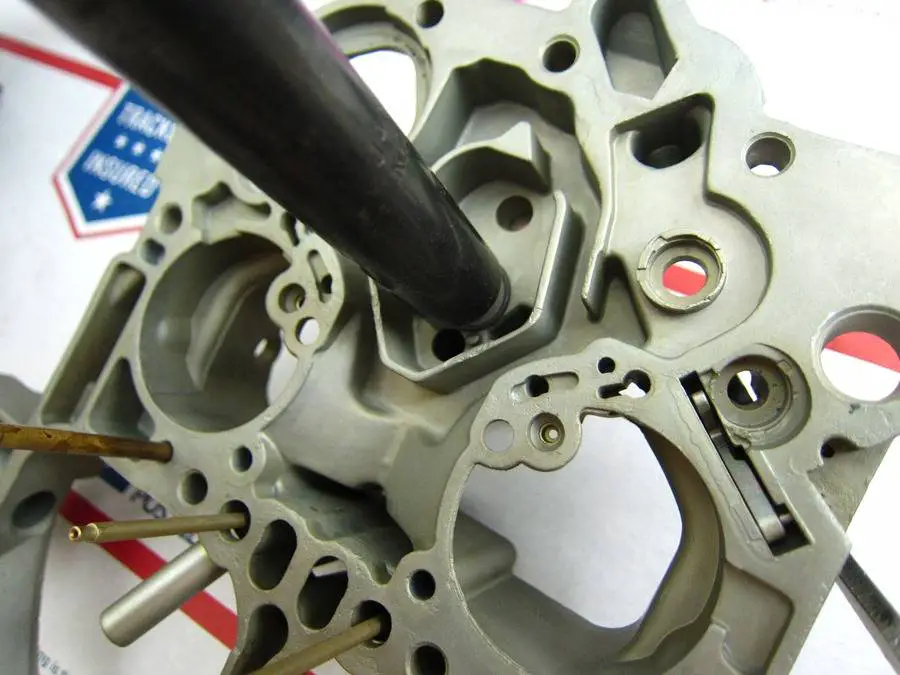

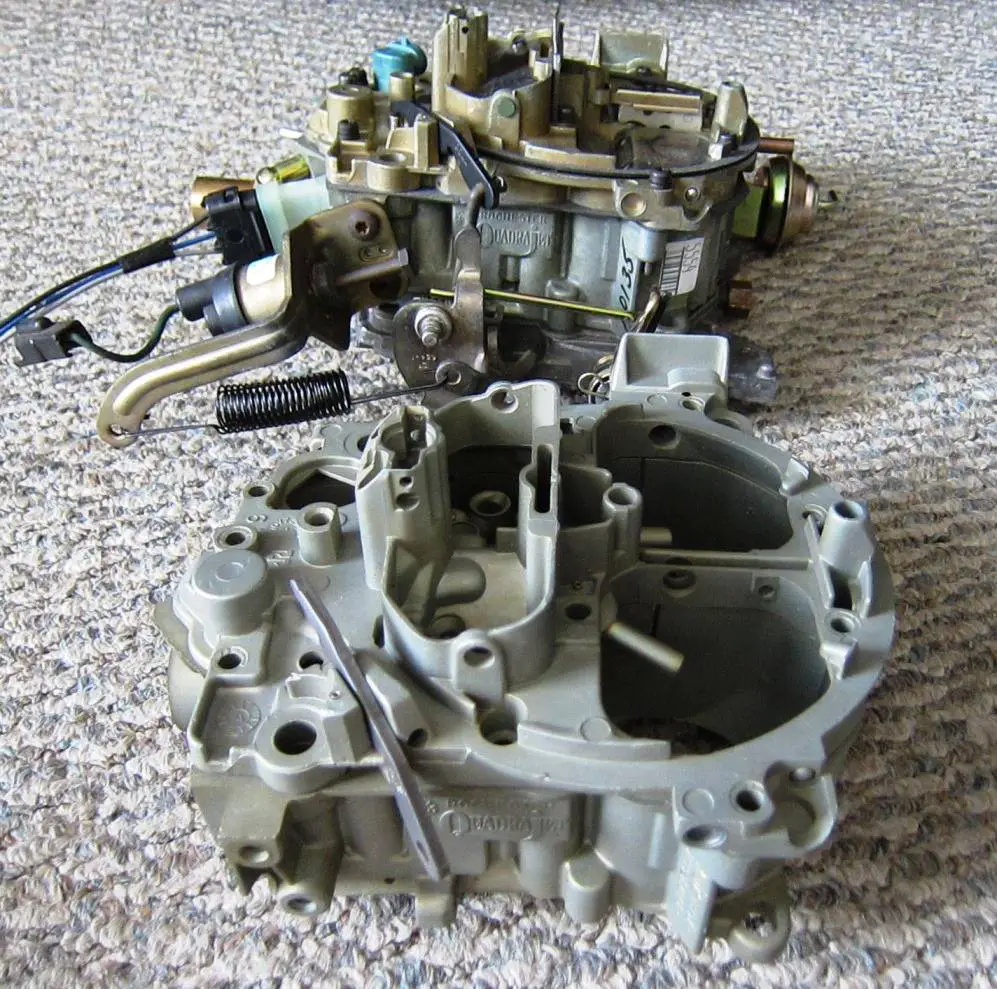

Yup. This is the carb I sent!

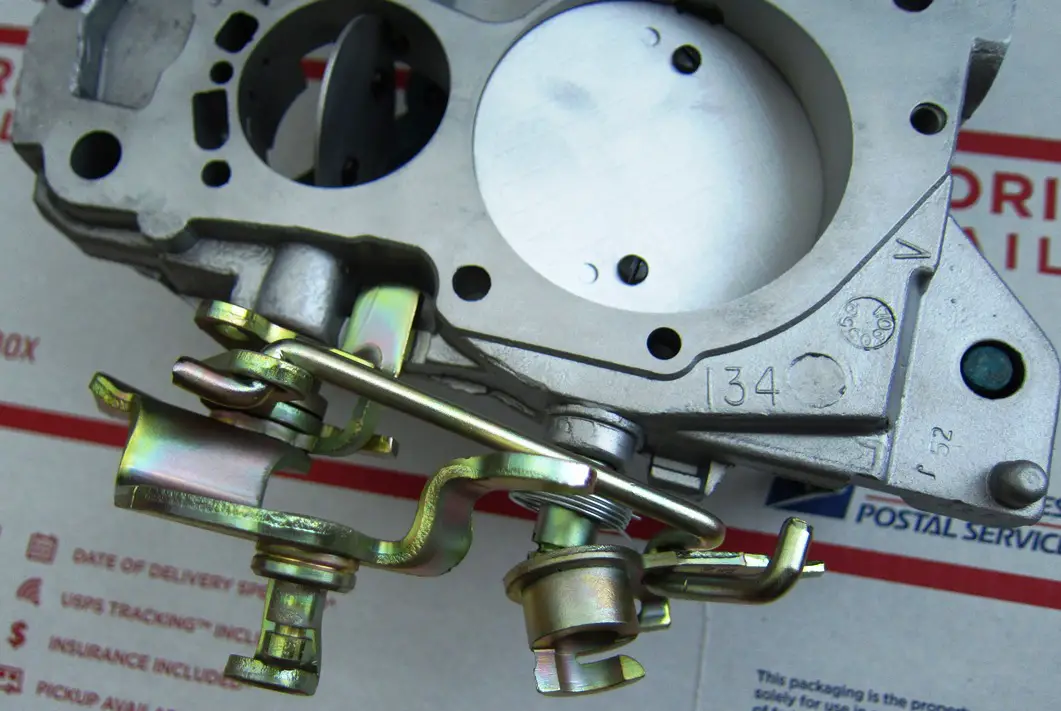

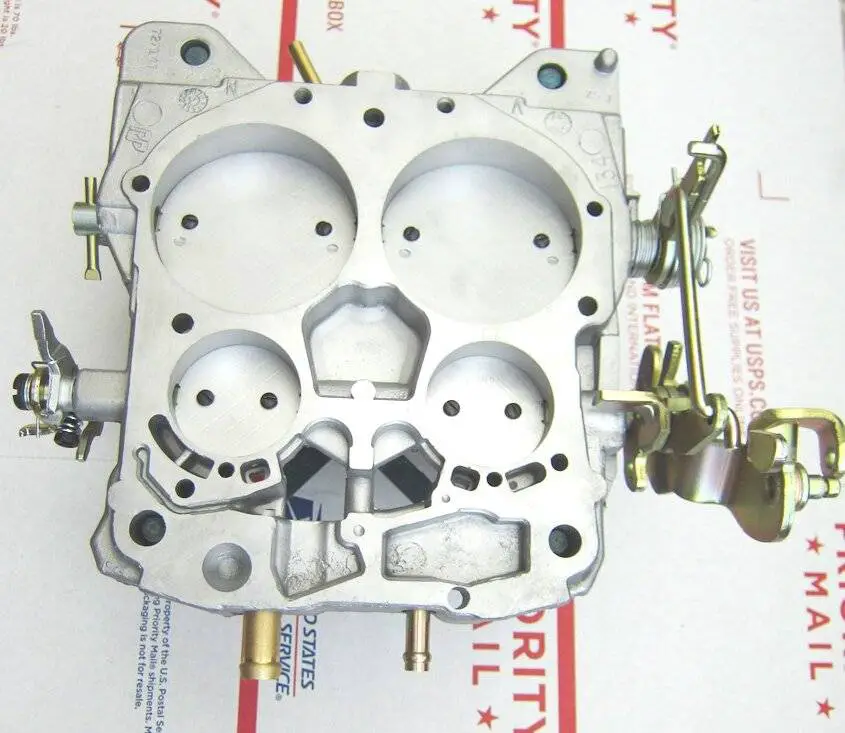

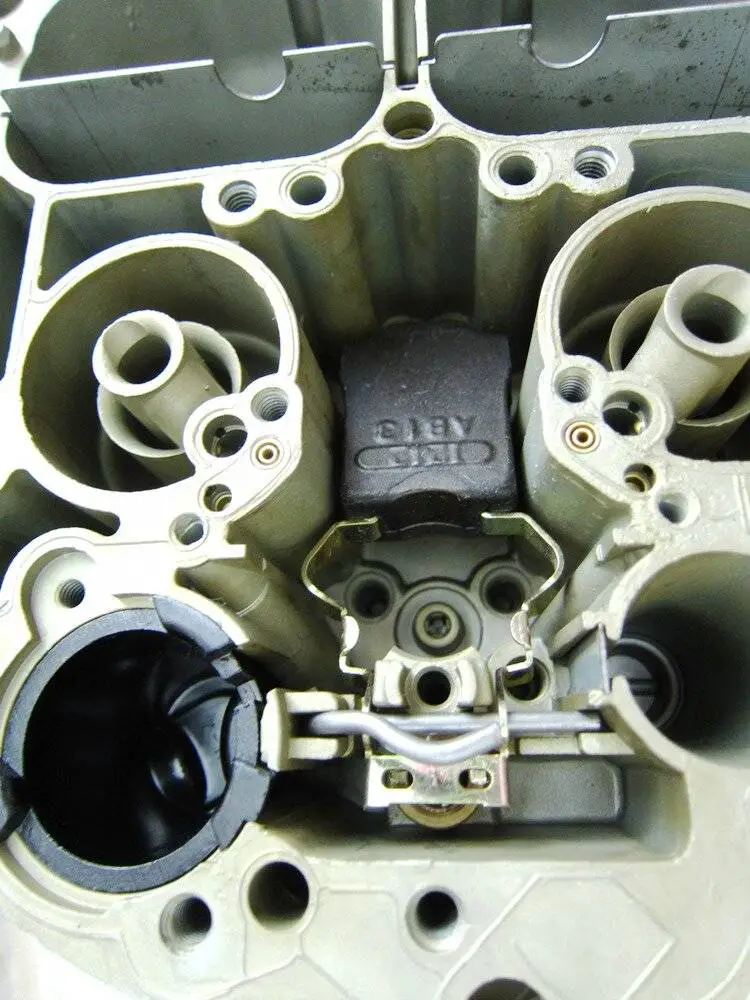

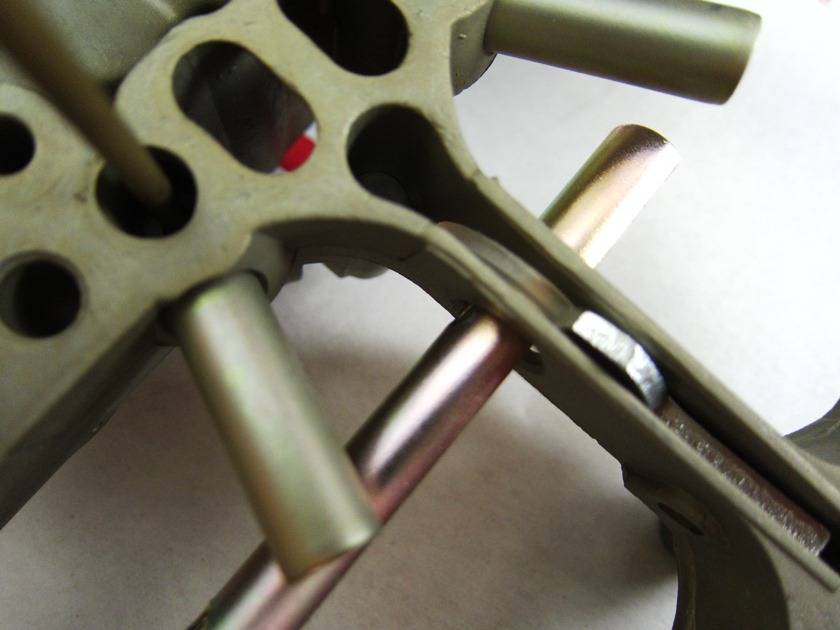

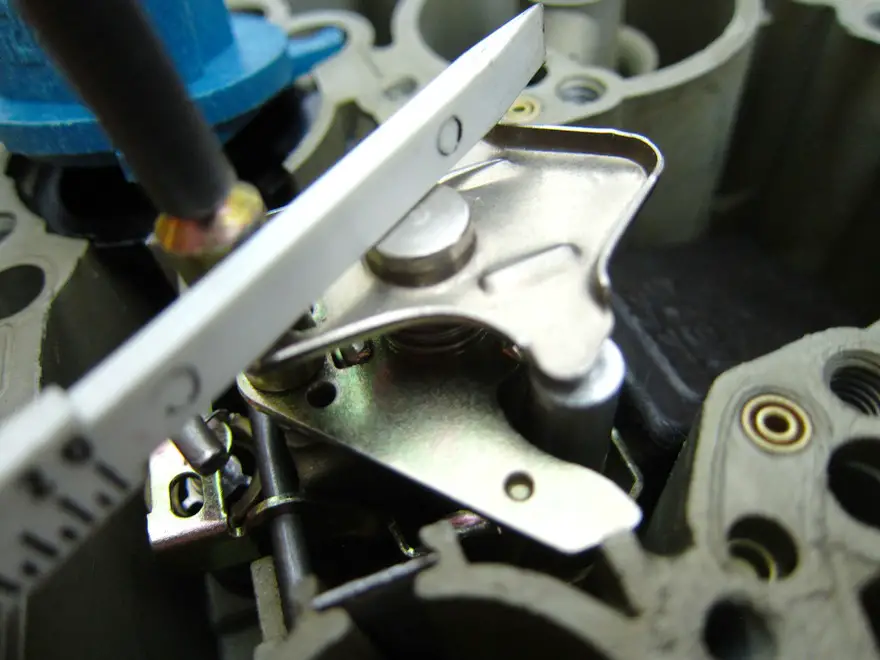

If you look close at the bodies of both carbs, they're the same color of muddled green with a hint of gold. I'm pleased with the way it turned out. It'd be a tad nicer had it came out with a bit more gold hues in it, but overall it's within the shade tolerances of NOS carbs. So I'm good with it. The carb in the background is my Frankencarb made up of NOS VIN Y float bowl, modified Chevy air horn, and used VIN 9 baseplate. Carb was built to VIN 9 specs. You can see it has a home-made on-the-car test jumper for the TPS so the voltmeter can easily be hooked up to it when adjusting it on the car.

Probably start putting this bad boy back together tomorrow. Stand by for updates as I get to them...

His name is Harold Demes, from Vail, AZ. His email addy is [email protected] if you wish to inquire about his services. I can tell you from experience, it took about a month and a half from when I sent mine out until I got it back.

Cost to send it to him via FedEx was around $35.

I stripped the carb down to parade rest. I only included things that were crucial to the replating/refinishing and cleaning procedures he was going to use. No electronics made it to him, or primary guts or secondary rods.

His price to clean/refinish/replate the stuff I sent him was $100, and he charged $50 to rebush the primaries. I had a standing order to do the secondaries if he deemed necessary, but he didn't believe it needed it. Not many do, and this one was no exception. A flat $20 return trip. Total cost with turnaround was $205. Your price may vary, that's up to him. So if you're interested, contact him. MANY many people with Quadrajets are pleased with his services. And now I am too. I'm not sure what he'd charge to do a complete top to bottom restoration, but again, he likes doing the older, non-CCC carbs the best.

I have the skills, tools and parts to do mine myself, so why not? If I had all the cool plating stuff, I'd do that myself too, but I don't.

As received.

Looks pretty good overall.

Yup. This is the carb I sent!

If you look close at the bodies of both carbs, they're the same color of muddled green with a hint of gold. I'm pleased with the way it turned out. It'd be a tad nicer had it came out with a bit more gold hues in it, but overall it's within the shade tolerances of NOS carbs. So I'm good with it. The carb in the background is my Frankencarb made up of NOS VIN Y float bowl, modified Chevy air horn, and used VIN 9 baseplate. Carb was built to VIN 9 specs. You can see it has a home-made on-the-car test jumper for the TPS so the voltmeter can easily be hooked up to it when adjusting it on the car.

Probably start putting this bad boy back together tomorrow. Stand by for updates as I get to them...