Agree that POR 15 Gold really pops. Ever thought of a Wrinkle finish on the valve covers?

1987 Cutlass Build

- Thread starter 84dragcutlass

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

My vote is for CHROME COVERS!!!! Pricey yes, but will look great!

Actually the chrome isn't such a bad idea. Never had anything chrome plated before. I need to see if any shops around here do that sort of thingMy vote is for CHROME COVERS!!!! Pricey yes, but will look great!

Have never been a huge fan of the wrinkle finish. I've seen some things that look good but other that it just looks like someone spilled paint remover on itAgree that POR 15 Gold really pops. Ever thought of a Wrinkle finish on the valve covers?

Wow, this is different. Just seen the thread and being a recent repairer of a 6.5TD all I can say is better you than me. But one thing for sure, it will be the most unique G on the street AFAIC.

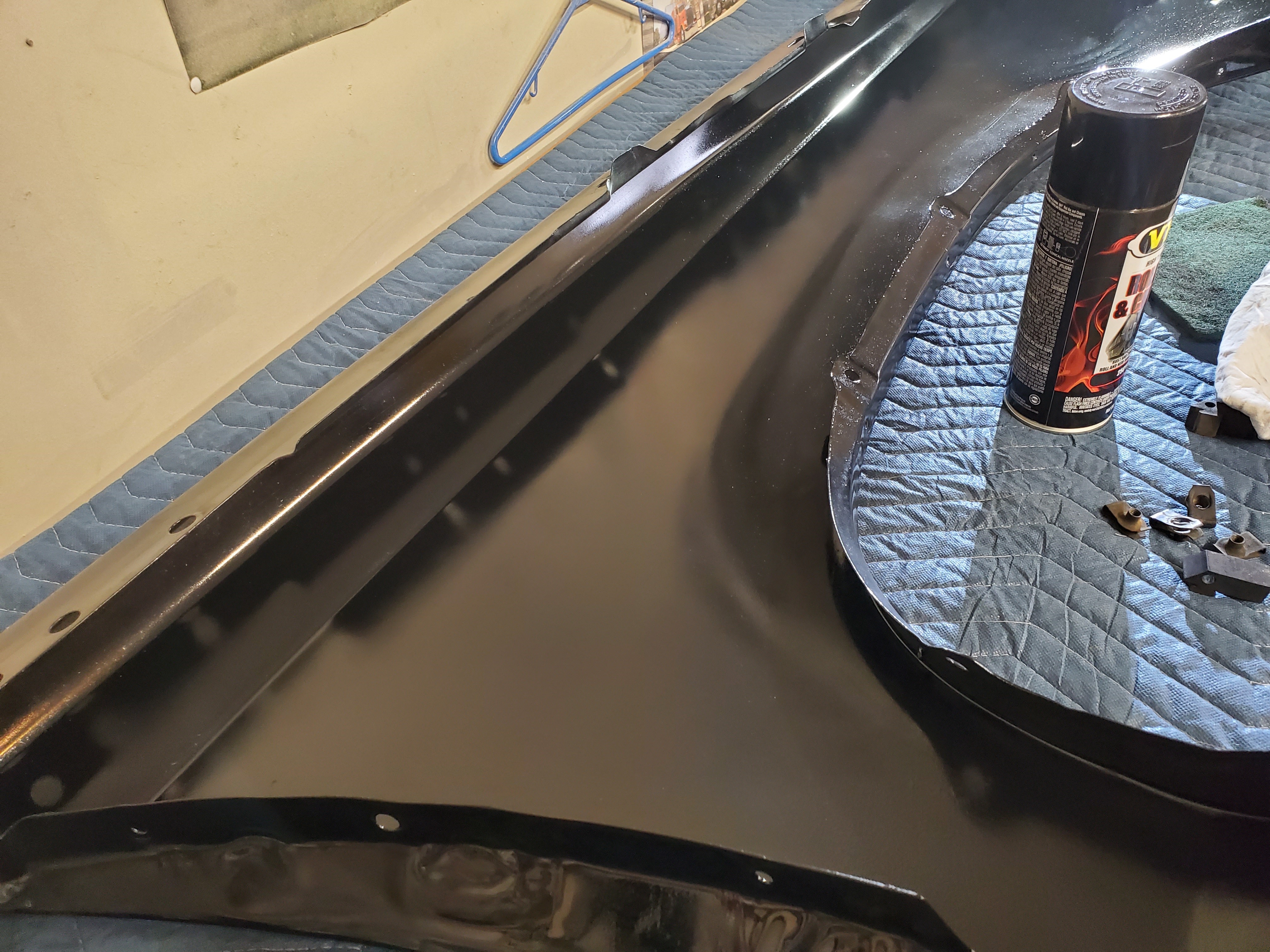

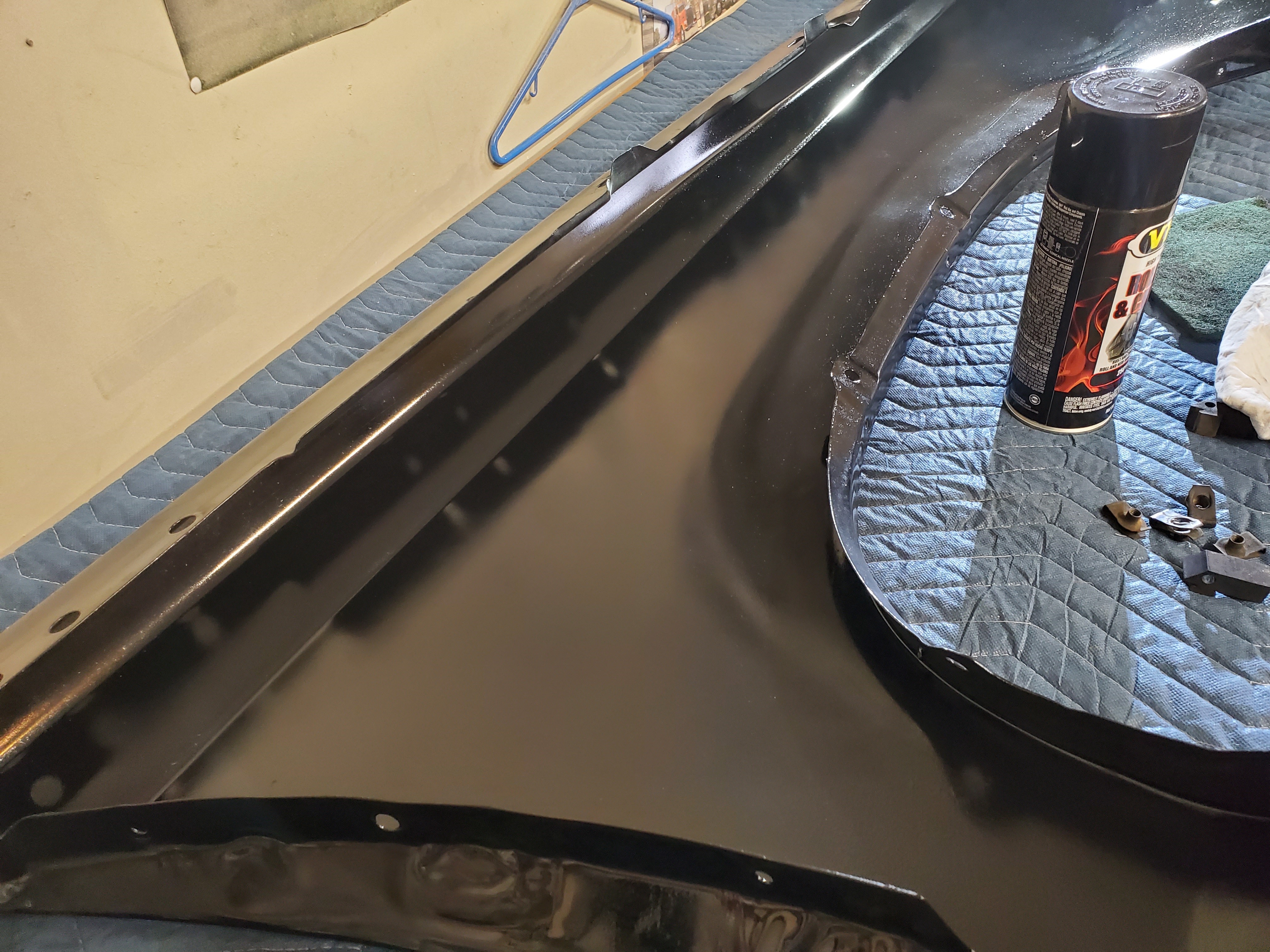

So yesterday i got to work with some final touches before i start reassembling the front fenders for hopefully the last time. My plan has always been to hide as much as possible in the fenders like the wiring harness. That may mean i have to lengthen the harness a bit but should be worth it for the overall look. I wanted to get the back side of the fender skin looking better so i pulled the driver side and gave it a scrub down with a scotch bright pad to knock down any high spots or dirt and get it ready for some VHT chassis and roll bar paint. I really like the durability of this stuff and i think it should go really good inside the fender where nothing will really touch it again.

After i had it all finished and cleaned i masked off the edges, this car is about a 100 footer currently but id like to keep it the best i can and don't need anymore overspray than it already had.

Now onto shooting some paint, nothing special here just wanted to bring a nice smooth look to the inside so that when the hood is open the visible parts of the outer fender skin look as nice as the powder coated inner fender panels.

Gave it one more coat after the last picture was taken and it really smoothed out nice, so tonight since its cold and rainy i will pull the inner fender off the car and reassemble the two halves together for the first time in a long time. After this step is complete since its getting warmer slowly i will back the car out of the shop a little and pull the engine and trans and get it fitted up for the 4L80 trans and tend to the firewall while im there. I did that process once a long time ago and was never happy with the results so ill be giving it another go to try and make it look as nice as the UMI firewall panel.

After i had it all finished and cleaned i masked off the edges, this car is about a 100 footer currently but id like to keep it the best i can and don't need anymore overspray than it already had.

Now onto shooting some paint, nothing special here just wanted to bring a nice smooth look to the inside so that when the hood is open the visible parts of the outer fender skin look as nice as the powder coated inner fender panels.

Gave it one more coat after the last picture was taken and it really smoothed out nice, so tonight since its cold and rainy i will pull the inner fender off the car and reassemble the two halves together for the first time in a long time. After this step is complete since its getting warmer slowly i will back the car out of the shop a little and pull the engine and trans and get it fitted up for the 4L80 trans and tend to the firewall while im there. I did that process once a long time ago and was never happy with the results so ill be giving it another go to try and make it look as nice as the UMI firewall panel.

Got to assembly of the fender last night, all went smooth. All new hardware from Belmetric and i gotta say that made things a lot easier.

I used the bolts without washers on all the upper visible bolts and on the fender lip i used bolts with a floating washer for a little more contact area i have seen these pop through the fender in the past.

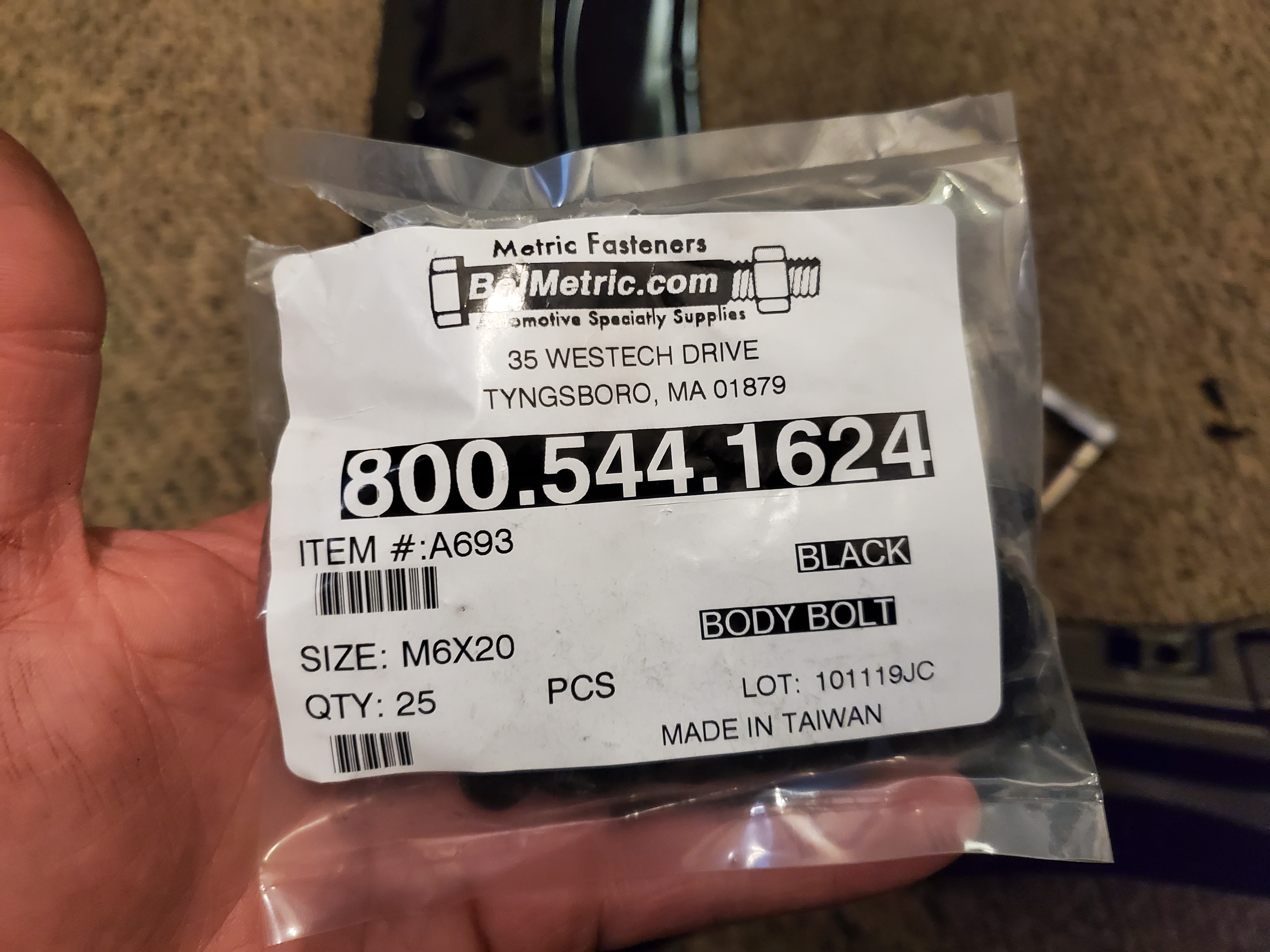

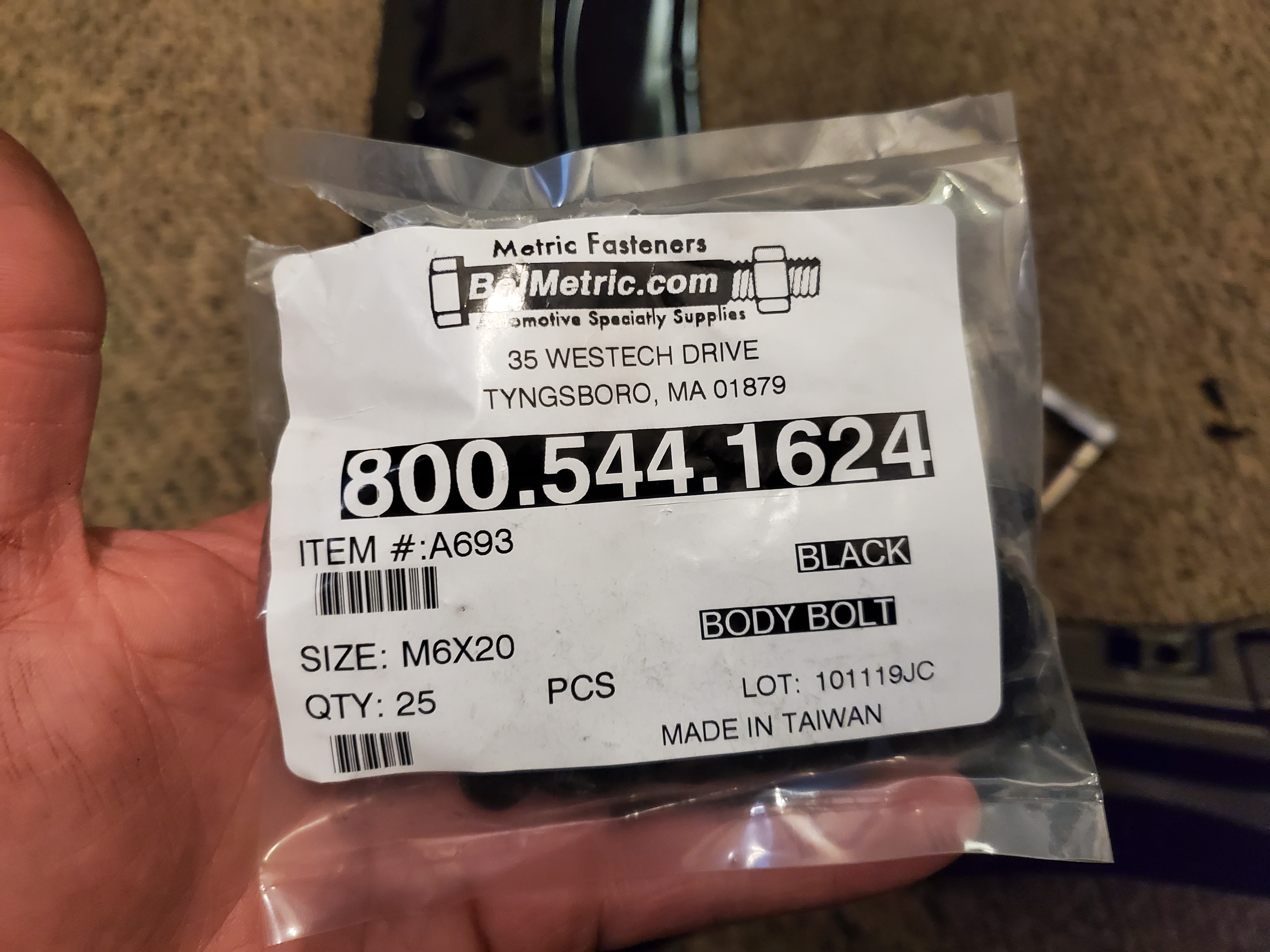

Here are the part numbers to the bolts i used, this company is really great actually. Had no issues ordering them and they got to my door really quickly. Beats trying to find metric bolts anywhere near where i live.

Final product, couldn't be happier with the way it turned out. These are really going to make the underhood area look great. I have one of the plastic inner fenders done as well and will have to test fit that in the car soon. Onto the passenger fender within the next day or two and then it will be engine removal time.

I used the bolts without washers on all the upper visible bolts and on the fender lip i used bolts with a floating washer for a little more contact area i have seen these pop through the fender in the past.

Here are the part numbers to the bolts i used, this company is really great actually. Had no issues ordering them and they got to my door really quickly. Beats trying to find metric bolts anywhere near where i live.

Final product, couldn't be happier with the way it turned out. These are really going to make the underhood area look great. I have one of the plastic inner fenders done as well and will have to test fit that in the car soon. Onto the passenger fender within the next day or two and then it will be engine removal time.

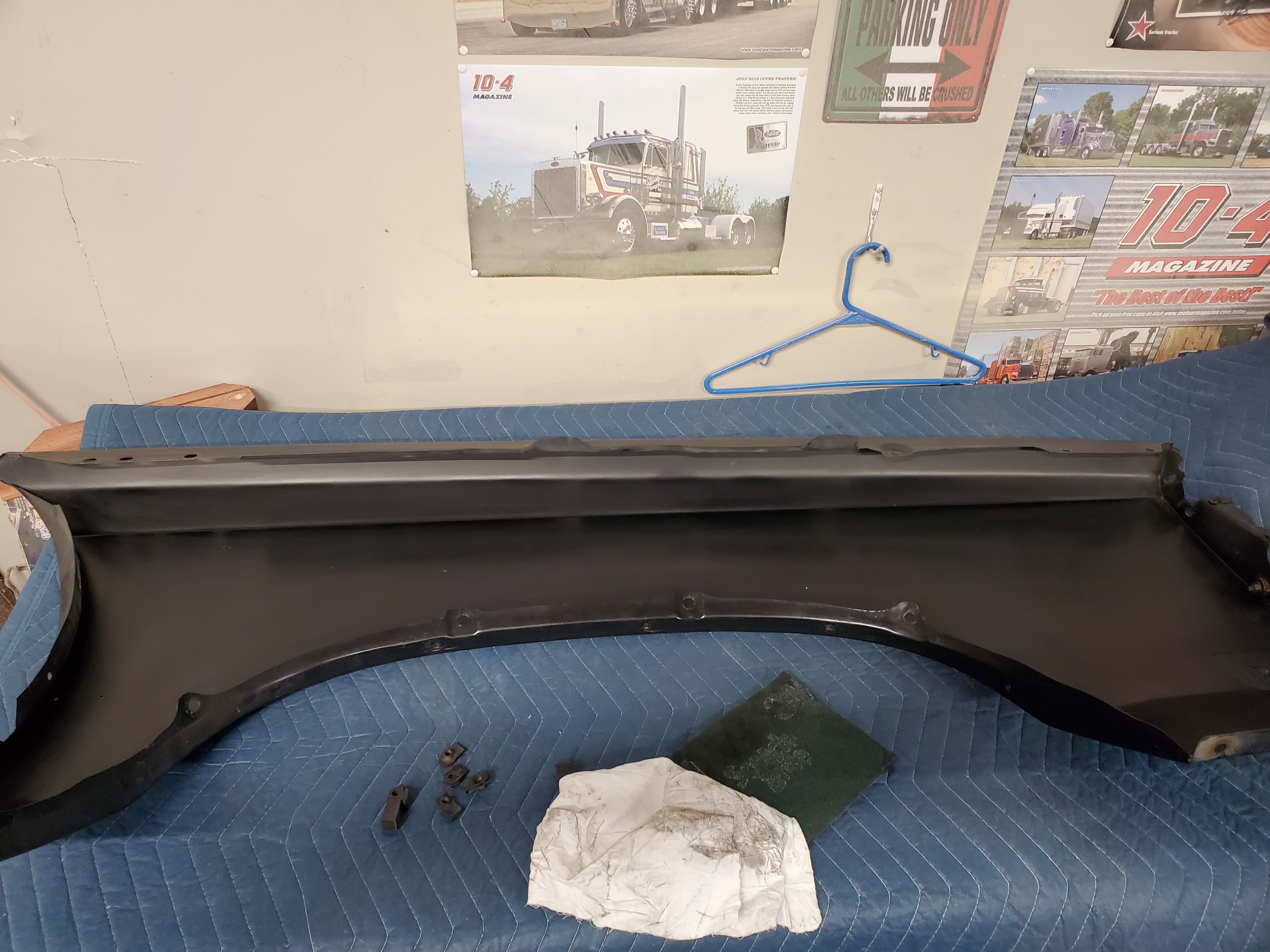

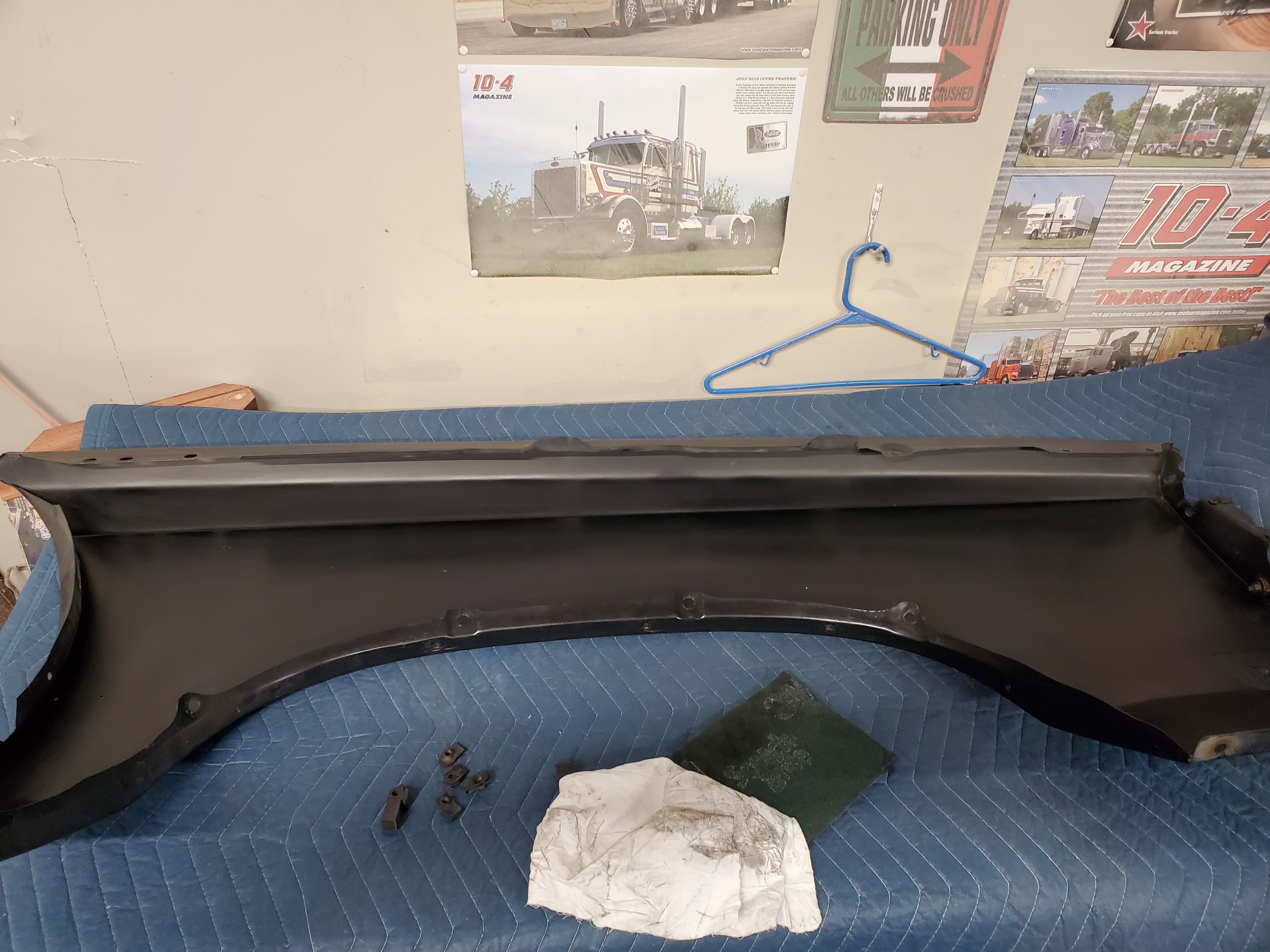

Next small job was the bumpers. I pulled them out of their long term storage in my shed and almost just installed them on the car before my OCD got the best of me and I had to have the inner supports powder coated. Here are some pictures of the teardown

The rear bumper still looked fairly good, with the exception of a fairly large mouse nest in it. Wonder how long that has been there...

The front was in slightly worse condition on the aluminum side. You could really tell where the steel was touching. Not bad enough to cause me not to he able to use it though

The inside portion of the rear bumper had some surface rust starting so I coated just the rusted areas with some POR 15 just to make sure it didn't get any worse.

Lastly the finished product. I had the inner supports powder coated metalic silver. They are one of the things nobody will ever see but I know its there and the results speak for themselves.

I cleaned the chrome up the best it would go with some never dull and besides the blotches it came out pretty good. Later that day my son and I moved along to pulling the engine out of the car so we could do some final fitment of some brake lines and finish up the last bits of work that need to happen before the engine and Trans can go back in for the work to make the manifolds fully fit. More on that later

The rear bumper still looked fairly good, with the exception of a fairly large mouse nest in it. Wonder how long that has been there...

The front was in slightly worse condition on the aluminum side. You could really tell where the steel was touching. Not bad enough to cause me not to he able to use it though

The inside portion of the rear bumper had some surface rust starting so I coated just the rusted areas with some POR 15 just to make sure it didn't get any worse.

Lastly the finished product. I had the inner supports powder coated metalic silver. They are one of the things nobody will ever see but I know its there and the results speak for themselves.

I cleaned the chrome up the best it would go with some never dull and besides the blotches it came out pretty good. Later that day my son and I moved along to pulling the engine out of the car so we could do some final fitment of some brake lines and finish up the last bits of work that need to happen before the engine and Trans can go back in for the work to make the manifolds fully fit. More on that later

Nice work!. I remember going through that process and being surprised at how much time I had wrapped up into R&R on a bumper. I installed aluminum bumper reinforcements for weight reduction on the front and rear but sandblasted them. Powder coating is a nice touch.

- Status

- Not open for further replies.

Similar threads

- Replies

- 0

- Views

- 114

- Replies

- 1

- Views

- 644

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.