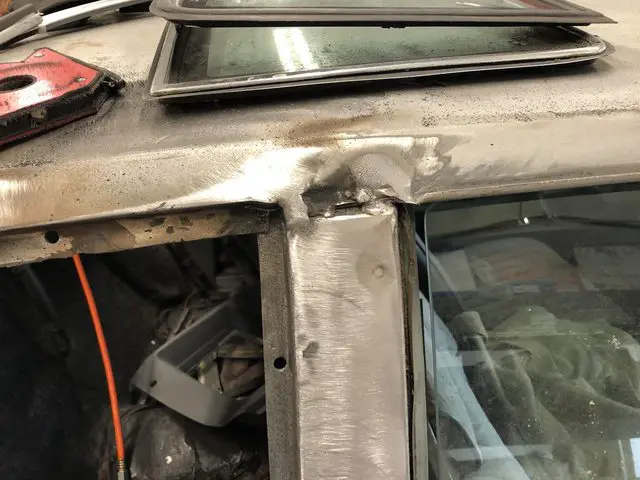

Been slowly chipping away at the metal work. I give anyone who does this on a regular basis props. I have had so many times ive been grinding and get it so thin that i had to goober it back up to shape it, those edges on the roof are no joke.

Second patch is in, and still have some more to do where the little pin holes are.

Roof seam is welded back in

Working on the Pass side roof to sail panel seam. Still have to add a little bit of material.

Building up the edge so that the window doesnt have a gap and the trim has something to sit on.

Driver side quarter window trim edge being built up.

Driver side roof to sail panel seam, think this one is pretty close still have some fine tuning to do.

Now to the point of no (Just really hard) return. I have decided to ditch the chrome side trim, which means all the nubs had to be ground off.

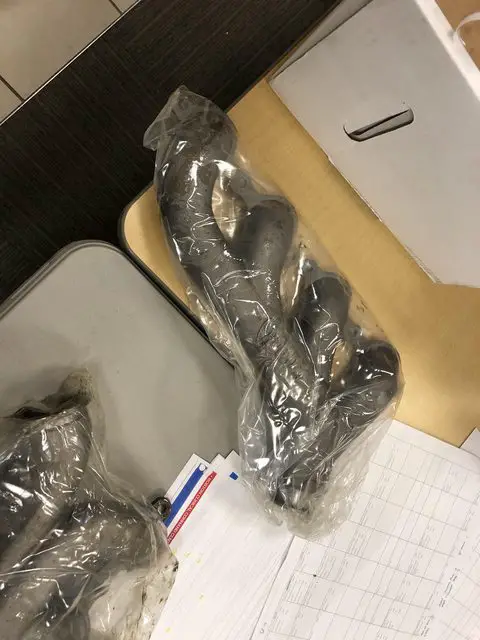

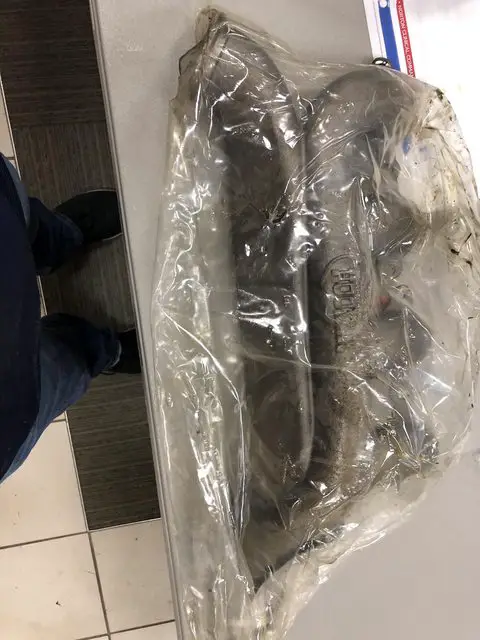

Also my Holley Manifolds finally showed up!!

And last, this is the inspiration and basically what i have in my head this whole time for a look i am going for.

Now a question for you guys, oviously my car doesnt have the little trim nibs on the inside of the window edge for the rear. I dont have access to a stud gun to weld the nib on. Has anyone had any luck with these little screw on ones? I am worried about using them because obviously puts you at risk for water and bare metal again...

My buddy and i are going to keep pecking away at the metal work and then finally dissasembling the car and stripping to bare metal. We will wet coat the entire car in the epoxy and start the body work with filler and glaze! Chipping away one day at a time, we are hoping to get her in paint by the end of the year so i can focus on the frame and engine in the spring.