After reading waaaay too much on this (hey, I'm easily amused) I would agree, especially after reading some posts by people that claim to have worked in the foundryThe high nickel 010 block is a myth. The casting code on the front of the block behind the timing chain cover only refers to core box patterns for block casting assembly, not nickel or tin content. All normal factory SBC blocks are made of the same cast iron alloy.

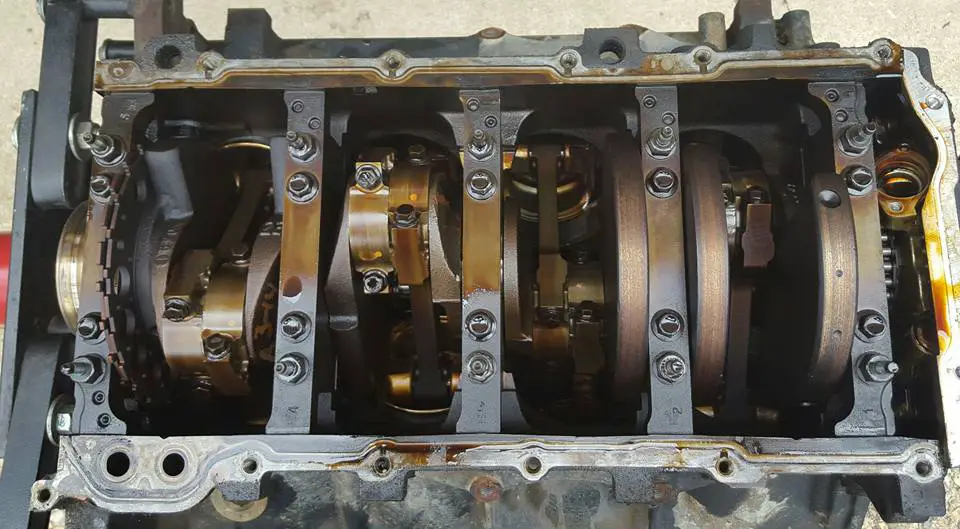

2 bolt/ 4 bolt

- Thread starter Froh

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

First I've heard of using the LS Engine Lifter Guide in an SBC, it's not a small piece. I'll have to look into that.

Bet those are also the same people who had "relative X" who worked at the assembly line or dealership to get that real one of none car ordered,After reading waaaay too much on this (hey, I'm easily amused) I would agree, especially after reading some posts by people that claim to have worked in the foundry

Its pretty much fact in the machine shop world that the 010 theory is all made up, but I keep that to myself. We used all different blocks when we built the engines. Core shift and cylinder wall thickness were more of a factor than casting number or 2 or 4 bolt. The 4 bolts were not necessarily weak for a performance motor, just that we were making more an more power and a splayed 4 bolt was stronger than a factory 4 bolt. So if it was a high hp small block, the 2 bolt core was more desirable. This was in like our circle track motors that ran 100's of laps in and out of the gas. But a stock 4 bolt block could go to 600 hp with no real issue. In low hp engines, we even searched for the hecho en mexico blocks because they were lighter. They could handle 4-450 hp and save a few pounds on the car weight. In today's world, the aftermarket blocks have taken over for anything other than a decent street performance motor just because it costs so much in machine work to prep a factory block.Bet those are also the same people who had "relative X" who worked at the assembly line or dealership to get that real one of none car ordered,

I paid $300 for a 350 vortec engine, with accessories about 3 years ago. That one has a provision for a fuel pump pushrod. Ran ok but I pulled it apart, and life got in the way. But for an engine with 170k on it, it had very little wear. Must be due to the fuel injection. I also grabbed another late model long block for $130 not long after that.

Im sure the engine blocks made in mexico are much worse.You are right on core shift. More of an issue than anything else.

I'm very happy with my BluePrint 383. And if you don't want a stroker engine their 355's are very nice and cost effective as well. 4 bolt main; Roller Cam; All new stuff and everything is matched. KaBam! One and done. Shop, Drop and Roll.Figure worse comes to worse, you could save the hasle of looking for that hard to find engine block by going with a crate engine from blueprint engines.

Very cost affective for what you get(new everything w/4bolt mains) versus the time spent looking for used parts and peicing it together and costing you more in the long run after all is said and done from all the machine shop work.

This ^^^^^ is what I've heard and my machine shop claims.Its pretty much fact in the machine shop world that the 010 theory is all made up, but I keep that to myself. We used all different blocks when we built the engines. Core shift and cylinder wall thickness were more of a factor than casting number or 2 or 4 bolt. The 4 bolts were not necessarily weak for a performance motor, just that we were making more an more power and a splayed 4 bolt was stronger than a factory 4 bolt. So if it was a high hp small block, the 2 bolt core was more desirable. This was in like our circle track motors that ran 100's of laps in and out of the gas. But a stock 4 bolt block could go to 600 hp with no real issue. In low hp engines, we even searched for the hecho en mexico blocks because they were lighter. They could handle 4-450 hp and save a few pounds on the car weight. In today's world, the aftermarket blocks have taken over for anything other than a decent street performance motor just because it costs so much in machine work to prep a factory block.

I take this to mean, for a hot street driver, 400hp or there abouts, any old 350 block will work and be more than reliable. For a strip car, they will will work fine also as long as you aren't taking a 250hp motor and putting a 300+ nitrous shot into it.

A stock block LS will definitely hold another 200-300 reliably, but for any thing that is serious, 4digit power, an aftermarket block is the solution. And that doesn't necessarily imply an LS aftermarket block. There are still alot of guys running aftermarket Gen1 blocks to make 1500+. Depending on who you listen to, the SBC head bolt pattern is much, much better for holding a head gasket than any LS due to bolt count and location.

Original question - what is a SBC core worth? Whatever you're willing to pay when you need one.

Similar threads

- Replies

- 0

- Views

- 183

- Replies

- 4

- Views

- 572

- Replies

- 26

- Views

- 2K

- Replies

- 9

- Views

- 639

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.