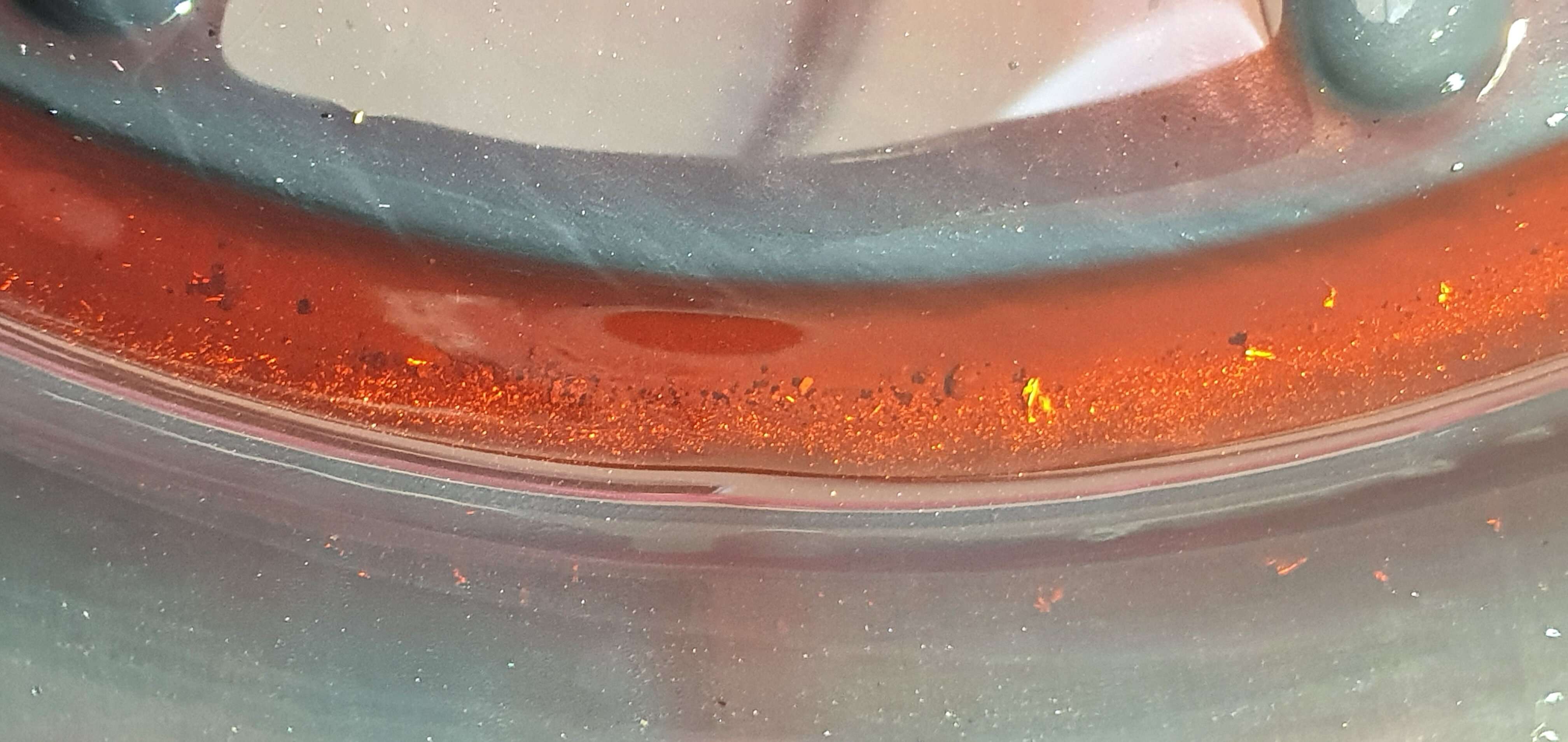

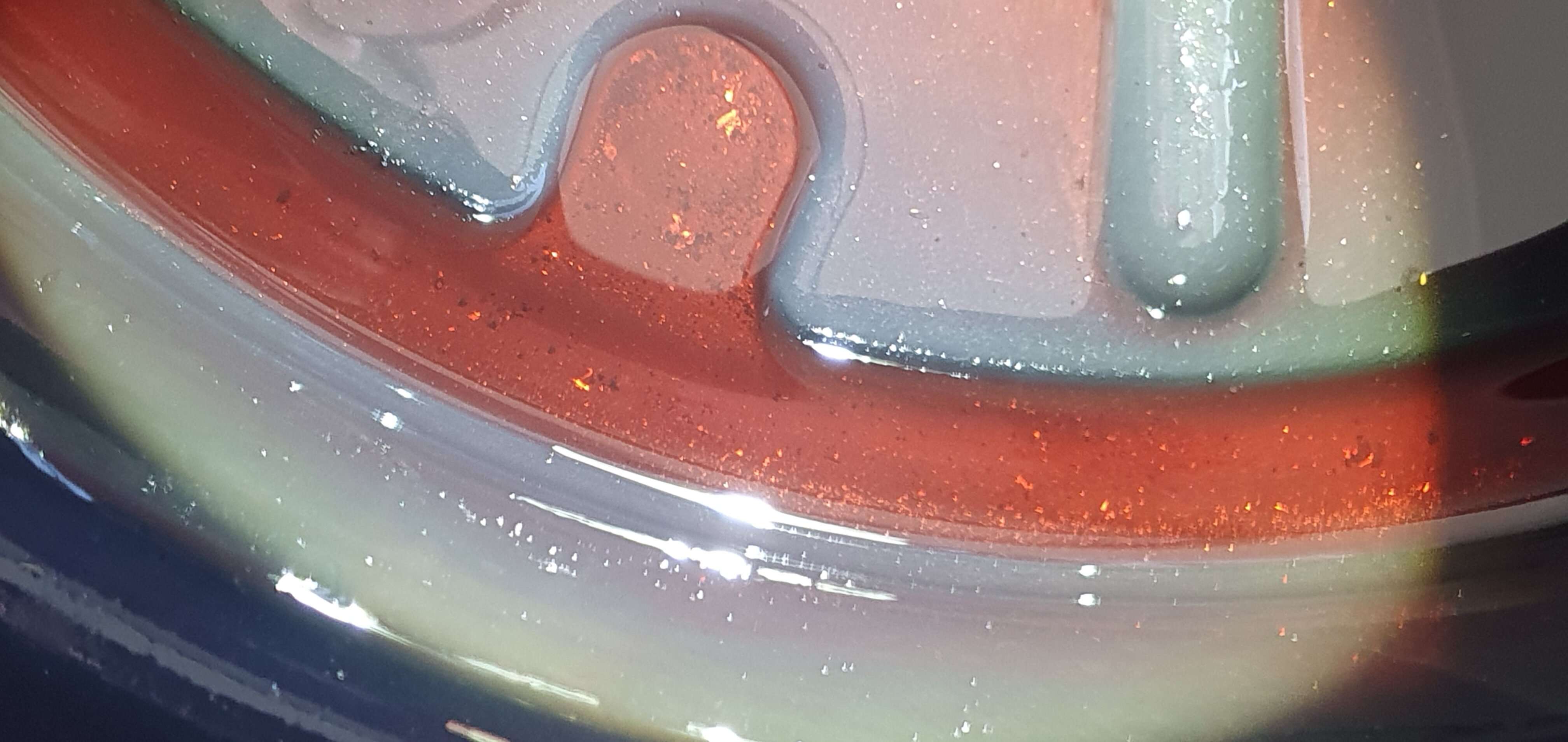

At the very least your motor needs to be completely torn down. Why? Because the material ground away from that thrust bearing had to go somewhere, and the block's oil passages are a good hiding place for evil. Even though the crank seems useable, the excessive heat it was exposed to is not a good thing, same/same with the rods. Subject to other considerations, your best option might be a long block replacement from somewhere such as Summit Racing or?? If you elect to have this mill rehabbed then be prepared for a long butcher's bill of machine shop costs as to do it right they will have to first take it apart, and then hot tank it, and then inspect and measure and mike everything,

Further, and beyond all this, you will have to get into that engine bay and cut away all that mickey mouse motor mount BS that supported your old motor. The factory uses bolts and biscuits on its mounts for a reason and trying to cut costs and time by welding them instead of taking the time to correctly locate and secure them properly; well, even as little as a 1/16th of an inch of misalignment during the welding process and the motor becomes "cocked" or mis-aligned. Gotta wonder at this point if what that shop did wasn't just to assemble the complete mounts to the engine, drop the whole business in the car and weld it in place just as it landed without taking a tape to it.

JUst me here, thinking aloud.