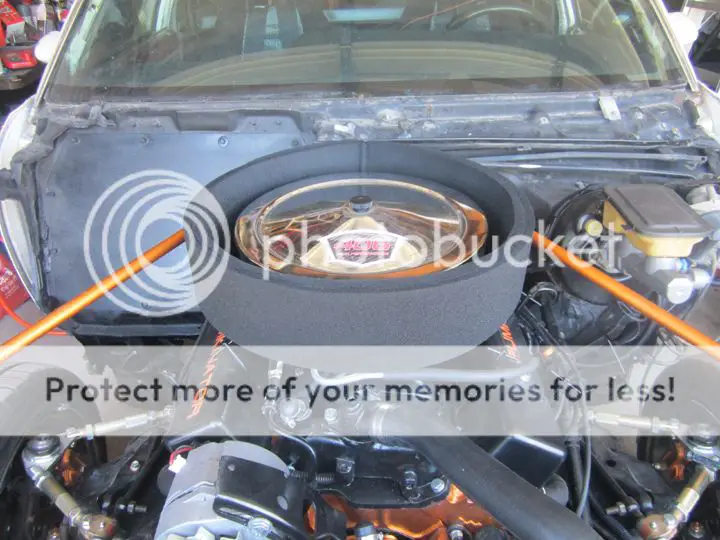

Pictured here is the 85 Wiper motor mocked up. One of the motor's mounting tabs, upper left as pictured, did not line up with the 79's mounting holes, see how it is offset about 3/4". Simply drilling a new hole and using a nut and bolt solved that issue. Everything works great, and having the switch on the column and using the delay system has been really nice.

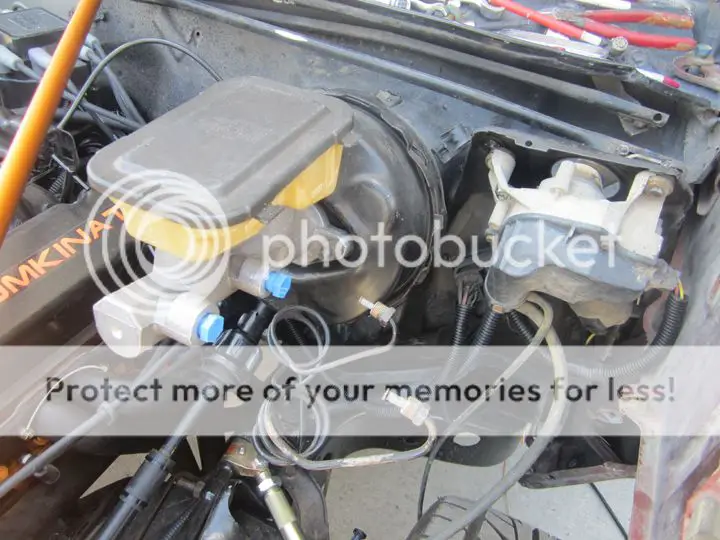

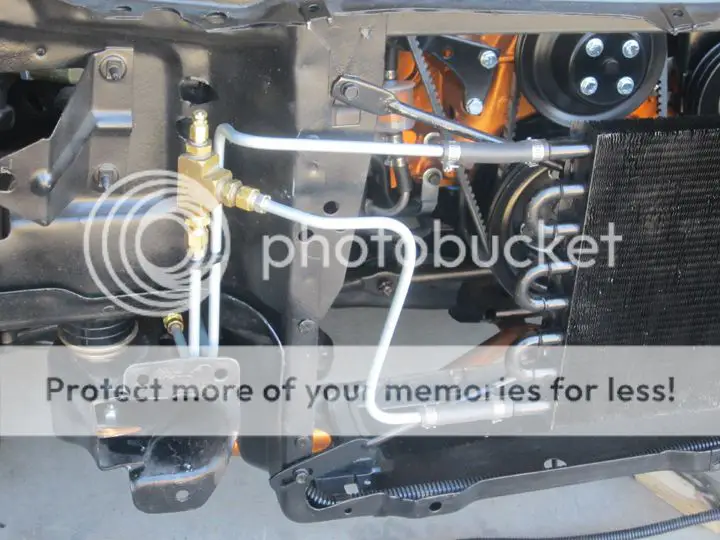

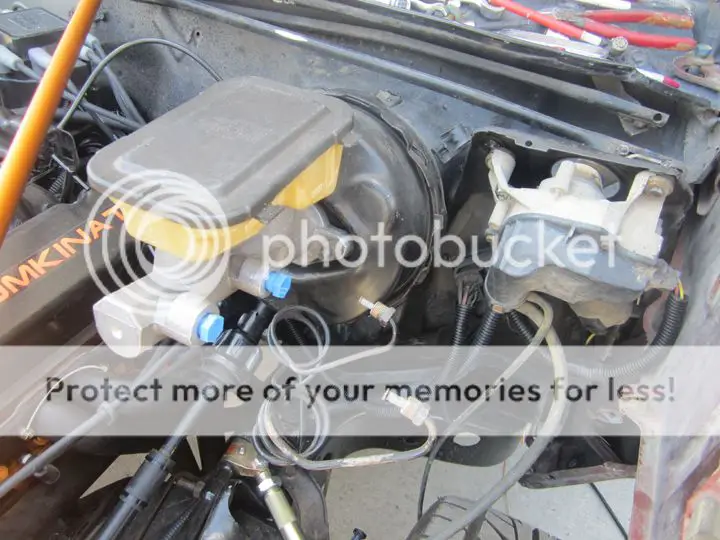

Also pictured here is the later model master cylinder. The 79 came with a small bore iron unit. While at the junkyard I picked up a booster that accepts the later 1 1/8" aluminum master. I ordered the new master from Oreily's, punching an 85 Monte Carlo SS into Oreily's online website search for the part number. Unfortunately the factory g-body brake proportioning valve is mounted down on the frame right next to the header, kind of a dumb place to put it. When I install the disc brake rear axle I'll update all the lines, eliminate the factory valve, and use an aftermarket valve located away from the heat.

Also pictured here is the later model master cylinder. The 79 came with a small bore iron unit. While at the junkyard I picked up a booster that accepts the later 1 1/8" aluminum master. I ordered the new master from Oreily's, punching an 85 Monte Carlo SS into Oreily's online website search for the part number. Unfortunately the factory g-body brake proportioning valve is mounted down on the frame right next to the header, kind of a dumb place to put it. When I install the disc brake rear axle I'll update all the lines, eliminate the factory valve, and use an aftermarket valve located away from the heat.