A couple of things to keep in mind : there is more than one way to skin this cat, and the amount of carrier preload and rotational torque are not precise number. Rear end setup is quite forgiving as long as your 'close'.

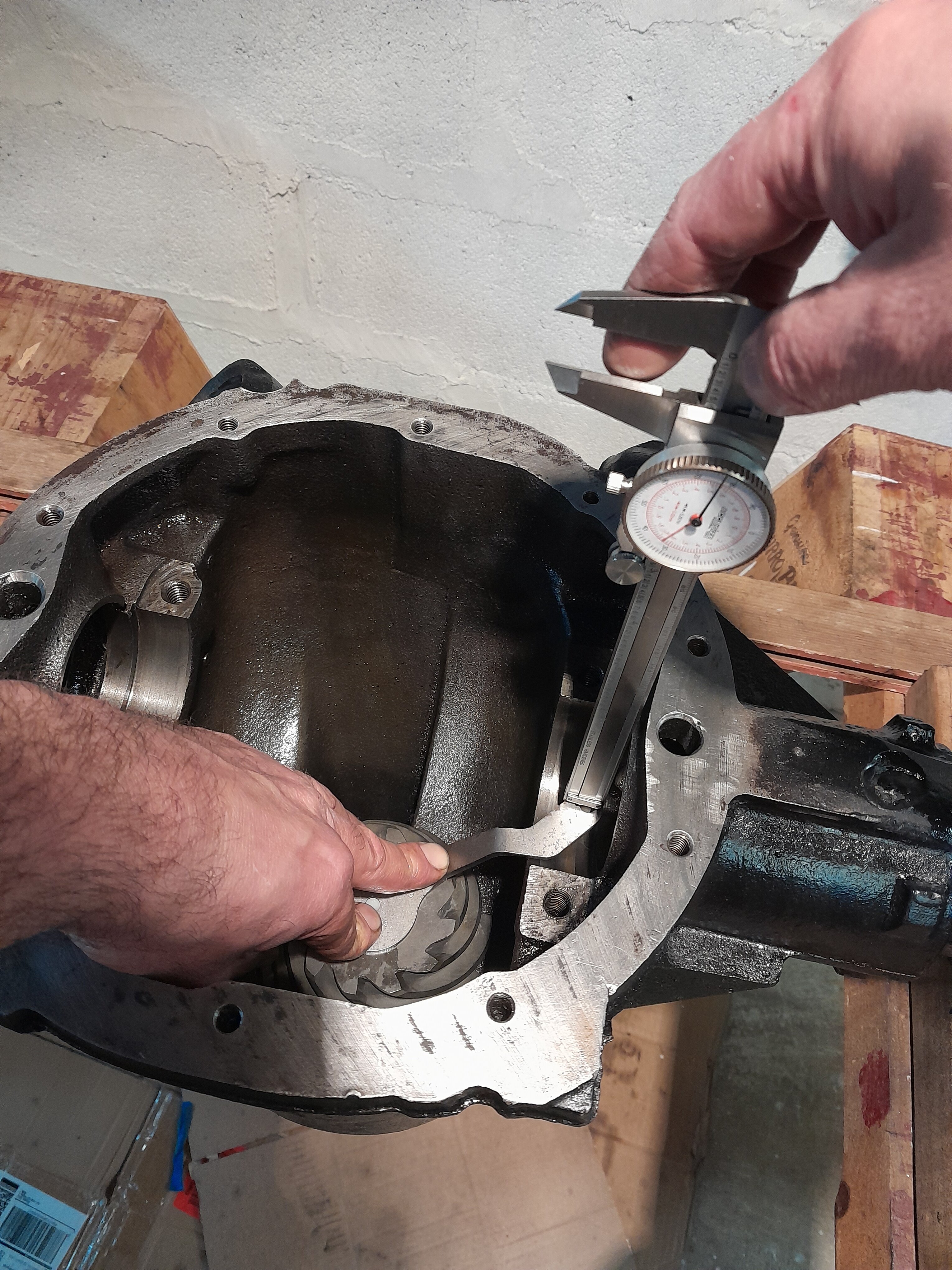

Two things you've mentioned that you need to address. Using the old bearing as the setup bearing will work if, repeat if, the bearing doesn't have much of any wear. From the looks of the carrier bearings that you attached pics of, I'll guess that you should use a new bearing. But I could be wrong. 2nd, and most importantly, when you're assembling for measuring setup, rotational torque, backlash, etc, be sure to have the bearings lubed. DO NOT assemble with the bearings dry and start rotating the pinion or carrier, especially with even a small amount of preload. Yes, this will be messy - welcome to gear work.

Also, when you go to crush the crush sleeve, be prepared for the amount of force it will take to actually crush it. It will be shockingly difficult without a good method for retaining the yoke in position.

Almost forgot, you mentioned possibly using a solid pinion spacer. They do work well, but are difficult IMO to get setup correctly. And they are unneeded until you start making a lot of HP. I ran a crush sleeve repeatedly for years and never experienced a problem until I consistently made over 900whp. But if you want to install it, then have at it - it won't hurt anything as long as you get it shimmed correctly.

I have a hone on order to make the old inner into a setup bearing; should be arriving today. Thanks again for the input!!!

To be clear: After I have pinion depth and mesh pattern and backlash satisfactory with the setup bearing, I will perform final assembly. Prior to final assembly I will make sure the new bearings are very lubed with gear oil.... and you are saying I should tighten the crush sleeve until I see 25-40 in-lbs of rotational torque with the pinion alone, or with the carrier installed? I ask, because that is outside of the recommended torque per my pair of references (a trade school video and a softcover book on rebuilding 10 and 12 bolts).

Also, I intend to use the crush sleeve, but have the solid spacer with shims as a backup. I haven't bought more crush sleeves. I'm not actually sure how the solid spacer does the same job as the crush sleeve. I have to research that. If you know the mechanics of how the solid spacer takes up the same preload as the crush sleeve, and you want to share your knowledge, please do so.

Two things you've mentioned that you need to address. Using the old bearing as the setup bearing will work if, repeat if, the bearing doesn't have much of any wear. From the looks of the carrier bearings that you attached pics of, I'll guess that you should use a new bearing. But I could be wrong. 2nd, and most importantly, when you're assembling for measuring setup, rotational torque, backlash, etc, be sure to have the bearings lubed. DO NOT assemble with the bearings dry and start rotating the pinion or carrier, especially with even a small amount of preload. Yes, this will be messy - welcome to gear work.

Also, when you go to crush the crush sleeve, be prepared for the amount of force it will take to actually crush it. It will be shockingly difficult without a good method for retaining the yoke in position.

Almost forgot, you mentioned possibly using a solid pinion spacer. They do work well, but are difficult IMO to get setup correctly. And they are unneeded until you start making a lot of HP. I ran a crush sleeve repeatedly for years and never experienced a problem until I consistently made over 900whp. But if you want to install it, then have at it - it won't hurt anything as long as you get it shimmed correctly.