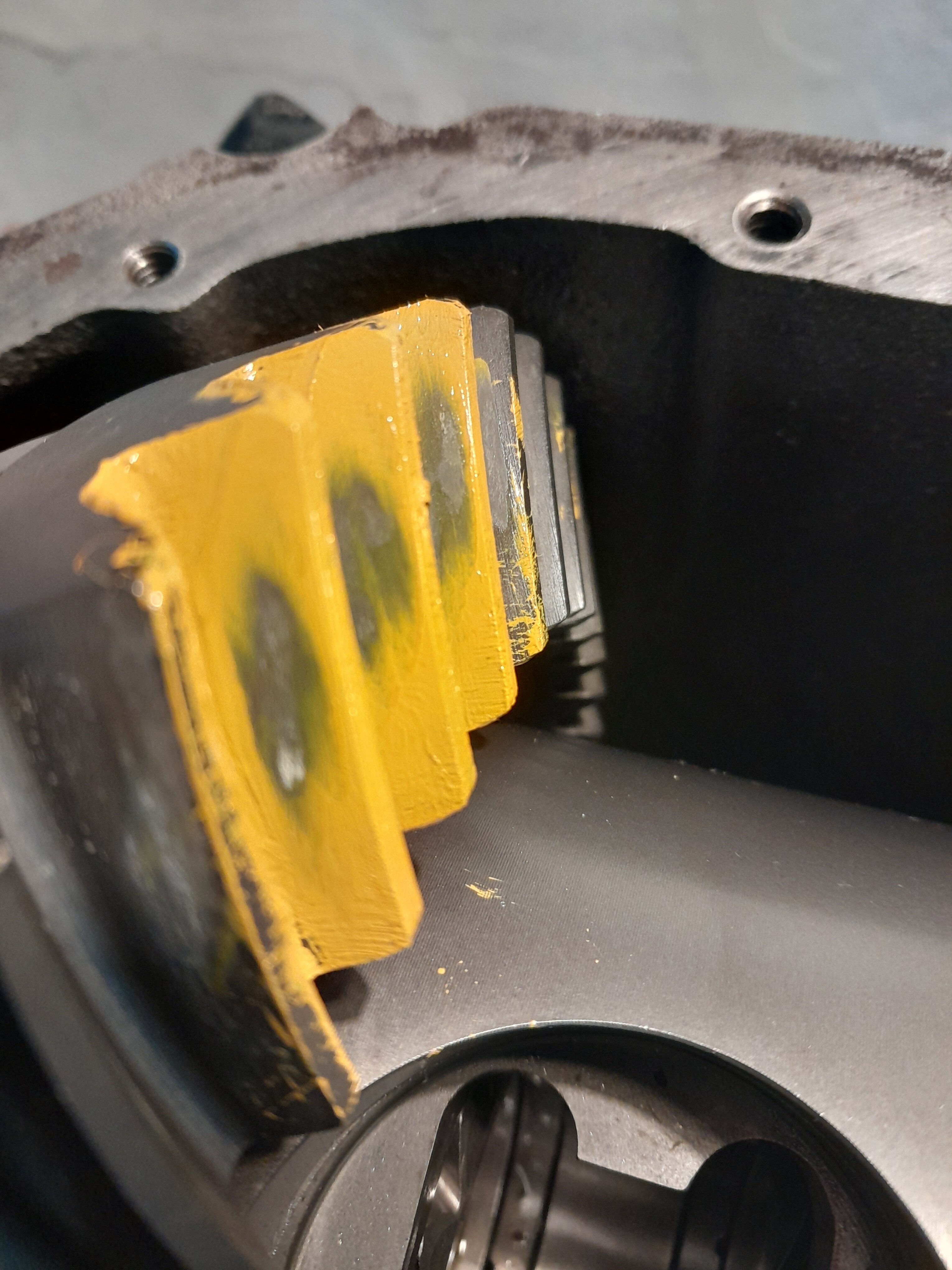

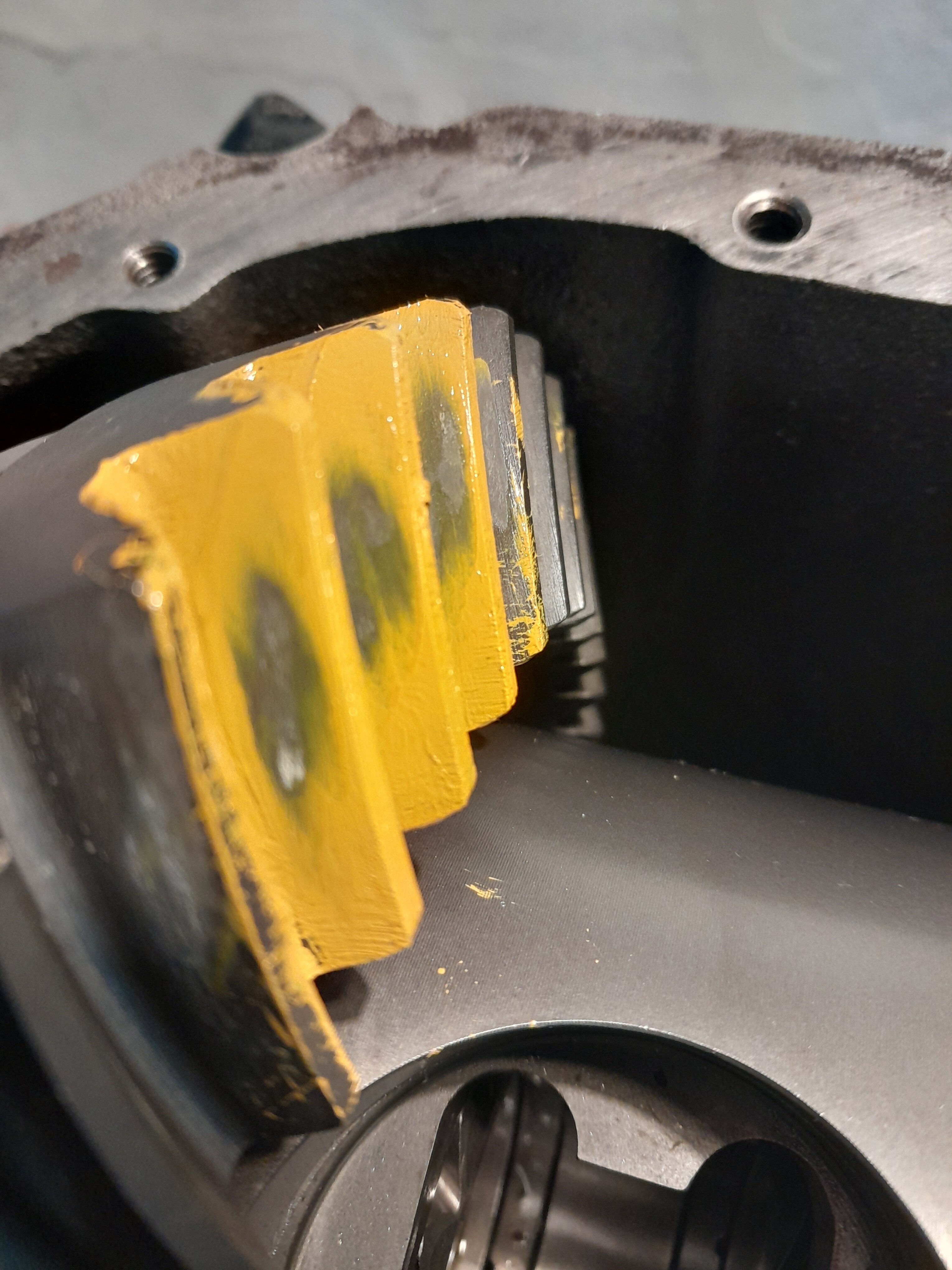

I reamed-out a new bearing and measured 0.042" pinion spacer needed with the new pinon. So, I assembled using the original 0.038" pinion spacer, without crush sleeve or seal, using new outer bearing and new setup bearing. I had to use the yoke and impact wrench to pull the new inner bearing onto the new pinion. I gave it just a little ugga to bring the bearings into the races lubed with mineral oil. There is a little bit of turning resistance. I put the carrier in with the 0.248" driver side cast iron factory shim and a 0.222" shim pack on the passenger side and found the ring gear had no backlash and the assembly was difficult to turn due to interference. I figured I was way off, so I took the carrier out and put it back in with 0.230" shim pack on driver side and 0.240" shim pack on the passenger side and I have 0.011" of backlash measured at three locations around the ring (i.e. just out of spec). I'll take first pattern now with the backlash just out of spec.

Attachments

Last edited: