This Is my 81 Cutlass supreme which started out as my winter beater but never made it that far. the sad 267 flattened a cam lobe so it sat in my driveway complety buried up until the snow melted enough to dig it out and swap in a vortec 305. Then like a fool after getting it running I tore into it and started to find all the rot.

Must have been 3 tons of snow on top

After getting it running and performing some one tire fire load tests. I drove into the back of the shop and tore it apart.

After getting it running and performing some one tire fire load tests. I drove into the back of the shop and tore it apart.

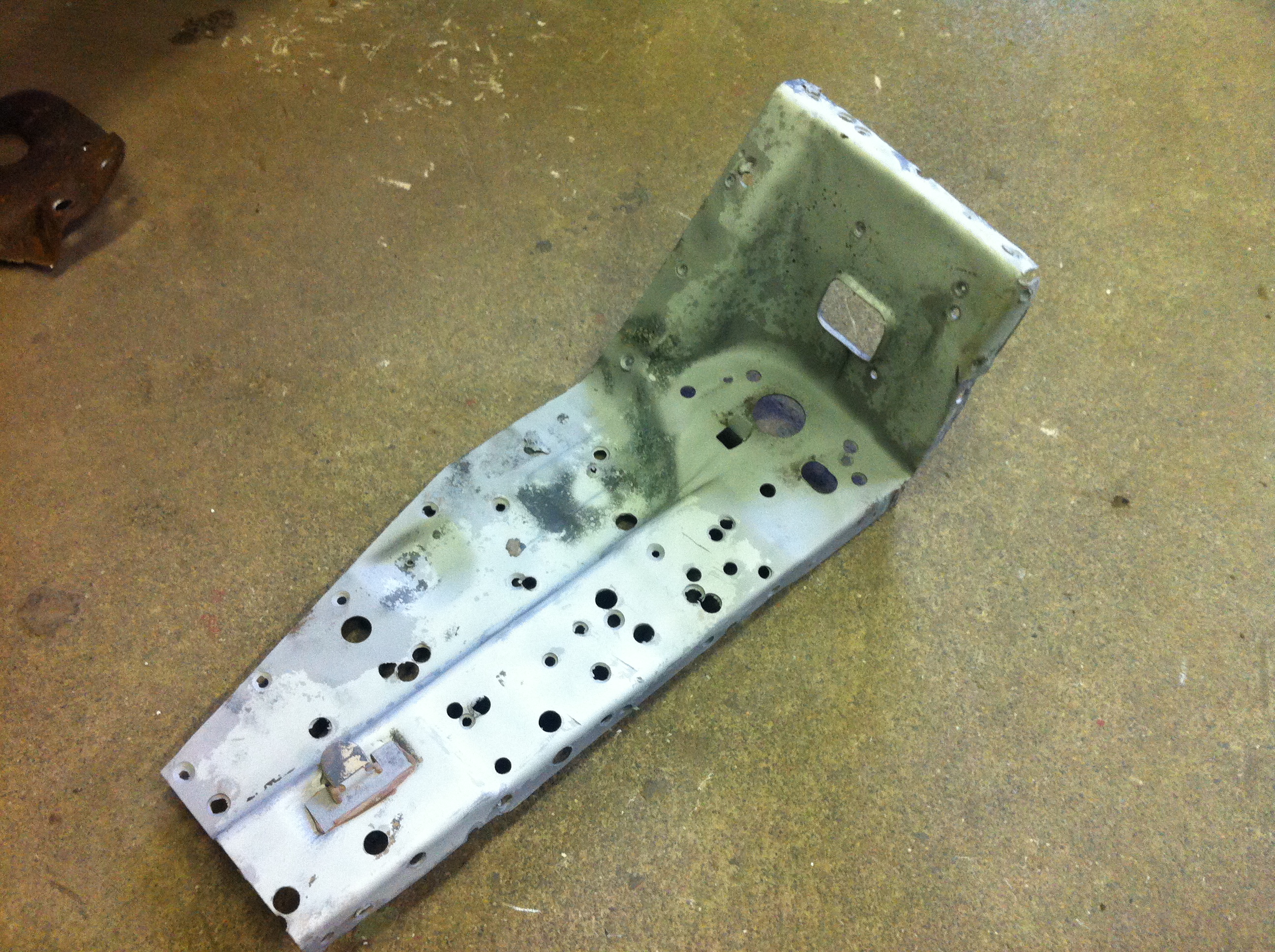

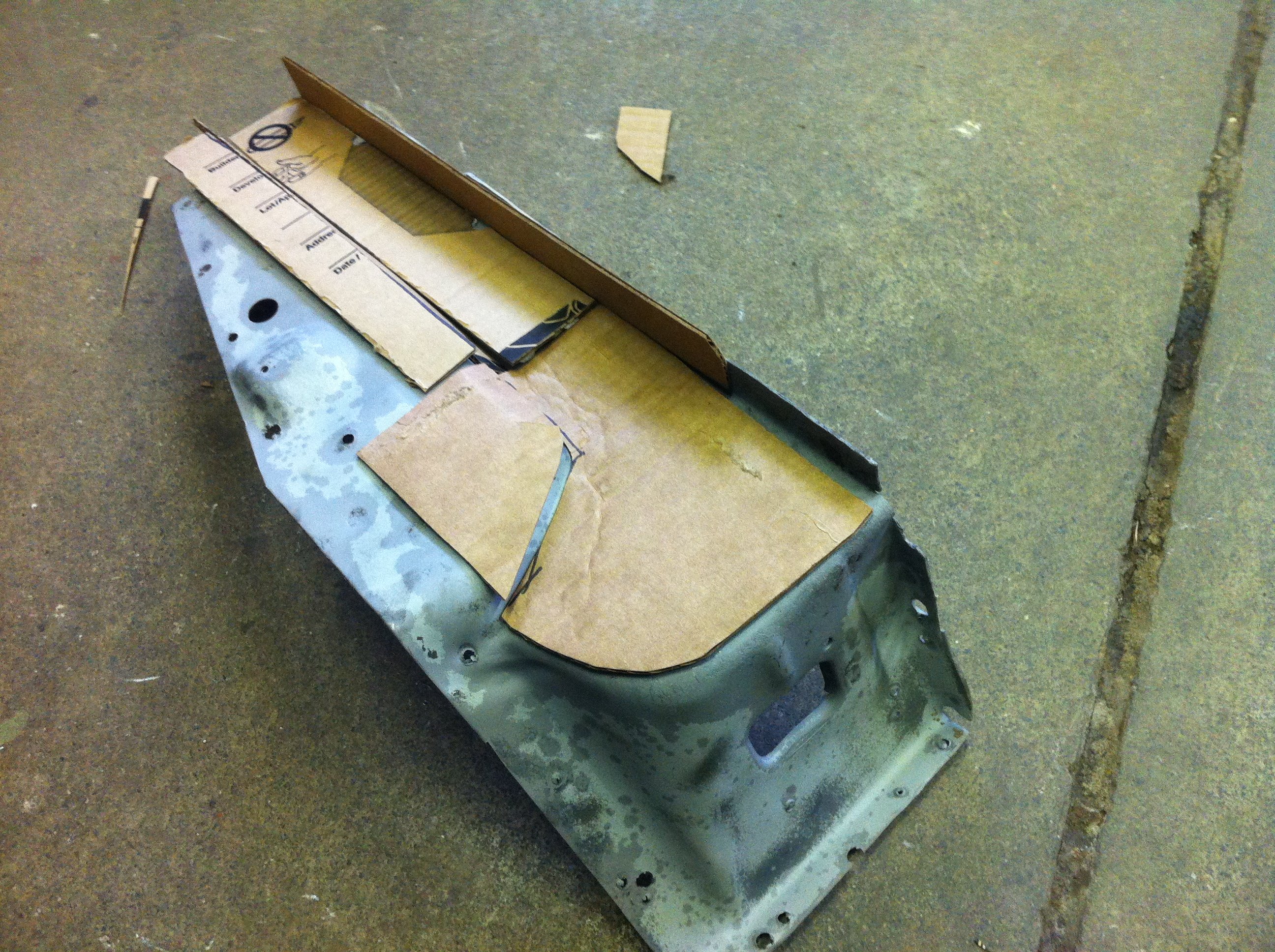

Driver side is in decent shape but pass side didn't fare so well. In front of the rear wheels and body mounts are bad both sides, trunk to wheel wells are gone and repaired with tin and rivets.

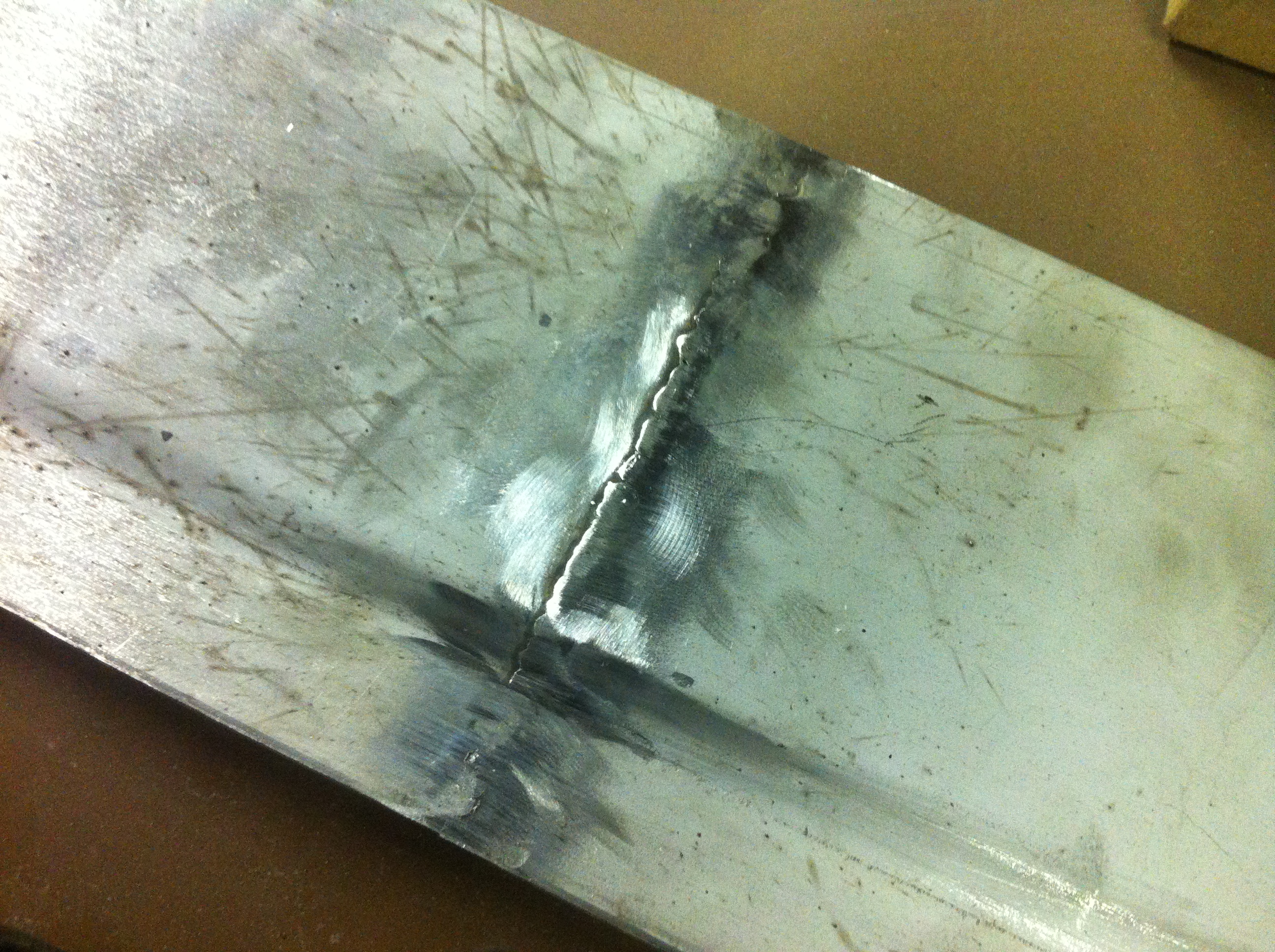

Cutting out the bad, trying to find some good

This is Going to be more of an exercise in body work and restoring a car then trying to make a hotrod. Chances are I'll sell it once its done to fund a Camaro I have. Im just into this for the experience.

Must have been 3 tons of snow on top

Driver side is in decent shape but pass side didn't fare so well. In front of the rear wheels and body mounts are bad both sides, trunk to wheel wells are gone and repaired with tin and rivets.

Cutting out the bad, trying to find some good

This is Going to be more of an exercise in body work and restoring a car then trying to make a hotrod. Chances are I'll sell it once its done to fund a Camaro I have. Im just into this for the experience.