Frustratingly nobody puts LS engines in the same place. Some people put them forward and low, some up and back.

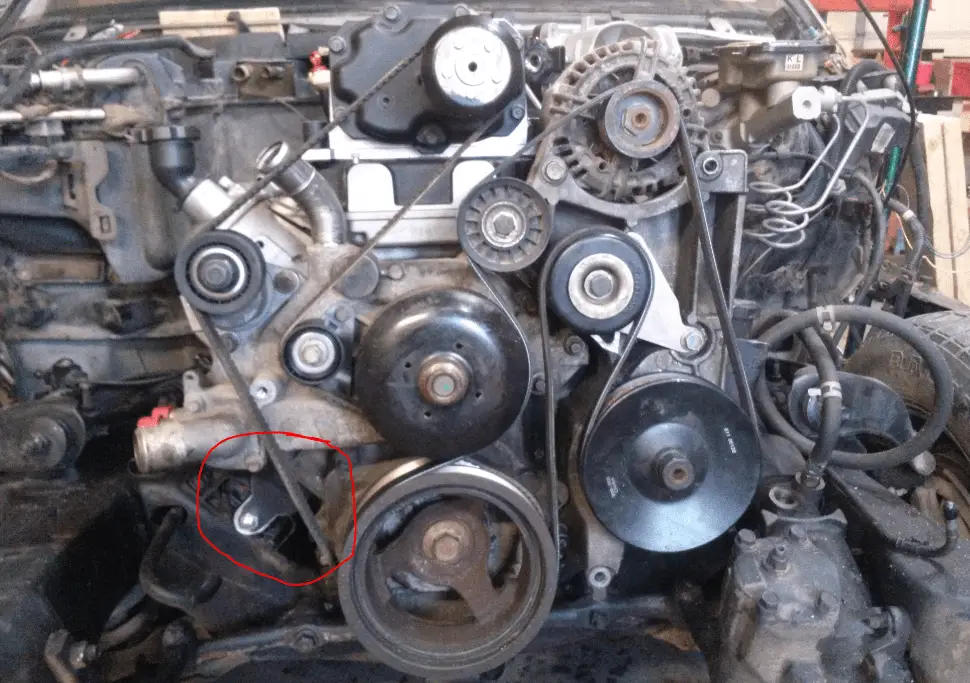

I home built my own mounts and have a stock truck PS pump pulley. Mine clears with 1" to the PS box.

Depending on the mount you can potentially slide the mounts back or use a different set of holes.

People use a 3.4 grand am PS pulley or the one off a 5.3 gmt360 chassis (TBSS, envoy denali or rainier) that is smaller.

View attachment 174495

Hey dude, i would like to pick your brain on details of your swap.

How did you fab your own mounts?

which way is the power steering clearing the steering box from, behind? over or off towards pass side?

Im running stock PS pulley too.

I bought some podoy chinese knockoffs of Lsx innovation type motor mounts for my 5.3LS swap into 84 cutlass. they dont fit maybe cuz the stock 307 was replaced with 305 and that guy messed with motor mount locations on the frame?

i dunno, but anyways i didnt find out until engine is wedged into place that neither mount is gonna work.

at first i tried using the pass side mount and was gonna dremel the other hole out bigger to fit but the oilpan was sitting right on the crossmember of pass side which im sure would crack it open or wear a hole thru.

this also left the engine tilted an inch lower on drivers side.

then i tried using drivers side mount and already fabbed a spacer bracket to lift the pass side high enough to clear crosssmember, only to find the drivers side manifold is not even close to fitting in there, it points right at the frame rails , right at the brake manifold and gear shifter mount.

Im running stock PS pulley too

So unless you have a better plan;

now that ive got engine sitting in my fabbed pass side mount, its already got the valve cover pressed against the heater box but at least that manifold fits with lotsa room.

the other side of engine is is hoisted in midair with engine hoist and level now but that mounting hole on frame bracket is about 3/4" lower than clamshell on engine AND the Drivers side manifold is pointing directly at frame and brake manifold bolted to the frame.

ive already cutoff about 3/4 off one manifold bolt but its not enough.

So i have to fab another mount spacer AND cut off the exhaust manifold flange and turn it ccw about 2 hrs and cut a wedge out of maniold to point it into the open space and re-weld that into place.

Im no great welder but i think i will need special rods to weld cast iron?