I’ve got an 85 ss monte carlo. It’s hard to explain what my driver side door issue is but the driver side door on my Monte is very hard to close. To get it to fully close and seal you have to slam it. If you don’t it will latch but not go all the way in. It also feels as if there’s resistance when push the door towards the car. Especially when the door is right before closing. It’s there’s tension on the door. Like I should be able to let go of the door and it will swing to the car. But my door seems to get resistance/tension/tightness when I get close to closing it. Also not sure if this is normal but the passenger side feels super tight. When I open it it’s kinda hard to pull the door handle but when it goes it pops open pretty hard.

85ss Monte Carlo door issues

- Thread starter Irishspring46

- Start date

-

- Tags

- door door striker doorhinges

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

While it is not offered as a repair part they can be repaired.Those roller pins are not rebuildable and not offered as a repair part.

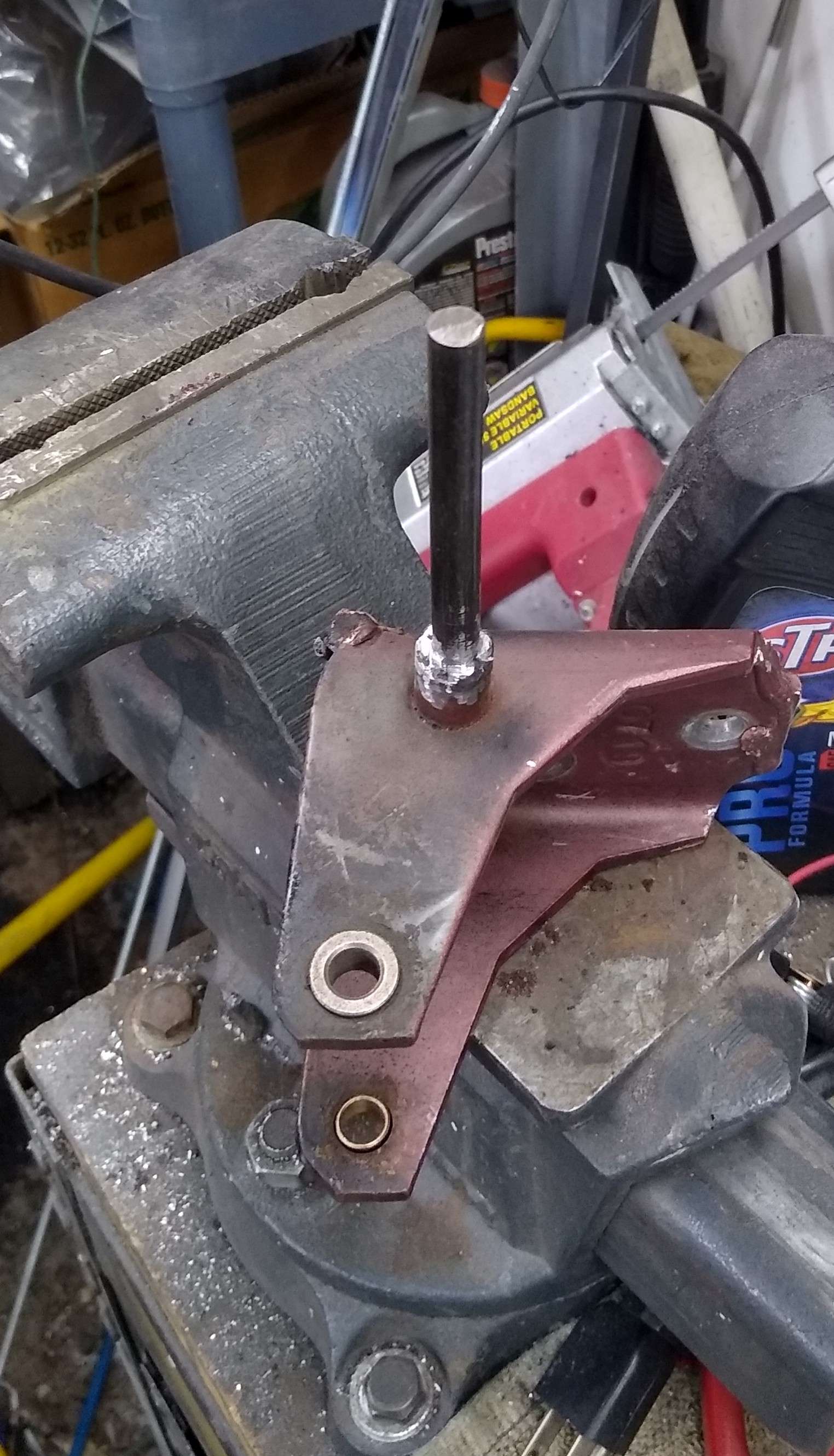

I used the left over pin and bushings from a repair kit to fix mine.

Nice, and a great idea. You could probably use the retired pins that got driven out from the original pin/bushing set up and repurpose them for just that reason.

It might also be possible to use a long shouldered bolt of the same outer diameter and use the head of the bolt as meat for when you weld it in place; something for the wire to hit on and work with.

Nick

It might also be possible to use a long shouldered bolt of the same outer diameter and use the head of the bolt as meat for when you weld it in place; something for the wire to hit on and work with.

Nick

Now that is slick. Am I correctly reading your drawing to say that you measured down an inch from the bottom of the shoulder and cut that section off to shorten the pin to fit? What bolt/thread did you cut into the new end?

Nick

Nick

That's exactly correct, cut one inch off from the shoulder and then drilled and tapped it 5/16 - 18 and used an allen head bolt. The diameter of the pin is perfect except the splines were kind of tight so I worked them down a little with a file so the bolt would pull the splines in. You could probably press the pin in first and not file down the splines, instead of using the bolt to pull it in.

The original pin needs to be sectioned inside of the hinge frame since the top comes down to be removed and the bottom needs to go up to be removed. Cut the top off so the roller end could go through the hole in the hinge frame.

The original pin needs to be sectioned inside of the hinge frame since the top comes down to be removed and the bottom needs to go up to be removed. Cut the top off so the roller end could go through the hole in the hinge frame.

Last edited:

Sectioning out the old pin sounds like a job for.......................................................wait for it......................................................Sooooper Dremel!!!! Either that or my air saw. It, being linear, might actually just fit a little better, thinking on it.

Nick

Nick

Used a dremel to section the pin. You have to cut at about 20-30 degree angle. Too much angle and the cutting wheel is not large enough in diameter. Too little angle and the tool body hits things and tries to force the angle and breaks the cutting wheel.

The saw might be a better option though I have not tried it.

The saw might be a better option though I have not tried it.

Had you gone with the rebuild option for your hinge, what you see above is what is included in a typical rebuild kit; some may also include a flat spring clip that presses over the end of the pin to keep it from trying to walk out.

The second shot is just a comparison of what the stock bushing would look like along with an example of the oversized outer diameter variant that is also included in the kit in the event you have oversize the hole to return it back to round and true. The serrations are there to lock the bushing in place to keep it from turning. Prior to install, miking this item is highly useful to determine what final size of hole you will need to get a light tap in fit. You can go tighter and use a press but risk the chance of cracking the bushing or bending the ear on the hinge section.

- Status

- Not open for further replies.

Similar threads

- Replies

- 0

- Views

- 192

- Replies

- 16

- Views

- 315

- Replies

- 0

- Views

- 94

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.