So, my goal this year has been to stay more busy and active, pain be d@%?ed. I listened to docs the last 6 years and '22 was my worst yet. Already told one I was taking myself off some of the meds he's got me on, and, that he could either write tapering scripts or I'd take myself off on my own. Scripts it was.

So, been keeping lots of irons in the fire and bouncing between projects. One of those is that I want to refinish some of my literally multiple hundreds of wheels I've got stored here, and, these are my first two desired wheel projects maybe someone has tips on.

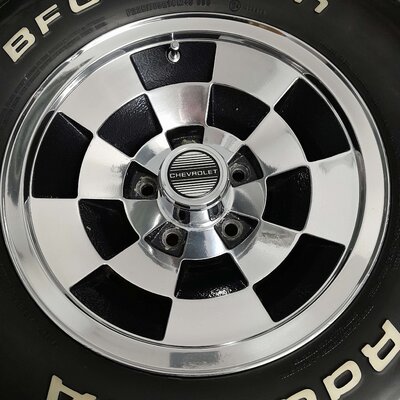

#1 - aluminum polishing. I'd like to begin with some of these style camaro rims I have:

What I'd like to do is leave 95% of them the hammered grey finish, but the thin flat circle around the edge and the two flat lines on each spoke edge running towards the center I'd like to get a nice shiny polished finish on.

To my knowlege they were never done as such from the factory.

Obviously the ball style attachments they make wouldn't work for such a fine area while leaving the rest untouched, is it something a Dremel tool with a fine tip would work well with? slightly concerned with pilishing just the surface away without wearing down into the surface level. I've never tried doing such a thing other than as maintenance of an existing polished surface, but, think they could look pretty sharp done up that way.

#2 - I've accumulated an excess of chevy rally wheels from full sized trucks. I'm thinking of having them powdercoated in batches if the price was economical enough on a per unit basis the plain factory light silver color and using a few sets to start with on my trucks, and maybe selling a few sets at the swap meets. Has anyone had experience with a known good shop in a range from say Charleston S.C., to Jacksonville FL, to Atlanta GA and points in between? I debated starting cleanup, but, since any vendor likely wants to clean them themselves to offer a warranty on the coating it seems like it may be wasted effort to do prematurely.

Looking to keep my project slate full since when ordering parts and pieces there's always delays and backorder on things. This won't be a year for sitting around if I can help it.

So, been keeping lots of irons in the fire and bouncing between projects. One of those is that I want to refinish some of my literally multiple hundreds of wheels I've got stored here, and, these are my first two desired wheel projects maybe someone has tips on.

#1 - aluminum polishing. I'd like to begin with some of these style camaro rims I have:

What I'd like to do is leave 95% of them the hammered grey finish, but the thin flat circle around the edge and the two flat lines on each spoke edge running towards the center I'd like to get a nice shiny polished finish on.

To my knowlege they were never done as such from the factory.

Obviously the ball style attachments they make wouldn't work for such a fine area while leaving the rest untouched, is it something a Dremel tool with a fine tip would work well with? slightly concerned with pilishing just the surface away without wearing down into the surface level. I've never tried doing such a thing other than as maintenance of an existing polished surface, but, think they could look pretty sharp done up that way.

#2 - I've accumulated an excess of chevy rally wheels from full sized trucks. I'm thinking of having them powdercoated in batches if the price was economical enough on a per unit basis the plain factory light silver color and using a few sets to start with on my trucks, and maybe selling a few sets at the swap meets. Has anyone had experience with a known good shop in a range from say Charleston S.C., to Jacksonville FL, to Atlanta GA and points in between? I debated starting cleanup, but, since any vendor likely wants to clean them themselves to offer a warranty on the coating it seems like it may be wasted effort to do prematurely.

Looking to keep my project slate full since when ordering parts and pieces there's always delays and backorder on things. This won't be a year for sitting around if I can help it.