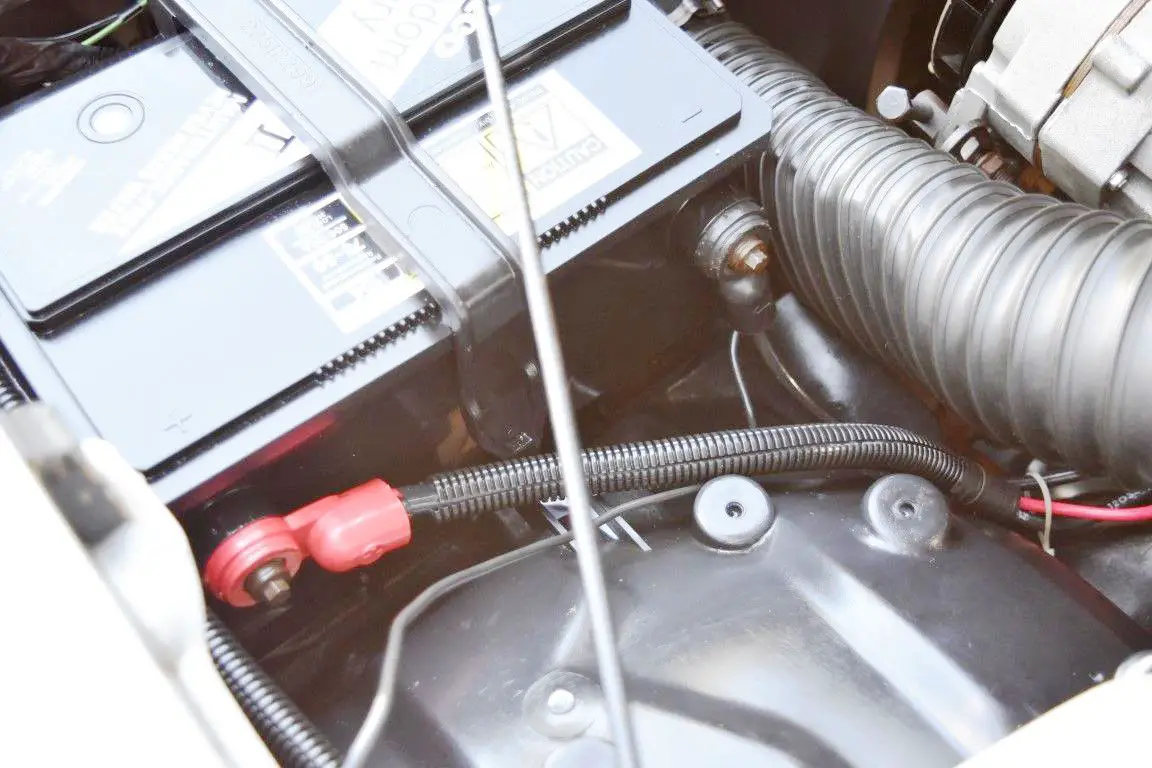

When it came time for me to buy cables for both of my cars my original plan was to have them made at the local auto parts. Then I found CE Auto Electric out in AR. Owners a car guy and drag racer. His cables are extremely well made. Not cheap but in my opinion worth every penny. Take a look at his website. Even if you have a set already. Great guy to deal with and I had them a few days after I ordered them.

Good stuff.

Good stuff.

Last edited: