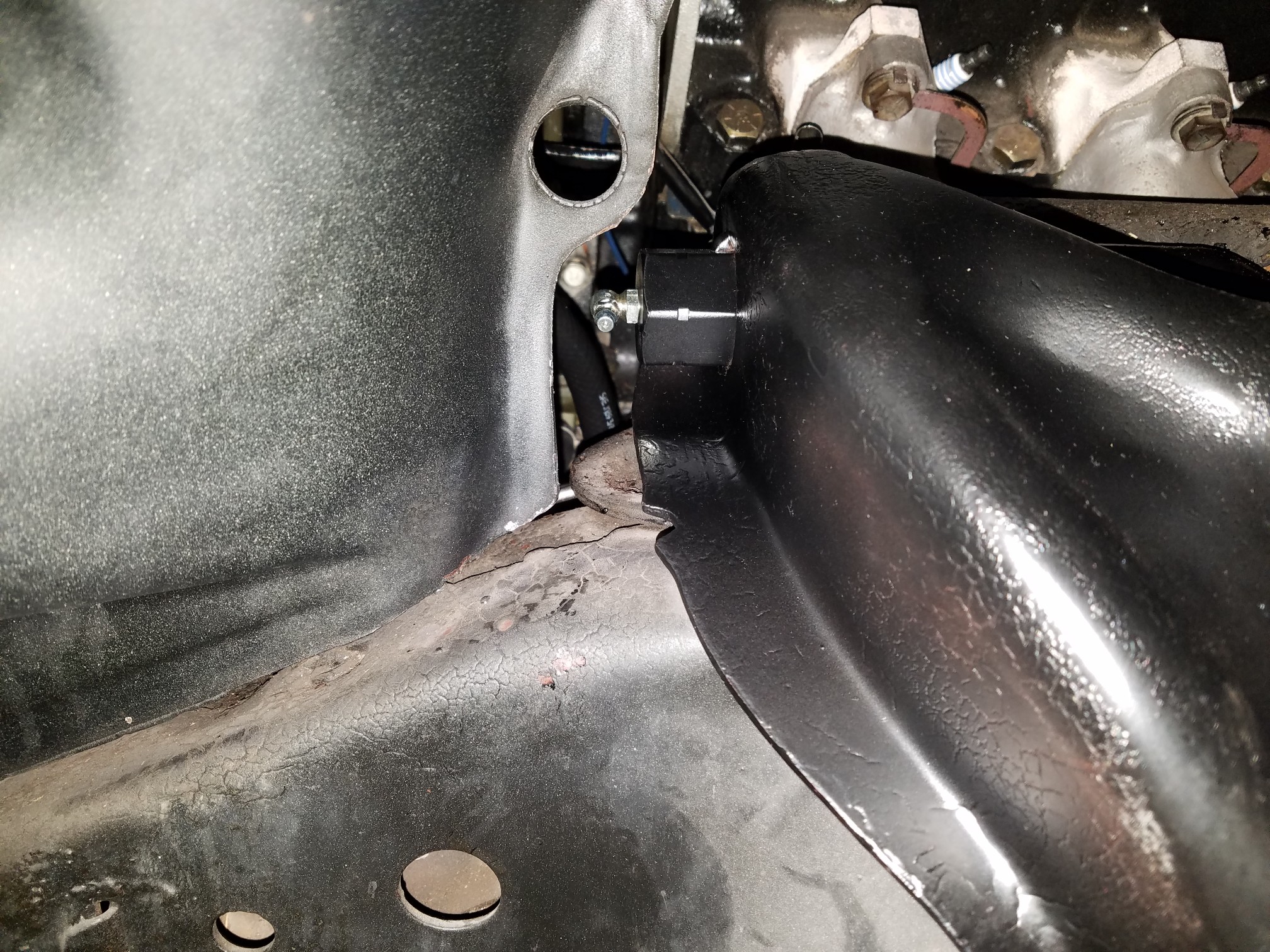

Sunday morning I went back to Dad's. We started out with making some measurements. It looked like our clearance was going to be in the ballpark on the driver's side and was going to be a little tight on the passenger side. We were hoping for 1/4". We decided it was going to be o.k. and moved forward with putting in the pan. After all, we'd run this setup with no issues for awhile. You have to hang the pickup by one bolt so you can swing it upward until it touches the crank. Then wiggle the pan in there until the pickup will clear the baffle and drop in to the sump. Then there is the joy of getting the other bolt started and getting both tightened up with the pickup in the highest possible position. Digging the ratchet and the bolt out of the bottom of the pan is also a treat. At last, we had the pan up there and torqued to the block. I tapped on the bottom of it with my knuckle in the center and "clang clang clang". sh*t. I tap on the corners with my knuckle and it sounds nice a hollow. Tap on the middle and clang. Strangely I could tap on the center with my finger nail and it wouldn't make the clang. At this point I felt like we needed to order the Milodon pickup to match the pan (stock depth pan) and see if we could get more favorable clearances. Dad didn't really want to do that. He remarked "I wish we could see it" and the lightbulb went off. I told Dad, lets go to Harbor Freight and buy an inspection camera. We can see through the drain plug hole. We ended up going to Home Depot to save time and spend a little more on a Ryobi inspection camera. I never begrudge spending money on tools. We get back to Dad's house, and of course, the Camera is shipped with a dead battery. The battery takes 10 hours to charge. Skunked again. I pulled the mechanical oil pressure gauge off and put the electric sender back on and hooked it up. It was early afternoon by now so I just went home with plans to come back over in the morning.

I went back to Dad's Monday morning. We got right to looking at the pickup with the inspection camera. We could clearly see the scratched finish on the floor of the pan and could clearly see that there was clearance between the pan and the pickup. I couldn't get the camera under the pickup so it was a bit tight on the passenger side as we anticipated. We decided it was ok and put the drain plug back in the pan. I primed a new oil filter and installed it. I put the sway bar back on. We dropped the car down off the stands and filled it up with oil. Dad cranked it up and it was immediate disappointment. 20 lbs. of oil pressure. No change. What the hell? I was standing at the front of the engine and it sounded good. It was quiet and seemed to be running smooth. Dad revved it up to maybe 1500-1800 RPM and there wasn't much change in oil pressure. We were both really disappointed. I figured we would have to try that Milodon pickup. Slowly, the pressure started coming up. It was strange. After a minute or two, it had better than 50 lbs. of pressure at idle. I put the digital multi-meter on it and switched it to 8 cylinder to use as a tach. I hooked up the timing light. I didn't end up adjusting timing. I just tweaked the idle speed. By the time it was up to temperature and really cranking some heat out of the radiator, it had 30 lbs. of pressure at hot idle. Problem solved. At last. All of this over carelessly dropping a washer down the hole for the distributor while pulling the intake! Of course, it was pouring down rain so we couldn't take the car out to test drive again. There are too many openings and unprotected places to take it out in the rain right now. I'm not crazy about taking it out in bad weather anyway.

That's where it stands for now. Dad wants to take it back out this coming Saturday to get it up to higher speeds and test the GearVendors. Hopefully it is a success. It isn't leaking and that's a start. The floor under the car is clean so, so far, that seems to be a success. Hopefully balancing the rear drums did something to smooth out the car. I looked at the pinion seal last weekend and it has seeped a little oil. Not enough to drip. That's pretty disappointing. We'll watch it and see what it does. We may have to take the center section back to the 'pros' anyway. We'll see. After the test drive, assuming it goes well, we plan to get on the front end work (springs, shocks, bushings, balljoints, etc.).

That's it for now guys. Hope I didn't wear you out with detail. Thanks as always for following along. I hope I have a good update next week. Until then.....

Best,

Jared

I went back to Dad's Monday morning. We got right to looking at the pickup with the inspection camera. We could clearly see the scratched finish on the floor of the pan and could clearly see that there was clearance between the pan and the pickup. I couldn't get the camera under the pickup so it was a bit tight on the passenger side as we anticipated. We decided it was ok and put the drain plug back in the pan. I primed a new oil filter and installed it. I put the sway bar back on. We dropped the car down off the stands and filled it up with oil. Dad cranked it up and it was immediate disappointment. 20 lbs. of oil pressure. No change. What the hell? I was standing at the front of the engine and it sounded good. It was quiet and seemed to be running smooth. Dad revved it up to maybe 1500-1800 RPM and there wasn't much change in oil pressure. We were both really disappointed. I figured we would have to try that Milodon pickup. Slowly, the pressure started coming up. It was strange. After a minute or two, it had better than 50 lbs. of pressure at idle. I put the digital multi-meter on it and switched it to 8 cylinder to use as a tach. I hooked up the timing light. I didn't end up adjusting timing. I just tweaked the idle speed. By the time it was up to temperature and really cranking some heat out of the radiator, it had 30 lbs. of pressure at hot idle. Problem solved. At last. All of this over carelessly dropping a washer down the hole for the distributor while pulling the intake! Of course, it was pouring down rain so we couldn't take the car out to test drive again. There are too many openings and unprotected places to take it out in the rain right now. I'm not crazy about taking it out in bad weather anyway.

That's where it stands for now. Dad wants to take it back out this coming Saturday to get it up to higher speeds and test the GearVendors. Hopefully it is a success. It isn't leaking and that's a start. The floor under the car is clean so, so far, that seems to be a success. Hopefully balancing the rear drums did something to smooth out the car. I looked at the pinion seal last weekend and it has seeped a little oil. Not enough to drip. That's pretty disappointing. We'll watch it and see what it does. We may have to take the center section back to the 'pros' anyway. We'll see. After the test drive, assuming it goes well, we plan to get on the front end work (springs, shocks, bushings, balljoints, etc.).

That's it for now guys. Hope I didn't wear you out with detail. Thanks as always for following along. I hope I have a good update next week. Until then.....

Best,

Jared

Last edited: