I'm getting behind on updates again, so here goes....

Two Saturdays ago, I went over to Dad's to continue working on the car. Dad had been working on installing the vinyl windlace that goes along the top of the side windows. It needs to go on first and then there are some tack strips for the headliner that go on afterward. Thankfully, Dad had kept the original vinyl windlace all these years. He was thinking along the lines of replacing it because it was an off-white color. Neither of us were aware of a reproduction. I examined the pieces when he got them down from the shelf and I was amazed by their condition. They were still pliable and weren't torn. I urged him to clean them up and use them. His concern was the color was wrong. He has a black headliner for the car. When the cars were new, they all had white headliners. He cleaned both up and they were kind of a dingy off-white. I told him no problem, we can paint those with SEM Color Coat. So the first thing we did two Saturdays ago was paint those pieces. I had Dad clean them with SEM Vinyl prep while I set up the gun. They turned out really well. Here is a look at one of the vinyl windlace pieces mocked up in the car earlier the week before. Not a great quality pic but the only one I have....

You can see the sort of ivory color. We spent about an hour and a half painting them. Afterword, we broke for lunch. After lunch, I got out to the garage a little after dad and was horrified to see he was already installing the freshly painted passenger side windlace! It had maybe been a little more than an hour since we had painted it. It was fine. That paint is tough. You have to stretch that windlace over hooks and you have to hammer down tabs on the roof inner structure. The paint took all of it with no damage. Here is a look at the piece back on the car, now Landau Black....

You can see I didn't get the very end of it with paint. Here is why....

I painted them hanging up. We had pulled plastic over the entire car, and I actually had them hanging from the garage door opener tract in the center of the open bay. It's no matter. It doesn't show. You can see in the pics above that Dad had to pull the chrome channel that the quarter window rolls up into along the top of the window opening in order to install this windlace.

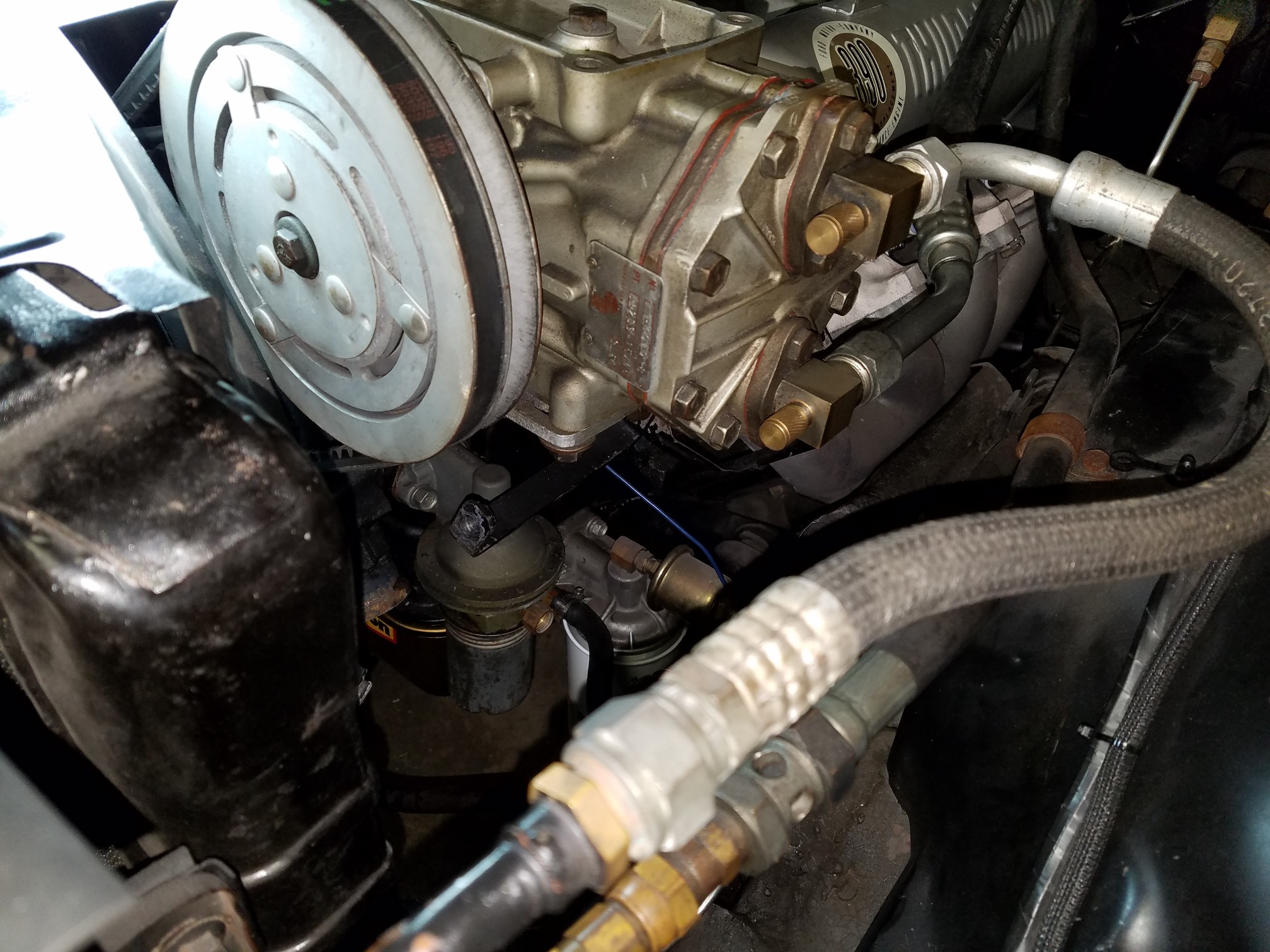

While Dad was putting the passenger side of the car together (windlace, tack strips, quarter window upper channel, inside A-pillar trim, outside A-pillar trim), I got under the car. No leak at the new pinion seal. I went ahead and re-installed the new drive shaft. Next, I went ahead and filled the GearVendors unit with Dexron III. This essentially completed the GearVendors installation. I moved forward and was pleased to see the drain plug on the Toploader dry. I've had a little trouble with a drop of gear oil forming on it after several weeks. It's a 9/16" square plug so I ended up putting a 15/16" wrench over the 9/16" wrench for a little more leverage and tightened the plug a little more the last time I worked on it. That seems to have done the trick. Next I moved forward and looked at the engine pretty carefully. Around a month ago I did a lot of cleaning and wiping of the pan, the sides of the block and the bellhousing. I wanted to make sure the oil pan wasn't leaking. As I mentioned before, we've had some trouble with oil on the bellhousing and in the clutch inspection cover. When the bellhousing was out of the car earlier this summer, I had come to the conclusion that the back of the intake was leaking, based on the witness marks. Finding everything clean and dry around the oil pan two Saturdays ago reinforced this diagnosis. I went ahead and drained the oil and pulled the oil filter. Then I started tearing the engine down to pull the intake manifold. This is about as far as I got....

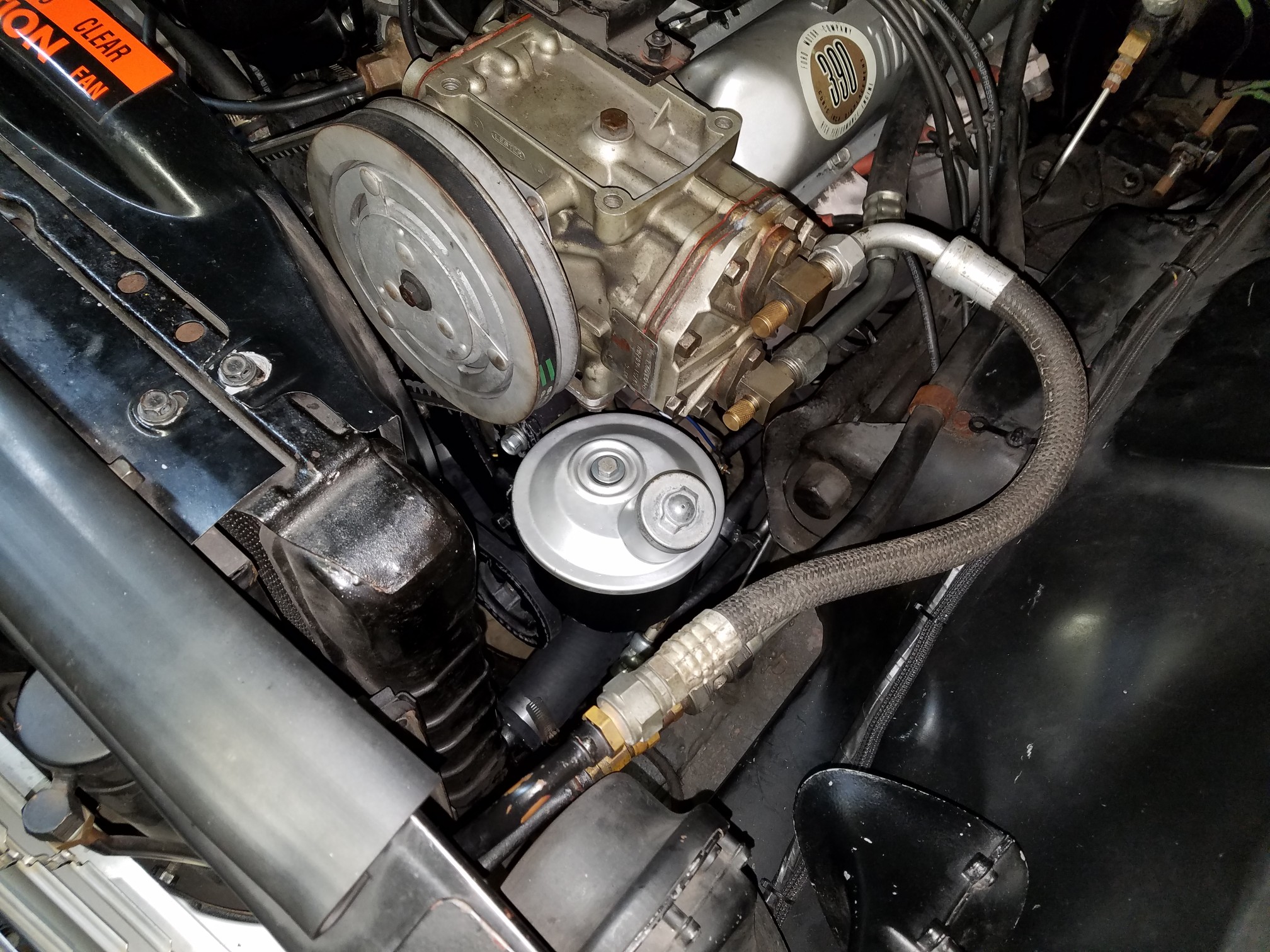

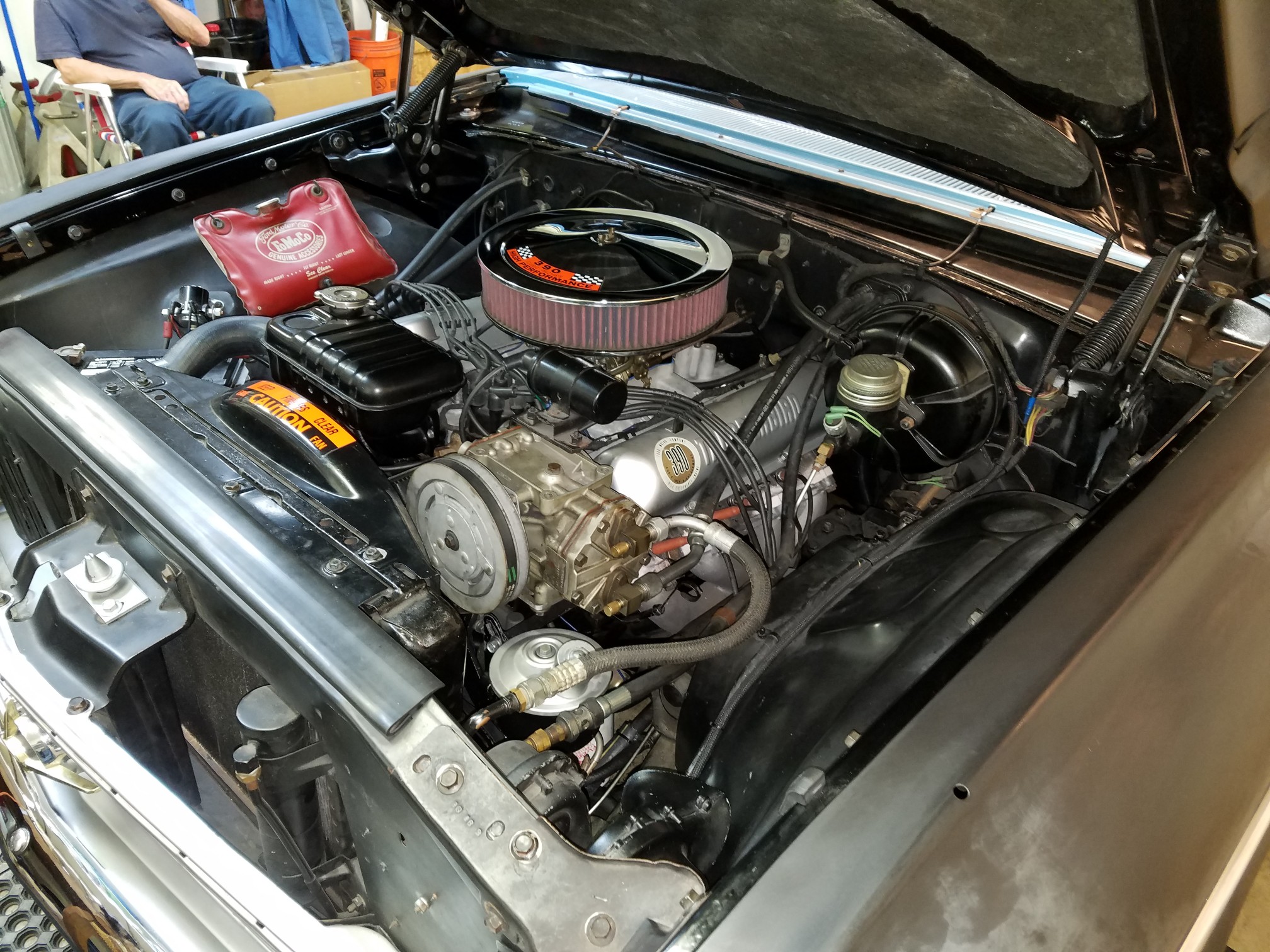

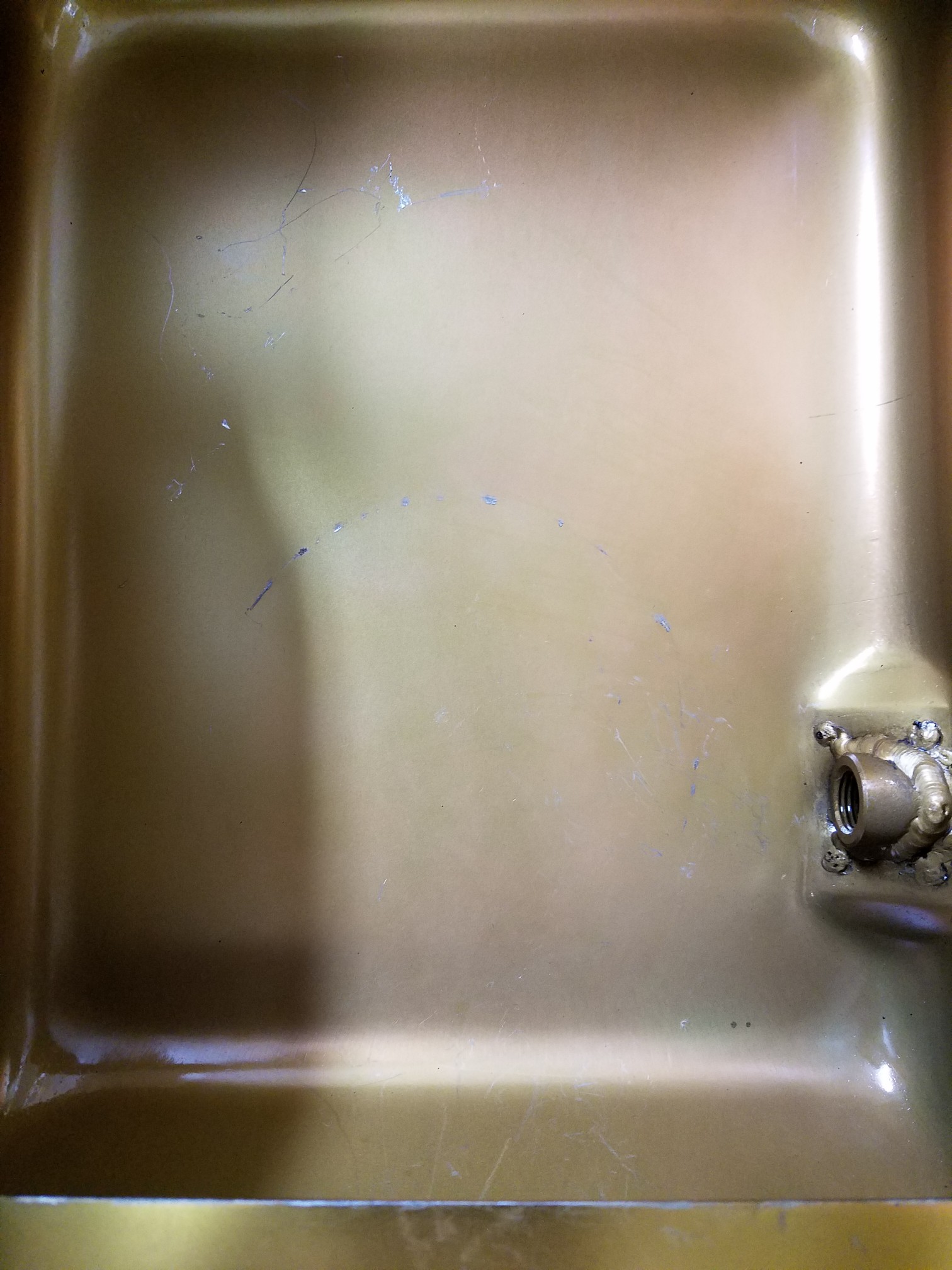

I didn't make it over there two Sundays ago. Last Saturday I went back over to get back on it. Dad was working on installing the all the windlace, tack strips, etc. on the Driver's side. I moved forward with getting the intake off. Unfortunately I was dumb and didn't plug the hole in the intake where the distributor was with paper towels. You guessed it, I dropped a flat washer off of one of the intake bolts down in the engine. Not fun. I had to pull the oil pan to retrieve it. It's not that terrible on this car. I pulled the sway bar loose for more room forward (it's a front sump pan on this car) and I dropped the oil pump down in the pan. I probably had it out in a half hour. I cleaned out the pan and no washer! Dang it! Fortunately I found the washer laying on the inside upper edge of the engine block casting oil pan rail. I got the oil pan rail scraped and cleaned up. I got the oil pan all cleaned up. I ordered another Milodon crush proof oil pan gasket from Summit. Then I got back on the intake. I got the intake pulled and got it all cleaned up, top and bottom. I didn't finish that until about 6 on Saturday. Here's a look at the engine torn down...

I still need to clean up along the intake side of the heads, and clean up the valve cover rails on the heads, as well as the front and rear rails of the block. When we put the intake on the engine, we did so on the engine stand. We used RTV. I guess it was just a little too thin along the back but I didn't see anything obviously wrong. I'm very confident of the diagnosis though. I guess it doesn't matter much. I'm doing the intake, the valve covers, and the oil pan. We just don't want it to leak! We have a Felpro Performance intake gasket set to put it back together with. I'm leaning towards using the front and rear gaskets that came with it instead of RTV. What do you guys think? I really don't want to put this thing back together and have it leak oil. We've been plagued with leaks the entire time with this thing.

That's about it for now. As you can see, I have a hard time stopping and taking all the pictures I should. I need to take a picture of the cleaned up intake and need to take a few pics of Dad's completed windlace, tack strip, etc. assembly. It looks great. Sean, Dad and I are going to a concert Friday night and will likely have a pretty good time so I fear Saturday might not be super productive but I'm planning to go over on Sunday as well. I hope to have the intake and oil pan buttoned up by the end of the weekend. I ordered a new power steering pump earlier this week. I can't believe new ones are available. The one on the car is off a parts car that all the rest of the power steering came off of. Dad rebuilt it but it groans a little and when I pulled the lower radiator hose, so I could pull the fuel pump to carb fuel line off the fuel pump, I noticed it was leaking a little bit, so I think that is the next project. Anyway, I'll follow up with the progress. Until then, thanks for following along.

Best,

Jared

Two Saturdays ago, I went over to Dad's to continue working on the car. Dad had been working on installing the vinyl windlace that goes along the top of the side windows. It needs to go on first and then there are some tack strips for the headliner that go on afterward. Thankfully, Dad had kept the original vinyl windlace all these years. He was thinking along the lines of replacing it because it was an off-white color. Neither of us were aware of a reproduction. I examined the pieces when he got them down from the shelf and I was amazed by their condition. They were still pliable and weren't torn. I urged him to clean them up and use them. His concern was the color was wrong. He has a black headliner for the car. When the cars were new, they all had white headliners. He cleaned both up and they were kind of a dingy off-white. I told him no problem, we can paint those with SEM Color Coat. So the first thing we did two Saturdays ago was paint those pieces. I had Dad clean them with SEM Vinyl prep while I set up the gun. They turned out really well. Here is a look at one of the vinyl windlace pieces mocked up in the car earlier the week before. Not a great quality pic but the only one I have....

You can see the sort of ivory color. We spent about an hour and a half painting them. Afterword, we broke for lunch. After lunch, I got out to the garage a little after dad and was horrified to see he was already installing the freshly painted passenger side windlace! It had maybe been a little more than an hour since we had painted it. It was fine. That paint is tough. You have to stretch that windlace over hooks and you have to hammer down tabs on the roof inner structure. The paint took all of it with no damage. Here is a look at the piece back on the car, now Landau Black....

You can see I didn't get the very end of it with paint. Here is why....

I painted them hanging up. We had pulled plastic over the entire car, and I actually had them hanging from the garage door opener tract in the center of the open bay. It's no matter. It doesn't show. You can see in the pics above that Dad had to pull the chrome channel that the quarter window rolls up into along the top of the window opening in order to install this windlace.

While Dad was putting the passenger side of the car together (windlace, tack strips, quarter window upper channel, inside A-pillar trim, outside A-pillar trim), I got under the car. No leak at the new pinion seal. I went ahead and re-installed the new drive shaft. Next, I went ahead and filled the GearVendors unit with Dexron III. This essentially completed the GearVendors installation. I moved forward and was pleased to see the drain plug on the Toploader dry. I've had a little trouble with a drop of gear oil forming on it after several weeks. It's a 9/16" square plug so I ended up putting a 15/16" wrench over the 9/16" wrench for a little more leverage and tightened the plug a little more the last time I worked on it. That seems to have done the trick. Next I moved forward and looked at the engine pretty carefully. Around a month ago I did a lot of cleaning and wiping of the pan, the sides of the block and the bellhousing. I wanted to make sure the oil pan wasn't leaking. As I mentioned before, we've had some trouble with oil on the bellhousing and in the clutch inspection cover. When the bellhousing was out of the car earlier this summer, I had come to the conclusion that the back of the intake was leaking, based on the witness marks. Finding everything clean and dry around the oil pan two Saturdays ago reinforced this diagnosis. I went ahead and drained the oil and pulled the oil filter. Then I started tearing the engine down to pull the intake manifold. This is about as far as I got....

I didn't make it over there two Sundays ago. Last Saturday I went back over to get back on it. Dad was working on installing the all the windlace, tack strips, etc. on the Driver's side. I moved forward with getting the intake off. Unfortunately I was dumb and didn't plug the hole in the intake where the distributor was with paper towels. You guessed it, I dropped a flat washer off of one of the intake bolts down in the engine. Not fun. I had to pull the oil pan to retrieve it. It's not that terrible on this car. I pulled the sway bar loose for more room forward (it's a front sump pan on this car) and I dropped the oil pump down in the pan. I probably had it out in a half hour. I cleaned out the pan and no washer! Dang it! Fortunately I found the washer laying on the inside upper edge of the engine block casting oil pan rail. I got the oil pan rail scraped and cleaned up. I got the oil pan all cleaned up. I ordered another Milodon crush proof oil pan gasket from Summit. Then I got back on the intake. I got the intake pulled and got it all cleaned up, top and bottom. I didn't finish that until about 6 on Saturday. Here's a look at the engine torn down...

I still need to clean up along the intake side of the heads, and clean up the valve cover rails on the heads, as well as the front and rear rails of the block. When we put the intake on the engine, we did so on the engine stand. We used RTV. I guess it was just a little too thin along the back but I didn't see anything obviously wrong. I'm very confident of the diagnosis though. I guess it doesn't matter much. I'm doing the intake, the valve covers, and the oil pan. We just don't want it to leak! We have a Felpro Performance intake gasket set to put it back together with. I'm leaning towards using the front and rear gaskets that came with it instead of RTV. What do you guys think? I really don't want to put this thing back together and have it leak oil. We've been plagued with leaks the entire time with this thing.

That's about it for now. As you can see, I have a hard time stopping and taking all the pictures I should. I need to take a picture of the cleaned up intake and need to take a few pics of Dad's completed windlace, tack strip, etc. assembly. It looks great. Sean, Dad and I are going to a concert Friday night and will likely have a pretty good time so I fear Saturday might not be super productive but I'm planning to go over on Sunday as well. I hope to have the intake and oil pan buttoned up by the end of the weekend. I ordered a new power steering pump earlier this week. I can't believe new ones are available. The one on the car is off a parts car that all the rest of the power steering came off of. Dad rebuilt it but it groans a little and when I pulled the lower radiator hose, so I could pull the fuel pump to carb fuel line off the fuel pump, I noticed it was leaking a little bit, so I think that is the next project. Anyway, I'll follow up with the progress. Until then, thanks for following along.

Best,

Jared