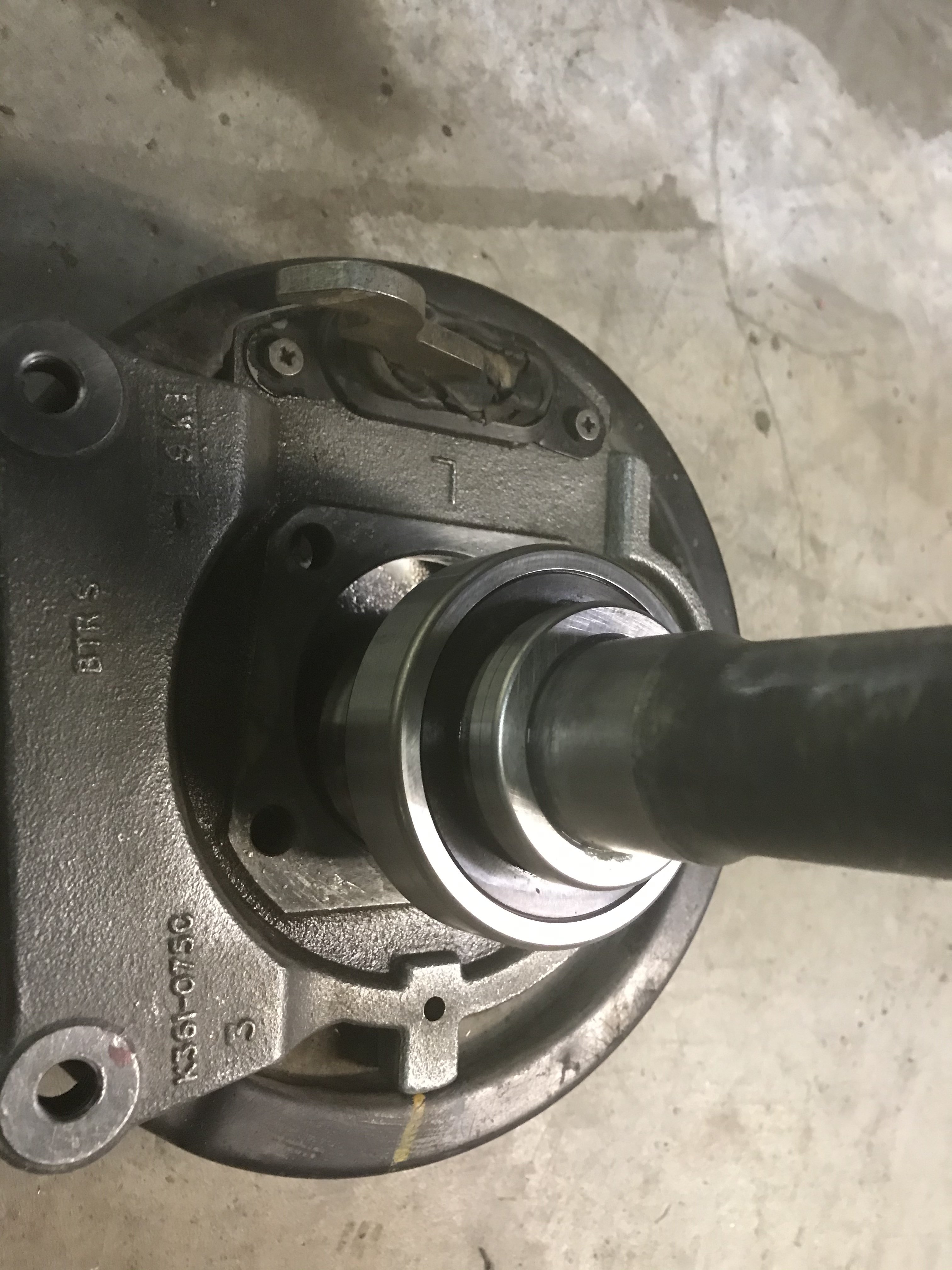

Just attach a section of hose to it and clip the other end up in the frame somewhere. Something like this in the other end. You just don't want bugs or water to get in.

www.summitracing.com

www.summitracing.com

Dorman 14689 Dorman Transmission Case Vents | Summit Racing

Free Shipping - Dorman Transmission Case Vents with qualifying orders of $109. Shop Transmission Vent Tubes at Summit Racing.

Last edited: