It's a Grade 8 bolt at 10mm diameter, pretty strongI don't think they were torqued to yielding from the factory. I'll just follow the gm procedure.

Head gasket/bolt reusable?

- Thread starter RabbitHoleSS

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

The original bolts are actually stronger after the heat cycles from a used engine.

There was a video on Sloppy a few years back where an engineer did some yield testing on them and the common cheap alternatives.

There was a video on Sloppy a few years back where an engineer did some yield testing on them and the common cheap alternatives.

Or, you use 2000 grit wet sand paper with WD40. Worked great for me, still using the same crank.That's how you polish a Crank.. 😉

When I saw the thread title I can to do a double take. Sounded like DRIVEN 's golden boy was back on the board at first after having missed the chances to call all of us a bunch of racists etc etc. 😆

But nah, nothing wrong with being a bit frugal now and again, just need to choose when and where.

Walla pass on the morning coffee or brown bag your lunch? By all means! But if you're skimping on something related to controlled explosions, or the ability to stop yourself while in motion, not the time for skimping

But nah, nothing wrong with being a bit frugal now and again, just need to choose when and where.

Walla pass on the morning coffee or brown bag your lunch? By all means! But if you're skimping on something related to controlled explosions, or the ability to stop yourself while in motion, not the time for skimping

BTR HEAD GASKET - 4.8/5.3/LS1 - SOLD INDIVIDUALLY - BTR89226

BTR HEAD GASKET - LS1 - SOLD INDIVIDUALLY - BTR89226

Notice these are out of stock. But these are a great choice.

As mentioned, it's been done alot with alot of success for both. But no one has mentioned you need to apply some common sense here. You took the bolts out, how did that go? If you twisted the heck out of a couple to get them out due to corrosion in the bolt holes, then don't re-use them imo. If the head gaskets have any swelling or junk in them that has swelled and left an imperfection, then don't use them. Most of the time this doesn't occur, but look the bolts and head gaskets over well. Be sure to clean all of the threads in the block well and clean out the holes. Happel has it in many of the older videos how to make and use an old head as a thread chaser - it works great. I clean the head gaskets with scotch brite pad (not a roloc disc) and brake clean.

I've done it several times with success. My 1st 4.8 I ran to 27psi of boost with the re-used head gaskets and bolts - no issues. I've used the BTR gaskets a couple of times as well and actually keep a set 'in stock' on the garage wall. But I've graduated to LS9 head gaskets now only because of the 9 layers being more resistant to leaking at 25+psi. I've never had a used or new LS head gasket leak other than from lifting the head - meaning it leaked, but just for a split second. Actually drove the car on and off the trailer and you'd never know there was an issue until it seen 5 psi (it filled the reservoir tank a couple of times before I threw in the towel on them - it was obvious where the leak was when I tore it apart.)

Definitely a little Russian Roulette is being played here if you reuse the head gaskets, but keep in mind how easy the head gasket is to change - 3-4 hours. I know a lot of guys don't like the thought of tearing something back apart that they recently put together. But as with all things LS, how much love do you have the motor and engine bay appearance? If a lot - then put in new.

BTW, you're going to have to work to be cheaper than I. but I'll let you wear the King of Cheap crown if you'd like haha.

I missed this post earlier. Man ain't this the truth. This describes paralysis by analysis. I have an old project not completed for that reason. As much as some may dislike the sloppy mechanic stuff (understandably), the unfinished project is much worse than the running and driving car that you can enjoy. RabbitHoleSS you seem like the type that wants to drive it, not park it in the garage and look at it. You can always update/improve later.The difference between where do you stop replacing parts and not replacing parts is how much do you owe your credit cards or how much is there in the bank? That is why so many garages have great cars to restore/fix being used as shelves; they ran out of both will and money, hard to tell which one 1st, I would say $$$$

That's it. 100%. Project creep is real and is the biggest threat to an incomplete project imo. I don't mind wrenching and I plan on driving the car. My son wants to go to the track with it. So we'll see how that goes. I went cheap on gaskets, Fel-Pro stock replacement permatorque I think. The old ones were cracked on a few corners and swollen with rust and carbon between the layers. The bolts came out smooth and pretty clean. I figured ill stop at 65-70 ft lb.I'll look into the sloppy thread chaser.I missed this post earlier. Man ain't this the truth. This describes paralysis by analysis. I have an old project not completed for that reason. As much as some may dislike the sloppy mechanic stuff (understandably), the unfinished project is much worse than the running and driving car that you can enjoy. RabbitHoleSS you seem like the type that wants to drive it, not park it in the garage and look at it. You can always update/improve later.

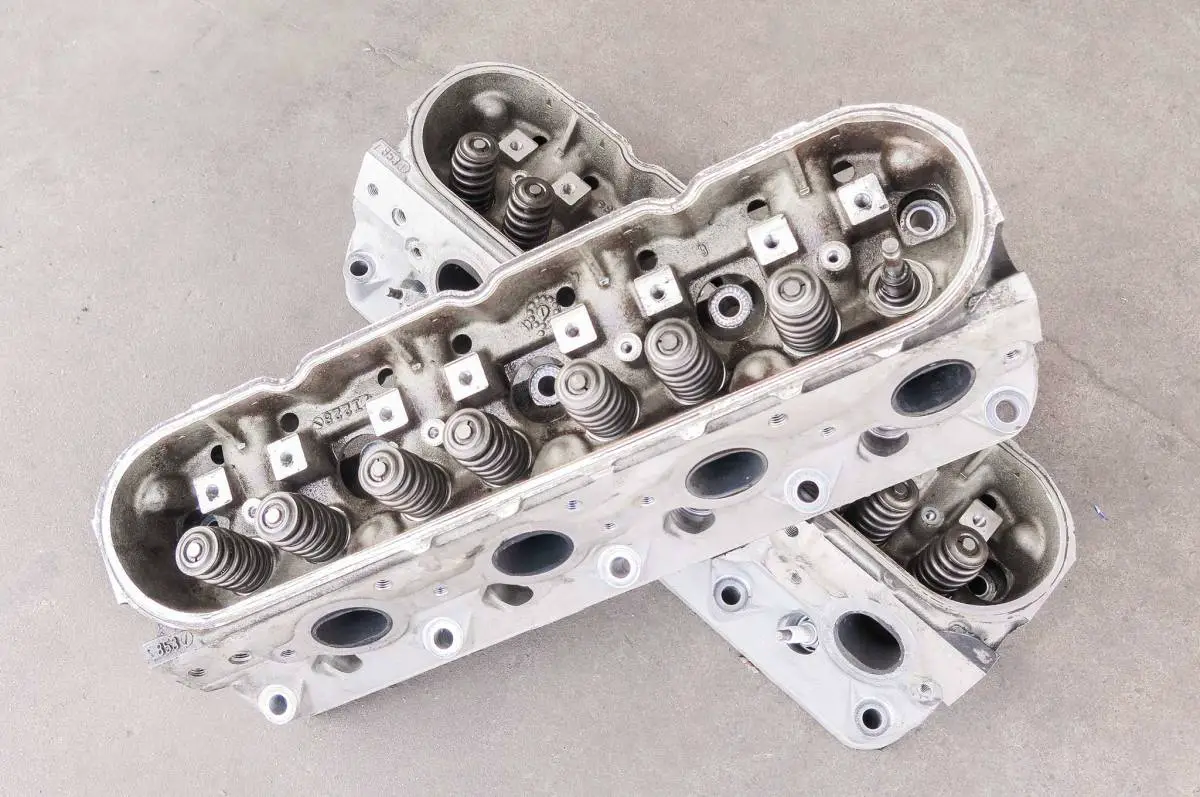

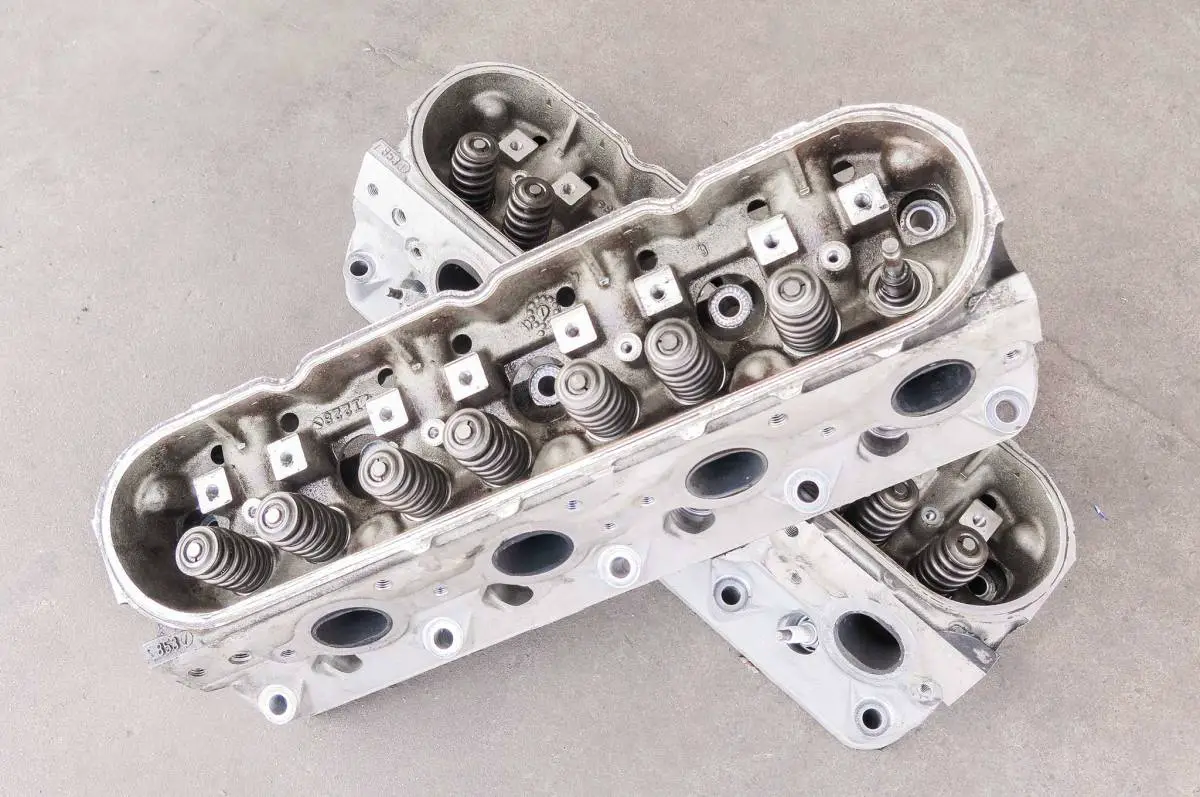

I'm gonna unshroud the valves on these 706 heads. Hopefully by then my converter shows up, he said this week a few times now so I'm sure it's really coming this time.

Thanks for the advice as always.

BTW, you're going to have to work to be cheaper than I. but I'll let you wear the King of Cheap crown if you'd like haha.

It's as simple as using a cut off wheel down the length of an old head bolt, 90° to the threads. This allows the cut edge of the threads on the bolt, to dig any crap out of the threads in the block.

I figured ill stop at 65-70 ft lb.

LS Cylinder Head Install Procedure

It’s not hard, but you have to install LS heads correctly with proper parts and tools.

build.torqued.io

build.torqued.io

Again, Happel has documented this pretty well in terms of how much torque the angle measurements are. Be careful using a generic torque on used bolts. You're motor has 2 different length 11mm head bolts, correct?

I think i have 10x of the same big bolts and 5 little bolts. I had just watched a sloppy video on torqing head bolts. He went from finger tight to 55 ft lb to 75 ft lb,lol that's why I said that but I think I have one of those torque angle gauges so might as well use it.I got it at a yardsale a few yrs ago. I didn't know what it was until yesterday when I googled it. Lol. Now I just need to find it.

LS Cylinder Head Install Procedure

It’s not hard, but you have to install LS heads correctly with proper parts and tools.build.torqued.io

Again, Happel has documented this pretty well in terms of how much torque the angle measurements are. Be careful using a generic torque on used bolts. You're motor has 2 different length 11mm head bolts, correct?

10 of the ones on the left. 5 of the ones on the right. Ill go to the junkyard(with 1 of my bolts) and pull a bolt for streetbu thread chaser.

Attachments

- Status

- Not open for further replies.

Similar threads

- Replies

- 5

- Views

- 651

- Replies

- 2

- Views

- 223

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.