Since im still on carburetor duty, i came across a used 600 metering block for cheap and decided to modify both upper and lower IFR and the PVCR channels for practice.

Knowing full well theres aftermarket billet metering blocks available that feature the same, affordable enough, it doesnt hurt to learn and do things yourself, figure i'll use it one day and see how it goes.

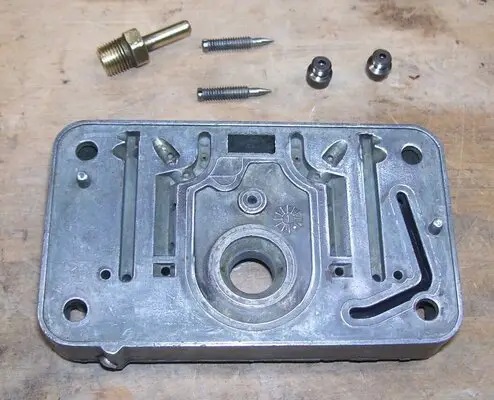

The metering block came without the holley inserted lower brass IFR, so there was a .090 hole in its place that it gets pressed into, the PVCR was .046, emulsion at .028 and the antisyphoning(kill bleed) is .027, typical for 600cfm vacsec.

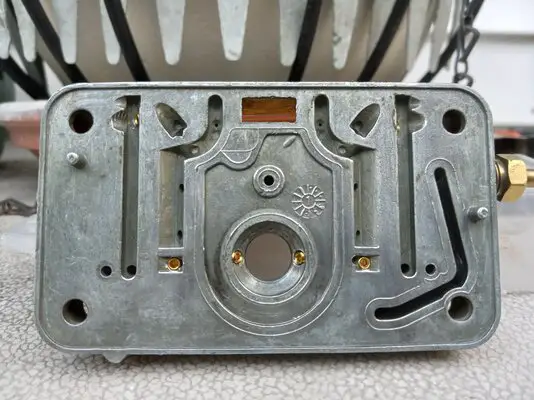

I started off with a 1/16(.060) drill bit to open the PVCR and gradually worked my way up to the 7/64(.106) drill bit using a hand held pin vise for more control and accuracy, using a dremel tool would be faster yes, but unless you have the hands of a surgeon, chances are you just might screw up the hole up or worse.

I then used a 6-32 plug tap(NC) to make the threads, better with bottom tap for almost instant tapping for better dept control for the 6-32 x 3/16 set screws, but its all i had on hand, i did get a pich into the PV top thread only, it happens, but i carefully lined up the PV to rethread it so it installs and removed without issue.

Next up was the lower IFR holes, since they were already .090(3/32 bit), next in line was the 7/64(.106) drill bit, opened it up slowly to go all the way through, but not with the tap, so when i get the set screws, i will set them to sit flush and tight just like the original pressed in ones do. I also threaded the upper IFR as well to experiment with, since aftermarket billet metering blocks have them set up on top, the hole there was already the correct size as the 7/64 drill bit, so all i had to do was just use the 6-32 tap to make the threads.

I currently dont have any set screws to put in, i'll have to get a few here soon, the brass ones are prefered to easier drill through to make the hole sizes needed, so after insertion, i'll post an updated picture then.

Enjoy

Knowing full well theres aftermarket billet metering blocks available that feature the same, affordable enough, it doesnt hurt to learn and do things yourself, figure i'll use it one day and see how it goes.

The metering block came without the holley inserted lower brass IFR, so there was a .090 hole in its place that it gets pressed into, the PVCR was .046, emulsion at .028 and the antisyphoning(kill bleed) is .027, typical for 600cfm vacsec.

I started off with a 1/16(.060) drill bit to open the PVCR and gradually worked my way up to the 7/64(.106) drill bit using a hand held pin vise for more control and accuracy, using a dremel tool would be faster yes, but unless you have the hands of a surgeon, chances are you just might screw up the hole up or worse.

I then used a 6-32 plug tap(NC) to make the threads, better with bottom tap for almost instant tapping for better dept control for the 6-32 x 3/16 set screws, but its all i had on hand, i did get a pich into the PV top thread only, it happens, but i carefully lined up the PV to rethread it so it installs and removed without issue.

Next up was the lower IFR holes, since they were already .090(3/32 bit), next in line was the 7/64(.106) drill bit, opened it up slowly to go all the way through, but not with the tap, so when i get the set screws, i will set them to sit flush and tight just like the original pressed in ones do. I also threaded the upper IFR as well to experiment with, since aftermarket billet metering blocks have them set up on top, the hole there was already the correct size as the 7/64 drill bit, so all i had to do was just use the 6-32 tap to make the threads.

I currently dont have any set screws to put in, i'll have to get a few here soon, the brass ones are prefered to easier drill through to make the hole sizes needed, so after insertion, i'll post an updated picture then.

Enjoy

Attachments

Last edited: