As mentioned before... if you're not comfortable modifying the metering block's IFR restrictors with 8-32 x 3/16" brass set screws to make them adjustable or cannot afford the billet metering blocks, the small wire method will work to reduce the surface area to help manage the fuel richness at idle.

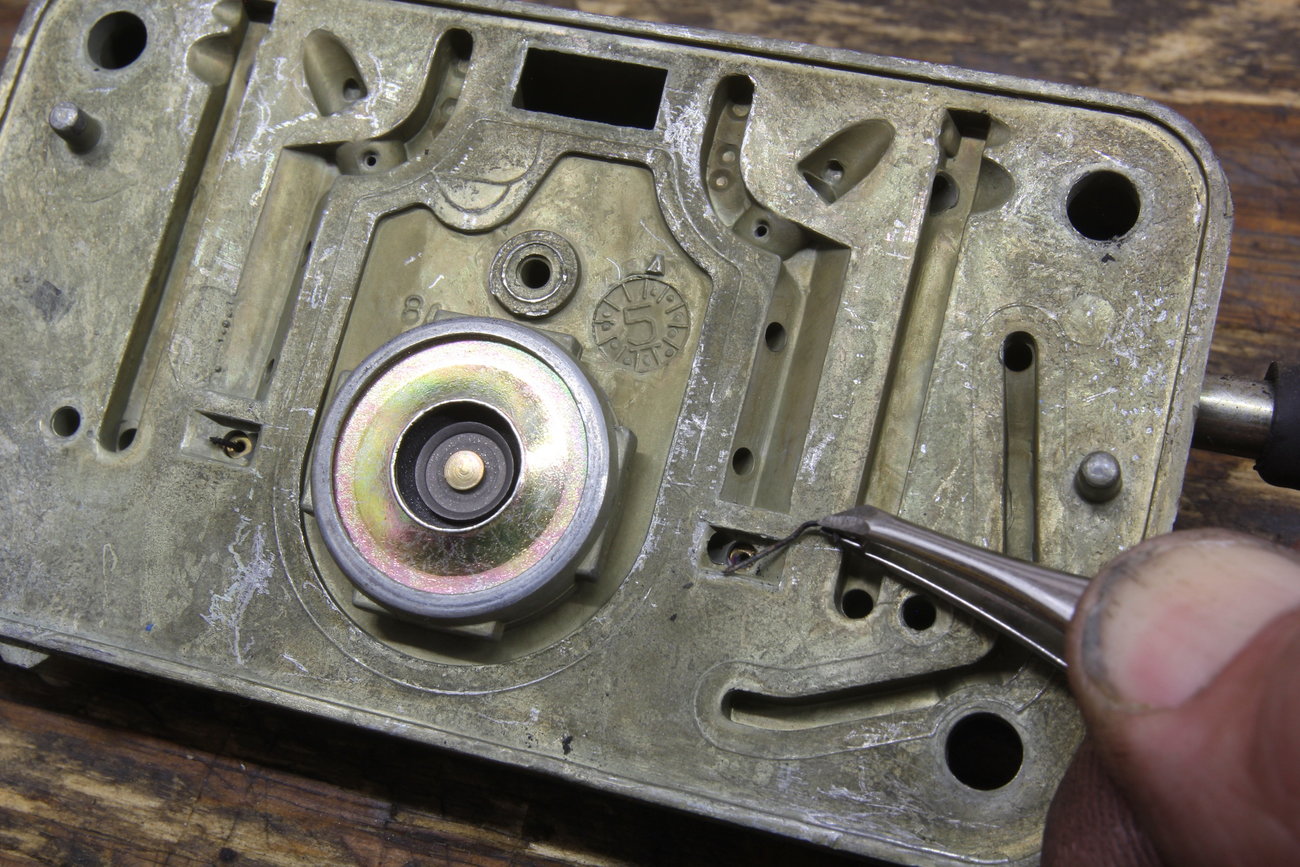

Example picture(not mine):

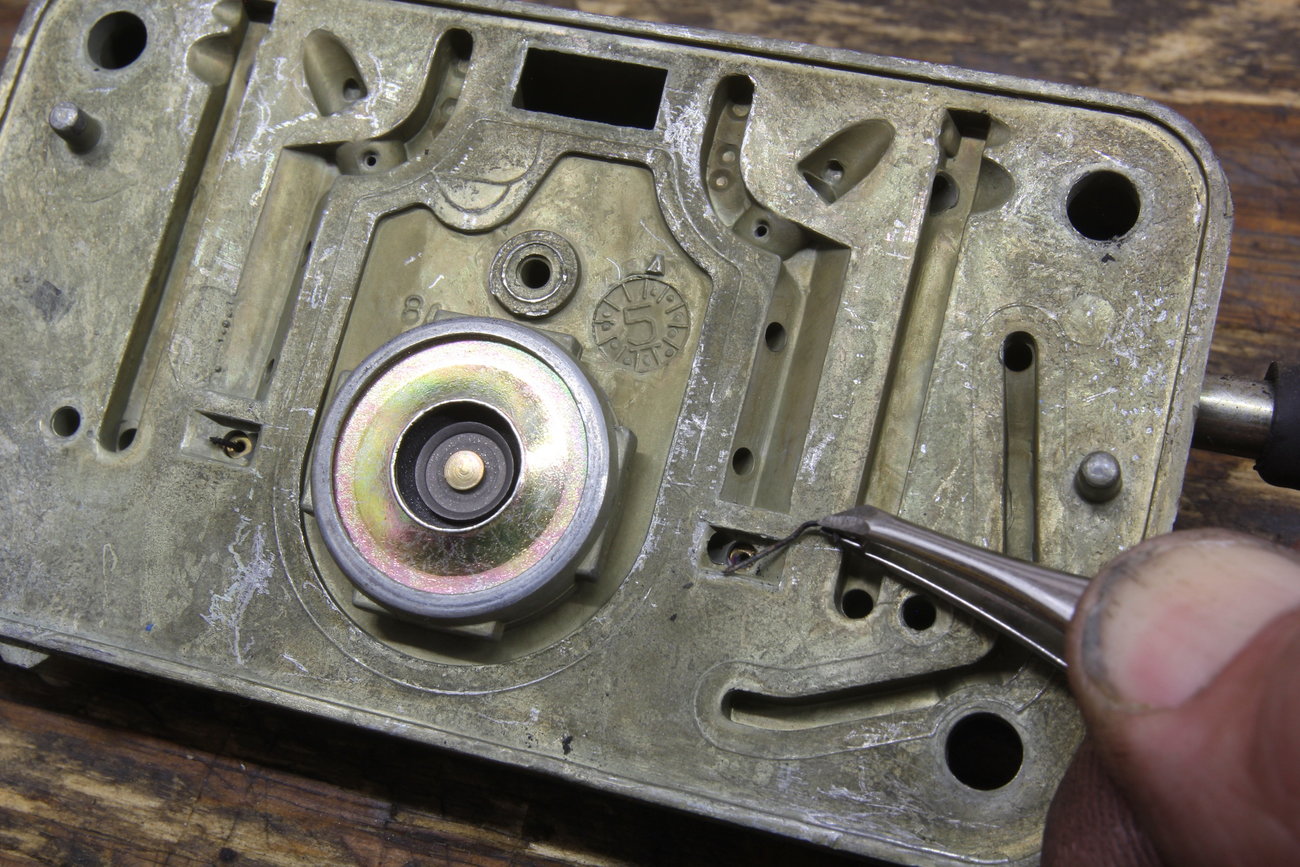

Example picture(not mine):