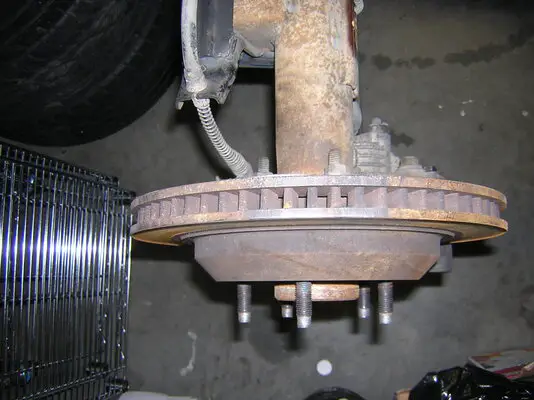

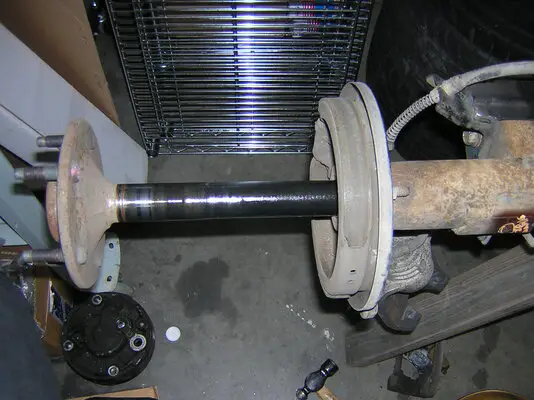

I picked up a complete 2000 Camaro rear axle at the boneyard. There have been some excellent descriptions and videos posted, but I keep finding questions about how to do this job, so I plan to take some photos and describe details to fill in some blanks. This is my first attempt at this kind of swap.

Nice step-by-step here: viewtopic.php?f=7&t=30606 and viewtopic.php?f=19&t=41067

Here is the as-found axle with brakes, lines, and brackets intact. This will take a few weeks to execute, so check back later.

Nice step-by-step here: viewtopic.php?f=7&t=30606 and viewtopic.php?f=19&t=41067

Here is the as-found axle with brakes, lines, and brackets intact. This will take a few weeks to execute, so check back later.

Attachments

Last edited: