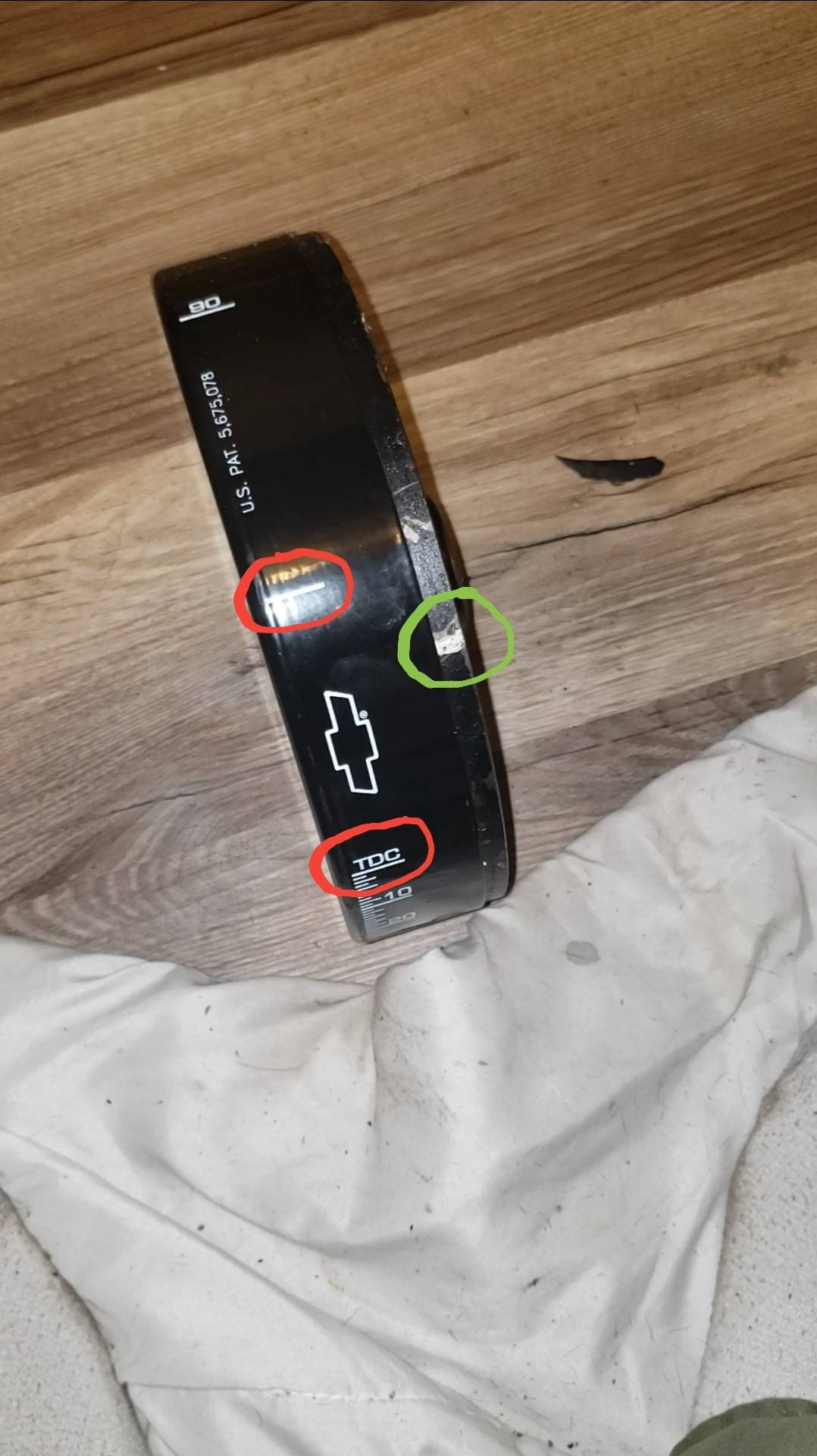

Is this harmonic balancer cover with timing marks fitted correctly on my 305 8" balancer ?

- Thread starter Tynan918

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

No im going to keep it stock.That is a 3 groove crank gear are you going to advance the cam timing? You have it set to stock timing now.

While the gears are timed TDC #1. Without the gasket on it place the timing chain cover on so the two pins hold it slide the new balancer on so it is on the keyway and mark where the timing mark is on the cover with a sharpie, That way you know if the pointer you install is correct.

I don't have the new pointer in the mail just yet.

Also waiting on timing tape to come in next Tuesday.

I bought the 6.75" balancer instead of an 8"... 8" balancers were used on 350 in trucks, 6.75" was used on cars.

Yea I'm not done in that area, what's a good procedure to get it off ?

That's why one would mark the cover now, You won't have to worry about not moving the crank while reassembling. You can verify the pointer is correct when you get it.I don't have the new pointer in the mail just yet.

Gotcha, I'll jump on that tomorrow morningThat's why one would mark the cover now, You won't have to worry about not moving the crank while reassembling. You can verify the pointer is correct when you get it.

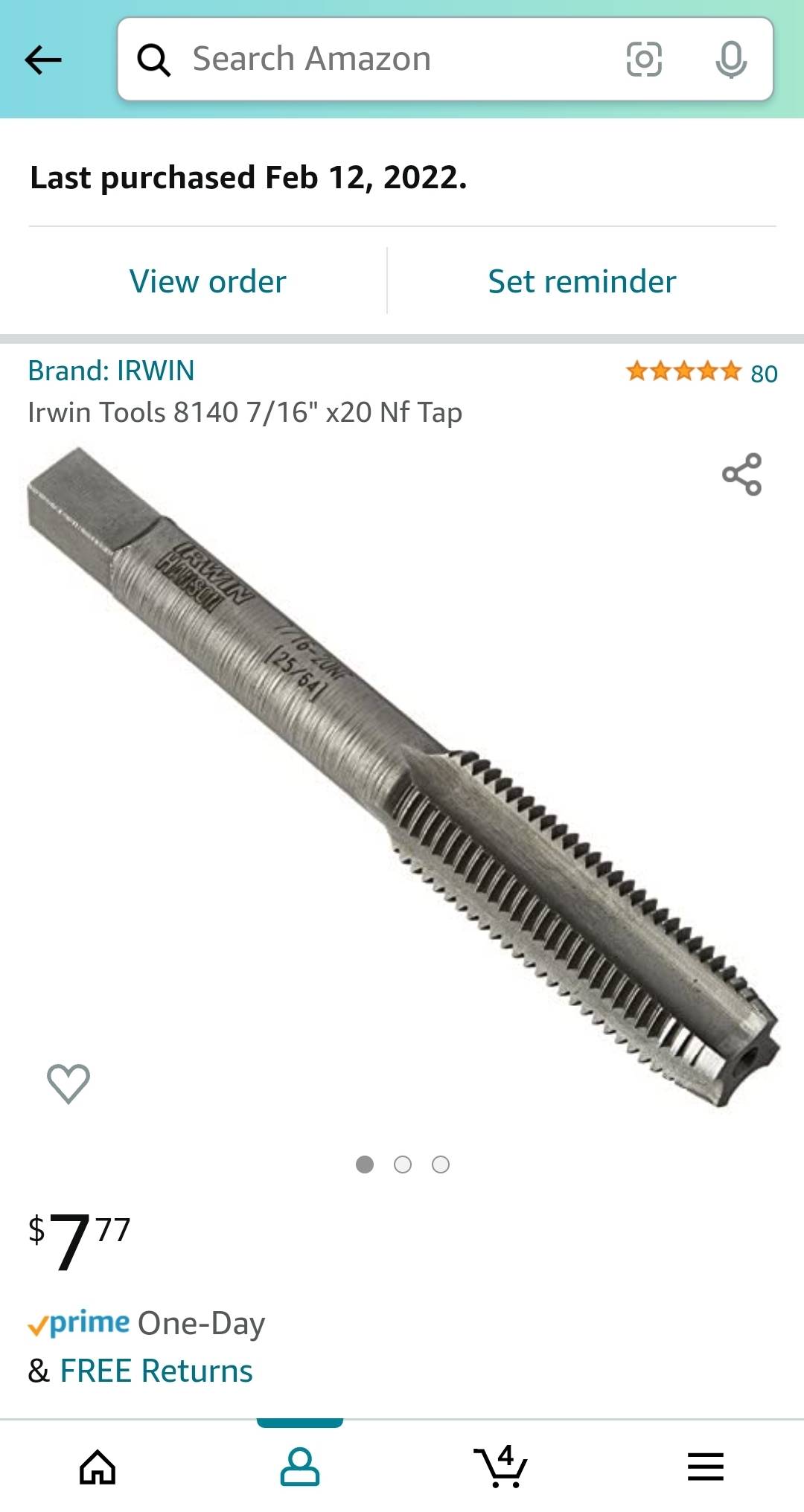

Balancer bolt is 7/16 - 20 fine thread. Get a bottoming tap to repair the threads.What would I need to rethread the crankshaft snout ?

Balancer size is of no consequence for a stock motor. I've run 6" on a 327 and 383 without issue. The only balancer fandango that throws a monkey wrench in the works is putting an external balanced one on anything other a short rod 383 or 400.

The way to fix the threads is at the machine shop. Perhaps you'll luck out with a tap as described above by ELCAM, but I've never had any success with that. There is an excellent chance that the damaged threads are only located on the outer 1/2-3/4" though. If that's the case, then buy an aftermarket crank bolt that is longer. If you have to cut it down, then so be it. And remeber, never turn the engine over by that bolt with either the rockers adjusted or spark plugs installed.

I always check the new balancer for amount of interference as well. If it's more than.0015, then I bust out the little dinglebrerry hones and get it to .001-.0015".

The way to fix the threads is at the machine shop. Perhaps you'll luck out with a tap as described above by ELCAM, but I've never had any success with that. There is an excellent chance that the damaged threads are only located on the outer 1/2-3/4" though. If that's the case, then buy an aftermarket crank bolt that is longer. If you have to cut it down, then so be it. And remeber, never turn the engine over by that bolt with either the rockers adjusted or spark plugs installed.

I always check the new balancer for amount of interference as well. If it's more than.0015, then I bust out the little dinglebrerry hones and get it to .001-.0015".

Definitely can't afford a machine shop...tapping it is my only option and I've had success tapping before...hopefully I'll luck out..Balancer size is of no consequence for a stock motor. I've run 6" on a 327 and 383 without issue. The only balancer fandango that throws a monkey wrench in the works is putting an external balanced one on anything other a short rod 383 or 400.

The way to fix the threads is at the machine shop. Perhaps you'll luck out with a tap as described above by ELCAM, but I've never had any success with that. There is an excellent chance that the damaged threads are only located on the outer 1/2-3/4" though. If that's the case, then buy an aftermarket crank bolt that is longer. If you have to cut it down, then so be it. And remeber, never turn the engine over by that bolt with either the rockers adjusted or spark plugs installed.

I always check the new balancer for amount of interference as well. If it's more than.0015, then I bust out the little dinglebrerry hones and get it to .001-.0015".

Today I'll sanding off the gasket material on the timing chain cover gasket area and fitting the timing cover and balancer...hopefully installing them today as well

Balancer bolt is 7/16 - 20 fine thread. Get a bottoming tap to repair the threads.

- Status

- Not open for further replies.

Similar threads

- Replies

- 6

- Views

- 226

- Replies

- 9

- Views

- 582

- Replies

- 6

- Views

- 244

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.