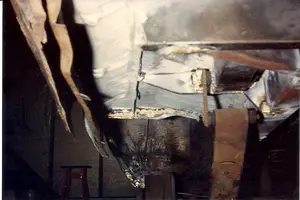

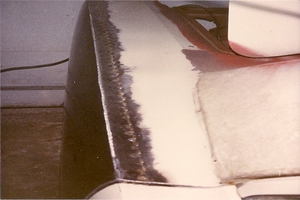

This pic shows the left frame rail cut (this is a uni-body car) and sandblasted. There was a pic of the right side too but I can't find it.

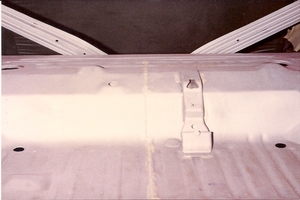

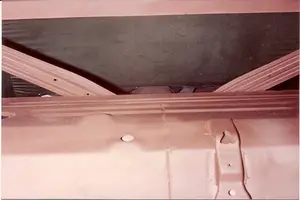

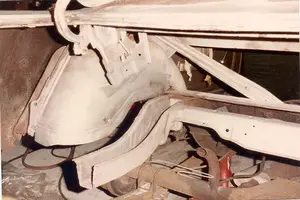

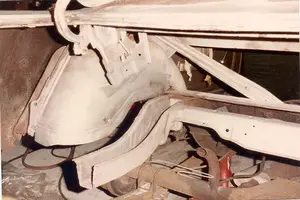

These next 4 pix show the new frame rails, braces and brackets welded in place. This step took a bit of time as I had to position and clamp it all in place and then take measurements. If anything had been out of place the whole back of the car would have been c*ck-eyed. This took several times to get right. BTW, all these pieces were custom made. I had to take measurements of what was left of the original pieces and then create a blueprint so the sheet metal shop could make the pieces. They made 10 pieces.

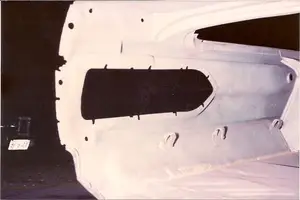

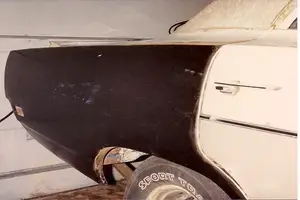

These next 3 pix show the finished product primered.

These next 4 pix show the new frame rails, braces and brackets welded in place. This step took a bit of time as I had to position and clamp it all in place and then take measurements. If anything had been out of place the whole back of the car would have been c*ck-eyed. This took several times to get right. BTW, all these pieces were custom made. I had to take measurements of what was left of the original pieces and then create a blueprint so the sheet metal shop could make the pieces. They made 10 pieces.

These next 3 pix show the finished product primered.