Bummer,

But the tig should do you up right!

But the tig should do you up right!

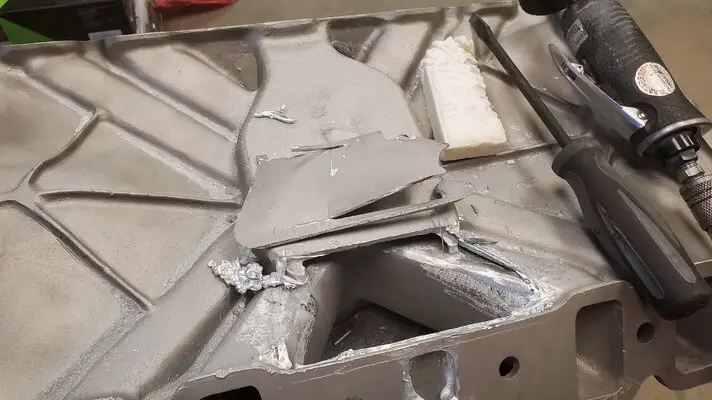

3 strikes and I'm out. Booooo! The flux ain't work; those rods work like flux core solder on wire. I tried a bunch of different shjt with temperature and just couldn't get it. I'm throwing in the towel in, and getting it TIGged.

View attachment 167440View attachment 167441

Conceding defeat sucks.

You guys dog the SBO but I can run an RPM with a spacer and the stock air cleaner under my 70S hood. Even under the W25 hood, a bunch of monkeying and milling needs done using anything but the stock and OB4 intakes. There is a reason a 4.5" stroke easily fits, I believe 4.8" is possible, it is a very tall block. The torquer is good intake, too bad Edelbrock would not tweak it a bit and be a Torquer 2. They did it for nearly every other make but the same can be said about their fancy cast valve covers. I am shocked Mark convinced them to redo their heads for Olds.

You guys dog the SBO but I can run an RPM with a spacer and the stock air cleaner under my 70S hood. Even under the W25 hood, a bunch of monkeying and milling needs done using anything but the stock and OB4 intakes. There is a reason a 4.5" stroke easily fits, I believe 4.8" is possible, it is a very tall block. The torquer is good intake, too bad Edelbrock would not tweak it a bit and be a Torquer 2. They did it for nearly every other make but the same can be said about their fancy cast valve covers. I am shocked Mark convinced them to redo their heads for Olds.

Let's see some pics before the Olds gang gets rowdy.No pics because shame. Long story short, I warped the head flange, and the machine shop won't touch the Air Gap Torker abomination. The block might even be being assembled? Who knows?

I feel your pain. I have also experienced multiple set backs, it is best to move on and focus elsewhere. Have you considered the Pro Comp single plane intake or a Street Dominator if you can find one? Me, I'm just driving a clattering mess across town everyday thanks to not checking rod bearings and the Mallory Ignition which is going in a box, maybe a garbage can. Refocus and regroup is all we can do👍.No pics because shame. Long story short, I warped the head flange, and the machine shop won't touch the Air Gap Torker abomination. The block might even be being assembled? Who knows?

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.