Yeah it just wasn't fitting without that fender in place lol. I should be able to cut a little out of it and put it back in though. They do take up a TON of space.Just seeing this. Man is there alot of room when the inner fenders are out. I left a both of them in and it definitely made for more of a packaging challenge. But I'm glad I did though FWIW.

I read back a couple of pages and seen the flex section discussion. I've had good luck with the Summit brand pieces and I've also used the Vibrant flex's and they work great as well. I've had them installed for a couple of years with no issues. I'm a firm believer in using flex joints. Before I started using them I fixed cracked pipes and headers too often - it got old after the 4th or 5th time apart and together. I'm at the point now with these hot side designs that I can remove every piece individually without having to remove another piece. FWIW, I didn't do that on the 1st couple of builds. What a PITA to remove the turbo, downpipe, WG, etc to change plugs and wires on one bank.

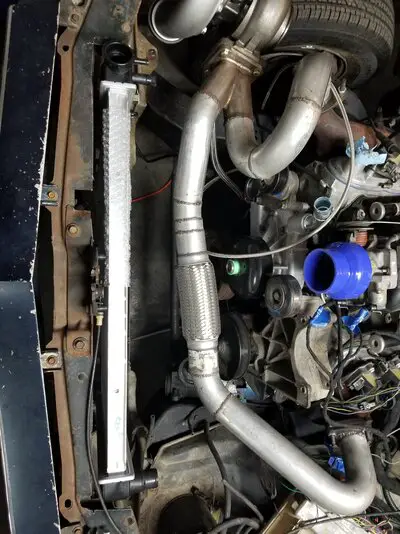

I'm definitely glad I installed the flex section. I can remove the whole hotside with the turbo connected (mind you it's cumbersome as hell) because of the flex joint. My buddy didn't think I would be able to lift it all past the manifold studs but with a little bend it comes off just fine!