BUILD THREAD Project Olds Cool (Recognition!!)

- Thread starter Rktpwrd

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I am currently checking on the cost of flights from you to me... I need to hire the Rust Terminator.

Really amazing job getting that sunroof panel fixed up, Donavan, great job!

Little more done this week...

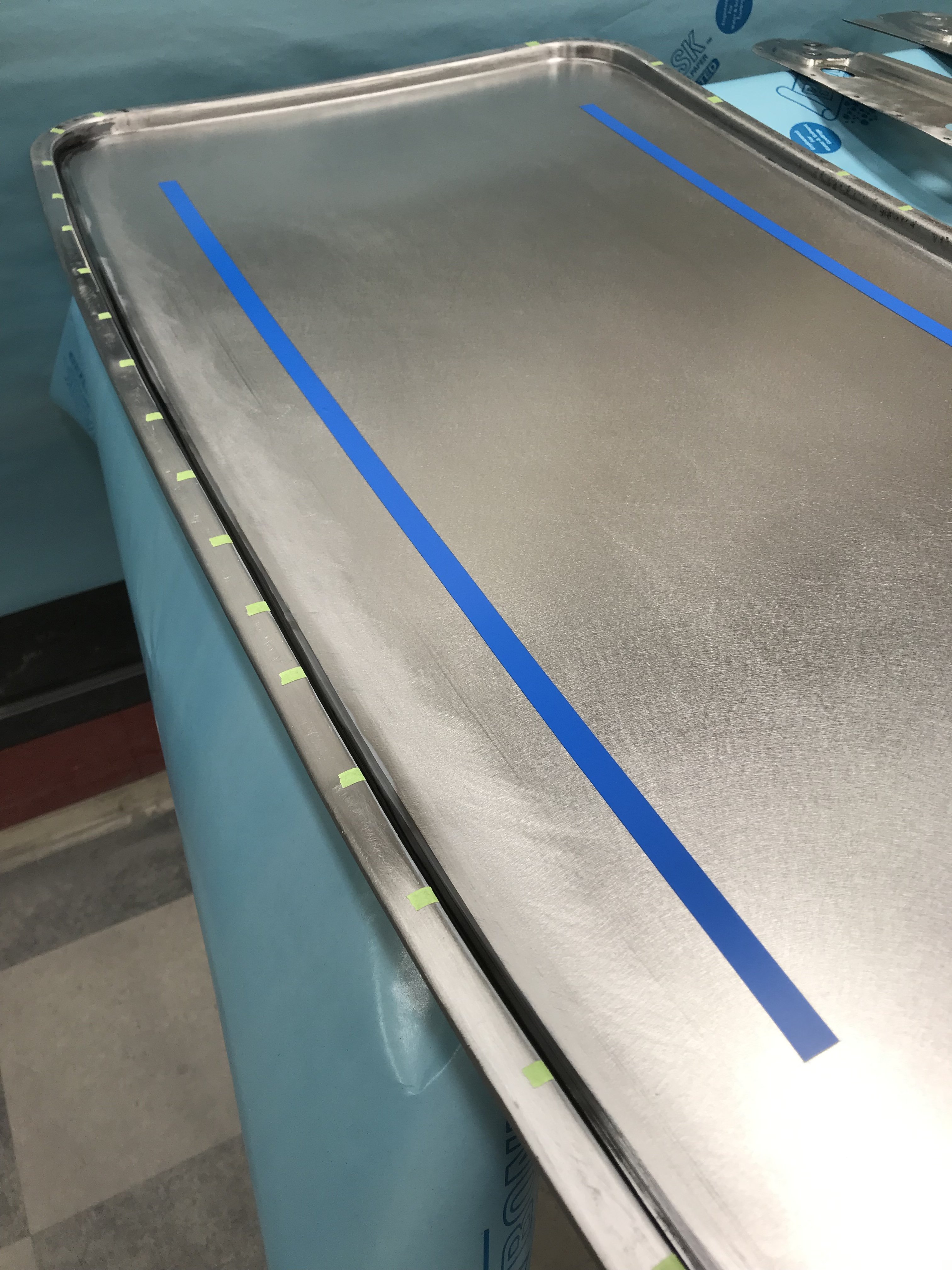

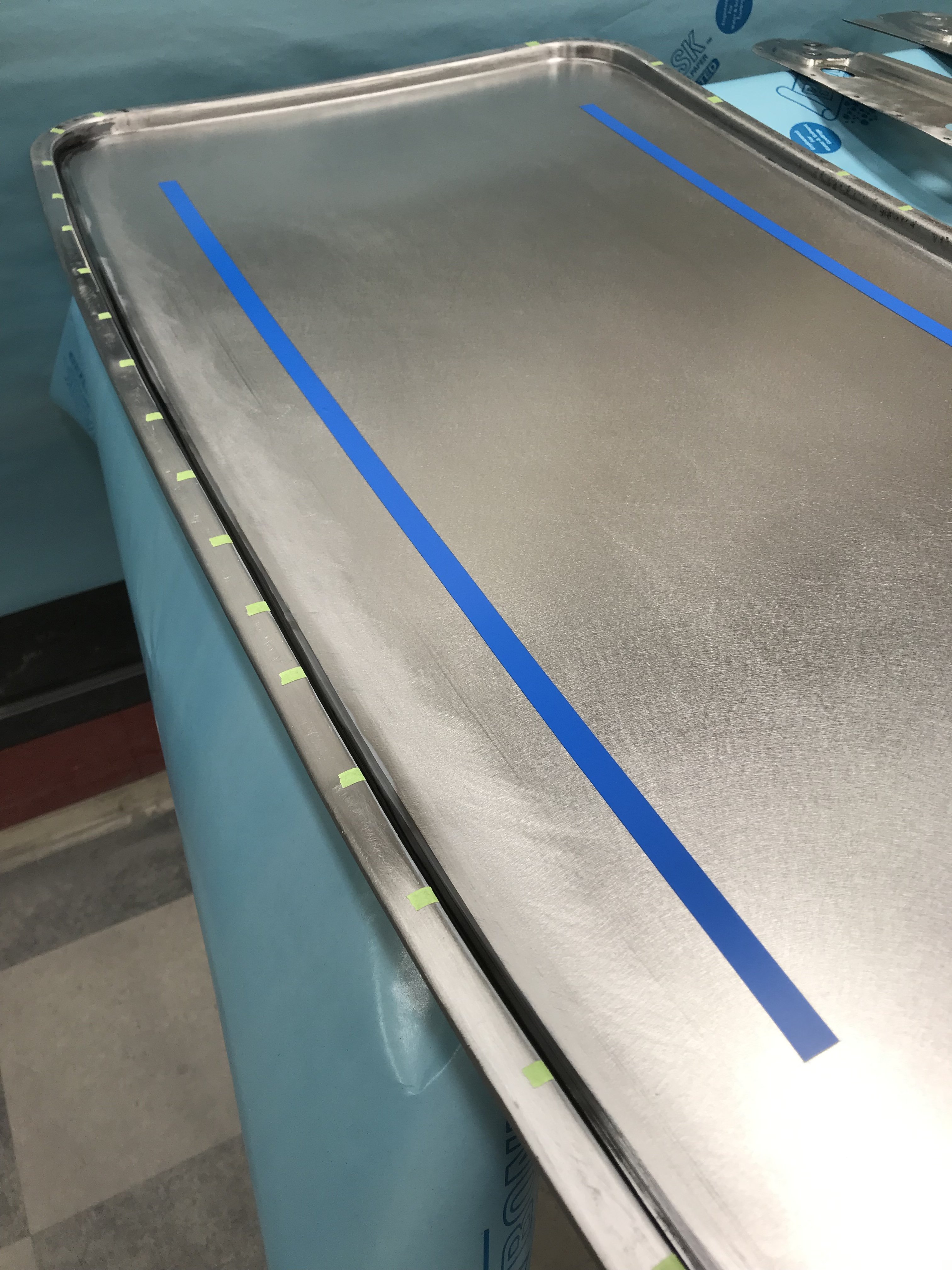

The blue fine line masking tape is where the insides of the braces need to attach to the inside of the pan, the green masking bits are to keep paint off of the areas to be re-spot welded.

As a precaution, I applied some epoxy with a brush to the inside front corner and then seam sealed over it. With all the welding I did in this area I didn’t want to run the risk of having a pinhole in one of my welds leak water into the car.

Parts in epoxy:

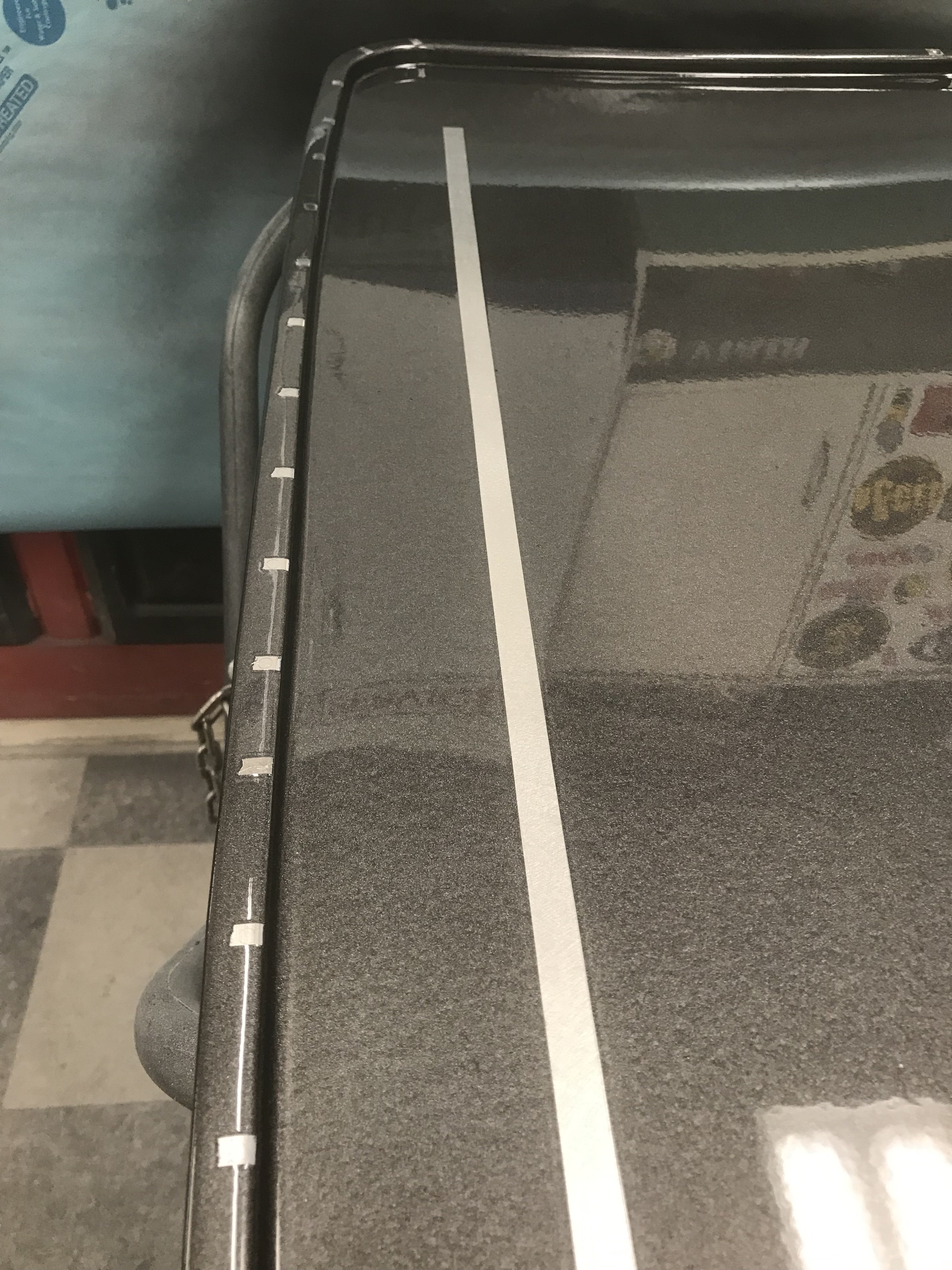

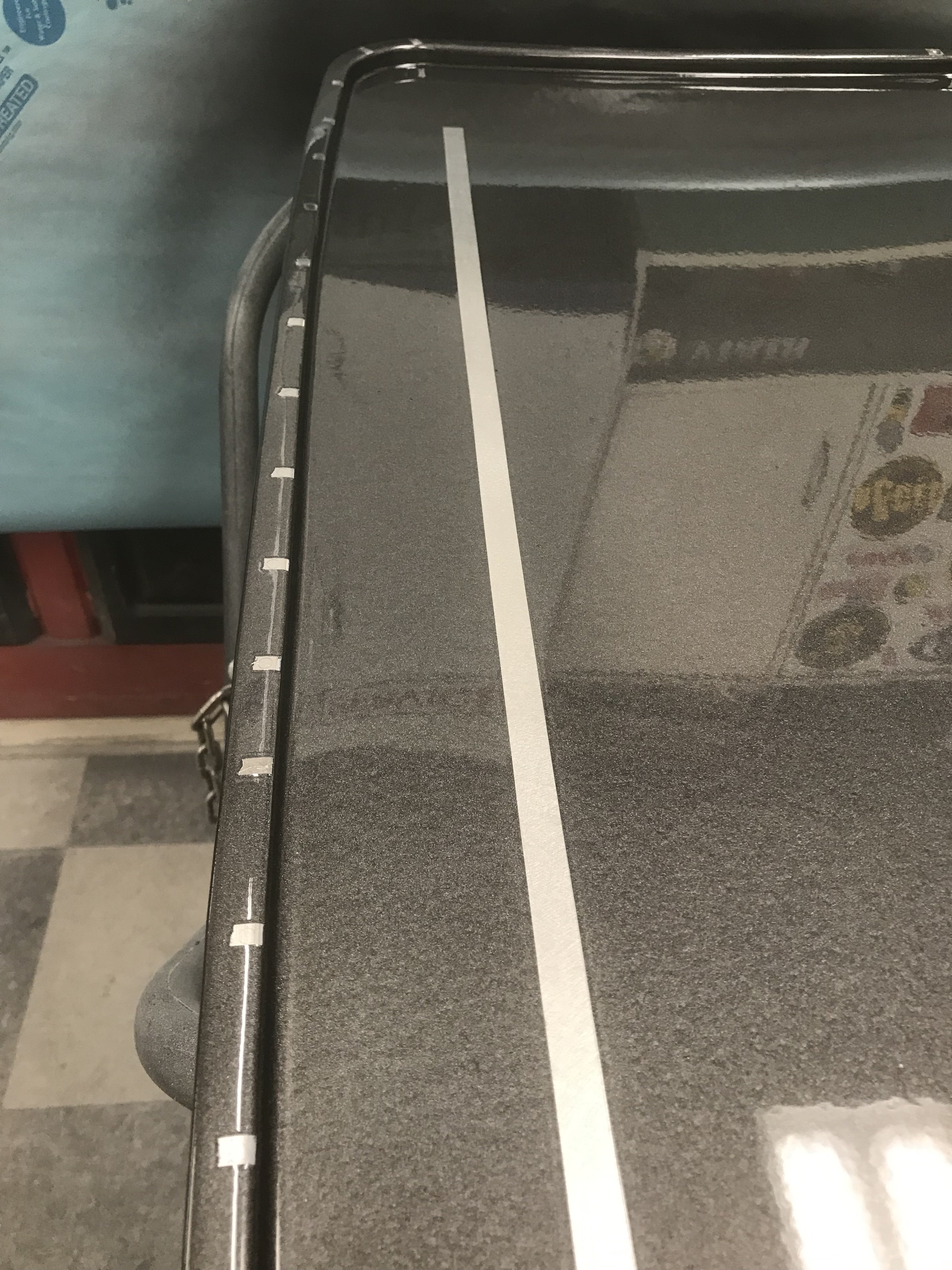

Then 3 coats of color. There’s lots of dust and trash in the paint along with some mottling of the metallics, but I don’t really care. This area literally never gets seen anyways. Having the coverage in here is all about protection from rusting again and nothing else.

Unmasked (before it became impossible to do so):

Stripped the paint off the areas to be bonded that I forgot to mask off in my haste to get this stuff painted:

The factory was lacking the technology to do what they wanted back in the day, originally to bond the insides of the braces to the pan they had just used a thin bead of seam sealer.

Naturally, it didn’t hold.

So this time around, I used Panel Bond to attach the pieces along the inside flanges. That’s why these areas needed to remain bare metal, Panel Bond does not hold well on primed or painted surfaces.

The Panel Bond was carefully spread out to coat the entire areas...

...then carefully aligned and clamped together:

Both braces:

Ran outta time for this week, when I get back on it again the perimeters can be plug welded back up and the bottoms of these braces can receive some paint.

Then it’s onto the outside of the pan!

That’s all for now gents till next time, thanks for following along.

D.

The blue fine line masking tape is where the insides of the braces need to attach to the inside of the pan, the green masking bits are to keep paint off of the areas to be re-spot welded.

As a precaution, I applied some epoxy with a brush to the inside front corner and then seam sealed over it. With all the welding I did in this area I didn’t want to run the risk of having a pinhole in one of my welds leak water into the car.

Parts in epoxy:

Then 3 coats of color. There’s lots of dust and trash in the paint along with some mottling of the metallics, but I don’t really care. This area literally never gets seen anyways. Having the coverage in here is all about protection from rusting again and nothing else.

Unmasked (before it became impossible to do so):

Stripped the paint off the areas to be bonded that I forgot to mask off in my haste to get this stuff painted:

The factory was lacking the technology to do what they wanted back in the day, originally to bond the insides of the braces to the pan they had just used a thin bead of seam sealer.

Naturally, it didn’t hold.

So this time around, I used Panel Bond to attach the pieces along the inside flanges. That’s why these areas needed to remain bare metal, Panel Bond does not hold well on primed or painted surfaces.

The Panel Bond was carefully spread out to coat the entire areas...

...then carefully aligned and clamped together:

Both braces:

Ran outta time for this week, when I get back on it again the perimeters can be plug welded back up and the bottoms of these braces can receive some paint.

Then it’s onto the outside of the pan!

That’s all for now gents till next time, thanks for following along.

D.

The factories bond bedsides on newer trucks. Along with a bunch of other parts. Cool stuff and really strong!

I am stealthily stalking this build thread to learn how to do body work.

It's better than any of those sunday morning car shows for sure 🙂

Really great attention to detail!

It's better than any of those sunday morning car shows for sure 🙂

Really great attention to detail!

Similar threads

- Replies

- 25

- Views

- 851

- Replies

- 14

- Views

- 773

- Replies

- 10

- Views

- 467

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.